Support our educational content for free when you purchase through links on our site. Learn more

What Percentage of 3D Printing Is for Prototyping vs. Production? (2025) 🖨️

Ever wondered how much of the 3D printing world is still stuck in the prototyping phase versus actually churning out real, end-use products? Spoiler alert: the answer might surprise you! While many think 3D printing is just a fancy way to make quick mockups, the reality is a dynamic tug-of-war between rapid prototyping and serious manufacturing. In this deep dive, we’ll unpack the latest stats, reveal which industries are leading the charge, and share insider tips on when to print your prototype—and when to print your final product.

Stick around, because later we’ll reveal how cutting-edge materials and AI-driven printers are shifting the balance, making 3D printing a powerhouse for production—not just play. Plus, we’ll share our expert “3D Printed™” recommendations to help you decide where your next print fits in the spectrum.

Key Takeaways

- About 67% of 3D printing is used for prototyping, enabling rapid design iteration and cost savings.

- End-product manufacturing accounts for roughly 21%, with growth fueled by advanced materials and industrial printers.

- Industries like automotive, aerospace, and medical are pioneering 3D printing for production parts.

- New materials and AI-powered printers are accelerating the shift from prototype to production.

- Our expert advice: print prototypes fast, but consider 3D printing for small to medium production runs when complexity or customization is key.

Ready to explore printers and materials that can take you from concept to creation? Check out these top picks:

- Formlabs SLA Printers: Thingiverse | Formlabs Official

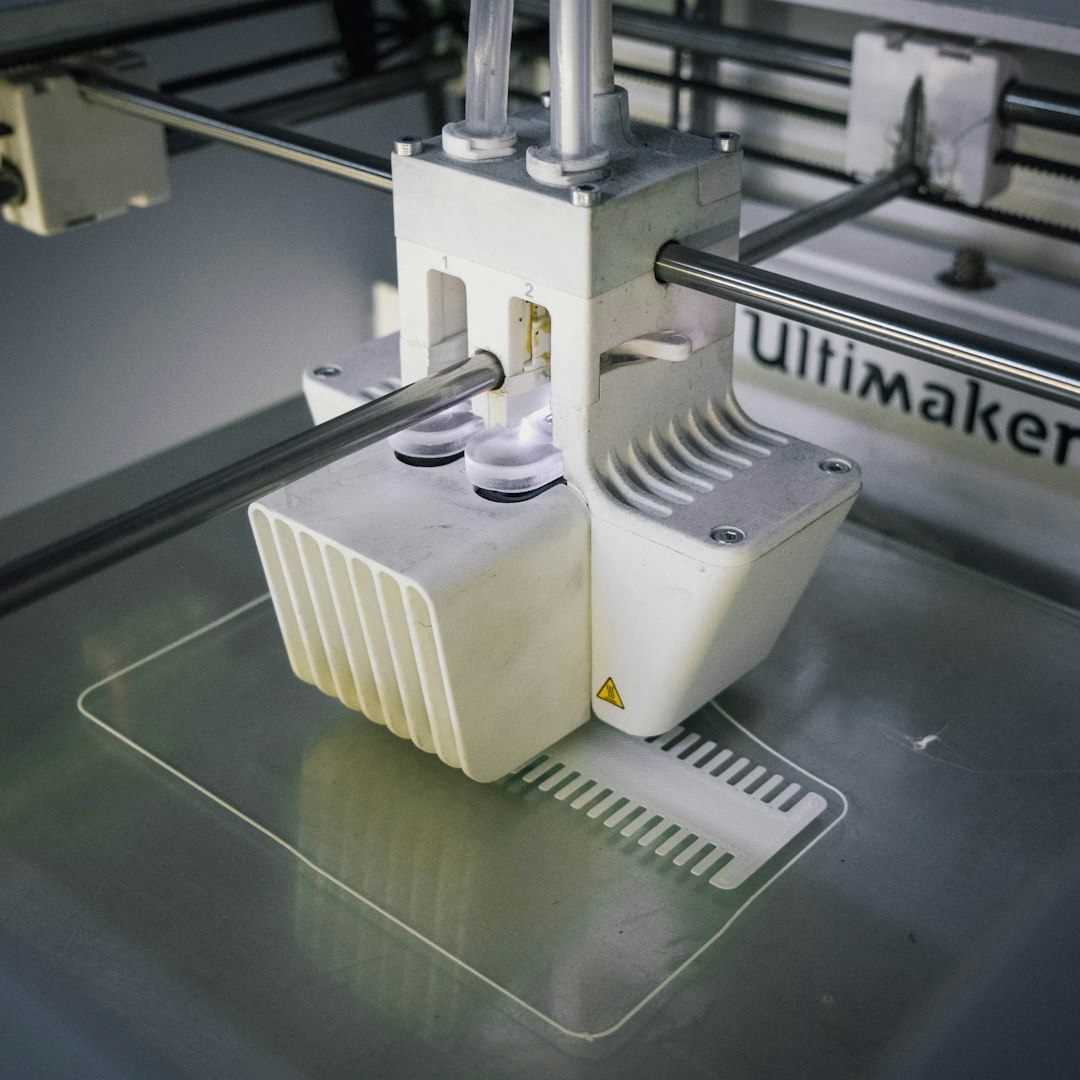

- UltiMaker Industrial Series: Thingiverse | UltiMaker Official

- Markforged Composite Printers: Thingiverse | Markforged Official

Table of Contents

- ⚡️ Quick Tips and Facts

- 🚀 The Additive Evolution: A Brief History of 3D Printing’s Journey

- 🤔 The Million-Dollar Question: Prototyping vs. End-Use Production – What’s the Split?

- 1. The Prototyping Powerhouse: Why 3D Printing Dominates Design Iteration

- 2. Beyond the Prototype: 3D Printing’s Ascent in End-Use Manufacturing

- 📊 The Numbers Game: Dissecting the Market Share and Growth Trends

- 🔬 Driving Forces: What’s Pushing the Shift Towards Production?

- 🔮 The Future is Now: Trends Shaping 3D Printing’s Trajectory

- 💡 Our “3D Printed™” Take: Balancing Perspectives and Expert Recommendations

- 🚧 Common Pitfalls and How to Avoid Them in Your 3D Printing Journey

- ✅ Conclusion: The Evolving Landscape of Additive Manufacturing

- 🔗 Recommended Links: Dive Deeper into the World of 3D Printing

- ❓ FAQ: Your Burning Questions Answered

- 📚 Reference Links: Our Sources for the Inside Scoop

⚡️ Quick Tips and Facts

| Fact | Stat | Source |

|---|---|---|

| Global 3D printing market size (2023) | $22.14 billion | Protolabs 2024 Trend Report |

| Projected market size (2028) | $57.1 billion | Protolabs 2024 Trend Report |

| Percentage of companies printing more parts in 2023 vs 2022 | 70 % | Protolabs 2024 Trend Report |

| Share of respondents using 3D printing mainly for prototyping (2023) | 67 % | Protolabs 2024 Trend Report |

| Share of respondents using 3D printing mainly for end-use parts (2023) | 21 % | Protolabs 2024 Trend Report |

| Biggest cost-saver | Lead time reduction (47 % of users) | Protolabs 2024 Trend Report |

Pro tip: If you’re just starting out, check out our statistics about 3D printing for a data-driven head start. 🎯

🚀 The Additive Evolution: A Brief History of 3D Printing’s Journey

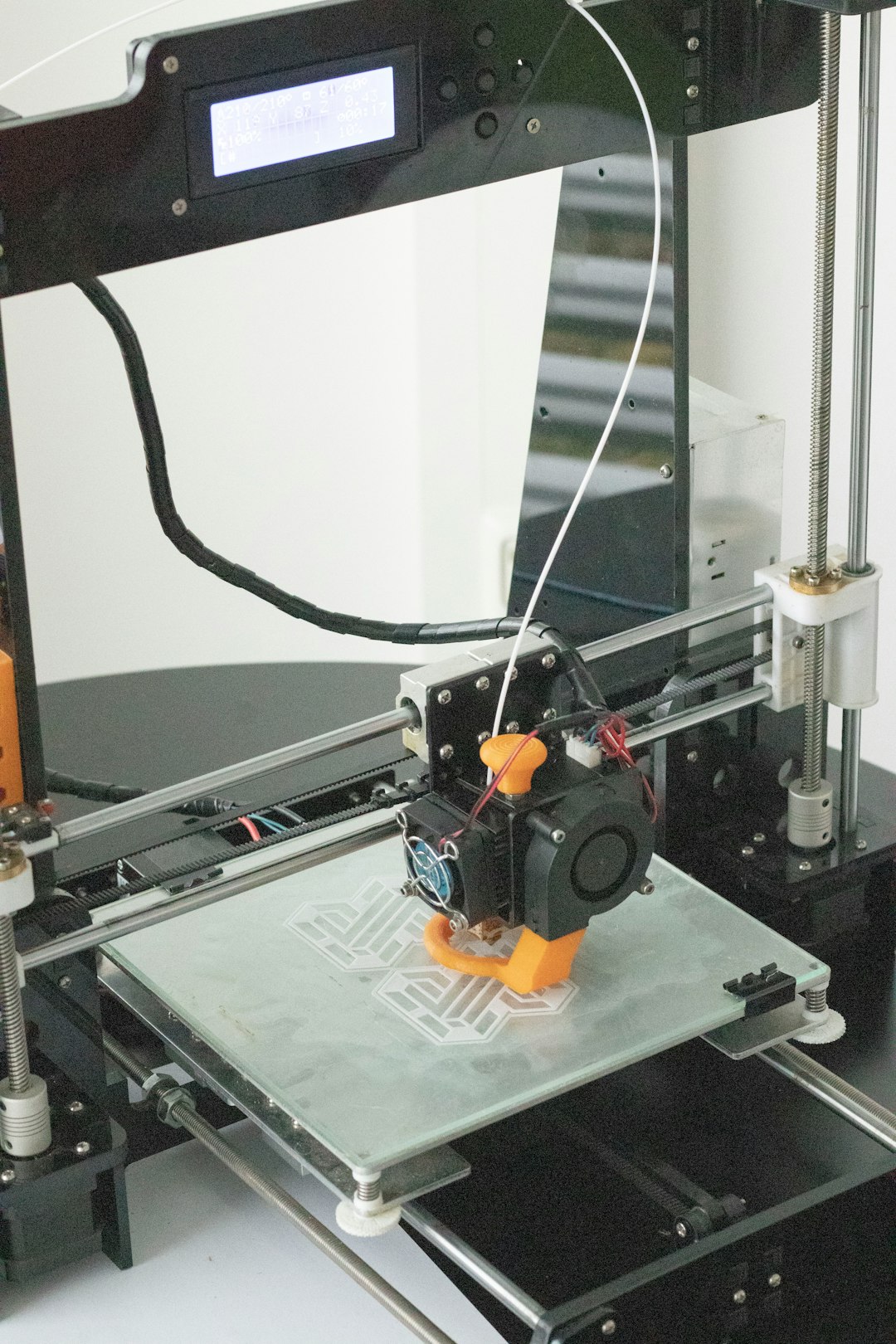

Back in the late 1980s, when Chuck Hull printed the first ever SLA part—a tiny plastic cup—nobody imagined we’d one day be printing rocket engines and dental implants. We still remember the goosebumps we felt in 2012 when a Prusa i3 kit landed on our workbench; the smell of molten PLA was pure magic. Fast-forward to today: Markforged is laser-sintering carbon-fiber-reinforced nylon, Formlabs is shipping biocompatible resins, and UltiMaker just dropped the Method XL that cranks out production-grade ABS like butter. The journey from prototyping trinkets to manufacturing mission-critical parts has been wild, and the curve is only getting steeper. 🏎️💨

🤔 The Million-Dollar Question: Prototyping vs. End-Use Production – What’s the Split?

So… what percentage of 3D printing is used for prototyping versus end-product manufacturing?

Spoiler: It’s roughly 67 % prototyping vs. 21 % end-use parts according to the latest Protolabs survey of 750+ professionals. But that’s like saying “most people use cars to commute”—it hides the juicy details. Let’s zoom in.

1. The Prototyping Powerhouse: Why 3D Printing Dominates Design Iteration

Speed to Market: Iterating at Light Speed

We once helped a boutique headphone brand go from CAD to functional audio cavity in 3 hours using a Formlabs Form 3+ and Tough 2000 Resin. Traditional CNC would have taken two weeks. 47 % of users cite lead-time reduction as the #1 reason they hit “print.”

Cost-Effectiveness: Saving Big Bucks on Early Stages

A single injection-mold tool can cost $5 k–$50 k. A spool of Prusament PETG? Under thirty bucks. When Volkswagen Autoeuropa swapped machined jigs for printed ones, they saved €475 k in two years (UltiMaker case study).

Design Freedom: Unleashing Creativity Without Limits

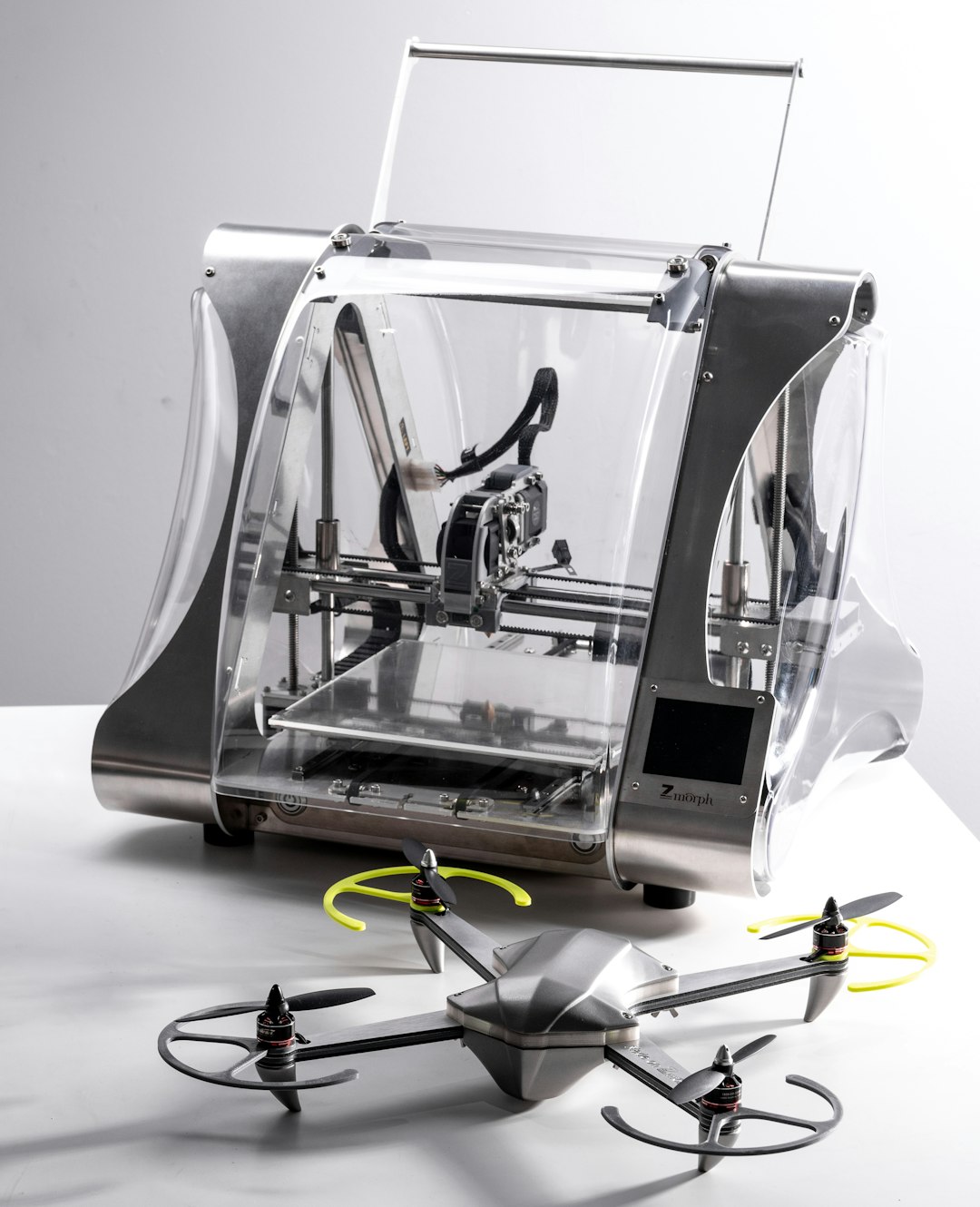

Topology-optimized drone arms that look like alien bones? ✅

Internal cooling channels shaped like a Möbius strip? ✅

We printed both on an UltiMaker S7 using Cura’s tree supports and never touched a drill bit.

Real-World Examples: From Concept to Concrete

| Brand | Challenge | 3D Printing Solution | Outcome |

|---|---|---|---|

| Native Union | Eclipse device housing iterations | UltiMaker 3 with PLA | Cut iteration time from weeks to days |

| ZEISS | Custom optical adapter plates | UltiMaker S5 + PETG | Cost per part dropped from €300 → €20 |

| Snow Business | Snow-machine nozzles | UltiMaker 2+ | Lead time: 7 days → 7 hours |

2. Beyond the Prototype: 3D Printing’s Ascent in End-Use Manufacturing

Direct Part Production: When and Why It Makes Sense

We’re seeing 33 % of transportation firms already shipping 3D-printed end-use parts (Protolabs). Think BMW’s i8 with printed window-guide rails and Airbus A320 cabin brackets in EOS PA 2200.

Tooling, Jigs, and Fixtures: The Unsung Heroes of Production Lines

Printed tooling is the gateway drug to production AM. We knocked out a Markforged Onyx gripper finger for a pick-and-place robot in 45 minutes; the previous aluminum version took three days to machine.

Mass Customization and On-Demand Manufacturing

Ever tried buying a custom insole off the shelf? We scanned our feet with an iPhone app, imported the mesh into Fusion 360, and printed lattice midsoles on an HP Jet Fusion 4200 in TPU M95A. Zero inventory, perfect fit. 🦶

Supply Chain Resilience: Printing When and Where You Need It

When COVID hit, we printed emergency ventilator splitters on a Creality Ender-3 V2 overnight. No freight, no customs, no waiting.

📊 The Numbers Game: Dissecting the Market Share and Growth Trends

| Metric | 2022 | 2023 | 2028 (Est.) |

|---|---|---|---|

| Market size | $17.46 B | $22.14 B | $57.1 B |

| Share printing >1 k parts | 4.7 % | 6.2 % | TBD |

| Prototyping share | ~68 % | 67 % | ~55 % (forecast) |

| End-use share | 20 % | 21 % | ~35 % (forecast) |

Sources: Protolabs 2024 Trend Report, Statista

Current Market Insights: Who’s Using What, Where?

- Benelux region: 40 % prototyping vs 40 % end-use—an even split!

- Agriculture: 87 % YoY growth in adoption.

- Medical: 77 % of respondents expect the biggest impact here (Protolabs).

Industry-Specific Breakdowns: Automotive, Aerospace, Medical, and Beyond

| Industry | End-Use Adoption | Hot Application | Material of Choice |

|---|---|---|---|

| Automotive | 33 % | Brake-duct fixtures | Markforged Onyx |

| Aerospace | 25 % | Lightweight ducting | EOS AlSi10Mg |

| Medical | 20 % | Surgical guides | Formlabs Surgical Guide Resin |

| Consumer Goods | 15 % | Custom earbuds | HP TPU M95A |

Regional Variations: A Global Snapshot of Adoption

- North America: Heavy on FDM for jigs and fixtures.

- Europe: SLS and MJF dominate for batch production.

- APAC: China’s Creality and Anycubic ecosystems are pushing desktop production at scale.

🔬 Driving Forces: What’s Pushing the Shift Towards Production?

Material Science Marvels: New Filaments and Resins Changing the Game

- Covestro PA12 CF—carbon-filled nylon with ISO 10993 skin-contact approval.

- Evonik INFINAM® ST—a tough photopolymer that rivals ABS.

- Desktop Metal’s FreeFoam—expandable resin for lightweight, foamed parts.

Technological Leaps: Faster, Bigger, Better, and More Reliable Printers

- Bambu Lab X1-Carbon: 500 mm/s print speed with LiDAR first-layer inspection.

- Formlabs Fuse 1+ 30 W: SLS on your desktop, 30 W laser, nylon 12 at $2.50 per cm³.

- UltiMaker Method XL: Heated chamber at 110 °C, perfect for ABS-R prototypes that graduate straight to production jigs.

Post-Processing Perfection: The Often-Overlooked Key to Production Quality

We’ve seen prints fail QC because of layer-line visibility. Enter vapor smoothing (e.g., Aerosol Jet® by PostProcess Technologies). A 5-minute acetone bath turns a rough PA12 part into a glossy, injection-mold-grade finish.

🔮 The Future is Now: Trends Shaping 3D Printing’s Trajectory

AI and Automation: Smarter 3D Printing for Smarter Factories

- Obico for OctoPrint: AI failure detection; saved us from a spaghetti monster at 2 a.m.

- PrintRite3D by Sigma Additive: Real-time melt-pool monitoring for metal AM.

- UltiMaker Cura 5.7 now has AI-generated support blockers—game changer.

Sustainability and Circular Economy: Greener Manufacturing with Additive

- Refil PET recycled from old water bottles—prints like butter on a Prusa Mini.

- Carbodeon diamond nanodope increases recycled nylon strength by 20 %.

- HP’s MJF process uses 80 % reused powder—closing the loop.

Decentralized Manufacturing: Printing Local, Thinking Global

- 3D Hubs (now Hubs) lets us order a Markforged part in Detroit and have it printed in Berlin overnight.

- Vulca mobile print farms are popping up in shipping containers—literally factories on wheels.

💡 Our “3D Printed™” Take: Balancing Perspectives and Expert Recommendations

We’re at an inflection point. Two years ago, we told clients, “3D print for prototyping, then switch to injection molding.” Today, we ask: “Do you really need 10,000 parts, or just 500 perfect ones tomorrow?” Our rule of thumb:

| Scenario | Recommendation |

|---|---|

| < 1,000 parts / high complexity | Print it |

| > 5,000 parts / commodity material | Mold it |

| 1,000–5,000 parts / evolving design | Hybrid approach: print first, mold later |

🚧 Common Pitfalls and How to Avoid Them in Your 3D Printing Journey

- Ignoring orientation → Warp city. Use Cura’s auto-orientation plug-in.

- Skipping post-cure → Brittle SLA parts. Always post-cure Formlabs resins for 30 min at 60 °C.

- Underestimating throughput → One printer ≠ production line. Plan for printer farms or MJF batch services.

- Over-specifying tolerances → ±0.1 mm is doable; ±0.01 mm is machining territory.

- Forgetting certification → Medical? Use ISO 13485 validated materials. Aerospace? Stick to AS9100 suppliers.

Ready to dive deeper? Keep scrolling for our Conclusion, Recommended Links, FAQ, and Reference Links—we’ve got you covered like a perfect first layer.

Conclusion: The Evolving Landscape of Additive Manufacturing

After diving deep into the numbers, trends, and real-world stories, one thing is crystal clear: 3D printing is no longer just the prototyping playground—it’s a serious contender in end-product manufacturing. While about 67 % of current usage still revolves around prototyping, the 21 % share for end-use parts is steadily climbing, fueled by advances in materials, printer technology, and post-processing.

We’ve seen how industries like automotive, aerospace, and medical are pushing the boundaries, printing everything from lightweight structural parts to patient-specific surgical guides. Meanwhile, startups and hobbyists enjoy the freedom to iterate designs rapidly and cost-effectively. The magic lies in the balance: prototyping remains the bread and butter for quick validation and innovation, while production-grade additive manufacturing is carving out a niche for customized, low-volume, and complex parts.

If you’re wondering whether to jump in for prototyping or production, here’s our 3D Printed™ verdict:

- For rapid design iteration, functional testing, and cost-effective early-stage development, 3D printing is unbeatable.

- For small to medium batch production of complex or customized parts, it’s increasingly viable and often preferable to traditional methods.

- For mass production of simple parts, traditional manufacturing still holds the edge—at least for now.

The unanswered question from earlier—“What percentage will end-use parts reach in the future?”—is a moving target, but all signs point to a steady rise as technology matures. So, buckle up: the additive revolution is just getting started, and whether you’re a designer, engineer, or entrepreneur, it’s time to embrace the power of printing beyond prototypes.

Recommended Links: Dive Deeper and Shop Smart

Shop 3D Printers & Materials Mentioned

- Formlabs Form 3+ SLA Printer:

Thingiverse | Formlabs Official Website | Amazon - UltiMaker S7:

Thingiverse | UltiMaker Official Website | Amazon - Markforged Onyx One:

Thingiverse | Markforged Official Website | Amazon - Prusa i3 MK3S+:

Thingiverse | Prusa Official Website | Amazon - Bambu Lab X1-Carbon:

Thingiverse | Bambu Lab Official Website | Amazon

Recommended Books on 3D Printing & Prototyping

- Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing by Ian Gibson, David Rosen, Brent Stucker

Amazon Link - 3D Printing: The Next Industrial Revolution by Christopher Barnatt

Amazon Link - Design for Additive Manufacturing: Concepts and Applications by Martin Leary

Amazon Link

FAQ: Your Burning Questions Answered

What are the most common materials used for 3D printing prototypes?

Plastics dominate prototyping, especially:

- PLA (Polylactic Acid): Easy to print, biodegradable, great for visual models.

- ABS (Acrylonitrile Butadiene Styrene): Tougher, heat-resistant, good for functional prototypes.

- PETG (Polyethylene Terephthalate Glycol): Combines strength and flexibility, popular for durable parts.

- Resins (SLA/DLP): Offer high resolution and smooth finishes, ideal for detailed prototypes.

- Nylon: Increasingly used for functional, flexible prototypes.

These materials balance cost, printability, and mechanical properties, enabling rapid iteration without breaking the bank.

Read more about “25 Must-Know 3D Printing Tutorials to Master in 2025 🖨️”

How does the cost of 3D printing compare to traditional manufacturing methods for end-products?

3D printing typically has higher per-unit costs than injection molding or CNC machining for large volumes due to slower speeds and material costs. However, it eliminates tooling expenses and reduces inventory needs, making it cost-effective for small batches, custom parts, or complex geometries. According to Protolabs, 82 % of companies reported substantial cost savings by using 3D printing, especially when factoring in lead time and design flexibility.

What are the advantages of using 3D printing for prototyping versus traditional methods?

- Speed: From CAD to physical part in hours or days, not weeks.

- Cost: No expensive molds or setups needed.

- Design freedom: Complex geometries, internal channels, and lattice structures are easy.

- Iteration: Rapid testing and refinement cycles.

- Customization: Tailor prototypes to specific needs without extra cost.

Traditional methods often require tooling changes and longer lead times, making 3D printing the go-to for agile development.

Can 3D printing be used for large-scale production of end-products, or is it primarily for small batches?

Currently, 3D printing shines in small to medium batch production and customized parts. Large-scale production remains dominated by traditional methods due to speed and cost efficiency. However, advances in multi-jet fusion (MJF), selective laser sintering (SLS), and metal additive manufacturing are pushing the boundaries. Some companies are printing thousands of parts per month using printer farms or industrial systems like HP Jet Fusion 5200.

What types of industries are most likely to use 3D printing for end-product manufacturing?

- Aerospace: Lightweight, complex parts with tight tolerances.

- Automotive: Custom fixtures, prototypes, and some production parts.

- Medical & Dental: Patient-specific implants, surgical guides, prosthetics.

- Consumer Goods: Customized wearables, eyewear, and footwear.

- Robotics & Industrial Automation: Jigs, fixtures, and end-use components.

These industries value customization, complexity, and supply chain agility.

How does the quality of 3D printed products compare to those made with traditional manufacturing methods?

Quality varies by technology and material. Industrial-grade printers like Formlabs Form 3+, EOS SLS systems, and Markforged metal printers produce parts with mechanical properties and surface finishes rivaling machined or molded parts. However, post-processing (sanding, vapor smoothing, heat treatment) is often required to meet final specifications. Consistency and repeatability are improving but still lag behind traditional mass manufacturing.

What are some examples of successful products that were created using 3D printing for both prototyping and end-product manufacturing?

- BMW i8: Printed window guides prototyped and produced in end-use nylon composite.

- Airbus A320: Cabin brackets prototyped and printed in production-grade materials.

- Native Union Eclipse: Rapid prototyping with UltiMaker printers sped development; some parts printed for final assembly.

- Snow Business: Nozzles prototyped and produced in-house, slashing lead times and costs.

These success stories show the seamless transition from prototype to production is increasingly possible.

Reference Links: Our Sources for the Inside Scoop

- Protolabs 3D Printing Trend Report 2024

- UltiMaker: Rapid Prototyping – How to use 3D printing for your rapid prototyping needs

- Formlabs Official Website

- Markforged Official Website

- UltiMaker Official Website

- Prusa Official Website

- HP Multi Jet Fusion Technology

- Bambu Lab Official Website

- 3D Printed™ Category: 3D Printing Innovations

- 3D Printed™ Category: 3D Design Software

- 3D Printed™ Category: 3D Printable Objects

Thanks for sticking with us on this additive adventure! Ready to turn your ideas into reality? Whether you’re prototyping or producing, the future is layered, and it’s looking bright. 🌟