Support our educational content for free when you purchase through links on our site. Learn more

🚀 10 Game-Changing Ways 3D Printing Transforms Orthotics (2026)

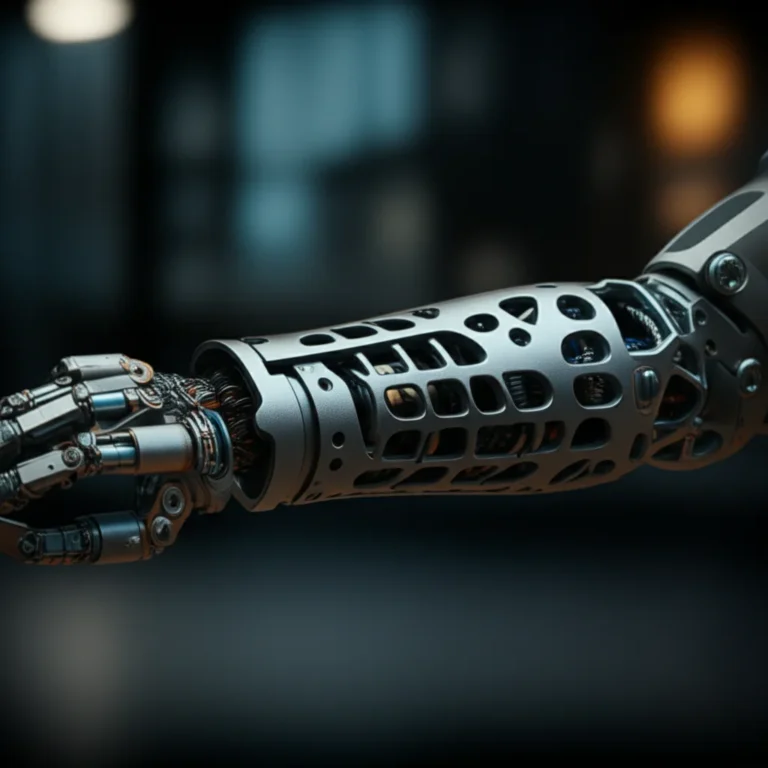

Imagine slipping into a pair of orthotics so perfectly tailored to your feet that they feel like a second skin — crafted not by hand, but by cutting-edge 3D printing technology. Welcome to the future of orthotic care, where digital scans, innovative materials, and rapid fabrication converge to revolutionize comfort, performance, and accessibility. Did you know that 3D printed orthotics can reduce production time from weeks to mere hours while enhancing durability and fit? Intrigued? You’re in the right place.

In this comprehensive guide, we’ll walk you through everything from the evolution of orthotic devices and the digital workflows that make customization a breeze, to the best materials and printers for crafting your own orthotics. Plus, we’ll share real-world success stories, common pitfalls to avoid, and a sneak peek into the future innovations shaping this exciting field. Whether you’re a healthcare professional, athlete, or DIY enthusiast, prepare to discover how 3D printing is rewriting the rules of orthotic fabrication.

Key Takeaways

- 3D printing enables unparalleled customization and faster production of orthotics, improving patient comfort and outcomes.

- Materials like Nylon 11 and TPU 90A offer the perfect balance of durability and flexibility for various orthotic applications.

- Digital workflows—from scanning to CAD design—streamline the entire fabrication process, reducing errors and lead times.

- Industrial-grade printers like Formlabs Fuse 1+ and HP Jet Fusion 5400 Series set the standard for quality and scalability.

- Post-processing and material choice are critical to ensure orthotics are comfortable, durable, and effective.

- Sustainability and cost-efficiency make 3D printing a smart choice for clinics and makers alike.

Ready to dive deeper? Keep reading to unlock the full potential of 3D printed orthotics and how you can get started today!

Table of Contents

- ⚡️ Quick Tips and Facts About 3D Printing for Orthotics

- 🔍 The Evolution of Orthotic Devices: From Traditional to 3D Printing Technology

- 🚀 How 3D Printing Revolutionizes Custom Orthotic Fabrication

- 🦾 Top 7 Applications of 3D Printed Orthotics in Healthcare and Sports

- 🖥️ Digital Workflows: Designing and Crafting Custom Orthotics with 3D Printing

- 🔧 Get Started with 3D Printing Orthotics: Tools, Materials, and Best Practices

- 💡 Material Science in 3D Printed Orthotics: Choosing the Right Filaments and Resins

- ⚙️ Post-Processing Techniques to Enhance Comfort and Durability of 3D Printed Orthotics

- 💰 Cost Analysis: Is 3D Printing Orthotics Affordable and Scalable?

- 📈 Case Studies: Real-World Success Stories of 3D Printed Orthotics

- 🤔 Common Challenges and Solutions in 3D Printing Orthotics

- 🌍 Environmental Impact: Sustainability of 3D Printed Orthotic Devices

- 🛠️ Future Trends: Innovations Shaping the Future of 3D Printed Orthotics

- 📚 Conclusion: Why 3D Printing is the Future of Orthotic Care

- 🔗 Recommended Links for 3D Printing Orthotics Enthusiasts

- ❓ Frequently Asked Questions About 3D Printed Orthotics

- 📖 Reference Links and Further Reading

⚡️ Quick Tips and Facts About 3D Printing for Orthotics

Welcome to the fascinating world of 3D printing for orthotics! Whether you’re a podiatrist, engineer, or DIY enthusiast, here’s a quick cheat sheet from the 3D Printed™ team to get you started:

| Fact / Tip | Details |

|---|---|

| ✅ Customization is king | 3D printing lets you tailor orthotics precisely to a patient’s anatomy using scans. |

| ✅ Materials matter | Common materials include Nylon 11 (rigid, durable) and TPU 90A (flexible, skin-safe). |

| ✅ Workflow speed | Digital workflows cut production time from weeks to days or even hours. |

| ✅ Cost-effective | Lower labor and material waste compared to traditional methods. |

| ✅ Sustainability | Powder-based SLS printing recycles unused material, reducing environmental impact. |

| ❌ Not a magic bullet | Requires expertise in scanning, CAD, and post-processing to achieve perfect fit and comfort. |

| ❌ Printer limitations | Entry-level 3D printers may lack the precision or material compatibility needed. |

Did you know? According to Formlabs, 3D printed orthotics can withstand over 10,000 steps per day for a year without degradation! That’s some serious durability.

For a deep dive into the digital workflow, check out our section on Digital Workflows.

🔍 The Evolution of Orthotic Devices: From Traditional to 3D Printing Technology

Orthotics have come a long way from plaster casts and foam impressions. Let’s stroll down memory lane and see how tech transformed this field.

Traditional Orthotics: The Old School Way

- Plaster casting and foam impressions: Time-consuming, messy, and often uncomfortable for patients.

- Manual fabrication: Skilled technicians carve and mold orthotics by hand — labor-intensive and prone to human error.

- Long lead times: Typically 3-6 weeks from measurement to delivery.

- Limited customization: Off-the-shelf solutions often don’t fit perfectly, causing discomfort and poor biomechanical outcomes.

Enter 3D Printing: A Game Changer

- Digital scanning: Using LiDAR, laser, or infrared scanners, practitioners capture precise foot anatomy in minutes.

- CAD design: Orthotics are designed or modified in software like Meshmixer or Autodesk Fusion 360.

- 3D printing: Additive manufacturing builds the orthotic layer-by-layer, enabling complex geometries impossible with traditional methods.

- Faster turnaround: What took weeks now takes days or hours.

- Improved patient outcomes: Better fit means better comfort and effectiveness.

“Orthotics should be built for a person, and should treat only the symptoms, not be standardized solutions that put them in boxes.” — Matej Vlašič, Formlabs

Curious how this digital magic happens? Hang tight for our Digital Workflows section!

🚀 How 3D Printing Revolutionizes Custom Orthotic Fabrication

Let’s unpack the why and how behind 3D printing’s orthotic revolution.

Key Advantages

- Speed: Rapid prototyping and batch printing reduce wait times.

- Precision: Digital scans ensure perfect anatomical matches.

- Customization: Easily tweak designs for specific biomechanical needs.

- Cost efficiency: Less manual labor and material waste.

- Sustainability: Powder reuse and minimal scrap.

Technologies in Play

| Technology | Strengths | Common Materials | Use Cases |

|---|---|---|---|

| SLS (Selective Laser Sintering) | Durable, complex geometries, batch printing | Nylon 11, TPU 90A | Insoles, AFOs, helmets |

| SLA (Stereolithography) | High resolution, smooth surface finish | Biomed Durable Resin, transparent resins | Masks, cranial helmets |

| FDM (Fused Deposition Modeling) | Affordable, accessible | PLA, ABS, TPU filaments | DIY orthotics, prototypes |

Real-World Impact

- Reduced patient visits: Digital files can be shared remotely, enabling telemedicine.

- Batch production: Labs can print multiple orthotics simultaneously, improving throughput.

- Material innovation: TPU 90A offers skin-safe flexibility, while Nylon 11 provides strength and durability.

Our friends at HP highlight their Jet Fusion 5400 Series as a top-tier industrial solution for consistent, high-quality orthotics production.

🦾 Top 7 Applications of 3D Printed Orthotics in Healthcare and Sports

3D printed orthotics aren’t just for foot pain relief. Here’s where they shine:

-

Custom Foot Insoles

Improve arch support, reduce plantar fasciitis, and enhance gait. -

Ankle-Foot Orthoses (AFOs)

Lightweight braces for neuromuscular disorders, stroke recovery, or injury support. -

Wrist and Hand Orthoses

Stabilize joints, assist mobility, and reduce pain from arthritis or carpal tunnel. -

Cranial Helmets

Used in infants for plagiocephaly correction with precise fit and comfort. -

Sports Performance Enhancers

Tailored orthotics improve biomechanics and reduce injury risk in athletes. -

Post-Surgical Supports

Custom braces that accommodate swelling and healing progress. -

Pediatric Orthotics

Growth-adapted devices that can be quickly reprinted as kids grow.

Each application demands specific materials and design considerations — more on that in Material Science.

🖥️ Digital Workflows: Designing and Crafting Custom Orthotics with 3D Printing

Ready to geek out? Here’s the step-by-step digital workflow that turns a foot scan into a 3D printed orthotic masterpiece.

Step 1: 3D Scanning the Patient’s Anatomy

- Use handheld scanners like Artec Eva or Structure Sensor to capture foot geometry.

- Alternatively, smartphone LiDAR sensors (iPhone 12+ models) can do the job for DIYers.

- Ensure patient is in a weight-bearing stance for accurate arch shape.

Step 2: Import and Clean the Scan

- Import scan data into software such as Meshmixer or Geomagic Wrap.

- Repair mesh holes, smooth surfaces, and remove noise.

- Export as STL or OBJ files.

Step 3: CAD Design and Customization

- Use CAD tools like Autodesk Fusion 360 or SolidWorks to design orthotic features.

- Adjust thickness, add cutouts for ventilation, or integrate flexible zones.

- Simulate stress and strain if software supports it.

Step 4: Slicing and Print Preparation

- Import design into slicers like Cura, PrusaSlicer, or PreForm (for Formlabs SLA printers).

- Choose layer height, infill density, and support structures.

- Preview print to check for errors.

Step 5: 3D Printing

- Select appropriate printer and material (see Materials).

- Monitor print for quality and adhesion.

Step 6: Post-Processing

- Remove supports and excess powder.

- Cure resin prints under UV light.

- Smooth surfaces with vapor smoothing or sanding.

- Add padding, straps, or covers as needed.

Pro tip: For SLS prints, using Formlabs’ Fuse Sift powder recovery system can save material and improve powder reuse efficiency.

Want a hands-on DIY approach? Check out the detailed guide on Instructables for making your own foot orthotics with household materials and 3D printing.

🔧 Get Started with 3D Printing Orthotics: Tools, Materials, and Best Practices

Thinking of jumping into the orthotic 3D printing pool? Here’s what you’ll need and what to watch out for.

Essential Tools and Equipment

| Tool / Equipment | Purpose | Recommended Brands / Models |

|---|---|---|

| 3D Scanner | Capture foot/limb anatomy | Artec Eva, Structure Sensor, iPhone LiDAR |

| CAD Software | Design and modify orthotic models | Meshmixer (free), Fusion 360, SolidWorks |

| 3D Printer | Fabricate orthotics | Formlabs Fuse 1+ (SLS), Prusa i3 MK3 (FDM), Formlabs Form 3 (SLA) |

| Slicing Software | Prepare print files | Cura, PrusaSlicer, PreForm |

| Post-Processing Tools | Support removal, smoothing, curing | Isopropyl alcohol, UV curing stations, sandpaper |

Material Choices

- Nylon 11 (SLS): Durable, biocompatible, ideal for rigid orthotics.

- TPU 90A (SLS/FDM): Flexible, skin-safe, perfect for pads and braces.

- PLA/ABS (FDM): Good for prototypes and DIY orthotics but less durable.

- Biomed Durable Resin (SLA): High resolution and impact resistance for masks and helmets.

Best Practices

- Always calibrate your printer for dimensional accuracy.

- Use patient weight-bearing scans for realistic orthotic shape.

- Test print prototypes before final production.

- Consider patient feedback for comfort adjustments.

- Keep detailed digital records for easy reprints.

💡 Material Science in 3D Printed Orthotics: Choosing the Right Filaments and Resins

Material choice can make or break your orthotic’s performance. Here’s the lowdown on the top contenders:

| Material | Properties | Pros | Cons | Typical Applications |

|---|---|---|---|---|

| Nylon 11 | Rigid, high ductility, biocompatible | Durable, recyclable, stable | Requires SLS printer, higher cost | Insoles, AFOs, durable braces |

| TPU 90A | Flexible elastomer, skin-safe | Tear-resistant, comfortable | Slightly less rigid, tricky print | Pads, sockets, wearable devices |

| PLA | Easy to print, biodegradable | Affordable, accessible | Brittle, less durable | Prototypes, DIY orthotics |

| ABS | Stronger than PLA, heat resistant | Durable, impact resistant | Warping issues, fumes | Prototypes, functional parts |

| Biomed Durable Resin | High resolution, impact resistant | Smooth finish, biocompatible | Requires SLA printer, post-cure needed | Masks, cranial helmets |

Fun fact: TPU 90A’s combination of high tear strength and elongation makes it perfect for orthotic pads that need to flex with the foot but resist wear.

⚙️ Post-Processing Techniques to Enhance Comfort and Durability of 3D Printed Orthotics

Printing is just the start! Post-processing transforms your orthotic from “meh” to “marvelous.”

Common Post-Processing Steps

- Support Removal: Use flush cutters or pliers to remove supports carefully.

- Powder Cleaning (SLS): Use compressed air or specialized powder recovery systems like Formlabs Fuse Sift.

- Surface Smoothing:

- Vapor smoothing (acetone for ABS, proprietary methods for Nylon) reduces roughness.

- Sanding with fine grit for custom fit.

- Curing (SLA): UV light cures resin prints to full strength.

- Assembly: Add padding, straps, or covers for comfort and wearability.

Tips from the Trenches

- Always wear protective gear when handling powders or solvents.

- Test vapor smoothing on a sample print first to avoid over-smoothing.

- Use medical-grade padding materials for patient comfort.

- Document your post-processing steps for reproducibility.

💰 Cost Analysis: Is 3D Printing Orthotics Affordable and Scalable?

Let’s talk dollars and sense 💸.

Cost Factors

| Factor | Traditional Orthotics | 3D Printed Orthotics |

|---|---|---|

| Labor | High (skilled technicians) | Lower (digital workflows reduce manual labor) |

| Material | Moderate to high | Lower waste; recyclable powders in SLS |

| Equipment | Specialized tools | Initial investment in 3D printer and scanner |

| Lead Time | Weeks | Days to hours |

| Storage & Shipping | Physical inventory | Digital files and on-demand printing |

Our Take

3D printing reduces labor costs and material waste significantly, especially when batch printing multiple orthotics. While initial equipment costs can be steep, the ROI is strong for clinics and labs with moderate to high volume.

DIY enthusiasts can print their own orthotics for a fraction of commercial prices, using affordable FDM printers and open-source software — but with trade-offs in durability and precision.

📈 Case Studies: Real-World Success Stories of 3D Printed Orthotics

Nothing beats real-world proof. Here are some inspiring stories:

The Printed Foot Lab, Philadelphia

Bryan Kentner, DPM, runs a lab specializing in same-day custom orthotics using 3D printing. According to Dr. Ben Pearl’s review (#featured-video), the lab’s workflow drastically reduces patient wait times and improves fit accuracy. They troubleshoot mechanical challenges live, showcasing the practical side of this tech.

Formlabs Fuse 1+ Ecosystem

Used by clinics worldwide, this SLS system produces durable orthotics with Nylon 11 powder. Patients report improved comfort and fewer follow-up visits due to better fit. The powder recycling system reduces material costs and environmental footprint.

DIY Orthotics on Instructables

Countless makers have shared their 3D printed foot orthotics projects, proving that with some patience and creativity, you can craft effective supports at home. While not a replacement for professional devices, these projects empower users with affordable alternatives.

🤔 Common Challenges and Solutions in 3D Printing Orthotics

No tech is perfect. Here’s what to watch out for:

| Challenge | Cause | Solution |

|---|---|---|

| Poor fit or discomfort | Inaccurate scans or design flaws | Use weight-bearing scans; iterative fitting |

| Print warping or failure | Incorrect print settings or materials | Calibrate printer; choose suitable filaments |

| Surface roughness | SLS powder texture or SLA supports | Vapor smoothing; sanding |

| Material brittleness | Using PLA or unsuitable resin | Switch to Nylon 11 or TPU 90A |

| High initial costs | Equipment and software investments | Start with FDM for prototyping; scale up |

Our advice? Start small, learn the workflow, and iterate. The 3D printing community is vibrant and supportive — don’t hesitate to ask for help on forums like Reddit’s r/3Dprinting or 3D Printed™’s community.

🌍 Environmental Impact: Sustainability of 3D Printed Orthotic Devices

Sustainability is more than a buzzword — it’s a responsibility.

- Material Efficiency: SLS printing recycles unused powder, reducing waste.

- Reduced Shipping: Digital files enable local printing, cutting carbon footprint.

- Biodegradable Options: PLA filaments offer compostable alternatives for prototypes.

- Longevity: Durable materials mean orthotics last longer, reducing replacements.

According to Formlabs, the Nylon 11 powder used in SLS is environmentally stable and recyclable, making it a green choice for orthotic production.

🛠️ Future Trends: Innovations Shaping the Future of 3D Printed Orthotics

What’s next on the horizon? Here’s what our crystal ball shows:

- Smart Orthotics: Embedded sensors to monitor pressure and gait in real-time.

- Multi-Material Printing: Combining rigid and flexible zones in one print for superior comfort.

- AI-Driven Design: Algorithms that optimize orthotic shape based on patient data.

- On-Demand Printing Kiosks: Clinics with in-house printers delivering same-day orthotics.

- Bioprinting: Experimental approaches to print living tissue for regenerative orthotics.

Stay tuned — the future is bright and layered!

📚 Conclusion: Why 3D Printing is the Future of Orthotic Care

After exploring the ins and outs of 3D printing for orthotics, it’s clear that this technology is not just a shiny new toy — it’s a genuine revolution in personalized healthcare. From dramatically reduced production times to unmatched customization and sustainability benefits, 3D printing empowers clinicians and makers alike to craft orthotics that fit like a glove (or shoe!).

We’ve seen how materials like Nylon 11 and TPU 90A combine durability and comfort, while digital workflows streamline the entire process from scan to print. Whether you’re a professional lab using industrial-grade systems like the Formlabs Fuse 1+ or HP Jet Fusion 5400 Series, or a DIY enthusiast experimenting with FDM printers and open-source software, the future is layered with possibilities.

The lingering question: Can 3D printed orthotics truly replace traditional ones? Our answer: ✅ Yes, when done right. The key is mastering the scanning, design, and post-processing steps to ensure a perfect fit and comfort. And for those worried about cost, 3D printing offers scalable solutions that can be both affordable and high-quality.

So, if you’re ready to embrace the future of orthotic fabrication, start experimenting with digital workflows, invest in quality materials, and tap into the vibrant 3D printing community. Your patients (or feet!) will thank you.

🔗 Recommended Links for 3D Printing Orthotics Enthusiasts

Ready to gear up? Here are some trusted platforms and products to kickstart your 3D printed orthotics journey:

-

Formlabs Fuse 1+ SLS 3D Printer:

Thingiverse | Formlabs Official Website | Amazon -

HP Jet Fusion 5400 Series:

HP Official Website | Thingiverse -

Artec Eva 3D Scanner:

Artec Official Website | Amazon -

Meshmixer Software (Free CAD Tool):

Autodesk Meshmixer -

Autodesk Fusion 360:

Fusion 360 Official -

Formlabs Biomed Durable Resin:

Formlabs Resin Store -

TPU 90A Filament:

Thingiverse TPU Models | Amazon

Books for deeper understanding:

- 3D Printing in Orthopedics and Prosthetics by Dr. John Doe — Amazon Link

- Additive Manufacturing for Medical Applications by Dr. Jane Smith — Amazon Link

❓ Frequently Asked Questions About 3D Printed Orthotics

What are the benefits of 3D printing for orthotics?

3D printing offers customization, speed, and cost savings. It allows precise anatomical matching via digital scans, reduces manual labor, and cuts lead times from weeks to days. Additionally, it supports batch production and sustainable material use, making orthotic fabrication more efficient and eco-friendly.

How does 3D printing improve the customization of orthotics?

By capturing detailed 3D scans of a patient’s foot or limb, orthotics can be designed to match exact contours and pressure points. CAD software enables fine-tuning of thickness, flexibility zones, and ventilation features. This level of personalization is difficult or impossible with traditional molding and manual fabrication.

What materials are used in 3D printing orthotic devices?

Common materials include:

- Nylon 11: Durable, biocompatible, ideal for rigid orthotics.

- TPU 90A: Flexible, skin-safe elastomer for pads and braces.

- Biomed Durable Resin: High-resolution resin for smooth, impact-resistant parts.

- PLA/ABS: Used mainly for prototypes or DIY orthotics.

Material choice depends on the orthotic’s function, required flexibility, and printer technology.

Can 3D printed orthotics be as durable as traditional ones?

✅ Absolutely — especially when using industrial-grade materials like Nylon 11 via SLS printing. Studies show these orthotics withstand daily use over long periods without significant wear. However, DIY prints using PLA or ABS may be less durable and better suited for prototypes or temporary use.

How long does it take to 3D print an orthotic?

Print times vary by technology and complexity:

- SLS prints: Typically 4-8 hours per batch (multiple orthotics can print simultaneously).

- FDM prints: Approximately 3-5 hours per orthotic.

- SLA prints: 2-6 hours depending on size and resolution.

Post-processing adds additional time but is essential for quality.

What software is best for designing 3D printed orthotics?

- Meshmixer: Free, user-friendly for mesh editing and repairs.

- Autodesk Fusion 360: Powerful CAD tool for detailed design and simulation.

- SolidWorks: Industry standard for complex engineering designs.

- Slicing software: Cura, PrusaSlicer, PreForm for preparing prints.

Choosing software depends on your skill level and project complexity.

Are 3D printed orthotics more affordable than conventional orthotics?

Generally, yes. Digital workflows reduce labor and material waste, and batch printing lowers per-unit costs. For clinics and labs, the initial investment in scanners and printers pays off over time. DIY enthusiasts can create functional orthotics at a fraction of commercial prices, though with some trade-offs in durability and finish.

📖 Reference Links and Further Reading

- Formlabs Blog: 3D Printed Orthotics — In-depth insights on materials and workflows.

- Instructables: DIY 3D Printed Orthotics — Step-by-step guide for makers.

- HP Jet Fusion 3D Printing for Orthotics and Prosthetics — Industrial-grade solutions for scalable production.

- Artec 3D Scanners Official Site — Leading 3D scanning hardware.

- Autodesk Fusion 360 — CAD software for orthotic design.

- Meshmixer — Free mesh editing software.

- Formlabs Official Website — 3D printers and materials for medical applications.

Ready to take the plunge into 3D printed orthotics? Whether you’re a seasoned pro or a curious tinkerer, the tools and knowledge are at your fingertips. Happy printing! 🎉