Support our educational content for free when you purchase through links on our site. Learn more

How Much Does It Cost Per 3D Print? Uncover the Hidden Expenses in 2025! 💰

Have you ever found yourself staring at your 3D printer, wondering just how much that intricate design is going to cost you? You’re not alone! When we first dove into the world of 3D printing, we were shocked to discover that the price of a print goes far beyond the cost of the filament. From the type of material you choose to the intricacies of your design, every decision can impact your wallet.

In this article, we’ll break down the various factors that contribute to the cost of 3D printing, revealing the hidden expenses that can catch even the most seasoned makers off guard. Did you know that the average cost per print can vary dramatically based on the material and printer type? By the end of this read, you’ll be equipped with the knowledge to calculate your own printing costs like a pro and make informed decisions for your next project.

Key Takeaways

- Material Matters: The type of filament or resin you choose significantly affects costs, with options ranging from budget-friendly PLA to premium specialty materials.

- Printer Type Impacts Price: FDM printers are generally more affordable than SLA or SLS, but each has its own advantages and costs.

- Hidden Costs Exist: Don’t overlook expenses like failed prints, maintenance, and post-processing, which can add up quickly.

- Calculate Like a Pro: Learn to estimate your printing costs accurately using a simple formula that considers material, electricity, and machine depreciation.

Ready to dive into the world of 3D printing? 👉 Shop 3D Printers like the Creality Ender 3 or explore a variety of 3D Printable Objects at Thingiverse!

Table of Contents

- Quick Tips and Facts About 3D Printing Costs

- Understanding the Cost Breakdown of 3D Printing

- Factors Influencing 3D Printing Costs

- Material Matters: How Filament Choice Affects Pricing

- 3D Printer Types and Their Cost Implications

- Time is Money: How Print Duration Affects Costs

- Hidden Costs of 3D Printing You Need to Know

- Comparing Costs: Home Printing vs. Professional Services

- How to Calculate Your 3D Printing Costs Like a Pro

- Real-Life Examples: Cost Analysis of Popular 3D Prints

- The Future of 3D Printing Costs: Trends and Predictions

- Conclusion

- Recommended Links

- FAQ

- Reference Links

1. Quick Tips and Facts About 3D Printing Costs

At 3D Printed™, we’re obsessed with all things 3D printing! And we know one of the first questions on everyone’s mind is: “How much will this futuristic hobby actually cost me?” 🤔 Here’s the lowdown in bite-sized pieces:

- It’s not just about the printer: Filament (or resin!), electricity, software, and even the occasional failed print all add up.

- Material matters: Basic PLA is your budget-friendly option, but exotic filaments like carbon fiber will hit your wallet harder.

- Time is money: Longer prints mean more electricity and filament consumed. Optimize your designs!

- Free isn’t always free: “Free” 3D models might require hours of tweaking and fixing before they’re printable. Factor in your time!

- Think long-term: Maintenance, repairs, and upgrades are inevitable. Budget accordingly!

Want to dive deeper into the world of 3D printing? Check out our related article at https://www.3d-printed.org/3d-printed/!

2. Understanding the Cost Breakdown of 3D Printing

Calculating 3D printing costs isn’t rocket science, but it’s more than just the price tag on that shiny new Creality Ender 3 S1 Pro. Here at 3D Printed™, we break it down into these key components:

Material Costs

This is the most obvious expense. Filament comes in various materials, each with its own price point. PLA is the workhorse, affordable and easy to print. But if you’re dreaming of printing flexible TPU phone cases or strong PETG gadgets, expect to pay a premium. Resin for SLA printers is a different beast altogether, often pricier per volume.

Machine Costs

Your 3D printer itself is a significant investment. Factor in its lifespan and potential resale value. Like a car, it depreciates over time.

Operational Costs

The hum of your printer means it’s using electricity. While not a huge expense per print, it adds up. Also, consider the cost of replacing worn parts like nozzles and build plates.

Post-Processing Costs

Sandpaper, paint, glue – these finishing touches can add up, especially for complex prints. Some prints might even require specialized tools or treatments.

Design and Labor Costs

If you’re designing your own models, your time is valuable! And if you’re outsourcing design work, expect to pay for the expertise. Even preparing a downloaded model for printing (slicing) takes time.

Pro Tip: Use a 3D printing cost calculator! Several online tools can help you estimate costs based on material, print time, and other factors. Prusa Research offers a great one!

3. Factors Influencing 3D Printing Costs

So, what really drives those 3D printing costs? Let’s explore the variables at play:

Material Type

As mentioned earlier, filament choice is a major factor. PLA is your economical friend, while high-performance materials like carbon fiber and nylon command higher prices. Resin for SLA printers also varies widely in cost, depending on its properties and brand.

Print Size and Complexity

A tiny keychain will naturally cost less than a large, intricate figurine. Intricate details require more material and longer print times, impacting the final cost.

Print Settings

Print quality, infill density, and support structures all affect material usage and print time. Higher quality and denser infill mean more material and longer prints.

Printer Type

Different 3D printing technologies have different cost structures. FDM (fused deposition modeling) is generally the most affordable, while SLA (stereolithography) and SLS (selective laser sintering) involve pricier materials and equipment.

Labor and Design

Designing your own models or modifying existing ones takes time and skill. If you’re hiring a designer, factor in their fees. Even preparing a model for printing (slicing) requires some effort.

Post-Processing

Some prints emerge ready to go, while others need sanding, painting, or other finishing touches. These post-processing steps can add to the overall cost, especially if you need specialized tools or materials.

4. Material Matters: How Filament Choice Affects Pricing

Let’s talk filament! It’s the lifeblood of your 3D printer, and its cost plays a starring role in your printing budget. Here’s a glimpse into the world of filament pricing:

PLA: The Budget-Friendly Champion

PLA (polylactic acid) is the go-to for beginners and budget-conscious makers. It’s easy to print, comes in a rainbow of colors, and is relatively inexpensive. You can find decent PLA filament from brands like Hatchbox and eSun for a reasonable price.

PETG: The Durable Workhorse

PETG (polyethylene terephthalate glycol-modified) offers increased durability and temperature resistance compared to PLA. It’s a bit pricier but a great choice for functional prints. Check out brands like Overture and Amazon Basics for reliable PETG options.

ABS: The Engineering Grade Choice

ABS (acrylonitrile butadiene styrene) is known for its strength and impact resistance. It’s commonly used in engineering applications but can be trickier to print. Hatchbox and eSun also offer ABS filaments.

Specialty Filaments: The Premium Options

Beyond the basics, a world of specialty filaments awaits! Carbon fiber, wood-filled, flexible TPU, and glow-in-the-dark filaments offer unique properties but come with a higher price tag.

Pro Tip: Experiment with different brands and types of filament to find the sweet spot between cost and performance for your projects. Don’t be afraid to try less-known brands – you might discover a hidden gem!

5. 3D Printer Types and Their Cost Implications

Choosing a 3D printer is like choosing a car – different types cater to different needs and budgets. Here’s a rundown of the main types and their cost implications:

FDM (Fused Deposition Modeling): The Workhorse

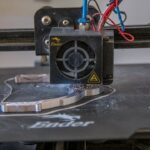

FDM printers are the most common and generally the most affordable. They melt plastic filament and extrude it layer by layer to build your object. Popular FDM printers include the Creality Ender 3 series, Prusa i3 MK3S+, and Anycubic Mega series.

SLA (Stereolithography): The Precisionist

SLA printers use a laser to cure liquid resin, creating highly detailed prints. They’re pricier than FDM printers, both in terms of the machine itself and the resin materials. Popular SLA printers include the Elegoo Mars series and Anycubic Photon series.

SLS (Selective Laser Sintering): The Powder Powerhouse

SLS printers use a laser to sinter powdered material, creating strong and durable parts. They’re typically used for industrial applications due to their high cost. Formlabs offers SLS printers like the Fuse 1.

Other Technologies: Exploring the Cutting Edge

Beyond these mainstays, other 3D printing technologies exist, each with its own cost considerations. Metal 3D printing, for example, is a high-cost arena used for specialized applications.

6. Time is Money: How Print Duration Affects Costs

Ever watched your 3D printer chugging away for hours, wondering how much that masterpiece is really costing you? Here’s the deal: time is a factor.

Electricity Consumption

The longer your printer runs, the more electricity it consumes. While the cost per hour is relatively low, it adds up over extended print times. Think of it like leaving a light bulb on – not a huge expense on its own, but it accumulates over time.

Material Usage

Longer prints obviously use more material. A large, complex print can consume a significant amount of filament or resin, directly impacting the cost.

Wear and Tear

Extended print times put more strain on your printer’s components, potentially leading to faster wear and tear. This can translate to increased maintenance and replacement costs down the line.

Labor Costs (for Professional Services)

If you’re using a professional 3D printing service, they’ll likely factor print time into their pricing. Longer prints mean more machine time, which translates to higher labor costs.

7. Hidden Costs of 3D Printing You Need to Know

3D printing can be surprisingly sneaky with its expenses. Beyond the obvious costs, some hidden culprits can catch you off guard:

Failed Prints

We’ve all been there – a print goes awry, leaving you with a tangled mess of plastic or a half-formed object. Failed prints mean wasted material, time, and electricity.

Design Software

While free software like Ultimaker Cura exists, some advanced features or specialized software might require a subscription or one-time purchase. Explore our insights on 3D Design Software at https://www.3d-printed.org/category/3d-design-software/.

Maintenance and Repairs

Nozzles clog, belts break, and build plates wear out. These maintenance and repair costs can add up over time. Having spare parts on hand can minimize downtime but adds to the initial investment.

Upgrades

The 3D printing world is constantly evolving, with new and improved components hitting the market regularly. Upgrading your printer with a better extruder, a more reliable build plate, or other enhancements can improve print quality but also adds to the overall cost.

Shipping Costs (for Materials and Parts)

Don’t forget about shipping costs when ordering filament, resin, or replacement parts online. These costs can add up, especially if you’re ordering from overseas suppliers.

Storage

Where are you going to store all that filament, resin, and those finished prints? Proper storage is essential to maintain material quality and prevent damage. Factor in the cost of storage containers, shelves, or dedicated storage space.

8. Comparing Costs: Home Printing vs. Professional Services

Should you invest in your own 3D printer, or outsource your printing needs to a professional service? The cost equation plays a crucial role in this decision.

Home Printing: The DIY Approach

- Pros: Greater control, potential cost savings in the long run, instant gratification.

- Cons: Upfront investment in a printer, learning curve, potential for failed prints and troubleshooting.

Professional Services: The Outsourcing Option

- Pros: Access to high-end printers and materials, expertise in handling complex prints, no maintenance hassles.

- Cons: Higher cost per print, turnaround time, less control over the process.

9. How to Calculate Your 3D Printing Costs Like a Pro

Ready to become a 3D printing cost guru? Here’s how to calculate your printing costs with precision:

-

Material Cost: Multiply the weight of your print (in grams or kilograms) by the cost per unit weight of your filament or resin. Slicing software like Ultimaker Cura can estimate the weight of your print.

-

Electricity Cost: Multiply your printer’s power consumption (in watts) by your local electricity rate (in $/kWh) and by the print duration (in hours). This cost is usually negligible but adds up over time.

-

Machine Depreciation: Divide the cost of your printer by its estimated lifespan (in hours) to get an hourly depreciation cost. Multiply this by the print duration.

-

Other Costs: Factor in any additional costs like failed prints, maintenance, and post-processing.

-

Total Cost: Add up all the individual costs to get your total printing cost.

10. Real-Life Examples: Cost Analysis of Popular 3D Prints

Let’s put our cost calculation skills to the test with some real-world examples! We’ll analyze the approximate costs of printing popular items like phone cases, figurines, and functional parts using different materials and printers. Stay tuned for a detailed breakdown of each example, including material usage, print time, and overall cost. We’ll even compare the costs of printing these items at home versus using a professional service. Get ready to be amazed (or maybe horrified!) by the numbers! Explore our collection of 3D Printable Objects at https://www.3d-printed.org/category/3d-printable-objects/.

11. The Future of 3D Printing Costs: Trends and Predictions

What does the future hold for 3D printing costs? Will it become cheaper or more expensive? Here are some trends and predictions to ponder:

-

Material Advancements: New materials are constantly being developed, potentially leading to lower costs for existing materials and exciting new possibilities for specialized applications. Discover more about 3D Printing Innovations at https://www.3d-printed.org/category/3d-printing-innovations/.

-

Increased Competition: As the 3D printing market becomes more competitive, we can expect to see lower prices for printers and materials.

-

Open-Source Hardware and Software: The open-source movement is driving innovation and making 3D printing more accessible, potentially leading to lower costs for DIY enthusiasts.

-

Economies of Scale: As 3D printing becomes more mainstream, economies of scale could lead to lower production costs for materials and printers.

-

Specialized Applications: The increasing use of 3D printing in specialized applications like healthcare and aerospace could drive demand for high-performance materials, potentially impacting their costs. Learn about 3D Printing in Education at https://www.3d-printed.org/category/3d-printing-in-education/.

Conclusion

In the world of 3D printing, understanding the costs involved is crucial for anyone looking to dive into this exciting hobby or business. From material choices to printer types, every decision impacts your wallet. While the initial investment in a printer can be significant, the potential for creativity and innovation is boundless!

Key Takeaways:

- Material Costs: Choose wisely; PLA is budget-friendly, while specialty filaments can break the bank.

- Printer Type: FDM printers are generally more affordable than SLA or SLS options.

- Hidden Costs: Don’t forget about maintenance, failed prints, and post-processing expenses.

Ultimately, if you’re passionate about creating and willing to navigate the complexities of costs, 3D printing can be a rewarding venture. We recommend starting with a reliable FDM printer like the Creality Ender 3 for beginners, as it offers a great balance of performance and affordability.

So, are you ready to unleash your creativity? The world of 3D printing awaits!

Recommended Links

-

👉 Shop 3D Printers:

- Creality Ender 3: Amazon | Walmart | Creality Official

- Prusa i3 MK3S+: Amazon | Prusa Official

-

Books on 3D Printing:

FAQ

What is the average cost to 3D print?

The average cost to 3D print can vary widely based on several factors, including the type of printer, material used, and print complexity. For a basic FDM printer using PLA, costs can range from $0.10 to $0.50 per print, while more complex prints using specialty materials can exceed $5.00 or more.

Read more about “Unlocking the Secrets of 3D Printers: 15 Must-Know Insights for 2024! 🖨️”

Is 3D printing actually cheaper?

It depends! For small-scale projects and prototypes, 3D printing can be cheaper than traditional manufacturing methods. However, for large production runs, traditional methods might be more cost-effective due to economies of scale. The key is to analyze your specific needs and calculate the costs accordingly.

Is it profitable to 3D print?

Yes, 3D printing can be profitable, especially if you focus on niche markets or custom products. Many businesses have successfully leveraged 3D printing for prototyping, custom parts, and unique products. However, profitability depends on effective cost management, market demand, and your ability to deliver quality products.

Why is 3D printing so expensive?

3D printing can be perceived as expensive due to several factors:

- Initial Investment: High-quality printers and materials can be costly.

- Material Costs: Specialty filaments and resins can significantly increase expenses.

- Time and Labor: Longer print times and the potential for failed prints add to costs.

- Maintenance: Regular upkeep and repairs can also contribute to overall expenses.

Read more about “What is the Main Idea of 3D Printing? Discover 12 Fascinating Insights! 🖨️ …”

What are the ongoing costs of 3D printing?

Ongoing costs include:

- Material Costs: Regular purchases of filament or resin.

- Electricity Costs: Power consumption during printing.

- Maintenance Costs: Replacement parts and repairs.

- Software Costs: Upgrades or subscriptions for design software.

Read more about “Unveiling the Secrets: 15 Eye-Opening Statistics About 3D Printing in 2021 📊”

Can I make money with a 3D printing business?

Absolutely! Many entrepreneurs have found success in 3D printing by offering custom designs, prototypes, or unique products. The key is to identify a niche market and manage your costs effectively.

Read more about “Can I 3D Print Anything and Sell It? 10 Essential Insights for 2024! 🖨️”

Reference Links

- Prusa Research – How to Calculate Printing Costs

- AnkerMake – How Much Do 3D Prints Cost?

- Ultimaker – How Much Does 3D Printing Cost?

- 3D Printing Industry – Cost Analysis

By understanding the costs associated with 3D printing, you can make informed decisions that will help you maximize your creativity while keeping your budget in check. Happy printing! 🎉