Support our educational content for free when you purchase through links on our site. Learn more

How Much Does It Cost to Make a 3D Print? (2026) 💸

Ever wondered why some 3D prints cost just a few cents while others run into the hundreds? Spoiler alert: it’s not just about the filament spool! From the type of printer you use to how long your print takes, the true cost of 3D printing is a fascinating puzzle that many overlook. At 3D Printed™, we’ve crunched the numbers, dissected the hidden expenses, and uncovered insider tips to help you master your printing budget like a pro.

Did you know that a tiny 6-gram figurine might cost you just over a dollar to print, but a complex, multi-day project can easily cost 50 times more? Stick around as we break down every factor—from materials and machine wear to labor and post-processing—and reveal 10 proven strategies to slash your 3D printing costs without sacrificing quality. Ready to become a 3D printing cost wizard? Let’s dive in!

Key Takeaways

- Material choice is the biggest cost driver—standard PLA is affordable, but specialty filaments and resins can skyrocket expenses.

- Printer type impacts cost and quality—FDM printers offer budget-friendly printing, while SLA and SLS deliver finer detail at higher prices.

- Print time and complexity multiply costs—longer, detailed prints increase electricity, labor, and failure risk.

- Maintenance and post-processing add hidden expenses that many beginners overlook.

- Smart design and workflow optimization can dramatically reduce costs—hollow models, minimal supports, and batch printing save time and money.

- Outsourcing vs. in-house printing depends on your volume and control needs—owning a reliable printer often pays off for hobbyists and small businesses.

Curious about which printers deliver the best bang for your buck in 2026? Or how to calculate your exact print cost step-by-step? Keep reading for all this and more!

Table of Contents

- ⚡️ Quick Tips and Facts About 3D Printing Costs

- 🔍 Understanding the True Cost of 3D Printing: A Deep Dive

- 🏭 Materials Matter: How Filament and Resin Affect Your Budget

- 🖨️ Printer Types and Their Impact on Cost: FDM, SLA, SLS Explained

- ⏳ Time is Money: How Print Speed and Complexity Drive Expenses

- ⚙️ Maintenance and Upkeep: Hidden Costs of Owning a 3D Printer

- 💡 Energy Consumption and Environmental Costs of 3D Printing

- 📐 Design and Post-Processing: Additional Expenses You Can’t Ignore

- 💰 10 Proven Strategies to Reduce Your 3D Printing Costs

- 📊 How to Calculate 3D Printing Costs: Step-by-Step Guide

- 🛠️ Best Budget 3D Printers for Cost-Effective Printing in 2024

- 📦 Outsourcing vs. In-House Printing: Which Saves You More?

- 🤖 Future Trends: How Advances in 3D Printing Will Affect Costs

- 🎯 Conclusion: Making Smart Choices to Optimize Your 3D Printing Budget

- 🔗 Recommended Links for 3D Printing Cost Insights

- ❓ Frequently Asked Questions About 3D Printing Costs

- 📚 Reference Links and Resources

⚡️ Quick Tips and Facts About 3D Printing Costs

Welcome to the thrilling world of 3D printing costs! Whether you’re a curious newbie or a seasoned maker, understanding what goes into the price tag of your next print is like cracking the code to a secret treasure chest. 🏴☠️

Here’s a quick cheat sheet from our team at 3D Printed™ to get you started:

- Material costs dominate — filament or resin can be anywhere from a few cents to hundreds of dollars per kilogram depending on quality and specialty.

- Printer operation costs (electricity, wear & tear) are surprisingly low but add up over time.

- Labor and preparation time can be a hidden expense, especially for complex models needing manual support or design tweaks.

- Post-processing (sanding, painting, curing) often doubles the time and cost but makes your print shine.

- Profit margins for commercial printing services typically add 30-90% on top of base costs to cover failures and overhead.

- Print time and complexity are your biggest cost multipliers — a 2-hour simple print vs. a 48-hour detailed sculpture can differ by orders of magnitude.

We’ll unpack all these nuggets with real-world examples and formulas, plus some juicy insider tips. Ready to become a 3D printing cost wizard? 🧙♂️ Let’s dive in!

🔍 Understanding the True Cost of 3D Printing: A Deep Dive

3D printing costs are like an onion — peel back one layer, and there’s another underneath. To truly grasp what you’re paying for, you need to consider multiple factors beyond just the filament spool price.

The Four Pillars of 3D Printing Cost

-

Material Cost

The raw filament or resin is the most obvious expense. For example, Prusament PLA Orange costs about $25/kg, and a small model might use just 6 grams, costing roughly $0.15. Specialty filaments like carbon fiber or flexible TPU can push costs way higher.Material cost = (Filament price per gram) × (Model weight in grams)

-

Printer Operation Cost

This includes electricity (usually pennies per print), plus amortized printer cost. For instance, a Prusa MK3S+ might have a fixed hourly cost of around $0.21 to recoup your investment over thousands of hours.

Electricity is minimal — a typical print might consume less than $0.03 worth of power. -

Labor and Preparation

Time spent slicing, setting up supports, and monitoring the print can add up. For a simple print, prep might be just 5 minutes (~$0.80 labor cost at average wages), but complex prints can require 30+ minutes or more. -

Post-Processing and Finishing

Cleaning resin prints, sanding filament prints, painting, or assembling parts adds both time and materials (e.g., sandpaper, paint). These costs are often overlooked but essential for professional results.

Real-World Example: The “Treefrog” Model

- Filament: 6.27g → $0.15

- Labor: 5 minutes → $0.80

- Printer operation: 1h16m → $0.21 × 1.27h = $0.27

- Profit margin: 30% on material → $0.05

- Total cost: ~$1.3

This tiny print is a steal compared to large, complex prints that can run into the hundreds of dollars.

🏭 Materials Matter: How Filament and Resin Affect Your Budget

Your choice of material is like choosing the fuel for a rocket — it determines speed, quality, and cost.

| Material Type | Typical Cost per Kg | Pros | Cons | Best For |

|---|---|---|---|---|

| PLA (Polylactic Acid) | $20 – $30 | Easy to print, biodegradable | Brittle, lower heat resistance | Beginners, prototypes, toys |

| ABS (Acrylonitrile Butadiene Styrene) | $20 – $35 | Durable, heat resistant | Warping, fumes | Functional parts, automotive |

| PETG (Polyethylene Terephthalate Glycol) | $25 – $40 | Strong, flexible, food safe | Stringing, slower cooling | Mechanical parts, containers |

| TPU (Thermoplastic Polyurethane) | $40 – $70 | Flexible, impact resistant | Difficult to print, slow | Wearables, phone cases |

| Carbon Fiber Filaments | $70 – $120 | Very stiff, lightweight | Abrasive on nozzles, expensive | Drones, automotive, aerospace |

| Resin (Standard) | $50 – $100 per liter | High detail, smooth finish | Requires curing, messy | Miniatures, jewelry, dental |

| Specialty Resins | $150 – $300+ per liter | Tough, flexible, castable | Very expensive, complex handling | Engineering prototypes, dental |

Pro Tip: Use filament brands like Prusament, Hatchbox, or MatterHackers for reliable quality and consistent pricing. For resin, Elegoo and Anycubic offer excellent entry-level options.

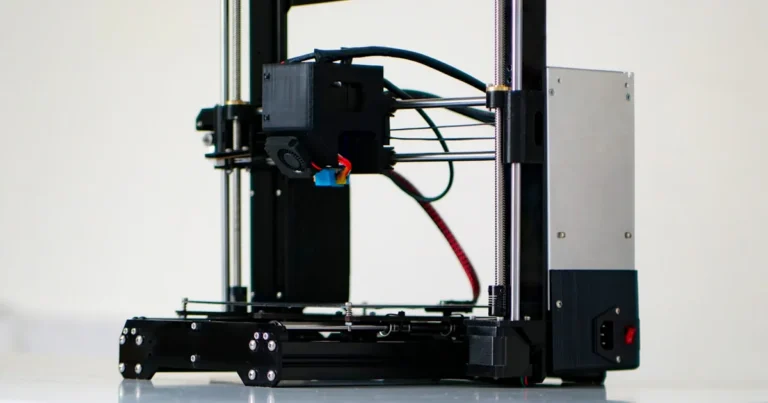

🖨️ Printer Types and Their Impact on Cost: FDM, SLA, SLS Explained

The type of 3D printer you use dramatically affects your cost breakdown.

| Printer Type | Technology | Material | Typical Cost Range | Print Quality | Speed | Maintenance | Cost Impact |

|---|---|---|---|---|---|---|---|

| FDM (Fused Deposition Modeling) | Melts filament and extrudes layer by layer | PLA, ABS, PETG, TPU | $150 – $3,000+ | Medium | Fast | Moderate | Low material cost, moderate labor |

| SLA (Stereolithography) | Cures liquid resin with UV laser | Resin | $300 – $5,000+ | High (fine detail) | Slower | High (cleaning, curing) | Higher material cost, more post-processing |

| SLS (Selective Laser Sintering) | Fuses powder with laser | Nylon, metal powders | $10,000 – $500,000+ | Very high | Medium | High | Industrial scale, very expensive |

Our Take: For hobbyists and small businesses, FDM printers like the Creality Ender 3 V2 or Prusa MK3S+ offer the best balance of cost and quality. If you want ultra-fine detail and don’t mind post-processing, SLA printers like the Anycubic Photon Mono X are worth considering.

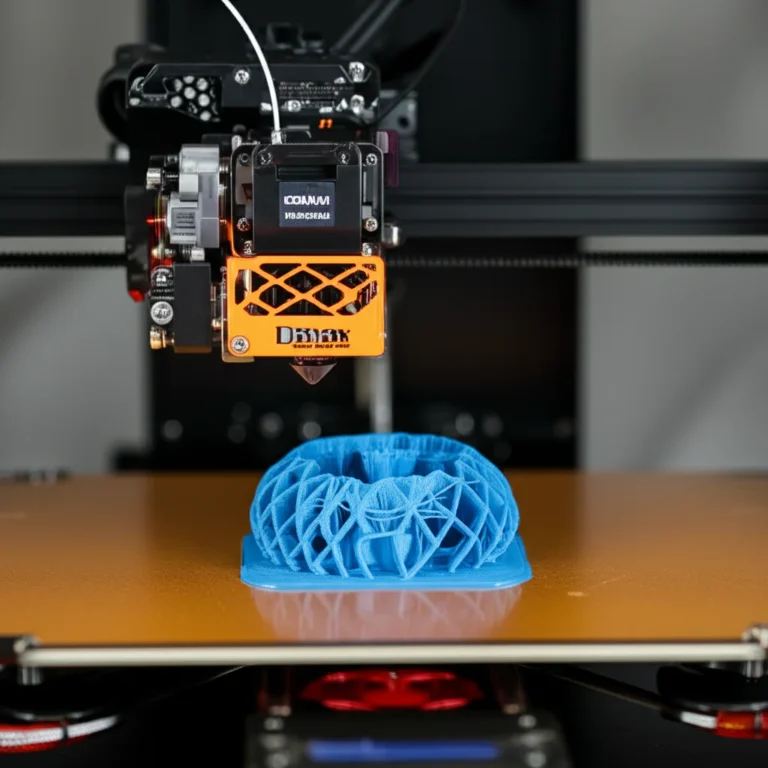

⏳ Time is Money: How Print Speed and Complexity Drive Expenses

Ever heard the phrase, “Time is money”? In 3D printing, it’s gospel.

- Longer print times = higher electricity and machine wear costs.

- Complex models require more supports and manual intervention, increasing labor costs.

- Higher resolution prints take longer but yield finer details.

For example, printing a detailed figurine at 0.05mm layer height might take 10+ hours, while a rough prototype at 0.3mm could finish in under 2 hours.

Did you know? According to Prusa’s cost calculator, a 42-hour print using carbon fiber filament can cost upwards of $75 in materials alone!

⚙️ Maintenance and Upkeep: Hidden Costs of Owning a 3D Printer

Owning a 3D printer is like having a pet — it needs regular care.

- Nozzle replacements: Brass nozzles last 3-6 months; hardened steel nozzles cost more but resist abrasive filaments.

- Bed surfaces: PEI sheets, glass, or BuildTak surfaces wear out and need periodic replacement.

- Lubrication and calibration: Regular maintenance keeps prints consistent.

- Firmware updates and troubleshooting: Time investment that can add to labor costs.

Ignoring maintenance can lead to failed prints, wasting material and time — a double whammy for your budget.

💡 Energy Consumption and Environmental Costs of 3D Printing

Electricity costs for 3D printing are surprisingly low but worth tracking.

- Typical desktop FDM printers consume 50-150 watts.

- A 5-hour print might use around 0.5-0.75 kWh, costing under $0.10 in most regions.

- SLA printers use UV lights and pumps, slightly increasing consumption.

Environmental note: Recycling failed prints or support material using filament recyclers like the Filabot EX2 can reduce waste and save money long-term.

📐 Design and Post-Processing: Additional Expenses You Can’t Ignore

Your print isn’t done when the nozzle stops. Post-processing can be a cost sinkhole.

- Support removal: Time-consuming and may require tools.

- Sanding and smoothing: Materials like resin prints cure to a smooth finish but filament prints often need sanding.

- Painting and finishing: Adds materials and labor.

- Assembly: Multi-part prints require glue or fasteners.

Insider tip: Designing with cost in mind (hollowing models, minimizing supports) can save both material and time.

💰 10 Proven Strategies to Reduce Your 3D Printing Costs

Ready to save some 💸? Here are our top tips:

- Optimize model design: Hollow out large parts, reduce infill.

- Choose the right material: Don’t over-specify specialty filaments unless necessary.

- Batch prints: Print multiple parts in one go to save setup time.

- Use reliable printers: Fewer failed prints mean less wasted material.

- Recycle scraps: Use filament recyclers or donate failed prints for reuse.

- Maintain your printer: Prevent costly breakdowns.

- Print at optimal speeds: Balance speed and quality to avoid reprints.

- Leverage free 3D models: Use platforms like Thingiverse or MyMiniFactory to avoid design costs.

- Post-process smartly: Use quick finishing techniques to save time.

- Calculate costs upfront: Use tools like the Prusa 3D Printing Price Calculator to budget accurately.

📊 How to Calculate 3D Printing Costs: Step-by-Step Guide

Let’s break down the math so you can price your prints like a pro.

Step 1: Calculate Material Cost

- Weigh your model or estimate filament used from slicer software.

- Use the formula:

Material Cost = (Filament Price per gram) × (Model Weight in grams)

Step 2: Calculate Printer Operation Cost

- Determine your printer’s amortized hourly cost (Printer price ÷ expected lifetime hours).

- Multiply by print time in hours.

- Add electricity cost (Power consumption in kW × print time × cost per kWh).

Step 3: Calculate Labor Cost

- Estimate time spent on setup, monitoring, and post-processing.

- Multiply by your hourly labor rate.

Step 4: Add Profit Margin or Contingency

- Typically 20-50% of total cost to cover failures and overhead.

Example Calculation:

| Cost Element | Value |

|---|---|

| Material (30g PLA) | $0.60 |

| Printer Operation (2h @ $0.21/h) | $0.42 |

| Electricity (0.1 kWh @ $0.12/kWh) | $0.012 |

| Labor (30 min @ $15/h) | $7.50 |

| Subtotal | $8.532 |

| Profit Margin (30%) | $2.56 |

| Total Cost | $11.09 |

🛠️ Best Budget 3D Printers for Cost-Effective Printing in 2024

Here’s a quick rating table for some fan favorites in the budget category:

| Printer Model | Design (1-10) | Functionality (1-10) | Ease of Use (1-10) | Reliability (1-10) | Overall Score (1-10) |

|---|---|---|---|---|---|

| Creality Ender 3 V2 | 8 | 8 | 7 | 7 | 7.5 |

| Prusa MK3S+ | 9 | 9 | 9 | 9 | 9 |

| Anycubic i3 Mega S | 7 | 7 | 8 | 7 | 7.25 |

| Artillery Sidewinder X1 V4 | 8 | 8 | 7 | 7 | 7.5 |

Why These?

- Creality Ender 3 V2: Affordable, large community, great for beginners.

- Prusa MK3S+: Industry gold standard, excellent print quality, reliable.

- Anycubic i3 Mega S: Solid entry-level with touchscreen and metal frame.

- Artillery Sidewinder X1 V4: Large build volume, quiet operation.

📦 Outsourcing vs. In-House Printing: Which Saves You More?

Should you buy a printer or pay for a print service? The answer depends on your needs.

| Factor | In-House Printing ✅ | Outsourcing Printing ❌ |

|---|---|---|

| Initial Investment | High (printer cost) | None or low |

| Per-Print Cost | Low (material + labor) | High (service fees + profit) |

| Control over Quality | Full control | Variable |

| Turnaround Time | Immediate | Days to weeks |

| Complexity Handling | Limited by printer | Access to industrial tech |

| Maintenance | Your responsibility | Included in price |

Our advice: Hobbyists and small businesses benefit from owning a reliable printer like the Prusa MK3S+. Large, complex, or one-off projects might be better outsourced to services like Shapeways or i.materialise.

🤖 Future Trends: How Advances in 3D Printing Will Affect Costs

The 3D printing landscape is evolving fast:

- Faster printers with multi-nozzle setups reduce print time and labor costs.

- New materials like bio-based and recyclable filaments may lower material costs and environmental impact.

- AI-driven slicing and error detection will cut down failed prints and wasted material.

- Mass production via 3D printing could disrupt traditional manufacturing costs.

Curious how these will change your printing budget? Stay tuned as we explore these innovations in our 3D Printing Innovations section.

#featured-video The Real Cost Per Print: Insights from a Popular YouTube Breakdown

One of the best ways to understand 3D printing costs is to see them in action. A popular YouTube video breaks down the cost per print using real printers like the Creality Ender 3 V2, Prusa MK3S+, and Artillery Sidewinder X1 V4.

- Filament cost estimated at $20/kg → $0.02/g.

- Prints ranged from tiny 2g rocket parts ($0.04) to a large 270g long holder ($5.40).

- Electricity for a 5.5-hour print was just $0.08.

- The video also highlights filament recycling with machines like the Filabot EX2.

This practical perspective aligns well with our detailed cost breakdowns and shows how accessible 3D printing can be when you understand the numbers.

🎯 Conclusion: Making Smart Choices to Optimize Your 3D Printing Budget

So, how much does it really cost to make a 3D print? As we’ve unraveled, the answer is delightfully complex — a blend of material prices, printer operation, labor, post-processing, and even your own savvy as a designer and operator. From tiny trinkets costing mere cents to intricate, multi-day prints that can run into the hundreds, the cost spectrum is wide and fascinating.

Here’s the bottom line from the 3D Printed™ team:

- Materials are king. Choosing the right filament or resin for your project can make or break your budget.

- Printer choice matters. FDM printers like the Prusa MK3S+ offer excellent cost-efficiency and reliability, while SLA printers provide finer details at a higher price.

- Time is money. Optimize print speed and complexity to avoid runaway costs.

- Maintenance and post-processing are hidden but real expenses. Don’t overlook them!

- Outsourcing vs. in-house printing depends on your volume, complexity, and control needs.

If you’re a hobbyist or small business, investing in a quality FDM printer like the Prusa MK3S+ or Creality Ender 3 V2 is a smart move. For ultra-fine detail or professional prototypes, SLA printers such as the Anycubic Photon Mono X shine despite higher costs.

Remember our teaser question about how to become a 3D printing cost wizard? Now you have the tools, formulas, and insider tips to confidently calculate and optimize your printing expenses. Your next print will not only look great but also make cents! 💰

🔗 Recommended Links for 3D Printing Cost Insights

Ready to shop or learn more? Check out these trusted products and resources:

-

Prusa MK3S+

Thingiverse | Prusa Official Website | Amazon Search for Prusa MK3S+ -

Creality Ender 3 V2

Thingiverse | Creality Official Website | Amazon Search for Creality Ender 3 V2 -

Anycubic Photon Mono X

Thingiverse | Anycubic Official Website | Amazon Search for Anycubic Photon Mono X -

Filabot EX2 Filament Recycler

Filabot Official Website | Amazon Search for Filabot EX2 -

Books on 3D Printing and Cost Management:

- 3D Printing Failures: How to Diagnose and Repair All 3D Printing Issues by Sean Aranda

- The 3D Printing Handbook: Technologies, design and applications by Ben Redwood, Filemon Schöffer, Brian Garret

❓ Frequently Asked Questions About 3D Printing Costs

Do 3D printing costs vary depending on the type of printer used?

Absolutely! The printer type—FDM, SLA, or SLS—significantly influences costs. FDM printers generally have lower material and operation costs but moderate print quality. SLA printers offer high detail but use more expensive resin and require more post-processing. Industrial SLS printers are costly to operate and maintain but excel in complex, durable parts. Choose based on your quality needs and budget.

What is the average cost of electricity for 3D printing?

Electricity costs are surprisingly low. A typical desktop FDM printer consumes about 50-150 watts. For a 5-hour print, expect less than $0.10 in electricity costs in most regions. SLA printers consume slightly more due to UV curing lights but still remain a minor part of total cost.

What factors affect the cost of 3D printing an object?

Key factors include:

- Material type and amount

- Print time and complexity

- Printer amortization and electricity

- Labor for preparation and post-processing

- Failure rates and waste

- Profit margins if using commercial services

Are there any additional costs associated with post-processing 3D printed objects?

Yes! Post-processing can include support removal, sanding, painting, curing (for resin prints), and assembly. These steps require materials (sandpaper, paint, solvents) and time, adding to both labor and material costs.

What are some ways to reduce the cost of 3D printing at home?

- Optimize your model design to reduce material use

- Use standard filaments like PLA instead of specialty materials

- Batch print multiple parts

- Maintain your printer to avoid failed prints

- Recycle failed prints or scraps

- Use free 3D models from platforms like Thingiverse

Can I save money by using cheaper 3D printing materials?

Sometimes, but be cautious. Cheaper filaments may have inconsistent quality, leading to failed prints and wasted material. It’s often better to buy reliable brands like Prusament or Hatchbox to avoid costly mistakes.

How much does 3D printer filament cost per kilogram?

Standard PLA or ABS filaments typically cost between $20 and $30 per kilogram. Specialty filaments like carbon fiber or flexible TPU can cost $70 to $120+ per kilogram. Resin prices vary widely, from $50 to over $300 per liter.

What are some ways to optimize my 3D print design to save on costs?

- Hollow out large parts to reduce material

- Use minimal infill percentages where strength isn’t critical

- Design with fewer supports to reduce waste and cleanup

- Combine parts to print in batches

Can I reduce the cost of 3D printing by using recycled or DIY materials?

Yes, but with caveats. DIY filament extruders like the Filabot EX2 can recycle failed prints and scraps, lowering material costs. However, recycled filament quality can vary, potentially causing print issues. Proper testing and calibration are essential.

How much does 3D printing filament cost per meter?

Filament cost per meter depends on diameter and density but roughly ranges from $0.02 to $0.05 per meter for standard 1.75mm PLA. This varies with filament type and brand.

Are there any free or low-cost 3D modeling software options for creating prints?

Definitely! Popular free options include:

- Tinkercad (great for beginners)

- Fusion 360 (free for hobbyists and startups)

- Blender (powerful open-source tool)

- FreeCAD (parametric modeling)

Using these can save you design costs compared to hiring professionals.

What are the costs associated with owning a 3D printer for hobbyist use?

Beyond the initial printer purchase, expect to budget for:

- Filament or resin

- Replacement parts (nozzles, bed surfaces)

- Maintenance supplies

- Electricity (minimal)

- Occasional upgrades or accessories

How does the size of a 3D print affect its cost?

Larger prints use more material and take longer, increasing both material and operation costs. Also, bigger prints may require more supports and post-processing, adding labor time.

What is the average cost per hour of 3D printing?

Amortized printer costs typically range from $0.10 to $0.30 per hour for hobbyist machines. Adding electricity and labor, expect roughly $0.20 to $1.00 per hour depending on your setup and wage assumptions.

How do the costs of 3D printing compare to traditional manufacturing methods for similar objects?

3D printing excels at low-volume, customized, or complex parts where traditional tooling costs are prohibitive. For mass production, injection molding or CNC machining is usually cheaper per unit but requires high upfront tooling costs.

What are the costs associated with maintaining and upgrading a 3D printer?

Maintenance includes nozzle replacements ($5-$25), bed surface replacements, lubrication, and occasional firmware updates. Upgrades like auto bed leveling or better extruders can range from $50 to several hundred dollars.

How do 3D printing speed and quality settings influence the cost of a print?

Higher resolution (thinner layers) increases print time significantly, raising operation and labor costs. Faster print speeds can reduce time but may lower quality or increase failure risk, potentially increasing waste.

How do I choose the most cost-effective 3D printing material for my project?

Balance your project’s strength, flexibility, and finish requirements against material cost. PLA is great for most beginners and prototypes; ABS or PETG for functional parts; specialty filaments for demanding applications.

Can I save money by 3D printing in bulk or with a subscription service?

Yes! Bulk printing batches parts reduces setup and labor costs per item. Subscription services like MatterHackers’ Build Series or filament clubs offer discounts on materials, lowering per-print costs.

What are some ways to reduce the cost of 3D printing without sacrificing quality?

- Use trusted filament brands

- Optimize print settings and model design

- Maintain your printer regularly

- Avoid unnecessary high-resolution prints

- Recycle and reuse material scraps

📚 Reference Links and Resources

- Prusa 3D Printing Price Calculator — Official cost calculator by Prusa Research

- How Much Does 3D Printing Cost? [2021 Update] – PrintAWorld — Comprehensive guide and pricing overview

- Creality Official Website

- Prusa Official Website

- Anycubic Official Website

- Filabot Official Website

- Thingiverse — Free 3D printable models

- MyMiniFactory — Curated 3D models

- MatterHackers — Filament and printer supplies

Ready to start printing smarter and cheaper? Dive into our other guides at 3D Printed™ and keep your prints crisp and your wallet happy! 🎉