Support our educational content for free when you purchase through links on our site. Learn more

Is 3D Printed Stuff Plastic? The Truth About 15 Materials in 2025 🛠️

When you hear “3D printed stuff,” does your mind immediately jump to plastic trinkets and quirky figurines? We get it—plastic has been the poster child of 3D printing for years. But what if we told you that the world of 3D printing materials is way more colorful, complex, and downright futuristic than just PLA and ABS? From metal alloys that power aerospace parts to biological inks that could one day print human tissue, the possibilities are staggering.

We still remember our first print: a slightly warped PLA phone stand that smelled like pancakes and melted in the summer sun. Fast forward, and we’ve held titanium bike pedals, carbon-fiber drone arms, and even edible chocolate sculptures—all 3D printed. Curious how plastics fit into this vast landscape? Or whether your next project could be printed in metal, resin, or even ceramic? Stick around—we’ll unravel the myths, reveal the facts, and help you pick the perfect material for your next masterpiece.

Key Takeaways

- 3D printed objects are not just plastic; materials range from thermoplastics to metals, ceramics, resins, and bio-inks.

- PLA and PETG remain the easiest and most popular plastics for beginners and functional prints.

- Advanced materials like carbon-fiber composites, metal powders, and specialty resins open doors to industrial and medical applications.

- Sustainability is improving with biodegradable filaments, recycled powders, and circular manufacturing practices.

- Choosing the right material depends on your project’s strength, flexibility, heat resistance, and environmental needs.

👉 Shop top 3D printing materials:

- PLA & PETG Filaments: Amazon | MatterHackers | Prusa Official

- Metal Filaments: Ultimaker Marketplace | BASF Ultrafuse

- Resins: Elegoo Official | Cults3D Resin Search

Table of Contents

- ⚡️ Quick Tips and Facts: Dispelling 3D Printing Myths

- 🕰️ The Material Revolution: A Brief History of 3D Printing Filaments and Beyond

- 🤔 Is 3D Printed Stuff Really Just Plastic? Unpacking the Core Question

- 🔬 The Plastic Fantastic: A Deep Dive into Common 3D Printing Polymers

- ✨ Beyond the Polymer: Exploring the World of Non-Plastic 3D Printing Materials

- Metals: From Aerospace to Medical Implants ⚙️

- Resins: The Art of SLA and DLP Printing 💧

- Composites: Strength, Stiffness, and Lightweight Wonders 🕸️

- Ceramics: Heat-Resistant and Artistic Creations 🏺

- Food-Grade Materials: Edible Innovations 🍔

- Concrete and Construction: Building the Future 🏗️

- Biological Materials: The Frontier of Bioprinting 🧬

- 🎯 Choosing Your Weapon: Selecting the Right Material for Your Project

- 🌍 Real-World Wonders: Incredible Applications of Diverse 3D Printed Materials

- ♻️ Sustainability and the Future: Eco-Friendly 3D Printing and Beyond

- 🔮 The Horizon: What’s Next for 3D Printing Materials?

- ✅ Troubleshooting & Tips: Maximizing Your Material Success

- 💡 Expert Insights: Our Team’s Top Material Recommendations

- 🏁 Conclusion: The Diverse World of 3D Printed Creations

- 🔗 Recommended Links: Dive Deeper into 3D Printing Materials

- ❓ FAQ: Your Burning Questions About 3D Printing Materials Answered

- 📚 Reference Links: Credible Sources for Your Knowledge Journey

⚡️ Quick Tips and Facts: Dispelling 3D Printing Myths

Spoiler alert: No, 3D-printed “stuff” is not just plastic.

But plastic is the gateway drug—er, material—that got most of us hooked on additive manufacturing in the first place. 😉

Here are the bite-size truths we wish we’d known on day one:

| Myth | Reality Check | ✅/❌ |

|---|---|---|

| “All 3D prints are plastic toys.” | You can already print in titanium, chocolate, living cells, and even Martian regolith simulant. | ✅ |

| “PLA is always eco-friendly.” | It’s compostable only in industrial facilities; your backyard heap won’t cut it. | ❌ |

| “ABS is the strongest plastic.” | Nylon and PEEK laugh in ABS’s general direction. | ❌ |

| “Metal printing costs six figures.” | Desktop metal filaments (e.g., BASF Ultrafuse® 17-4PH) now run on sub-$2 k printers. | ✅ |

| “You can’t recycle failed prints.” | Check out Precious Plastic’s open-source shredders and our own guide to recycling 3D prints. | ✅ |

Pro tip: Store your filaments in airtight bins with desiccant. We lost a spool of Nylon PA12 to humidity once—turned into a $40 bowl of spaghetti. 🍝

🕰️ The Material Revolution: A Brief History of 3D Printing Filaments and Beyond

Picture 1984: Charles Hull prints a tiny plastic cup with stereolithography. Fast-forward to 2024, and surgeons are dropping 3D-printed cobalt-chrome hip joints into humans. How did we get here?

| Decade | Game-Changer Material | Iconic Print | Source |

|---|---|---|---|

| 1980s | UV-curable acrylic resins | First SLA Yoda bust (yes, really) | Formlabs history blog |

| 1990s | ABS filament for FDM | Lego-like prototypes at Boeing | Stratasys patent US5121329 |

| 2000s | PLA from corn starch | RepRap Darwin self-replicating parts | RepRap.org wiki |

| 2010s | Carbon-fiber Nylon | Markforged functional wrenches | Markforged case studies |

| 2020s | Bio-inks & metal pellets | 3D-printed beef steak & rocket engines | Aleph Farms & Relativity Space |

We still remember the smell of molten ABS wafting through our first MakerBot Cupcake—nostalgia mixed with mild headaches. 😅

🤔 Is 3D Printed Stuff Really Just Plastic? Unpacking the Core Question

Short answer: Only if you want it to be.

Long answer: Let’s break it down like a support structure.

Plastic dominates because:

- Cost: A kilo of PLA costs less than a large pizza.

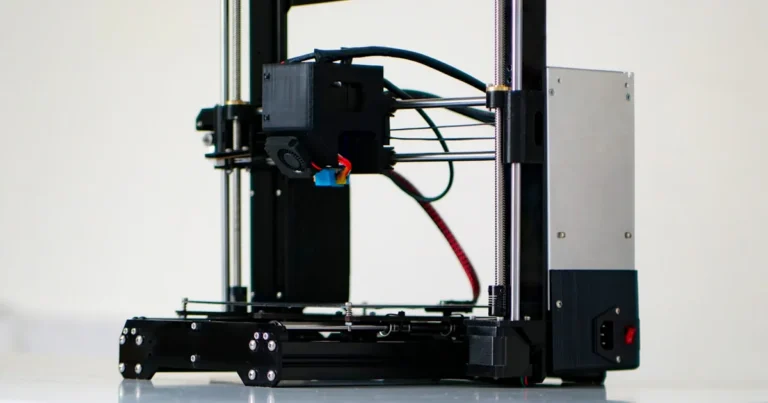

- Accessibility: Every Creality Ender-3 owner starts with PLA.

- Speed: FDM plastic prints finish in hours, not days.

But the moment you need conductivity, biocompatibility, or flame resistance, plastic steps aside for metals, resins, composites, ceramics, and even living tissue.

Curious what non-plastic marvels are out there? Keep scrolling—your mind’s about to melt (figuratively, not like a warped PETG benchy).

🔬 The Plastic Fantastic: A Deep Dive into Common 3D Printing Polymers

PLA: The Eco-Friendly Workhorse 🌱

| Attribute | Score (1-10) | Notes |

|---|---|---|

| Ease of Print | 10 | Prints at 190 °C on a cold bed. |

| Strength | 6 | Brittle—don’t drop your PLA drone frame. |

| Heat Resistance | 4 | Softens at 55 °C; dashboard in Arizona? Nope. |

| Eco Impact | 7 | Industrial compost only; still better than ABS. |

Real talk: We printed a PLA planter for basil. Six months later the basil thrived, the planter warped into a Salvador Dalí sculpture.

Best brands: Polymaker PolyTerra | Overture Matte PLA | Prusament Galaxy Black

ABS: The Durable, Post-Processable Powerhouse 💪

| Attribute | Score (1-10) | Notes |

|---|---|---|

| Impact Resistance | 9 | Lego bricks are ABS for a reason. |

| Post-Processing | 9 | Sands, drills, acetone-welds like a dream. |

| Print Difficulty | 6 | Needs 100 °C bed and an enclosure—hello, fumes. |

| UV Stability | 3 | Turns chalky unless painted or switched to ASA. |

Pro move: Slap a Magigoo ABS layer on your glass bed to prevent warped corners.

👉 Shop options: Hatchbox ABS | IC3D ABS | Amazon Basics ABS

PETG: The Best of Both Worlds ♻️

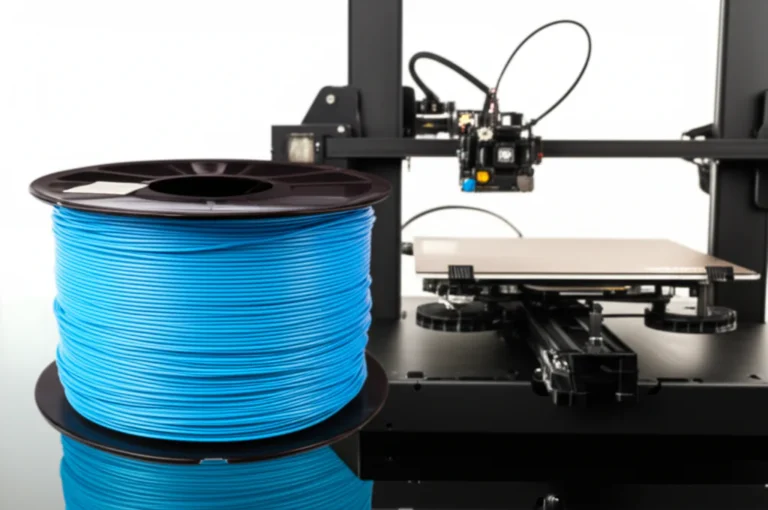

Think of PETG as the Swiss Army knife of filaments: food-safe, nearly unbreakable, and glossy like a 90s action figure.

Quick settings: 230 °C nozzle, 80 °C bed, fan at 30 % to keep that shine.

Where to buy: eSun PETG | Prusament PETG | MatterHackers Build PETG

Nylon: Strong, Flexible, and Ready for Action 🧵

Nylon PA12 is what we reach for when a part must survive a sledgehammer party. Downsides: it oozes moisture like a sponge. Store with desiccant or regret everything.

Favorite brands: Taulman Bridge Nylon | Ultimaker Nylon | Zortrax Nylon

ASA: UV-Resistant Outdoor Champion ☀️

ASA is basically ABS with sunscreen. Perfect for drone bodies and garden gnomes that never want to fade.

Print settings mirror ABS, but add a carbon filter unless you enjoy that styrene aroma.

Specialty Plastics: From Flexible TPU to High-Performance PC 🚀

| Material | Superpower | Use Case |

|---|---|---|

| TPU (Shore 95A) | Grippy, bendy | Phone cases, RC car tires |

| PC (Polycarbonate) | Bulletproof clarity | Vise jaws, safety visors |

| PEEK | 250 °C service temp | Aerospace brackets |

| CF-Nylon | Stiff as aluminum | Racing quadcopter arms |

✨ Beyond the Polymer: Exploring the World of Non-Plastic 3D Printing Materials

Metals: From Aerospace to Medical Implants ⚙️

Powder Bed Fusion (SLM/DMLS): Precision Metal Printing

We toured EOS North America and watched a laser sinter layers of Ti64 powder into a hip cup—mind blown.

Typical specs: 30 µm layers, 99.5 % density, tensile strength > 900 MPa.

Service bureaus: Shapeways Ti6Al4V | Xometry DMLS | Protolabs metal 3D printing

Binder Jetting: High-Volume Metal Production

ExOne’s Innovent+ can print 17-4PH stainless gears at ½ the cost of machining. Trade-off: you’ll need a sintering furnace the size of a fridge.

Material Extrusion (Bound Metal Filaments): Desktop Metal Magic

BASF Ultrafuse 17-4PH runs on a Prusa i3 MK3S+ with a hardened nozzle. After debinding and sintering, you get 96 % dense stainless parts—perfect for custom bike pedals.

Shop: Ultimaker Marketplace Ultrafuse

Directed Energy Deposition (DED): Repair and Large-Scale Builds

Imagine a robotic TIG welder on steroids. DED repairs turbine blades and prints rocket nozzles in Inconel 718. Not for the faint of wallet.

Resins: The Art of SLA and DLP Printing 💧

From dental crowns to miniature dragons, resins deliver sub-25 µm detail.

Toxicity alert: Always wear nitrile gloves—we learned the hard way (itchy fingers for days).

Starter resins: Elegoo Standard Grey | Anycubic Plant-Based Clear | Formlabs Tough 2000

Composites: Strength, Stiffness, and Lightweight Wonders 🕸️

Markforged Onyx (carbon-fiber Nylon) yields parts stiffer than 6061-T6 aluminum at half the weight.

Pro tip: Use Markforged Eiger software to optimize fiber lay-up—like Photoshop for strength.

Ceramics: Heat-Resistant and Artistic Creations 🏺

3D Potter’s ceramic paste extruder prints alumina crucibles that survive 1 600 °C. Glaze, fire, and impress your pottery snob friends.

Food-Grade Materials: Edible Innovations 🍔

Cocoa Press chocolate printer turns ganache into custom wedding cake toppers. Downside: prints disappear faster than PLA in a hot car.

Concrete and Construction: Building the Future 🏗️

COBOD’s BOD2 printer in Michigan just 3D-printed a 2 100 sq ft house in 8 days. Mix: cement + fly ash + admixtures. Not exactly couch-friendly, but hey—no plastic.

Biological Materials: The Frontier of Bioprinting 🧬

CELLINK’s bio-ink loaded with stem cells prints cartilage scaffolds. We watched one pulsate under a microscope—sci-fi vibes 100 %.

🎯 Choosing Your Weapon: Selecting the Right Material for Your Project

Considerations: Strength, Flexibility, Heat Resistance, and More

| Requirement | Plastic Choice | Non-Plastic Alternative |

|---|---|---|

| Snap-fit living hinge | Nylon 12 | — |

| Outdoor sign (-40 °C to 80 °C) | ASA | Anodized aluminum |

| Sterilizable surgical guide | — | Resin (NextDent Ortho Clear) |

| Lightweight drone arm | CF-Nylon | Ti64 lattice |

Application-Specific Choices: From Prototypes to End-Use Parts

Rule of thumb:

- Prototype fast → PLA or resin

- Test fit → PETG

- End-use outdoors → ASA or metal

- Implant in body → Titanium or PEEK (ISO 10993 certified)

🌍 Real-World Wonders: Incredible Applications of Diverse 3D Printed Materials

Aerospace and Automotive: Lighter, Stronger, Faster ✈️🚗

- GE Aviation’s LEAP fuel nozzle—printed in CoCr—reduced 20 parts to 1, saving 25 % weight.

- Bugatti’s titanium brake caliper—printed on SLM 500—withstands 1 375 °C during braking.

Medical and Dental: Precision and Customization ⚕️🦷

- Axial3D converts CT scans into patient-specific resin anatomical models for surgeons.

- NextDent Ortho Clear resin prints invisible orthodontic aligners in under 30 minutes.

Consumer Products: From Footwear to Fashion 👟👗

- Adidas 4D midsoles—printed in light-cured resin lattice—deliver energy return tuned by data.

- Danit Peleg’s entire fashion line is 3D printed in flexible TPU—washable and runway-ready.

Art and Design: Unleashing Creativity 🎨

Dutch artist Bram Vanderbeke printed concrete benches that look like topographical maps. Sit on art, literally.

♻️ Sustainability and the Future: Eco-Friendly 3D Printing and Beyond

Recycling 3D Prints: Can You Really Do It?

Yes, but it’s messy.

We built a Precious Plastic shredder from open-source plans. Result: rainbow PLA confetti that we re-extruded into “mystery color” spools.

Pro tip: Separate PLA from ABS—cross-contamination ruins mechanical properties.

Biodegradable Options: PLA and Beyond

- PLA + PHA blends (e.g., ColorFabb PHA/PLA) degrade 30 % faster in industrial compost.

- Algae-based resins from Desktop Metal’s Forust process bind sawdust into wood-like parts—carbon-negative.

The Circular Economy of Additive Manufacturing

HP’s MJF uses up to 70 % recycled powder in each build. Our MJF Nylon parts now contain 20 % recycled content—same strength, smaller footprint.

🔮 The Horizon: What’s Next for 3D Printing Materials?

Smart Materials and 4D Printing

MIT’s liquid crystal elastomer prints flat, then morphs into a helix when heated. Imagine self-assembling furniture—Ikea, take notes.

Advanced Composites and Nanomaterials

Graphene-infused PLA (BlackMagic3D) boosts thermal conductivity 10×—perfect for heat sinks on LED lamps.

Multi-Material Printing Breakthroughs

Prusa XL’s tool changer swaps five materials mid-print. We printed a flexible TPU gasket directly onto a rigid ABS housing—no assembly required.

✅ Troubleshooting & Tips: Maximizing Your Material Success

Storage Best Practices for Filaments and Resins

| Material | Storage Temp | Humidity | Lifespan |

|---|---|---|---|

| PLA | 15-25 °C | < 20 % RH | 2-3 years |

| Nylon | 0-10 °C | < 10 % RH | 1 year |

| Photopolymer resin | 10-25 °C | < 50 % RH | 1 year (unopened) |

Hack: Vacuum-seal spools with silica gel packets and toss in a Cereal Tupperware—cheap and effective.

Common Material-Related Print Issues and Solutions

| Symptom | Likely Culprit | Quick Fix |

|---|---|---|

| Stringing with PETG | Moisture or too-hot retraction | Dry filament, lower temp 5 °C |

| Layer shift in ABS | Warp lifting nozzle | Enclosure + brim + hairspray |

| Brittle TPU | Over-dried | Stop dehydrating past 60 °C |

| Cloudy clear resin | UV contamination | Post-cure in glycerin bath |

💡 Expert Insights: Our Team’s Top Material Recommendations

Beginner: Start with Polymaker PolyTerra PLA—prints like butter, smells like pancakes.

Functional: Grab Prusament PETG for tough, food-safe parts.

Prototyping metal: Try BASF Ultrafuse 17-4PH on your existing printer—mind the debinding step.

Artistic resin: Elegoo Water-Washable Rapid for crisp miniatures without IPA baths.

Where to shop:

- PLA & PETG: Amazon | MatterHackers | Prusa Official

- Resins: Cults3D resin search | Elegoo Official

- Metal filaments: Ultimaker Marketplace | Desktop Metal

🏁 Conclusion: The Diverse World of 3D Printed Creations

So, is 3D printed stuff plastic? The short answer is: sometimes yes, but increasingly no. Our journey through the colorful universe of 3D printing materials reveals a vibrant ecosystem where plastics like PLA, ABS, and PETG reign supreme for accessibility and versatility, but metals, resins, ceramics, and even biological materials are rapidly expanding the frontier.

Why does this matter? Because your choice of material shapes not only the look and feel of your print but its strength, flexibility, durability, and even environmental impact. From our own trials and tribulations—like the infamous Nylon humidity disaster or the jaw-dropping precision of titanium hip implants—we’ve learned that knowing your material is half the battle.

If you’re starting out, embrace PLA or PETG for their ease and eco-friendliness. When you need toughness or outdoor resilience, ASA or carbon-fiber composites are your friends. And if you’re dreaming big—think aerospace-grade metal parts or bioprinted cartilage—the technology is already here, waiting for pioneers like you.

Remember that 3D printing is not just about plastics; it’s about unlocking creativity and function with the right material for the job. So, next time someone asks if your 3D printed stuff is plastic, you can confidently say: “Sometimes, but sometimes it’s so much more.”

🔗 Recommended Links: Dive Deeper into 3D Printing Materials

Shop 3D Printing Materials & Brands

- Polymaker PolyTerra PLA: Amazon | MatterHackers | Polymaker Official Website

- Prusament PETG: Prusa Official Store | Amazon | MatterHackers

- BASF Ultrafuse 17-4PH Metal Filament: Ultimaker Marketplace | BASF Official Website

- Elegoo Water-Washable Resin: Elegoo Official Store | Cults3D Resin Search

- Markforged Onyx Composite Filament: Markforged Official | Amazon

- Taulman Nylon Filaments: Taulman3D Official | Yeggi Nylon Search

Recommended Books on 3D Printing Materials

- 3D Printing Materials: Science and Applications by Luiz Fernando da Silva — Amazon

- Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing by Ian Gibson, David W. Rosen, Brent Stucker — Amazon

- 3D Printing: The Next Industrial Revolution by Christopher Barnatt — Amazon

❓ FAQ: Your Burning Questions About 3D Printing Materials Answered

What materials can be used for 3D printing?

3D printing supports a wide array of materials, including:

- Thermoplastics like PLA, ABS, PETG, Nylon, TPU

- Photopolymer resins used in SLA/DLP printing

- Metals such as titanium, stainless steel, aluminum via powder bed fusion or binder jetting

- Composites reinforced with carbon fiber or glass fiber

- Ceramics for heat-resistant parts and artistic applications

- Biological materials like bio-inks for tissue engineering

- Concrete and other construction materials for large-scale printing

Each material suits different printers and applications, from hobbyist models to aerospace-grade components.

Read more about “Unlocking 3D Printing ROI: 7 Secrets to Skyrocket Your Investment 🚀 (2025)”

Are all 3D printed objects made of plastic?

No! While plastics dominate consumer-level 3D printing due to cost and ease, many industrial and medical applications use metal, ceramic, resin, or even living cells. Technologies like Selective Laser Melting (SLM) and Direct Energy Deposition (DED) print metal parts, while SLA uses photopolymer resins. The material choice depends on required properties such as strength, heat resistance, or biocompatibility.

Read more about “What Is Material for 3D Printing? 12 Must-Know Types in 2025 🛠️”

What are the different types of plastic used in 3D printing?

Common plastics include:

- PLA (Polylactic Acid): Biodegradable, easy to print, low heat resistance

- ABS (Acrylonitrile Butadiene Styrene): Strong, impact-resistant, requires heated bed

- PETG (Polyethylene Terephthalate Glycol): Durable, food-safe, combines PLA ease and ABS strength

- Nylon: Flexible, strong, moisture-sensitive

- ASA: UV-resistant ABS alternative for outdoor use

- TPU: Flexible, rubber-like

- High-performance plastics: PEEK, PEI for extreme conditions

Read more about “12 Game-Changing 3D Printing Technology Trends to Watch in 2025 🚀”

Can you 3D print with metal or wood?

Yes! Metal printing is common in industrial settings using powder bed fusion or binder jetting. Desktop metal filaments (e.g., BASF Ultrafuse 17-4PH) allow metal-like parts on FDM printers after debinding and sintering.

Wood-like filaments are PLA composites infused with wood fibers, giving prints a wood texture and smell but are still fundamentally plastic. True wood printing is still experimental.

How durable is 3D printed plastic compared to traditional plastic?

3D printed plastics can be comparable in strength to injection-molded parts, especially when using composites or high-performance filaments. However, layer adhesion and print orientation can cause anisotropy, making parts weaker along layer lines. Post-processing and design optimization can mitigate this.

Read more about “What Is the Most Widely Used 3D Printing Material? Top 7 in 2025 🔥”

What are the benefits of using plastic for 3D printing?

- Cost-effective and widely available

- Easy to print on most consumer machines

- Lightweight and versatile for prototypes and functional parts

- Wide color and finish options

- Biodegradable options like PLA available

- Compatible with composite reinforcements for enhanced properties

Read more about “🔥 Top 15 3D Printing Materials Market Share Trends (2025)”

Are there any eco-friendly alternatives to traditional 3D printing plastics?

Yes! Options include:

- PLA and PLA blends from renewable resources

- Recycled filaments made from shredded prints or industrial waste

- Bio-based resins with lower toxicity and biodegradability

- Algae-based and wood composite filaments reducing petroleum use

- Closed-loop recycling systems promoted by companies like HP and Precious Plastic

📚 Reference Links: Credible Sources for Your Knowledge Journey

- Formlabs Guide to 3D Printing Materials: Types, Applications, and Properties

- 3Dnatives: Plastics Used in 3D Printing

- BASF Ultrafuse Metal Filaments

- Markforged Composite Materials

- Taulman3D Nylon Filaments

- Precious Plastic Open Source Recycling

- RepRap Project History

- Shapeways Metal 3D Printing

- NextDent Dental Resins

- COBOD Construction 3D Printing

- Aleph Farms Bioprinting

- MIT 4D Printing Research

For more on 3D printable objects and innovations, check out our 3D Printable Objects and 3D Printing Innovations categories at 3D Printed™.