Support our educational content for free when you purchase through links on our site. Learn more

Can You Make Money with a 3D Printer? 11+ Ways to Profit in 2025 💸

Ever wondered if your 3D printer could do more than just gather dust or churn out quirky trinkets? Spoiler alert: yes, it can make you money—and not just pocket change. From crafting custom cosplay props to selling digital 3D models, the possibilities are as vast as your filament spool collection. But how do you turn this nifty gadget into a reliable income stream without falling into common traps? Stick around, because we’re unpacking 11+ proven ways to print your way to profit, sharing insider tips, real-world stories, and the future trends that could skyrocket your earnings.

Did you know the global 3D printing market is expected to soar past $135 billion by 2034? That’s a goldmine waiting for savvy makers like you. Whether you’re a beginner or looking to scale your side hustle, this guide will help you navigate costs, niches, marketing, and even legal stuff — all while keeping your sanity intact. Ready to find out how much you can really earn and which printer models give you the best bang for your buck? Let’s dive in!

Key Takeaways

- You can absolutely make money with a 3D printer, but success depends on finding the right niche and delivering quality.

- 11+ business ideas range from selling physical products and offering printing services to creating digital designs and teaching others.

- Understanding costs and pricing is crucial to ensure profitability—don’t forget materials, time, and overhead.

- Marketing and customer service are just as important as your printing skills to build a loyal customer base.

- Recommended printers like the Creality Ender 3 V2, Prusa MK4, and Bambu Lab P1P balance quality and affordability for commercial use.

Ready to start your 3D printing business?

- 👉 Shop Creality Ender 3 V2: Amazon | Creality Official Website

- Explore Prusa MK4: Prusa Official Website | MyMiniFactory

- Check out Bambu Lab P1P: Bambu Lab Official Website | Thingiverse

Dive into the full guide to unlock your 3D printing profit potential!

Table of Contents

- ⚡️ Quick Tips and Facts for 3D Printing Profitability

- 🕰️ From Hobbyist’s Dream to Profit Machine: The Evolution of 3D Printing for Business

- 💰 The Million-Dollar Question: Can You Really Make Money with a 3D Printer?

- 🚀 11+ Proven Pathways to Print Your Way to Profit: Your Ultimate Guide to 3D Printing Business Ideas

- Crafting & Selling Unique 3D Printed Products Online

- Offering On-Demand 3D Printing Services & Prototyping

- Designing & Selling Digital 3D Models & STL Files

- Teaching the Art of 3D Printing: Workshops & Online Courses

- Becoming a 3D Printing Content Creator & Influencer

- Producing Custom Cosplay Props & Movie Replicas

- Creating Bespoke Jewelry & Fashion Accessories

- Manufacturing Niche Replacement & Repair Parts

- Developing Architectural Models & Miniatures

- Venturing into Small-Batch Manufacturing & Custom Components

- Exploring Specialized Applications: Medical, Dental & Beyond

- 💸 Crunching the Numbers: How Much Can You Earn from 3D Printing?

- 🎯 Navigating the 3D Printing Market: Finding Your Niche & Customers

- 🚧 Common Pitfalls & How to Avoid Them on Your 3D Printing Journey

- 🛠️ Essential Tools & Software for Your 3D Printing Business Arsenal

- 📈 Scaling Up Your 3D Printing Venture: From Hobby to Empire

- ⚖️ The Business Side of Printing: Legalities, Taxes & Intellectual Property

- 🔮 The Future is Printed: Emerging Trends in 3D Printing for Profit

- ✅ Conclusion: Your Blueprint for 3D Printing Success

- 🔗 Recommended Links for Aspiring Print-Preneurs

- ❓ Frequently Asked Questions (FAQ) About Making Money with 3D Printers

- 📚 Reference Links & Further Reading

⚡️ Quick Tips and Facts for 3D Printing Profitability

Welcome to the thrilling world of turning plastic spools and resin vats into cold, hard cash! At 3D Printed™, we’ve been down this road, and here’s the quick lowdown before we dive deep:

- ✅ Yes, you can make money with a 3D printer — but it’s not magic; it’s a business.

- ✅ Niche matters: From cosplay props to replacement parts, picking the right market is key.

- ✅ Quality sells: Crisp, durable prints beat cheap, sloppy ones every time.

- ✅ Marketing is your megaphone: Etsy, Shopify, social media, and 3D printing marketplaces are your best friends.

- ✅ Design skills = passive income: Selling STL files online can earn you dough while you sleep.

- ✅ Costs add up: Materials, maintenance, electricity, and your time must be factored in.

- ✅ Scaling is possible: From one printer in your garage to a small factory, growth is achievable.

Fun fact: The global 3D printing market is projected to hit nearly $135 billion by 2034 (source) — so the opportunity is massive!

Curious about how to turn your printer into a profit powerhouse? Keep reading!

🕰️ From Hobbyist’s Dream to Profit Machine: The Evolution of 3D Printing for Business

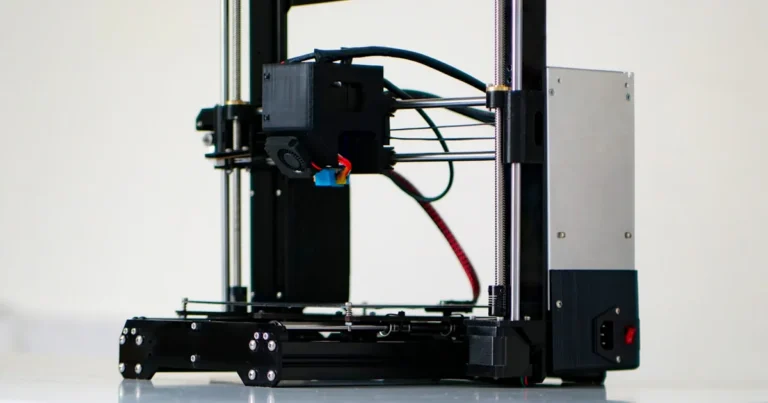

3D printing started as a niche tech for engineers and hobbyists, but today it’s a full-blown business ecosystem. Back in the early 2000s, 3D printers were expensive and slow. Now, with affordable models like the Creality Ender 3 and Prusa MK4, anyone can start printing at home or in a small workshop.

How did we get here?

- Early days: Prototyping and industrial use only.

- Maker movement: Affordable FDM printers sparked hobbyist creativity.

- Marketplace boom: Platforms like Etsy and Thingiverse created demand for unique prints.

- Service providers: Businesses offering on-demand printing and design services emerged.

- Digital design sales: Selling STL files became a passive income stream.

- Specialized niches: Medical, dental, aerospace, and fashion sectors adopted 3D printing for custom solutions.

This evolution means you’re not just buying a printer; you’re entering a dynamic marketplace where creativity meets commerce.

💰 The Million-Dollar Question: Can You Really Make Money with a 3D Printer?

Short answer: Absolutely! But it’s not a get-rich-quick scheme. Here’s what we’ve learned at 3D Printed™:

- Your success depends on solving a problem or fulfilling a desire. For example, a gamer wants custom miniatures, or a homeowner needs a rare replacement part.

- Avoid the race to the bottom on price. Cheap clients often waste your time and kill profits.

- Quality and uniqueness command premium prices. Custom finishing, post-processing, and design elevate your offerings.

- Marketing and customer service are as important as printing. A great product no one knows about won’t sell.

As Phrozen3D’s guide puts it: “The key to success is to find a niche, deliver high-quality prints, and market your products effectively.”

🚀 11+ Proven Pathways to Print Your Way to Profit: Your Ultimate Guide to 3D Printing Business Ideas

Ready to explore the treasure map? Here are 11+ ways to monetize your 3D printer, with insights from our team and industry pros.

1. Crafting & Selling Unique 3D Printed Products Online

What to sell? Think miniatures, phone cases, home decor, cosplay props, jewelry, and more.

- Platforms: Etsy, Amazon Handmade, eBay, and niche 3D marketplaces like Cults3D.

- Tips: Focus on a niche, use high-quality photos, and offer customization.

- Our story: We started selling custom phone stands and quickly found success by offering personalized engraving.

2. Offering On-Demand 3D Printing Services & Prototyping

Businesses and hobbyists often need prototypes or small runs.

- Clients: Startups, architects, engineers, game designers.

- Pricing: Charge for material, print time, and post-processing.

- Pro tip: Build relationships with local businesses for steady work.

3. Designing & Selling Digital 3D Models & STL Files

Passive income goldmine!

- Marketplaces: MyMiniFactory, CGTrader, Thingiverse.

- Skills needed: CAD and 3D modeling.

- Example: Lord of the Print earns thousands monthly selling miniatures on Patreon.

4. Teaching the Art of 3D Printing: Workshops & Online Courses

People want to learn!

- Formats: Local workshops, Udemy courses, YouTube tutorials.

- Focus: Solve specific problems, e.g., “How to print flawless cosplay props.”

- Our experience: Hosting a weekend workshop brought in new clients and boosted our brand.

5. Becoming a 3D Printing Content Creator & Influencer

Create videos, blogs, or podcasts.

- Monetize: Ads, sponsorships, affiliate marketing.

- Challenge: Requires consistency and creativity.

- Example: Channels like Maker’s Muse and 3D Printing Nerd have huge followings.

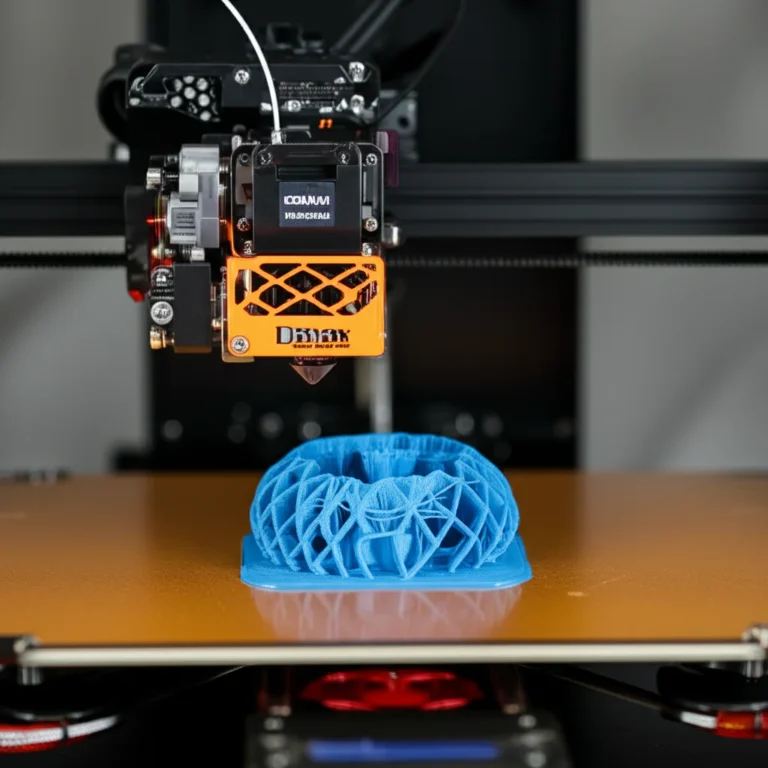

6. Producing Custom Cosplay Props & Movie Replicas

Cosplayers pay top dollar for accurate, durable props.

- Materials: Resin printers shine here for detail.

- Marketing: Instagram and cosplay conventions.

- Our tip: Partner with local cosplay groups for referrals.

7. Creating Bespoke Jewelry & Fashion Accessories

3D printing allows intricate designs impossible by traditional methods.

- Materials: Castable resins for lost-wax casting.

- Platforms: Etsy and specialized jewelry sites.

- Note: Requires design finesse and finishing skills.

8. Manufacturing Niche Replacement & Repair Parts

Many products have discontinued parts.

- Opportunity: Car parts, appliances, gadgets.

- Challenge: Precision and durability.

- Tip: Validate demand before investing time.

9. Developing Architectural Models & Miniatures

Architects and real estate firms need models.

- Benefit: High-value, low-volume.

- Tools: CAD software like SketchUp or Revit.

- Our insight: This niche demands tight deadlines and accuracy.

10. Venturing into Small-Batch Manufacturing & Custom Components

Produce limited runs for startups or inventors.

- Advantage: Higher margins than mass production.

- Requires: Good workflow and quality control.

11. Exploring Specialized Applications: Medical, Dental & Beyond

Highly technical but lucrative.

- Examples: Dental molds, prosthetics, surgical guides.

- Barrier: Certification and expertise.

- Potential: High-value contracts and repeat clients.

💸 Crunching the Numbers: How Much Can You Earn from 3D Printing?

Let’s talk dollars and sense. Earnings vary widely based on niche, skill, and effort.

Understanding Your Costs: Materials, Maintenance & More

| Cost Factor | Details | Typical Range |

|---|---|---|

| Printer amortization | Depreciation over 1-3 years | $0.10 – $1.00 per print hour |

| Materials | Filament (PLA, ABS), resin, support materials | $10 – $50 per kg or liter |

| Electricity | Power consumption during printing | $0.05 – $0.20 per hour |

| Post-processing | Sanding, painting, curing, finishing supplies | Variable, $0.50 – $5 per item |

| Time (your labor) | Design, setup, troubleshooting | Priceless but crucial |

| Maintenance | Replacement parts, calibration | $50 – $200 annually |

Pricing Your Prints & Services for Profit

- Material + time + overhead + profit margin = price.

- Example: A custom cosplay helmet might cost $30 in materials and 10 hours of labor. At $20/hour labor, that’s $230 minimum.

- Market research: Check competitors on Etsy or Shapeways.

- Tip: Don’t undervalue your time or craftsmanship.

🎯 Navigating the 3D Printing Market: Finding Your Niche & Customers

Identifying High-Demand Niches & Untapped Opportunities

- Use Google Trends, Etsy best-sellers, and forums like Reddit’s r/3Dprinting.

- Look for gaps: Are people asking for parts or designs that don’t exist?

- Our favorite niches? Custom miniatures and replacement parts — steady demand, low competition.

Marketing Your 3D Printing Business: Reaching Your Audience

- Build a website or Shopify store.

- Leverage Instagram, TikTok, and YouTube for demos and behind-the-scenes.

- Join Facebook groups and Discord servers.

- Collect reviews and showcase testimonials.

- Offer freebies or limited editions to build buzz.

🚧 Common Pitfalls & How to Avoid Them on Your 3D Printing Journey

Quality Control & Customer Satisfaction

- Problem: Warping, layer separation, or poor finishing can kill your reputation.

- Solution: Test prints thoroughly, invest in calibration tools, and never ship without inspection.

- Our experience: A batch of miniatures with brittle supports taught us to slow down and prioritize quality.

Time Management & Scalability Challenges

- 3D printing can be slow; managing multiple orders requires planning.

- Automate where possible: Use batch printing, outsource finishing, or hire help.

- Don’t overpromise delivery times — your reputation depends on reliability.

🛠️ Essential Tools & Software for Your 3D Printing Business Arsenal

Recommended 3D Printers for Commercial Use

| Printer Model | Print Technology | Build Volume (mm) | Reliability | Ease of Use | Our Rating (1-10) |

|---|---|---|---|---|---|

| Creality Ender 3 V2 | FDM | 220x220x250 | 8 | 8 | 8 |

| Prusa MK4 | FDM | 250x210x210 | 9 | 9 | 9 |

| Bambu Lab P1P | FDM | 256x256x256 | 9 | 9 | 9 |

| Anycubic Photon Mono 2 | Resin (MSLA) | 130x80x165 | 8 | 7 | 8 |

| Phrozen Sonic Mini 4K | Resin (MSLA) | 134x75x130 | 8 | 7 | 8 |

Why these? They balance price, quality, and community support — crucial for business success.

Must-Have Software for Design & Slicing

- CAD Software: Fusion 360 (free for hobbyists), TinkerCAD (beginner-friendly), Blender (free, powerful).

- Slicing Software: Cura, PrusaSlicer, Chitubox (especially for resin printers).

- Marketplaces for STL files: Thingiverse, MyMiniFactory, CGTrader.

📈 Scaling Up Your 3D Printing Venture: From Hobby to Empire

Investing in More Machines & Automation

- Add printers to increase capacity.

- Use print farms with remote monitoring.

- Automate post-processing with wash-and-cure stations (e.g., Phrozen Wash Mega S).

Building a Team & Outsourcing

- Hire designers, finishers, or marketers.

- Outsource complex post-processing or shipping.

- Focus on business growth and customer relations.

⚖️ The Business Side of Printing: Legalities, Taxes & Intellectual Property

Business Registration & Licensing

- Register as a sole proprietor, LLC, or corporation depending on your scale.

- Check local laws for home-based manufacturing.

- Keep records for taxes and deductions.

Understanding Copyright & Licensing for 3D Models

- Avoid printing copyrighted designs without permission.

- Use or create models with clear licenses (Creative Commons, commercial use allowed).

- Protect your own designs with copyright or trademarks.

- Platforms like MyMiniFactory enforce IP rights.

🔮 The Future is Printed: Emerging Trends in 3D Printing for Profit

- Multi-material printing: Combining plastics, metals, and ceramics.

- Bioprinting: Printing tissues and organs (still experimental).

- AI-driven design: Generative design tools creating optimized parts.

- Sustainability: Recycled filaments and eco-friendly resins.

- Mass customization: Personalized products at scale.

At 3D Printed™, we’re excited about these innovations — they’ll open new doors for entrepreneurs like you!

✅ Conclusion: Your Blueprint for 3D Printing Success

So, can you make money with a 3D printer? The answer is a resounding yes—but only if you treat it like a business, not just a hobby. From our experience at 3D Printed™, success boils down to finding your niche, delivering quality, and marketing like a pro. Whether you’re selling custom cosplay props, offering on-demand printing services, or designing STL files for passive income, the opportunities are vast and varied.

Remember the question we teased earlier: How much can you really earn? Well, it depends on your dedication, niche, and business savvy. Some hobbyists make a few hundred dollars monthly, while seasoned pros scale up to thousands or even tens of thousands. The key is to avoid cheap clients, focus on value, and continuously improve your craft.

If you’re serious about turning your 3D printer into a money-making machine, start small, learn from every print, and build your brand. The 3D printing market is booming, and with the right approach, you can carve out your own profitable corner.

🔗 Recommended Links for Aspiring Print-Preneurs

Ready to gear up? Here are some top picks and resources to jumpstart your 3D printing business:

-

Creality Ender 3 V2:

Amazon | Thingiverse | Creality Official Website -

Prusa MK4:

Prusa Official Website | MyMiniFactory -

Bambu Lab P1P:

Bambu Lab Official Website | Thingiverse -

Anycubic Photon Mono 2:

Anycubic Official Website | Cults3D -

Phrozen Sonic Mini 4K:

Phrozen Official Website | Thingiverse -

Books to Boost Your 3D Printing Business:

❓ Frequently Asked Questions (FAQ) About Making Money with 3D Printers

What are the most profitable things to 3D print and sell?

Answer:

Profitability depends on demand, complexity, and uniqueness. High-margin items include custom cosplay props, miniatures for tabletop games, bespoke jewelry, and replacement parts for discontinued products. These items command premium prices due to customization and scarcity. Additionally, selling digital 3D models (STL files) can generate passive income with minimal ongoing effort once designs are created.

How much money can you make with a 3D printing business?

Answer:

Earnings vary widely. Hobbyists might earn a few hundred dollars monthly, while dedicated entrepreneurs can scale to $3,000–$10,000+ per month. Factors influencing income include the number of printers, niche selection, pricing strategy, and marketing effectiveness. For example, offering specialized prototyping services or high-end cosplay props can significantly increase revenue.

What are some popular 3D printing products to sell online?

Answer:

Popular products include custom phone cases, miniatures, home decor items, cosplay accessories, jewelry, and functional replacement parts. These products are often sought after on platforms like Etsy, Amazon Handmade, and Cults3D. The key is to offer something unique or customizable to stand out.

Can you make a living with a 3D printer and an Etsy store?

Answer:

Yes, but it requires strategic planning. Success on Etsy demands high-quality products, excellent customer service, and effective marketing. Many sellers start part-time and scale up by expanding product lines and improving efficiency. Avoid competing solely on price; instead, focus on value and uniqueness.

How do I start a 3D printing side hustle and make extra income?

Answer:

Start by identifying a niche you’re passionate about. Create a few prototypes and test the market on platforms like Etsy or Facebook Marketplace. Invest time in learning design software and perfecting print quality. Use social media to showcase your work and gather feedback. As orders grow, consider reinvesting profits into better equipment or outsourcing.

What are the best 3D printing niches to make money in?

Answer:

Top niches include:

- Cosplay and collectibles

- Replacement parts for appliances and vehicles

- Architectural models

- Custom jewelry

- Prototyping for startups and inventors

- Educational tools and kits

Choosing a niche with passionate customers and low competition is crucial.

What are the pros and cons of starting a 3D printing business from home?

Answer:

Pros:

- Low startup costs compared to traditional manufacturing.

- Flexible hours and creative freedom.

- Ability to test multiple niches quickly.

Cons:

- Limited production capacity with a single printer.

- Noise, fumes, and space requirements.

- Need for strong self-discipline and business skills.

- Potential zoning or licensing restrictions.

📚 Reference Links & Further Reading

- Shopify: How To Make Money 3D Printing: 8 Ideas for 2025

- Phrozen 3D: How to Make Money with a 3D Printer

- Prusa Research: Original Prusa i3 MK4

- Creality: Creality Ender 3 V2

- Bambu Lab: Bambu Lab P1P

- Anycubic: Anycubic Photon Mono 2

- MyMiniFactory: 3D Models Marketplace

- Thingiverse: 3D Printable Objects

- CGTrader: 3D Model Marketplace

Ready to turn your 3D printer into a money-making machine? Dive into these resources, pick your niche, and start printing your way to profit today! 🚀