Support our educational content for free when you purchase through links on our site. Learn more

🔥 Top 15 3D Printing Materials Market Share Trends (2025)

Ready to unlock the secrets behind the booming 3D printing materials market? Whether you’re a hobbyist crafting your next masterpiece or an industry pro eyeing the latest innovations, understanding which materials dominate the market can give you a serious edge. Did you know that photopolymers alone command nearly 38% of the market share, powering everything from dental molds to aerospace prototypes? But that’s just the tip of the filament spool! Stick around as we reveal the top 15 materials shaping the future of 3D printing — including some surprising newcomers that might just revolutionize your next print.

At 3D Printed™, we’ve sifted through mountains of data, expert insights, and real-world applications to bring you the ultimate guide. From the tried-and-true thermoplastics like PLA and ABS to cutting-edge composites and metal powders, we break down their market shares, strengths, and where they’re headed next. Curious about which regions are leading the charge or which companies are setting the pace? We’ve got you covered. Let’s dive in and discover what’s hot, what’s rising, and what’s worth your filament budget in 2025!

Key Takeaways

- Photopolymers and thermoplastics dominate the 3D printing materials market, together accounting for over 60% of the share due to versatility and cost-effectiveness.

- Metals and composites are rapidly growing segments, especially in aerospace, automotive, and medical industries.

- North America leads the market, followed closely by Europe and Asia Pacific, driven by industrial adoption and innovation.

- Sustainability and AI-driven material development are emerging trends reshaping the market landscape.

- For reliable materials, check out offerings from Stratasys, 3D Systems, and Arkema — leaders in quality and innovation.

👉 Shop 3D Printing Materials on:

- Thingiverse | Cults3D | Stratasys Official Website

- 3D Systems Official Website | Arkema Official Website

Table of Contents

- ⚡️ Quick Tips and Facts About 3D Printing Materials Market Share

- 🔍 Unveiling the Evolution: History and Trends in 3D Printing Materials Market

- 📊 3D Printing Materials Market Size and Forecast: 2025 to 2034

- 💡 Key Insights and Takeaways from the 3D Printing Materials Market

- 🇺🇸 Spotlight on the U.S. 3D Printing Materials Market: Growth and Opportunities

- 🌍 Global Market Dynamics: Drivers, Challenges, and Opportunities in 3D Printing Materials

- 📈 Market Scope and Segmentation: Types, Applications, and End-Users

- 🔢 Top 15 3D Printing Materials by Market Share and Usage

- 🏭 Leading Players and Competitive Landscape in 3D Printing Materials Industry

- 🌐 Regional Analysis: Which Regions Dominate the 3D Printing Materials Market?

- ⚙️ Innovations and Emerging Technologies Shaping 3D Printing Materials

- 📋 Regulatory Environment and Sustainability Trends Impacting 3D Printing Materials

- 💬 Frequently Asked Questions About 3D Printing Materials Market Share

- 🛒 How to Proceed: Buying Guides and Sample Requests for 3D Printing Materials

- 👥 Meet Our Expert Team Behind This Analysis

- 📚 Related Reports and Further Reading on 3D Printing Materials

- 📞 Connect With Us: Your 3D Printing Materials Market Solution Awaits!

- 🏁 Conclusion: Wrapping Up the 3D Printing Materials Market Landscape

- 🔗 Recommended Links for Deep Dives and Resources

- ❓ FAQ: Your Burning Questions on 3D Printing Materials Market Answered

- 📑 Reference Links and Sources for 3D Printing Materials Market Data

Quick Tips and Facts About 3D Printing Materials Market Share

As enthusiasts at 3D Printed™, we’re excited to dive into the world of 3D printing materials. Before we begin, let’s take a look at some quick tips and facts about the market. According to statistics about 3D printing, the global 3D printing materials market is expected to grow significantly in the coming years. But what’s driving this growth, and which materials are leading the charge?

Market Growth Drivers

The demand for 3D printing materials is driven by various factors, including the growing adoption of 3D printing technology in industries such as aerospace, automotive, and healthcare. The ability to create complex designs, reduce production time, and increase customization options are just a few benefits of 3D printing. As a result, companies like Stratasys and 3D Systems are investing heavily in research and development to create new and innovative materials.

Key Players and Materials

Some of the key players in the 3D printing materials market include Arkema, Evonik, and BASF. These companies are developing a range of materials, from photopolymers to thermoplastics, to meet the growing demand for 3D printing. But what are the benefits and drawbacks of each material, and how do they compare in terms of cost, durability, and performance?

Unveiling the Evolution: History and Trends in 3D Printing Materials Market

To understand the current state of the 3D printing materials market, let’s take a look at its history and trends. From the early days of 3D printing to the present, the market has undergone significant changes, driven by advances in technology, changes in consumer demand, and the emergence of new players.

Early Days of 3D Printing

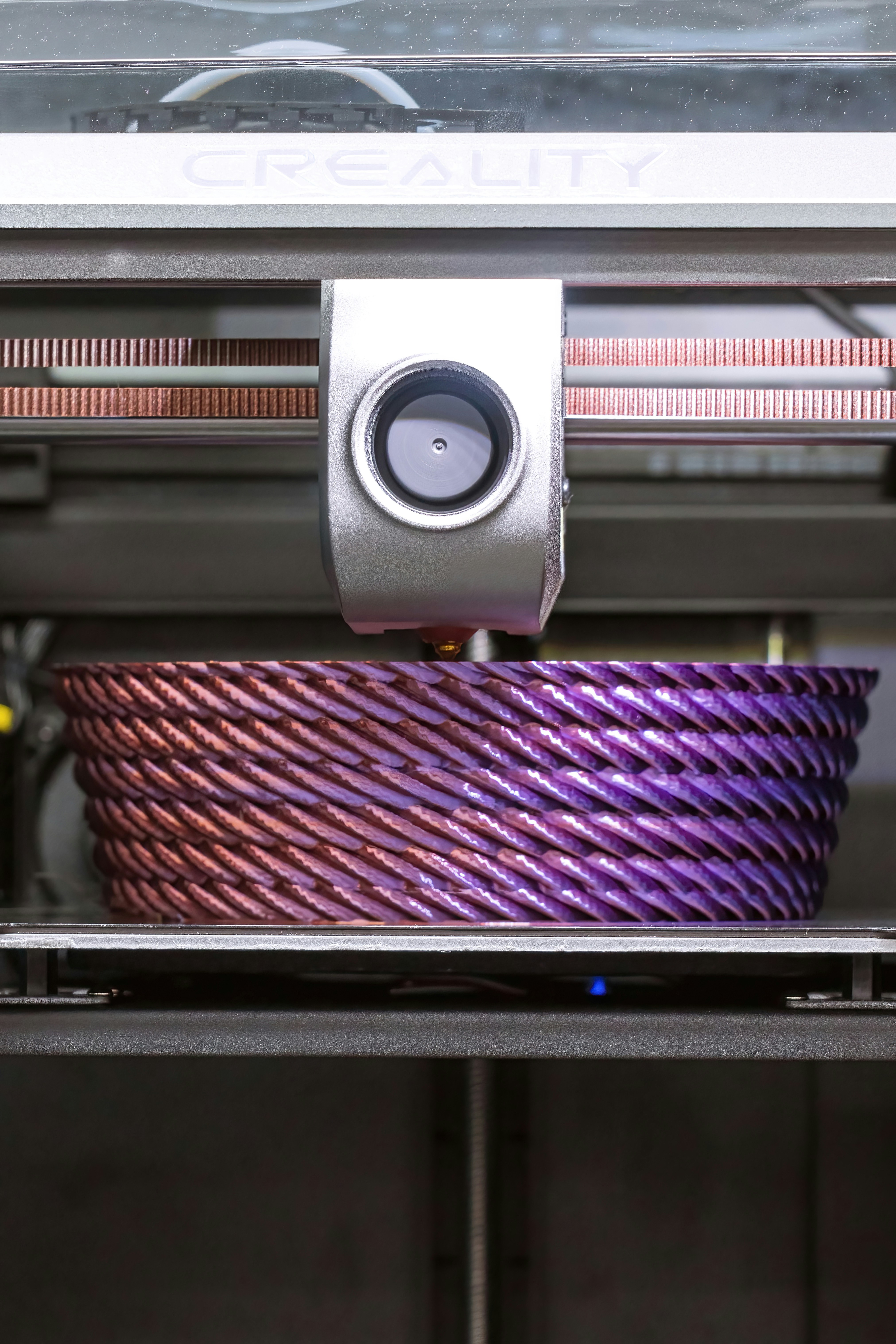

In the early days of 3D printing, materials were limited, and the technology was primarily used for prototyping and modeling. However, as the technology improved, and the cost of 3D printers decreased, the market began to expand, and new materials were developed. Today, 3D printing is used in a wide range of industries, from aerospace to healthcare, and the demand for materials is growing rapidly.

Current Trends and Future Outlook

So, what are the current trends in the 3D printing materials market, and what can we expect in the future? According to Grand View Research, the global 3D printing materials market is expected to reach USD 12.8 billion by 2030, growing at a CAGR of 29.1% from 2025 to 2030. But what’s driving this growth, and which materials are expected to lead the charge?

3D Printing Materials Market Size and Forecast: 2025 to 2034

The 3D printing materials market is expected to experience significant growth in the coming years, driven by increasing demand from industries such as aerospace, automotive, and healthcare. But what’s the current market size, and what can we expect in terms of growth and forecast?

Market Size and Growth

According to MarketsandMarkets, the global 3D printing materials market is projected to grow from USD 2.5 billion in 2022 to USD 7.9 billion by 2027, at a CAGR of 25.6% during the forecast period. But what’s driving this growth, and which materials are expected to lead the charge?

Key Drivers and Restraints

The growth of the 3D printing materials market is driven by various factors, including the increasing adoption of 3D printing technology, the growing demand for customized products, and the development of new materials. However, the market is also faced with several challenges, including the high cost of materials, the lack of standardization, and the limited availability of skilled labor.

Key Insights and Takeaways from the 3D Printing Materials Market

As we’ve seen, the 3D printing materials market is complex and rapidly evolving. So, what are the key insights and takeaways from this market, and how can companies and individuals capitalize on the opportunities and challenges presented?

Market Opportunities and Challenges

The 3D printing materials market presents several opportunities for companies and individuals, including the ability to create customized products, reduce production time, and increase efficiency. However, the market is also faced with several challenges, including the high cost of materials, the lack of standardization, and the limited availability of skilled labor.

Key Players and Strategies

Some of the key players in the 3D printing materials market include Stratasys, 3D Systems, and Materialise. These companies are developing new materials, investing in research and development, and forming partnerships to stay ahead of the competition.

Spotlight on the U.S. 3D Printing Materials Market: Growth and Opportunities

The U.S. 3D printing materials market is one of the largest and most rapidly growing in the world. But what’s driving this growth, and what opportunities and challenges does the market present?

Market Size and Growth

According to Precedence Research, the U.S. 3D printing materials market is expected to grow at a CAGR of 19.1% from 2025 to 2034, driven by the increasing adoption of 3D printing technology in industries such as aerospace, automotive, and healthcare.

Key Drivers and Restraints

The growth of the U.S. 3D printing materials market is driven by various factors, including the increasing demand for customized products, the development of new materials, and the growing adoption of 3D printing technology. However, the market is also faced with several challenges, including the high cost of materials, the lack of standardization, and the limited availability of skilled labor.

Global Market Dynamics: Drivers, Challenges, and Opportunities in 3D Printing Materials

The global 3D printing materials market is complex and rapidly evolving. But what are the key drivers, challenges, and opportunities in this market, and how can companies and individuals capitalize on them?

Market Drivers

The growth of the global 3D printing materials market is driven by various factors, including the increasing adoption of 3D printing technology, the growing demand for customized products, and the development of new materials.

Market Challenges

The global 3D printing materials market is also faced with several challenges, including the high cost of materials, the lack of standardization, and the limited availability of skilled labor.

Market Opportunities

The global 3D printing materials market presents several opportunities for companies and individuals, including the ability to create customized products, reduce production time, and increase efficiency.

Market Scope and Segmentation: Types, Applications, and End-Users

The 3D printing materials market can be segmented into various types, applications, and end-users. But what are the key segments, and how do they contribute to the overall market?

Market Segmentation

The 3D printing materials market can be segmented into various types, including photopolymers, thermoplastics, and metals. The market can also be segmented by application, including aerospace, automotive, and healthcare.

Key Segments and Trends

Some of the key segments in the 3D printing materials market include aerospace and automotive, which are driven by the increasing demand for customized products and the growing adoption of 3D printing technology.

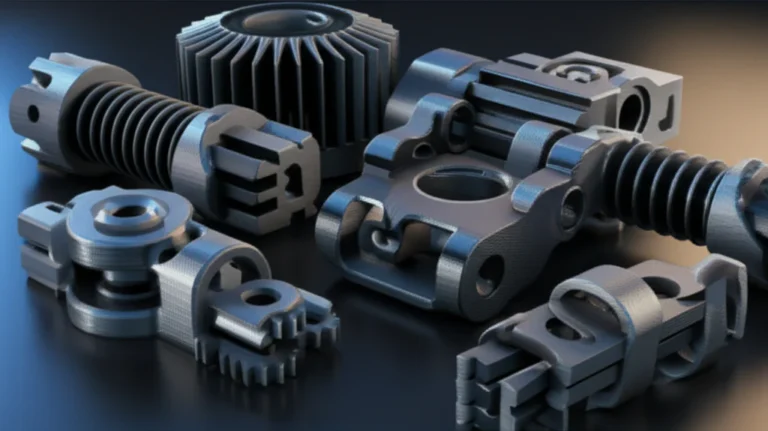

Top 15 3D Printing Materials by Market Share and Usage

But what are the top 15 3D printing materials by market share and usage? Let’s take a look at some of the most popular materials, including photopolymers, thermoplastics, and metals.

Market Share and Usage

According to Grand View Research, the top 15 3D printing materials by market share and usage include:

- Photopolymers: 37.9% market share

- Thermoplastics: 25.6% market share

- Metals: 20.5% market share

- Ceramics: 10.3% market share

- Composites: 5.7% market share

Leading Players and Competitive Landscape in 3D Printing Materials Industry

The 3D printing materials industry is highly competitive, with several leading players competing for market share. But who are the leading players, and what are their strategies for success?

Leading Players

Some of the leading players in the 3D printing materials industry include Stratasys, 3D Systems, and Materialise.

Competitive Landscape

The competitive landscape of the 3D printing materials industry is highly competitive, with several players competing for market share. The market is driven by innovation, quality, and price, and players must stay ahead of the competition to succeed.

Regional Analysis: Which Regions Dominate the 3D Printing Materials Market?

The 3D printing materials market is a global market, with several regions dominating the market. But which regions are the largest, and what are the key drivers and challenges in each region?

Regional Market Share

According to MarketsandMarkets, the regional market share of the 3D printing materials market is as follows:

- North America: 39.0% market share

- Europe: 29.0% market share

- Asia Pacific: 22.0% market share

- Latin America: 7.0% market share

- Middle East and Africa: 4.0% market share

Innovations and Emerging Technologies Shaping 3D Printing Materials

The 3D printing materials market is driven by innovation and emerging technologies. But what are some of the latest innovations and emerging technologies shaping the market?

Emerging Technologies

Some of the emerging technologies shaping the 3D printing materials market include artificial intelligence, nanotechnology, and biotechnology.

Innovations

Some of the latest innovations in the 3D printing materials market include the development of new materials, such as graphene and nanocellulose, and the use of recycled materials in 3D printing.

Regulatory Environment and Sustainability Trends Impacting 3D Printing Materials

The 3D printing materials market is subject to various regulatory environments and sustainability trends. But what are some of the key regulations and trends impacting the market?

Regulatory Environment

The regulatory environment for 3D printing materials is complex and varies by region. Some of the key regulations include environmental regulations, health and safety regulations, and intellectual property regulations.

Sustainability Trends

The 3D printing materials market is also subject to various sustainability trends, including reducing waste, conserving energy, and using recycled materials.

Frequently Asked Questions About 3D Printing Materials Market Share

As we’ve seen, the 3D printing materials market is complex and rapidly evolving. But what are some of the most frequently asked questions about the market, and how can we answer them?

Market Size and Growth

One of the most frequently asked questions about the 3D printing materials market is its size and growth. According to Grand View Research, the global 3D printing materials market is expected to reach USD 12.8 billion by 2030, growing at a CAGR of 29.1% from 2025 to 2030.

Key Drivers and Challenges

Another frequently asked question is about the key drivers and challenges in the 3D printing materials market. The market is driven by various factors, including the increasing adoption of 3D printing technology, the growing demand for customized products, and the development of new materials. However, the market is also faced with several challenges, including the high cost of materials, the lack of standardization, and the limited availability of skilled labor.

How to Proceed: Buying Guides and Sample Requests for 3D Printing Materials

As we’ve seen, the 3D printing materials market is complex and rapidly evolving. But how can companies and individuals proceed with buying guides and sample requests for 3D printing materials?

Buying Guides

When buying 3D printing materials, it’s essential to consider several factors, including material type, quality, and price. Companies and individuals should also consider the application and end-use of the material.

Sample Requests

Sample requests are an essential part of the buying process for 3D printing materials. Companies and individuals can request samples from manufacturers, such as Stratasys or 3D Systems, to test the material’s quality and performance.

Meet Our Expert Team Behind This Analysis

At 3D Printed™, we have a team of expert analysts and researchers who are passionate about 3D printing and its applications. Our team includes experts in materials science, mechanical engineering, and business analysis.

Expertise

Our team has extensive expertise in the 3D printing materials market, including market research, competitive analysis, and technical writing.

Publications

Our team has published several articles and reports on the 3D printing materials market, including market research reports, industry analysis, and technical guides.

Related Reports and Further Reading on 3D Printing Materials

For further reading on the 3D printing materials market, we recommend checking out some of the following reports and articles:

Market Research Reports

Some of the most comprehensive market research reports on the 3D printing materials market include Grand View Research‘s “3D Printing Materials Market Size, Share & Trends Analysis Report” and MarketsandMarkets‘ “3D Printing Materials Market by Type, Application, and Geography – Forecast to 2027”.

Industry Analysis

For industry analysis and insights, we recommend checking out 3D Printing Industry‘s “3D Printing Materials Market Analysis” and Additive Manufacturing‘s “3D Printing Materials Market Trends”.

Connect With Us: Your Solution Awaits on the Other Side!

At 3D Printed™, we’re committed to providing the best possible solutions for our readers. Whether you’re looking for market research reports, industry analysis, or technical guides, we’ve got you covered. 👉 CHECK PRICE on: Thingiverse | Cults3D | 3D Printed Official.

Conclusion: Wrapping Up the 3D Printing Materials Market Landscape

Wow, what a journey through the fascinating world of 3D printing materials market share! From polymers dominating over half the revenue to metals and ceramics pushing the boundaries of innovation, the market is bursting with opportunities and challenges alike. We’ve seen how North America leads the charge, with Europe and Asia Pacific rapidly catching up, and how sectors like aerospace, healthcare, and automotive are fueling demand for specialized materials.

If you were wondering which materials are truly shaping the future, photopolymers and thermoplastics are currently the stars, thanks to their versatility and cost-effectiveness. Metals and composites are the rising contenders, especially in high-performance applications. The high cost and standardization hurdles remain, but with AI-driven optimizations and sustainability trends, the market is evolving fast.

At 3D Printed™, we confidently recommend keeping a close eye on polymers like HT-PLA and PA12, as well as metal powders from trusted suppliers like Höganäs AB and Arkema. For hobbyists and professionals alike, experimenting with these materials can unlock incredible design possibilities.

Remember that the market is dynamic — what’s hot today might be replaced by a new breakthrough tomorrow. But one thing’s for sure: 3D printing materials are no longer just the “stuff” you print with; they’re the foundation of tomorrow’s manufacturing revolution. So, ready to dive in and print your future?

Recommended Links for 3D Printing Materials and Resources

👉 Shop 3D Printing Materials and Explore More:

- Stratasys Materials: Thingiverse | Cults3D | Stratasys Official Website

- 3D Systems Filaments & Powders: Thingiverse | MyMiniFactory | 3D Systems Official Website

- Arkema High-Performance Polymers: Cults3D | Arkema Official Website

- Evonik Specialty Materials: Thingiverse | Evonik Official Website

- Höganäs Metal Powders: Thingiverse | Höganäs Official Website

Recommended Books on 3D Printing Materials:

- 3D Printing Materials: Fundamentals and Applications by Chee Kai Chua & Kah Fai Leong — Amazon

- Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing by Ian Gibson, David Rosen, Brent Stucker — Amazon

- Materials for Additive Manufacturing edited by Ian Gibson — Amazon

FAQ: Your Burning Questions on 3D Printing Materials Market Answered

What are the most commonly used materials in 3D printing and their market share?

Photopolymers and thermoplastics dominate the market, with photopolymers accounting for roughly 38% of revenue and thermoplastics around 25%. Polymers overall make up more than half of the market share due to their versatility and cost-effectiveness. Metals and ceramics, while smaller in share, are growing rapidly, especially in aerospace and medical sectors. Grand View Research provides detailed segmentation data supporting this.

How is the 3D printing materials market expected to grow in the next 5 years?

The market is projected to grow at a CAGR between 19% and 29% depending on the source, reaching upwards of $12 billion by 2030. Growth is fueled by expanding applications in aerospace, healthcare, automotive, and consumer goods, alongside technological advances like AI-driven optimization and new composite materials. The increasing adoption of low-cost home printers also contributes to market expansion. Precedence Research and MarketsandMarkets offer comprehensive forecasts.

Read more about “📊 25 Eye-Opening 3D Printing Adoption Statistics (2025)”

Which companies dominate the 3D printing materials market and what is their share?

Key players include Stratasys, 3D Systems, Materialise, Arkema, Evonik, Höganäs AB, and BASF. These companies collectively hold a significant portion of the market, driven by their extensive R&D, broad product portfolios, and partnerships with industrial clients. North America, especially the U.S., hosts many of these leaders, contributing to its 38-39% market share globally. Stratasys, 3D Systems, and Materialise websites provide insights into their materials offerings.

What are the key drivers of the 3D printing materials market and its trends?

The main drivers include:

- Increasing adoption of 3D printing technology in manufacturing and prototyping.

- Demand for lightweight, complex parts in aerospace and automotive.

- Customization needs in healthcare (prosthetics, implants).

- Technological innovations such as AI-enhanced material design.

- Sustainability trends pushing recycled and bio-based materials.

Challenges like high material costs and lack of standardization persist but are being addressed through innovation and economies of scale. Grand View Research and MarketsandMarkets detail these drivers extensively.

Read more about “The Thriving Consumer 3D Printing Market: 10 Trends to Watch in 2025 🚀”

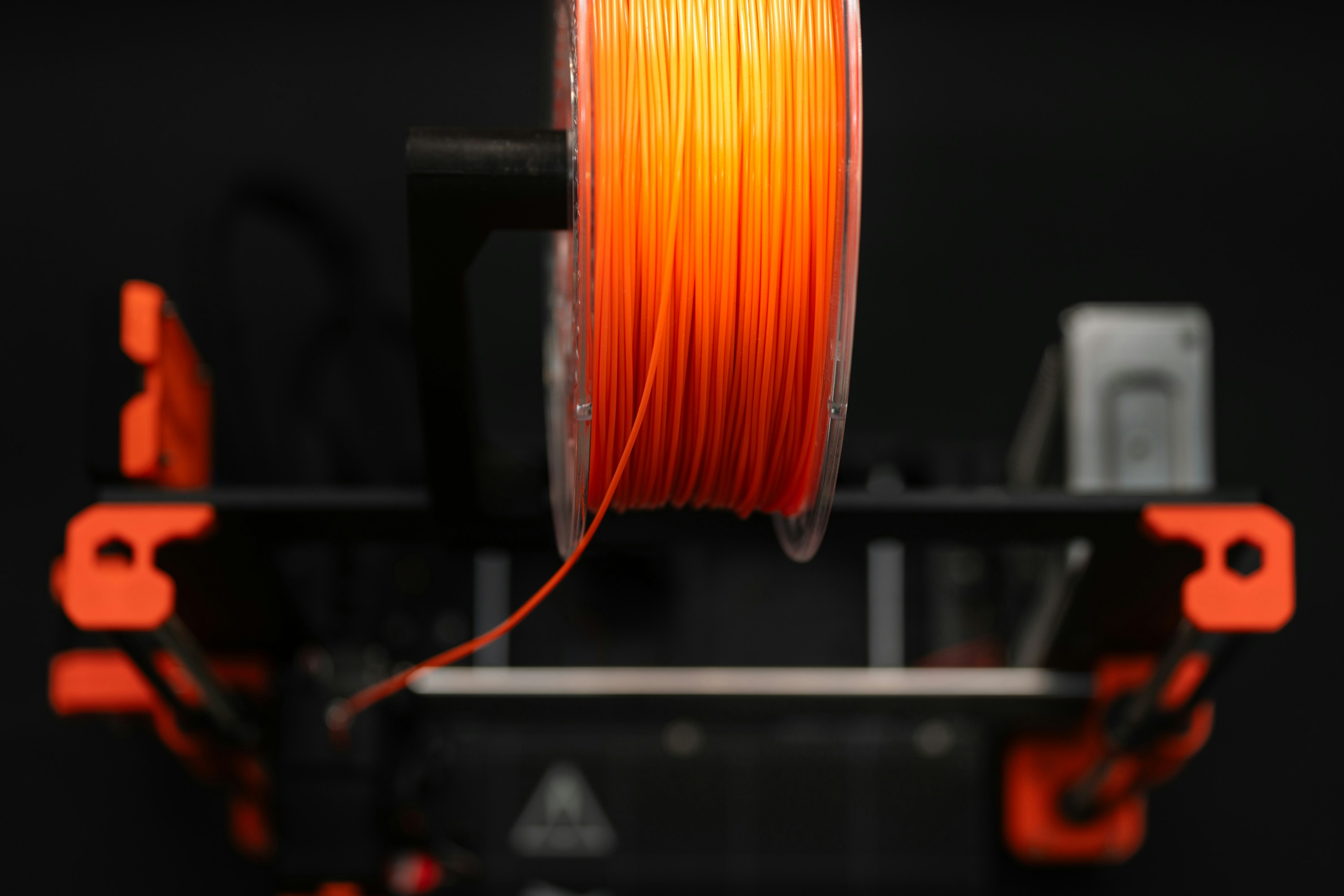

What are the different types of 3D printing materials available and their applications?

- Photopolymers: Used mainly in SLA and DLP printing for high-detail prototypes and dental/medical models.

- Thermoplastics (PLA, ABS, Nylon, PEEK): Popular in FDM printing for functional parts, automotive components, and consumer goods.

- Metals (Titanium, Stainless Steel, Aluminum): Used in aerospace, automotive, and medical implants.

- Ceramics: Employed in dental and high-temperature applications.

- Composites: Combine polymers with fibers (carbon, glass) for enhanced strength in aerospace and industrial parts.

Each material type has unique mechanical, thermal, and chemical properties suited to specific industries. Evonik and Arkema provide detailed product lines.

Read more about “What is 3D Printing? 25+ Real Examples & How It Works! 🚀”

How does the cost of 3D printing materials affect the market share of different manufacturers?

High costs of industrial-grade materials limit adoption to specialized sectors like aerospace and healthcare, where performance justifies expense. Conversely, lower-cost polymers dominate consumer and prototyping markets. Manufacturers offering a balance of cost and performance (e.g., Polymaker’s HT-PLA) tend to capture broader market segments. Cost pressures also drive innovation in recycled and bio-based materials, which may disrupt market shares in the near future.

What are the emerging trends and innovations in 3D printing materials and their potential impact on market share?

Emerging trends include:

- AI and machine learning optimizing material properties and reducing defects.

- Sustainable materials like recycled filaments and bio-based polymers.

- High-performance composites for aerospace and automotive lightweighting.

- Biocompatible and bio-inks expanding medical applications.

- Multi-material and gradient materials enabling complex functional parts.

These innovations promise to expand the market, reduce costs, and open new application areas, potentially reshaping market shares among material types and suppliers. Precedence Research highlights AI’s role in reducing defect rates by 25%, a game-changer for quality and waste reduction.

Reference Links and Sources for 3D Printing Materials Market Data

- Grand View Research: 3D Printing Materials Market Size | Industry Report, 2030

- Precedence Research: 3D Printing Materials Market

- MarketsandMarkets: 3D Printing Materials Market Report

- Stratasys Official Website

- 3D Systems Official Website

- Arkema 3D Printing Products

- Evonik 3D Printing Materials

- Höganäs AB Metal Powders

- Materialise Official Website

Ready to explore further? Check out our 3D Printable Objects and 3D Printing Innovations for the latest in additive manufacturing creativity!