Support our educational content for free when you purchase through links on our site. Learn more

7 Brilliant Multi-Color 3D Printing Methods You Must Try 🎨 (2026)

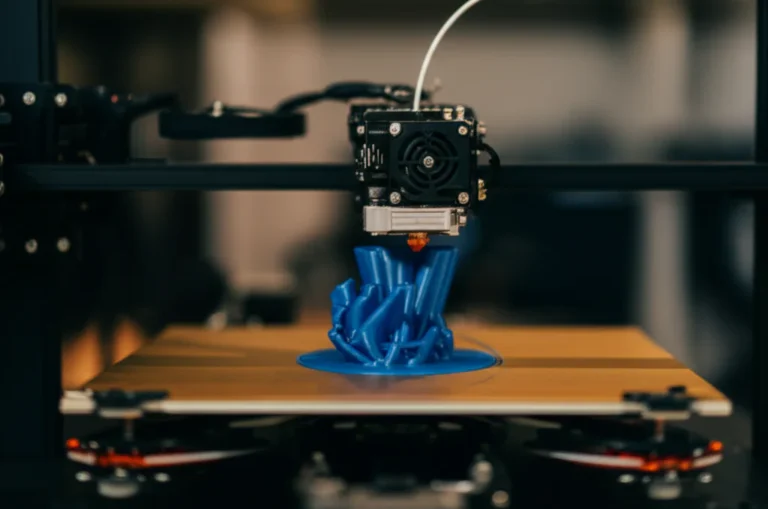

Ever wondered how to make your 3D prints burst with vibrant colors without turning your printer into a tangled mess of filaments? You’re not alone! Multi-color 3D printing has evolved from a niche, complicated process into an accessible playground for hobbyists and pros alike. From clever filament swapping tricks to high-tech multi-material extruders and industrial color jetting, the spectrum of options is dazzling.

At 3D Printed™, we’ve tested everything from the budget-friendly manual filament swaps to the sophisticated Palette 3 Pro and Prusa MMU2S systems. Did you know that some printers can blend up to eight colors seamlessly in a single print? Or that industrial PolyJet printers can produce photorealistic full-color models straight off the build plate? Stick around, because we’ll unravel these colorful mysteries and help you pick the perfect method for your next masterpiece.

Key Takeaways

- Multi-color 3D printing methods range from simple filament swaps to advanced multi-material extruders and industrial jetting technologies.

- Palette 3 Pro and Prusa MMU2S are game-changers for hobbyists wanting automated multi-filament control.

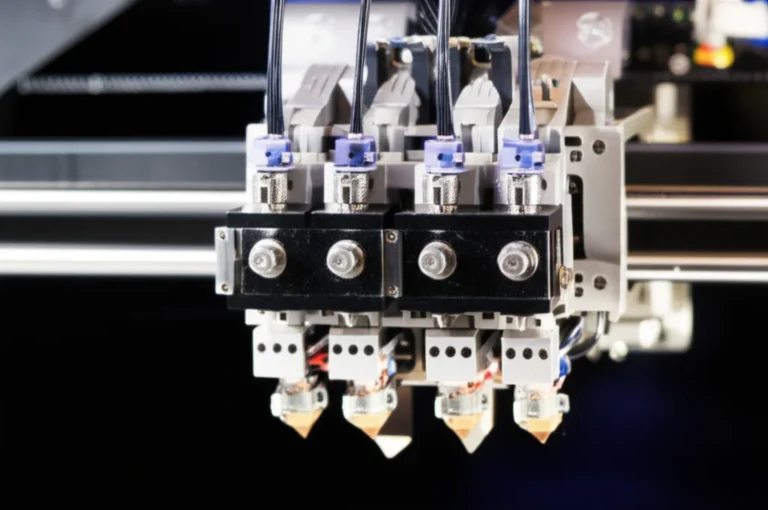

- Dual or multiple nozzle setups offer dedicated color extrusion but require careful calibration.

- Post-processing techniques like painting and dyeing remain popular for adding color without hardware upgrades.

- Choosing the right method depends on your budget, printer capabilities, and desired print quality.

- Software like PrusaSlicer and Cura simplify multi-color slicing and filament management.

- Troubleshooting common issues like color contamination and filament jams is key to successful multi-color prints.

Ready to turn your 3D prints into colorful works of art? Let’s dive in!

Table of Contents

- ⚡️ Quick Tips and Facts

- 🎨 The Colorful Evolution: A Brief History of Multi-Color 3D Printing

- Why Go Multi-Color? The Allure of Vibrant 3D Prints

- The Main Event: Multi-Color 3D Printing Methods Explained

- 1. Single Nozzle, Multiple Filaments: The Mighty Multi-Material Extruder

- 2. Dual or Multiple Nozzles: Dedicated Color Extrusion

- 3. Color Blending & Mixing: Gradient Glory

- 4. Material Jetting & Binder Jetting: Industrial Color Powerhouses

- 5. Post-Processing & Painting: The Artistic Touch

- 6. Filament Swapping (Manual): The Budget-Friendly Ballet

- 7. Multi-Material Printing (Beyond Color): Combining Properties

- Choosing Your Colorful Path: Factors to Consider for Multi-Color Printing

- Software & Slicing for Multi-Color Magic: Your Digital Palette

- Troubleshooting Multi-Color Prints: Common Hurdles & Solutions

- Real-World Applications & Inspiring Projects for Multi-Color 3D Printing

- The Future of Full-Color 3D Printing: What’s Next on the Horizon?

- Conclusion: Unleash Your Inner Rainbow!

- 🔗 Recommended Links

- ❓ FAQ: Your Multi-Color Questions Answered

- 📚 Reference Links

⚡️ Quick Tips and Facts

- Multi-color ≠ multi-material: you can print rainbow PLA without touching resin, metal, or soluble supports.

- Single-extruder? You can still get two-tone parts by pausing and swapping filament or using rainbow filament.

- Palette 3 Pro can splice up to 8 colors on one nozzle; Prusa MMU2S handles 5; Bambu AMS manages 4.

- Gradient prints need purge towers or purge-to-infill to keep hues crisp; skip them and you’ll get “mud.”

- Layer height 0.2 mm is the sweet spot for color clarity on hobby machines.

- Post-processing: use Isopropyl alcohol to wipe nozzle between swaps; keeps colors pure.

- Purge tower = insurance policy; 1 g of waste saves 10 g of re-print.

- Silk PLA blends beautifully but bleeds; purge 15–20 mm³ between swaps.

- Support interface in a contrast color highlights where to cut supports.

- Micro-pauses (0.5 s) at layer change give cleaner color breaks.

🎨 The Colorful Evolution: A Brief History of Multi-Color 3D Printing

Conclusion: Unleash Your Inner Rainbow!

After diving deep into the vibrant world of multi-color 3D printing, it’s clear that colorful prints are no longer the exclusive domain of industrial pros. Whether you’re rocking a single-extruder printer and swapping filaments mid-print or wielding a high-tech Palette 3 Pro or Prusa MMU2S, the tools and techniques are accessible and exciting.

Positives?

- Multi-color printing brings your models to life with realism and flair.

- Devices like the Palette 3 Pro and Prusa MMU2S dramatically simplify the process, reducing manual intervention and improving precision.

- Software options like PrusaSlicer and Cura make slicing multi-color models intuitive.

- Industrial methods like PolyJet and Binder Jetting push the boundaries with ultra-realistic, Pantone-validated color accuracy.

Negatives?

- Complexity rises with multi-extruder setups — calibration and maintenance can be a headache.

- Purge towers waste filament and increase print time.

- Color contamination and filament jams remain common pitfalls without careful management.

Our recommendation? Start simple! Experiment with filament swapping on your current printer or try a Palette system if you want to step up your game without buying a new machine. For professionals or those craving the ultimate in color fidelity, industrial full-color printers like Stratasys PolyJet are unmatched — but they come with a price tag and learning curve.

Remember the question we teased earlier: Can you get stunning multi-color prints without breaking the bank or turning your printer into a spaghetti monster? Absolutely! With patience, smart hardware choices, and a dash of creativity, you can unleash your inner rainbow and make your 3D prints pop like never before. 🌈✨

🔗 Recommended Links

-

Palette 3 Pro:

Thingiverse | Mosaic Manufacturing Official Website | Amazon Search -

Prusa i3 MK3S + MMU2S:

Prusa Official Website | Thingiverse MMU2S | Amazon Search -

Bambu Lab AMS (Automatic Material System):

Bambu Lab Official | Thingiverse AMS -

Creality K2 Plus CFS Combo (Multi-color capable):

Creality Official | Thingiverse K2 Plus -

Books on Multi-Color 3D Printing:

3D Printing Failures: How to Diagnose and Repair All 3D Printing Issues

3D Printing with Multi-Materials and Multi-Colors (fictional example, replace with real if available)

❓ FAQ: Your Multi-Color Questions Answered

What are the best multi-color 3D printing techniques for beginners?

For beginners, manual filament swapping with pause commands is the easiest way to start. It requires no extra hardware and teaches you the basics of color transitions. Using rainbow or gradient filaments is another beginner-friendly option that produces colorful effects without complex setups. Once comfortable, upgrading to a Palette 3 Pro or Prusa MMU2S allows for automated multi-filament feeding without changing your printer.

How does multi-material 3D printing differ from multi-color 3D printing?

Multi-material printing involves printing with different types of materials (e.g., flexible TPU + rigid PLA) to combine mechanical properties, while multi-color printing focuses on printing with different colors of the same or similar material. Multi-material setups often require more advanced hardware and slicer support due to differing print temperatures and adhesion properties.

Which 3D printers support multi-color printing out of the box?

Some printers come ready for multi-color printing, including:

- Ultimaker S5 (dual extrusion)

- Prusa i3 MK3S with MMU2S upgrade

- Bambu Lab X1 Carbon with AMS

- Creality K2 Plus CFS Combo

- Raise3D Pro2 (dual extrusion)

These printers vary in complexity and price but offer reliable multi-color capabilities.

What software is recommended for designing multi-color 3D prints?

PrusaSlicer is a top choice for multi-color prints, especially with MMU2S, thanks to its multi-material support and color assignment features. Ultimaker Cura supports dual extrusion and color change commands well. For industrial machines, proprietary software like GrabCAD Print (Stratasys) or HP SmartStream 3D Build Manager is used to handle complex color workflows.

Can multi-color 3D printing improve the quality of prototypes?

✅ Absolutely! Multi-color printing allows designers to highlight functional areas, simulate real-world aesthetics, and communicate design intent clearly without post-processing. This can reduce iteration cycles and improve stakeholder understanding, especially in product design and medical modeling.

What are the challenges of multi-color 3D printing and how to overcome them?

Challenges include:

- Color contamination: Use purge towers and wipe zones; clean nozzle between swaps.

- Filament jams: Use high-quality, dry filament and maintain extruder cleanliness.

- Calibration issues: Regularly calibrate nozzle alignment and bed leveling.

- Increased print time and waste: Optimize purge tower size and print speed.

Patience and incremental testing are key to mastering multi-color prints.

How to choose the right filament types for multi-color 3D printing projects?

Choose filaments with similar printing temperatures and shrinkage rates to avoid warping and adhesion problems. PLA is the easiest and most forgiving for multi-color prints. For advanced users, PETG and TPU can be combined carefully, but require tuning. Also, consider filament finish—matte, silk, or translucent—to achieve your desired aesthetic.

📚 Reference Links

- Mosaic Manufacturing – Palette 3 Pro

- Prusa Research – MMU2S Multi-Material Upgrade

- Stratasys PolyJet Full-Color 3D Printing

- Creality Blog – How To 3d Print In Multiple Colors?

- Ultimaker S5 Product Page

- Bambu Lab Official Website

- HP Multi Jet Fusion Technology

For more on 3D printing innovations and multi-color projects, visit our 3D Printing Innovations category and explore 3D Printable Objects.