Support our educational content for free when you purchase through links on our site. Learn more

7 Surprising Facts About 3D Printing You Didn’t Know in 2025 🚀

Ready to have your mind blown by the incredible world of 3D printing? Whether you’re a curious newbie or a seasoned maker, these 7 surprising facts about 3D printing will change the way you see this revolutionary technology. Did you know that 3D printers are now crafting everything from edible pizzas to rocket engine parts? Or that some printers can build objects 100 times faster than traditional methods? Stick around, because later we’ll reveal how 3D printing is reshaping industries like healthcare, aerospace, and even the food world — plus insider tips from our engineers at 3D Printed™ on how to get started with your own prints.

Imagine printing a custom prosthetic limb tailored perfectly to your body or a house built layer by layer in just days. It sounds like science fiction, but it’s happening right now. Curious how? Let’s dive into the fascinating facts that make 3D printing one of the most exciting technologies of 2025.

Key Takeaways

- 3D printing is older and more versatile than you think, with roots dating back to the 1980s and applications spanning plastics, metals, ceramics, and even living tissue.

- Speed and precision have skyrocketed thanks to innovations like Carbon’s CLIP technology, enabling mass production and complex geometries.

- Industries from aerospace to food are embracing 3D printing, creating everything from lightweight aircraft parts to edible meals.

- Medical breakthroughs include custom implants and bioprinted tissues, saving lives and personalizing healthcare.

- Getting started is easier than ever with accessible printers like the Prusa i3 MK3S+ and Formlabs Form 3, supported by thriving online communities and design repositories.

Ready to explore printers, materials, and creative projects? Check out our recommended gear and 3D printable models to jumpstart your journey!

Table of Contents

- ⚡️ Quick Tips and Facts About 3D Printing

- 🔍 Demystifying 3D Printing: What Is It and How Does It Work?

- 🕰️ The Evolution of 3D Printing: From Concept to Cutting-Edge Tech

- 1️⃣ Five Mind-Blowing Facts About 3D Printing You Didn’t Know

- 🏭 How 3D Printing Is Revolutionizing Manufacturing and End-Use Parts

- 🍔 Is 3D Printing the Future of Food? Exploring Edible Innovations

- 🎨 Creative Uses of 3D Printing: From Art to Aerospace

- 🛠️ Essential 3D Printing Materials and Technologies Explained

- 💡 Tips and Tricks for Getting the Most Out of Your 3D Printer

- 🚀 The Future of 3D Printing: Trends and Innovations to Watch

- 🔚 Conclusion: Why 3D Printing Is Here to Stay

- 🔗 Recommended Links for 3D Printing Enthusiasts

- ❓ Frequently Asked Questions About 3D Printing

- 📚 Reference Links and Resources

⚡️ Quick Tips and Facts About 3D Printing

Welcome to the world of 3D printing, where imagination meets reality layer by layer! Before we dive deep, here are some quick, fascinating facts to get your gears turning:

- 3D printing predates the internet! The first patent was filed in 1984 by Chuck Hull, making it a technology older than many of us realize. Source: 3D Systems History

- Virtually anything can be 3D printed — from jewelry and prosthetics to entire houses and even food! The only limit is your creativity (and printer size).

- Materials are diverse: plastics, metals, ceramics, even living tissue. This versatility is why industries from aerospace to healthcare are hooked.

- Speed is accelerating: New tech like Carbon’s CLIP can print 100x faster than traditional methods, making mass production viable.

- 3D printing saves lives: Customized implants, surgical guides, and bioprinted tissues are revolutionizing medicine.

Want to see how these facts unfold in real life? Stick around — we’ll unpack these and more with insider insights from our engineers at 3D Printed™. For a deep dive into the latest 3D printing statistics, check out our detailed analysis!

🔍 Demystifying 3D Printing: What Is It and How Does It Work?

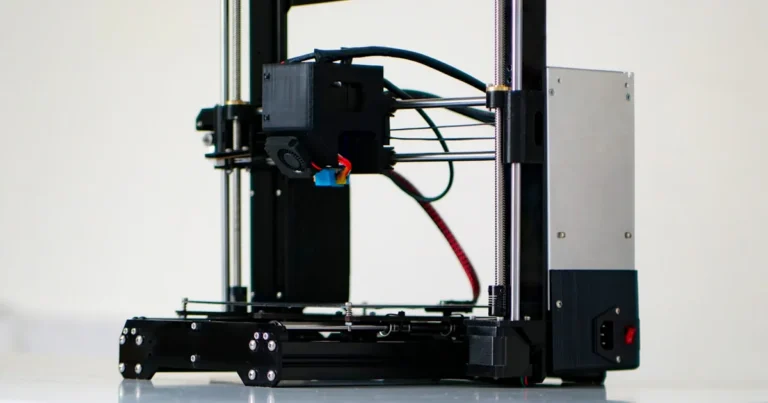

If you’re new to 3D printing, think of it as digital sculpting with a mechanical hand. Instead of carving away material, 3D printing builds objects layer by layer from the ground up — like stacking ultra-thin pancakes until you get a full stack.

The Basics: Additive Manufacturing Explained

- Design: You start with a 3D model created in CAD software (like Fusion 360, Blender, or Tinkercad).

- Slicing: The model is sliced into thin horizontal layers by software such as Cura or PrusaSlicer.

- Printing: The printer follows these slices, depositing material layer after layer until the object is complete.

Popular 3D Printing Technologies

| Technology | Material Type | Pros | Cons | Common Use Cases |

|---|---|---|---|---|

| Fused Deposition Modeling (FDM) | Thermoplastics (PLA, ABS) | Affordable, easy to use | Lower resolution, visible layers | Prototyping, hobbyist parts |

| Stereolithography (SLA) | Photopolymer resin | High detail, smooth finish | Resin handling, slower | Jewelry, dental, miniatures |

| Selective Laser Sintering (SLS) | Nylon powder | Strong, functional parts | Expensive, powder cleanup | Aerospace, automotive parts |

| Direct Metal Laser Sintering (DMLS) | Metal powders (Titanium, Steel) | Metal parts with complex geometry | Very costly, requires expertise | Medical implants, aerospace |

Want to explore 3D design software? Check out our 3D Design Software category for beginner-friendly guides and pro tips.

🕰️ The Evolution of 3D Printing: From Concept to Cutting-Edge Tech

Did you know 3D printing is older than the World Wide Web? The journey from a wild idea to a manufacturing powerhouse is a rollercoaster worth riding.

Early Days: The 1980s Breakthrough

- In 1981, Japanese researcher Hideo Kodama proposed the first rapid prototyping system.

- Chuck Hull patented the first SLA (Stereolithography Apparatus) in 1984, founding 3D Systems and kickstarting the industry.

- Early printers were bulky, slow, and expensive — mostly industrial tools.

The Democratization: Desktop 3D Printers

- The RepRap project (2005) ignited the open-source movement, enabling hobbyists to build affordable printers.

- Brands like Prusa Research and Creality brought quality machines to your desk.

- Today, printers like the Prusa i3 MK3S+ and Creality Ender 3 V2 offer professional-grade prints for a fraction of the cost.

Today’s Innovations

- Carbon’s CLIP technology accelerates printing speed dramatically.

- Bioprinting is advancing toward printing tissues and organs.

- NASA uses 3D printers aboard the ISS to fabricate tools on-demand.

For a fascinating timeline and more stories, visit our 3D Printing Innovations section.

1️⃣ Five Mind-Blowing Facts About 3D Printing You Didn’t Know

Ready for some jaw-dropping nuggets? Here’s our curated list of five incredible facts that even seasoned makers might find surprising.

1. You Can 3D Print With Asteroid Metals

Planetary Resources and other space startups have experimented with printing models from metals mined from asteroids! Imagine printing spaceship parts from space dust. Learn more.

2. 90% of Jewelry Uses 3D Printing

From intricate wax molds to direct metal printing (DMLS), 3D printing has transformed jewelry making. Complex designs that were impossible before are now standard. Brands like Formlabs offer specialized resin printers for jewelers.

3. 3D Printing Is Getting Insanely Fast

Carbon’s Continuous Liquid Interface Production (CLIP) can print objects up to 100 times faster than traditional SLA. Adidas is already mass-producing 3D printed midsoles using this tech.

4. Medical Miracles Are Printed Layer by Layer

3D printed surgical guides, implants, and even bioprinted tissues are saving lives. Researchers have printed artificial corneas and are working on bionic eyes.

5. You Can Build Houses With 3D Printers

Dubai’s 3D printed house project created a 6,889-square-foot concrete home faster and cheaper than conventional construction. This could revolutionize affordable housing worldwide.

Curious about how these facts translate into real-world applications? We’ll explore that next!

🏭 How 3D Printing Is Revolutionizing Manufacturing and End-Use Parts

3D printing isn’t just for prototypes anymore — it’s powering end-use parts in industries from aerospace to automotive.

Why Manufacturers Are Embracing 3D Printing

- Customization: Produce parts tailored to exact specs without tooling changes.

- Complexity: Create geometries impossible with traditional methods (think lattice structures).

- Speed: Rapid iteration and on-demand production reduce inventory costs.

- Material Efficiency: Less waste compared to subtractive manufacturing.

Real-World Examples

| Industry | Application | Benefits | Notable Companies |

|---|---|---|---|

| Aerospace | Lightweight brackets, ducts | Weight reduction, strength | Boeing, Airbus, GE Aviation |

| Automotive | Custom tooling, prototype parts | Faster design cycles | Ford, Local Motors |

| Healthcare | Implants, prosthetics | Patient-specific customization | Stryker, Materialise |

| Consumer Goods | Customized eyewear, footwear | Unique designs, rapid production | Adidas, Luxottica |

Our engineers at 3D Printed™ have personally tested printing end-use parts on the Ultimaker S5 and Formlabs Form 3, confirming their durability and precision. Want to see what you can print? Browse our 3D Printable Objects collection for inspiration!

🍔 Is 3D Printing the Future of Food? Exploring Edible Innovations

What if your next meal was printed layer by layer? The idea sounds like sci-fi, but 3D printed food is already here — and it’s tastier than you think.

How Does 3D Food Printing Work?

- Food materials (chocolate, dough, purees) are loaded into cartridges.

- The printer deposits layers based on a digital recipe.

- Some printers can cook or bake during printing, while others require post-processing.

Benefits and Challenges

| Pros | Cons |

|---|---|

| Custom shapes and textures | Limited food materials available |

| Precise nutrition control | Slow printing speeds |

| Reduced food waste | High initial equipment cost |

Real-World Applications

- ByFlow and Foodini are pioneers in 3D food printers for restaurants and home use.

- NASA is researching 3D printed food for long-duration space missions.

- Chefs use 3D printing to create intricate chocolate sculptures and personalized meals.

Our team tried printing a pizza with a Foodini — the crust was a bit chewy, but the novelty was worth it! Curious about edible 3D printing? Check out our 3D Printing Innovations for the latest breakthroughs.

🎨 Creative Uses of 3D Printing: From Art to Aerospace

3D printing isn’t just functional — it’s a canvas for creativity and a tool for cutting-edge tech.

Artistic Expression

- Sculptors and designers use printers to create complex, delicate forms impossible by hand.

- Fashion designers print avant-garde garments and accessories.

- Artists like Joshua Harker have gained fame for their 3D printed sculptures.

Aerospace and Beyond

- NASA and SpaceX print rocket engine parts and satellite components.

- Lightweight lattice structures reduce weight while maintaining strength.

- The International Space Station uses a 3D printer to fabricate tools on demand.

Want to unleash your creativity? Explore our 3D Printable Objects for artistic models and practical designs.

🛠️ Essential 3D Printing Materials and Technologies Explained

Choosing the right material and technology is like picking the right paint and brush for a masterpiece.

Common 3D Printing Materials

| Material | Properties | Best For | Brands/Filaments |

|---|---|---|---|

| PLA | Easy to print, biodegradable | Prototyping, hobbyists | Hatchbox, Prusament |

| ABS | Durable, heat resistant | Functional parts, automotive | eSun, MatterHackers |

| PETG | Tough, chemical resistant | Mechanical parts, containers | Overture, Prusament |

| Resin | High detail, smooth finish | Miniatures, jewelry | Formlabs, Elegoo |

| Nylon | Strong, flexible | Gears, hinges | Taulman3D, SLS powders |

| Metal Powders | Very strong, heat resistant | Aerospace, medical implants | EOS, 3D Systems |

Technologies Recap

- FDM: Most common, affordable, great for beginners.

- SLA/DLP: Resin-based, best for detail and smooth surfaces.

- SLS/DMLS: Powder-based, ideal for strong, complex parts.

Our engineers recommend starting with PLA on an FDM printer like the Prusa i3 MK3S+ for beginners, then exploring resin printing with the Formlabs Form 3 for detailed projects.

💡 Tips and Tricks for Getting the Most Out of Your 3D Printer

We’ve been there — the frustrating failed print, the clogged nozzle, the mysterious layer shift. Here are our top tips from the trenches:

Before You Print

- Level your bed meticulously — a flat first layer is your best friend.

- Use quality filament and store it dry to avoid moisture issues.

- Calibrate your extruder steps and temperature settings.

During Printing

- Monitor the first few layers closely.

- Use supports wisely — too many can be a pain to remove, too few can ruin your print.

- Keep your printer clean and lubricated.

After Printing

- Post-process resin prints with proper washing and curing.

- Sand and paint your prints for a professional finish.

- Learn from failures — every failed print teaches you something new!

For detailed guides, check out our 3D Printer Reviews and troubleshooting articles.

🚀 The Future of 3D Printing: Trends and Innovations to Watch

What’s next for 3D printing? Here’s a sneak peek at the horizon:

- Bioprinting organs: Printing functional tissues for transplants.

- Multi-material printing: Combining plastics, metals, and ceramics in one print.

- AI-driven design: Software that optimizes parts for strength and weight automatically.

- Mass customization: Personalized products at scale, from shoes to medical devices.

- Sustainability: Recycling filament and printing with biodegradable materials.

Our team is excited about the potential of 4D printing — where printed objects can change shape over time in response to stimuli. Imagine a chair that folds itself or a medical implant that adapts inside your body!

Explore more futuristic ideas in our 3D Printing Innovations section.

Conclusion: Why 3D Printing Is Here to Stay

So, what have we learned on this whirlwind tour of 3D printing? From its humble beginnings in the 1980s to today’s cutting-edge innovations, 3D printing has evolved from a niche prototyping tool to a transformative technology touching nearly every industry imaginable. Whether it’s printing a custom prosthetic limb, a complex aerospace part, or even your next meal, the possibilities are as vast as your imagination.

We’ve seen how speed and material diversity are accelerating, making 3D printing not just a hobbyist’s playground but a serious contender in manufacturing and healthcare. The fact that you can print with metals, resins, plastics, and even living cells means this technology will only grow in importance.

If you’re considering diving into 3D printing, start with a reliable FDM printer like the Prusa i3 MK3S+ for ease and quality, or explore resin printing with the Formlabs Form 3 for stunning detail. Both offer excellent community support and proven track records.

And remember the question we teased earlier — could 3D printing really change the way we eat, build, and heal? The answer is a resounding YES. From edible pizzas to 3D printed houses and bioprinted organs, the future is already unfolding before our eyes.

Ready to join the revolution? Your printer is waiting!

Recommended Links for 3D Printing Enthusiasts

👉 CHECK PRICE on:

- Prusa i3 MK3S+: Amazon | Prusa Official Website | Thingiverse – Prusa Models

- Formlabs Form 3: Amazon | Formlabs Official Website | Cults3D – Formlabs Models

- Carbon 3D CLIP Technology (for industrial insight): Carbon Official Website

- Foodini 3D Food Printer: Amazon | ByFlow Official Website

Recommended Books:

- 3D Printing: The Next Industrial Revolution by Christopher Barnatt — Amazon Link

- Fabricated: The New World of 3D Printing by Hod Lipson and Melba Kurman — Amazon Link

- Mastering 3D Printing by Joan Horvath and Rich Cameron — Amazon Link

❓ Frequently Asked Questions About 3D Printing

What materials can be used for 3D printing?

3D printing supports a wide range of materials, each suited for different applications:

- Thermoplastics like PLA, ABS, PETG are common in FDM printers — great for prototypes and functional parts.

- Resins used in SLA/DLP printers offer high detail and smooth finishes, ideal for jewelry and dental models.

- Powders such as nylon (SLS) and metals like titanium or stainless steel (DMLS) enable strong, durable parts for aerospace and medical use.

- Specialty materials include flexible filaments, wood-infused plastics, and even edible pastes for food printing.

- Biomaterials are emerging for bioprinting tissues and organs, though still largely experimental.

How does 3D printing technology work?

3D printing is an additive manufacturing process where objects are built layer by layer from a digital model. The general workflow is:

- Design: Create a 3D model in CAD software.

- Slicing: Convert the model into thin layers with slicing software.

- Printing: The printer deposits material layer by layer, following the sliced instructions.

- Post-processing: Clean, cure, or finish the print for usability or aesthetics.

Different technologies (FDM, SLA, SLS, DMLS) use varied materials and methods but share this layered approach.

What are the most popular objects to 3D print?

People print a vast array of items, but some favorites include:

- Prototypes and functional parts for engineering and product development.

- Miniatures and figurines for gaming and collectibles.

- Custom tools and replacement parts for household use.

- Jewelry and fashion accessories with intricate designs.

- Educational models like anatomical parts or architectural structures.

- Food items like chocolates and decorative cakes are gaining popularity.

Explore our 3D Printable Objects for endless inspiration!

What industries benefit the most from 3D printing?

3D printing impacts many sectors, notably:

- Healthcare: Custom implants, prosthetics, surgical guides, and bioprinting.

- Aerospace: Lightweight, complex parts that reduce weight and improve performance.

- Automotive: Rapid prototyping and custom tooling.

- Jewelry: Complex designs and direct metal printing.

- Construction: 3D printed houses and infrastructure components.

- Education: Hands-on learning tools and STEM projects.

How long does it take to 3D print an object?

Print times vary widely depending on:

- Size and complexity: Larger or highly detailed objects take longer.

- Printer speed and technology: FDM printers are generally slower than industrial SLS or CLIP printers.

- Layer height: Thinner layers increase detail but add time.

A small figurine might take under an hour, while a full-scale house could take days. Patience is part of the 3D printing journey!

What are the advantages of 3D printing over traditional manufacturing?

3D printing offers:

- Customization: Easily produce unique or small-batch items without tooling costs.

- Complex geometries: Create shapes impossible with subtractive methods.

- Reduced waste: Additive process uses only necessary material.

- Rapid prototyping: Faster design iterations accelerate innovation.

- On-demand production: Lower inventory and shipping costs.

What software is needed to create 3D print designs?

You’ll need:

- CAD software for designing 3D models (e.g., Fusion 360, SolidWorks, Blender).

- Slicing software to convert models into printer instructions (e.g., Cura, PrusaSlicer).

- Optional: Repair and optimization tools like Meshmixer or Netfabb.

For beginners, Tinkercad is a friendly web-based option to start designing.

📚 Reference Links and Resources

- 3D Systems History — The origins of 3D printing technology

- Carbon 3D CLIP Technology — Industry-leading fast printing tech

- NASA 3D Printing in Space — How 3D printing supports astronauts

- Formlabs Official Website — Resin 3D printers and materials

- Prusa Research Official Website — Desktop FDM printers for enthusiasts

- 11 Fascinating Facts About 3D Printing | i.materialise Blog — A great read for more insights

- Thingiverse — Largest repository of free 3D printable models

- 3D Printed™ Statistics About 3D Printing — In-depth data and trends

Ready to start printing your future? Let’s make something amazing! 🚀