Support our educational content for free when you purchase through links on our site. Learn more

Do You Need CAD Software for 3D Printing? 7 Things to Know in 2025 🎨

If you’ve ever wondered whether you really need CAD software to start 3D printing, you’re not alone. The truth is, the answer isn’t a simple yes or no — it depends on what kind of maker you want to be. We’ve seen beginners jump straight into printing downloaded models, while pros swear by mastering CAD to unlock endless customization and precision. In this article, we’ll break down everything from the basics of CAD and slicing software to the top 7 CAD tools you should consider in 2025. Plus, we’ll share insider tips from our 3D Printed™ team that might just change how you approach your next print!

Did you know that over 60% of hobbyist 3D printers start without any CAD experience, relying solely on pre-made designs? Yet, those who learn CAD often find their creativity and project success skyrocket. Curious how to bridge that gap? Keep reading — we’ll guide you step-by-step through the software essentials, design tips, and slicing secrets that make 3D printing truly magical.

Key Takeaways

- You don’t always need CAD software to 3D print, but it dramatically expands your creative possibilities.

- Slicing software is essential for preparing any 3D model for printing, whether you designed it or downloaded it.

- Beginner-friendly CAD tools like TinkerCAD are perfect for newcomers, while Fusion 360 and SolidWorks serve pros and advanced hobbyists.

- Learning CAD unlocks customization, optimization, and unique designs that pre-made models can’t offer.

- System requirements vary, but most modern PCs can handle beginner CAD and slicing software comfortably.

- Remote and cloud-based CAD solutions are growing, making design and printing more accessible than ever.

Ready to explore CAD software options or find the perfect slicer? Check out our curated lists and expert reviews in the 3D Design Software and 3D Printer Reviews categories!

Happy printing and designing! 🚀

Table of Contents

- ⚡️ Quick Tips and Facts About CAD Software for 3D Printing

- 🔍 The Evolution of 3D Printing and CAD: A Dynamic Duo

- 🛠️ What Is CAD Software and Why Does It Matter for 3D Printing?

- 🎯 Do You Really Need CAD Software to 3D Print? Pros and Cons

- 1️⃣ Top 7 CAD Software Options for Designing Your 3D Prints

- 🎨 How to Design 3D Printable Parts: Tips, Tricks, and Pitfalls to Avoid

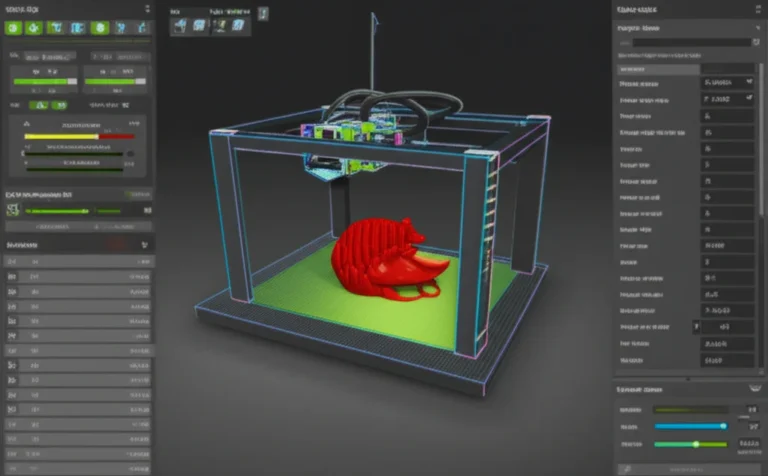

- 🔧 Understanding Slicing Software: The Bridge Between CAD and Your 3D Printer

- 🚀 From Design to Print: What Software Do You Need to Start Your 3D Printing Journey?

- 🌐 Remote 3D Printing and Cloud-Based CAD: The Future Is Now

- 💡 Expert Tips for Mastering CAD Software for 3D Printing Success

- 🤔 Common Questions About CAD and 3D Printing—Answered!

- 🏁 Conclusion: To CAD or Not to CAD? That Is the Question

- 🔗 Recommended Links for CAD Software and 3D Printing Resources

- ❓ FAQ: Your Burning Questions on CAD and 3D Printing

- 📚 Reference Links and Further Reading

Hey everyone, and welcome back to the 3D Printed™ blog! We’re your go-to team of

Conclusion: To CAD or Not to CAD? That Is the Question

After our deep dive into the world of CAD software and 3D printing, here’s the bottom line: you don’t always need CAD software to 3D print, but having it in your toolkit opens up a universe of creative freedom and customization. If you’re happy downloading ready-made models from platforms like Thingiverse or MyMiniFactory, you can absolutely skip the design phase and jump straight to slicing and printing. ✅

However, if you want to design your own parts, modify existing models, or optimize prints for specific functions, CAD software is your best friend. From beginner-friendly options like TinkerCAD to professional-grade tools like Fusion 360 or SolidWorks, there’s a CAD program tailored to your skill level and project needs. We’ve seen firsthand how mastering CAD can transform your 3D printing experience — it’s like going from coloring inside the lines to creating your own masterpiece.

Remember, slicing software is the essential bridge between your design and the printer, so even if you don’t design from scratch, you’ll need a slicer like Ultimaker Cura or PrusaSlicer. And if you’re curious about remote printing or cloud-based CAD, the future is bright and accessible.

So, whether you’re a casual hobbyist or a serious maker, investing some time in learning CAD will pay off in spades. Don’t let the jargon scare you — start small, experiment, and watch your ideas come to life layer by layer. Ready to unleash your inner designer? We thought so! 🎉

Recommended Links for CAD Software and 3D Printing Resources

👉 Shop CAD Software and Tools:

- TinkerCAD: Thingiverse | Autodesk Official

- Fusion 360: Thingiverse | Autodesk Official

- SolidWorks: Thingiverse | Dassault Systèmes Official

- Ultimaker Cura (Slicer): Ultimaker Official | Thingiverse

- PrusaSlicer: Prusa Official | Thingiverse

Books to Level Up Your CAD and 3D Printing Skills:

- 3D Printing Projects by DK — Amazon

- Mastering Autodesk Fusion 360 by Paul Tran — Amazon

- 3D Printing Failures by Sean Aranda — Amazon

FAQ: Your Burning Questions on CAD and 3D Printing

What is the best CAD software for 3D printing beginners?

For beginners, TinkerCAD is the gold standard. It’s free, browser-based, and uses an intuitive block-building approach that feels like digital Lego. You don’t need to install anything, and there’s a huge community with tutorials and ready-made shapes. Once you’re comfortable, you can graduate to Fusion 360, which offers more advanced parametric modeling and is free for hobbyists and startups. Both are widely supported in the 3D printing community, making troubleshooting and learning easier.

Read more about “Are There Any Free 3D Printing Software? 7 Best Picks for 2025 🎉”

How do I choose the right 3D modeling software for my 3D printing needs?

Choosing the right software depends on:

- Your skill level: Beginners should start simple; pros might want advanced features.

- Project complexity: Mechanical parts need parametric CAD (Fusion 360, SolidWorks), while artistic models might benefit from sculpting tools like Blender.

- Budget: Free options (TinkerCAD, Blender) vs. paid professional suites (SolidWorks, Siemens NX).

- File compatibility: Ensure the software exports STL or OBJ files, the standard for 3D printing.

- Community and support: Popular software has more tutorials, plugins, and forums.

Try out free trials or browser-based tools before committing. Our 3D Design Software category has detailed reviews and guides to help you decide.

Can I use free CAD software for 3D printing, or do I need to purchase a license?

✅ You can absolutely use free CAD software! Many hobbyists and professionals rely on free tools like TinkerCAD, Blender, FreeCAD, and Fusion 360’s free tier. These programs support exporting to STL/OBJ formats needed for 3D printing. Paid licenses often offer advanced features, better support, and integration with other software, but they’re not mandatory for most 3D printing projects. Start free, and upgrade if your needs grow.

What are the system requirements for running CAD software for 3D printing, and do I need a dedicated computer?

CAD software ranges from lightweight to resource-intensive. For beginner-friendly tools like TinkerCAD (browser-based) or FreeCAD, a standard modern PC or laptop with a decent internet connection suffices. More advanced software like Fusion 360 or SolidWorks benefits from:

- A multi-core processor (Intel i5/i7 or AMD Ryzen 5/7)

- 8GB+ RAM (16GB recommended for complex models)

- Dedicated graphics card (NVIDIA or AMD) for rendering and smooth viewport performance

- SSD storage for faster file handling

You don’t necessarily need a dedicated computer, but a reliable machine speeds up modeling and slicing. If you’re serious about CAD and 3D printing, investing in a capable workstation pays dividends.

How important is learning slicing software alongside CAD?

Slicing software is non-negotiable for 3D printing. Even if you download perfect STL files, you must slice them into printer-readable layers. Learning slicers like Ultimaker Cura or PrusaSlicer helps you optimize print settings, supports, and infill, which directly impact print quality and success rates. Many slicers integrate with CAD tools or offer plugins, streamlining the workflow. We recommend mastering both CAD and slicing to unlock your printer’s full potential.

Can I 3D print without designing anything myself?

Absolutely! The 3D printing community is rich with free, downloadable models on sites like Thingiverse, MyMiniFactory, and Cults3D. You can print toys, tools, art, and more without touching CAD software. However, knowing CAD lets you customize or create unique designs, which is where the magic truly happens.

Reference Links and Further Reading

- Ultimaker: What Software to Use for 3D Printing

- TinkerCAD Official Website

- PCMag: 3D Printing Basics: Your Questions Answered

- Autodesk Fusion 360

- SolidWorks by Dassault Systèmes

- Ultimaker Cura Software

- PrusaSlicer by Prusa Research

- Thingiverse 3D Models Repository

- MyMiniFactory 3D Models

- Cults3D Marketplace

We hope this comprehensive guide has cleared up the mystery of whether you need CAD software for 3D printing — spoiler alert: it’s a powerful tool that can elevate your 3D printing game, but it’s not mandatory for everyone. Whether you’re just starting or looking to level up, there’s a perfect software combo waiting for you. Happy printing! 🎉