Support our educational content for free when you purchase through links on our site. Learn more

What Are Most 3D Printed Objects Made of Today? Top 11 Materials (2025) 🛠️

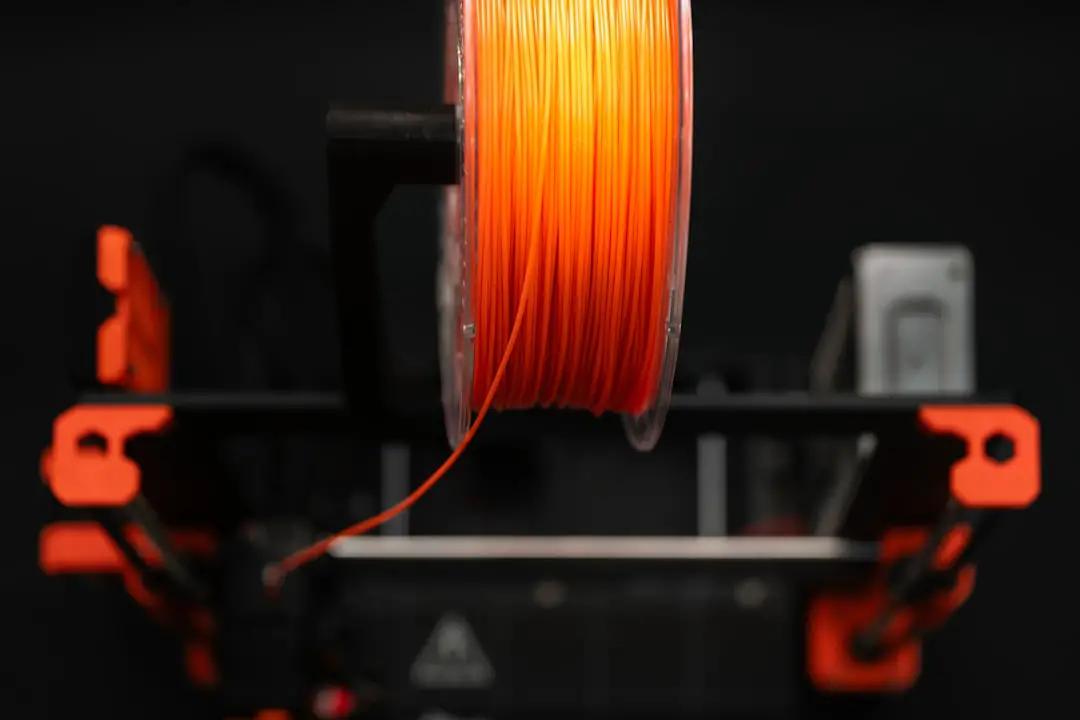

Imagine holding a tiny, intricate dragon figurine in one hand and a rugged, custom drone part in the other—both created layer by layer by a 3D printer. But have you ever stopped to wonder, what exactly are these objects made of? The answer is far from simple, as the world of 3D printing materials has exploded with options, each tailored for different uses, strengths, and finishes.

In this article, we’ll unravel the mystery behind the most popular 3D printing materials used today—from the beginner-friendly PLA to industrial-grade metals and futuristic bioinks. Whether you’re a hobbyist, educator, or professional, understanding these materials will help you pick the perfect filament or resin for your next project. Plus, we’ll share insider tips on storage, troubleshooting, and emerging trends that will keep you ahead of the curve.

Ready to discover the top 11 materials powering the 3D printing revolution? Let’s dive in!

Key Takeaways

- PLA remains the most popular filament for beginners due to its ease of use and eco-friendliness.

- ABS and PETG offer durability and heat resistance for functional parts and prototypes.

- Nylon and TPU provide strength and flexibility for mechanical and wearable applications.

- Resins dominate high-detail printing in miniatures, dental, and jewelry sectors.

- Metal and composite filaments are pushing industrial and aerospace boundaries.

- Proper material storage and troubleshooting are crucial for consistent print quality.

- The future holds exciting innovations like bioinks, smart materials, and multi-material printing.

👉 Shop top-rated filaments and resins here:

- PLA & PETG: Prusament PLA | eSun PETG

- ABS: MatterHackers PRO ABS

- Nylon & TPU: Taulman3D Nylon | NinjaTek TPU

- Resins: Formlabs Resin

Table of Contents

- ⚡️ Quick Tips and Facts: Unpacking 3D Printing Materials Today

- 🕰️ A Brief History of 3D Printing Materials: From Early Prototypes to Modern Marvels

- The Big Question: What Are Most 3D Printed Objects Made Of Today?

- 🌱 PLA (Polylactic Acid): The Eco-Friendly Workhorse

- 💪 ABS (Acrylonitrile Butadiene Styrene): The Durable Classic

- 💧 PETG (Polyethylene Terephthalate Glycol): The Best of Both Worlds

- ⚙️ Nylon (Polyamide): Strength and Flexibility Combined

- 🤸 TPU (Thermoplastic Polyurethane) & Other Flexible Filaments: Bend It Like Beckham!

- 🧪 Resins (SLA/DLP/LCD): Precision and Smoothness Unleashed

- 🔩 Metals: From Prototypes to Production Parts

- 🌿 Composites (Carbon Fiber, Glass Fiber, Wood, etc.): Enhanced Performance

- 🎨 Exotic & Specialty Filaments: Beyond the Ordinary

- 🍽️ Food-Safe & Biocompatible Materials: Eating and Healing with 3D Prints

- 🧱 Ceramics & Concrete: Artistic and Architectural Innovations

- Choosing Your Weapon: Factors Influencing 3D Printing Material Selection

- The Future is Now: Emerging Trends in 3D Printing Materials

- Common Misconceptions About 3D Printed Objects and Their Materials

- Keeping Your Filaments Fresh: Storage and Maintenance Tips for 3D Printing Materials

- When Things Go Wrong: Troubleshooting Material-Related 3D Printing Issues

- Conclusion: The Ever-Evolving World of 3D Printing Materials

- Recommended Links for Your 3D Printing Journey

- FAQ: Your Burning Questions About 3D Printing Materials Answered

- Reference Links: Dive Deeper into 3D Printing Material Science

⚡️ Quick Tips and Facts: Unpacking 3D Printing Materials Today

Welcome to the colorful, sometimes confusing world of 3D printing materials! If you’ve ever wondered what most 3D printed objects are made of today, you’re in the right place. Whether you’re a newbie or a seasoned maker, knowing your materials is like having the right paintbrush for your masterpiece.

Here’s a quick cheat sheet to get you started:

| Material | Common Use | Strength | Flexibility | Ease of Printing | Biodegradability | Typical Printer Type |

|---|---|---|---|---|---|---|

| PLA | Prototyping, toys, decorative | Medium | Low | ✅ Easy | ✅ Yes | FDM/FFF |

| ABS | Functional parts, automotive | High | Medium | ⚠️ Moderate | ❌ No | FDM/FFF |

| PETG | Mechanical parts, food containers | High | Medium-High | ✅ Easy | ❌ No | FDM/FFF |

| Nylon | Gears, hinges, wearables | Very High | High | ⚠️ Moderate | ❌ No | FDM/FFF |

| TPU | Flexible parts, phone cases | Medium | Very High | ⚠️ Challenging | ❌ No | FDM/FFF |

| Resin | Miniatures, dental, jewelry | High | Low | ✅ Easy (SLA/DLP) | ❌ No | SLA/DLP/LCD |

| Metal | Aerospace, medical implants | Very High | Low | ⚠️ Complex | ❌ No | SLS, DMLS |

| Composite | Reinforced parts | Very High | Varies | ⚠️ Depends | ❌ No | FDM/FFF |

Fun fact: PLA is made from renewable resources like corn starch, making it the eco-friendly darling of the 3D printing world. Meanwhile, ABS is the tough guy, favored for durable parts but requiring a bit more finesse in printing.

For a deep dive into the most useful 3D printed objects and their materials, check out our related article.

🕰️ A Brief History of 3D Printing Materials: From Early Prototypes to Modern Marvels

3D printing started in the 1980s with Charles Hull’s invention of stereolithography (SLA), which used photopolymer resins cured by UV light. Early materials were limited, mostly photopolymers and basic thermoplastics, but the technology has exploded since then.

The Evolution of Materials

- 1980s-1990s: Photopolymers and simple thermoplastics like ABS dominated.

- 2000s: Introduction of Fused Deposition Modeling (FDM) popularized PLA and ABS filaments.

- 2010s: Rise of composite filaments (carbon fiber, wood-filled), flexible filaments (TPU), and metal printing.

- Today: Hundreds of materials including biocompatible resins, ceramics, and food-safe filaments.

This evolution reflects the growing demand for functional, aesthetic, and specialized prints. As the materials improve, so do the possibilities—from medical implants to architectural models.

The Big Question: What Are Most 3D Printed Objects Made Of Today?

Let’s break down the top materials that dominate the 3D printing scene, based on our experience at 3D Printed™ and consumer insights.

1. 🌱 PLA (Polylactic Acid): The Eco-Friendly Workhorse

| Aspect | Rating (1-10) |

|---|---|

| Design | 8 |

| Functionality | 6 |

| Ease of Use | 9 |

| Environmental Impact | 9 |

| Versatility | 7 |

Why We Love PLA:

PLA is the go-to filament for beginners and hobbyists. It’s biodegradable, made from renewable resources like corn starch, and prints at relatively low temperatures (180-220°C). It’s perfect for decorative items, prototypes, and educational projects.

Drawbacks:

PLA can be brittle and less heat-resistant, so it’s not ideal for mechanical parts or outdoor use. It also doesn’t dissolve in acetone, making post-processing trickier compared to ABS.

Pro Tip: Use brands like Prusament PLA or Hatchbox PLA for consistent quality. You can find tons of PLA models on Thingiverse.

2. 💪 ABS (Acrylonitrile Butadiene Styrene): The Durable Classic

| Aspect | Rating (1-10) |

|---|---|

| Design | 7 |

| Functionality | 9 |

| Ease of Use | 6 |

| Environmental Impact | 4 |

| Versatility | 8 |

ABS is the tough, heat-resistant filament favored for functional parts like automotive components and household items. It prints at higher temps (215-250°C) and can be smoothed with acetone vapor for a glossy finish.

Challenges:

ABS requires a heated bed and good ventilation due to fumes. It can warp if cooled too quickly. However, its durability and ability to be glued with ABS slurry (ABS dissolved in acetone) make it a favorite for repair and post-processing.

Our Experience:

We’ve used MatterHackers PRO Series ABS for custom drone parts with great success. For more on finishing ABS prints, check out Make: Magazine’s guide.

3. 💧 PETG (Polyethylene Terephthalate Glycol): The Best of Both Worlds

| Aspect | Rating (1-10) |

|---|---|

| Design | 8 |

| Functionality | 8 |

| Ease of Use | 8 |

| Environmental Impact | 6 |

| Versatility | 8 |

PETG combines the ease of PLA with the strength of ABS. It’s chemical resistant, food-safe (in many cases), and less prone to warping. It prints at 230-250°C and is great for mechanical parts, water bottles, and protective cases.

Why Choose PETG?

If you want a durable, flexible, and easy-to-print filament, PETG is a solid choice. Brands like eSun PETG and Prusament PETG are reliable.

4. ⚙️ Nylon (Polyamide): Strength and Flexibility Combined

| Aspect | Rating (1-10) |

|---|---|

| Design | 7 |

| Functionality | 10 |

| Ease of Use | 5 |

| Environmental Impact | 5 |

| Versatility | 9 |

Nylon is a powerhouse material used for gears, hinges, and wearables. It’s strong, flexible, and abrasion-resistant but requires high printing temps (240-270°C) and low moisture environment.

Our Tip: Store nylon filaments in airtight containers with desiccants. Taulman3D Nylon 645 is a popular choice.

5. 🤸 TPU (Thermoplastic Polyurethane) & Other Flexible Filaments: Bend It Like Beckham!

| Aspect | Rating (1-10) |

|---|---|

| Design | 7 |

| Functionality | 8 |

| Ease of Use | 4 |

| Environmental Impact | 5 |

| Versatility | 7 |

TPU is the go-to for flexible prints like phone cases, wearables, and seals. It’s elastic and durable but can be tricky to print due to stringing and slow extrusion needs.

Brands to Try: NinjaTek Cheetah TPU is a favorite in the community.

6. 🧪 Resins (SLA/DLP/LCD): Precision and Smoothness Unleashed

| Aspect | Rating (1-10) |

|---|---|

| Design | 10 |

| Functionality | 7 |

| Ease of Use | 6 |

| Environmental Impact | 3 |

| Versatility | 7 |

Resin printing offers ultra-fine detail and smooth surfaces, perfect for miniatures, dental models, and jewelry. It uses photopolymer resins cured by UV light.

Caution: Resins can be toxic and require careful handling and post-curing. Formlabs and Anycubic resin printers are top picks.

7. 🔩 Metals: From Prototypes to Production Parts

| Aspect | Rating (1-10) |

|---|---|

| Design | 9 |

| Functionality | 10 |

| Ease of Use | 2 |

| Environmental Impact | 6 |

| Versatility | 9 |

Metal 3D printing (DMLS, SLS) is used in aerospace, medical implants, and automotive industries. Materials include titanium, stainless steel, and aluminum.

Note: Metal printing requires industrial-grade machines and is costly but offers unmatched strength and heat resistance.

8. 🌿 Composites (Carbon Fiber, Glass Fiber, Wood, etc.): Enhanced Performance

Composite filaments blend base plastics with fibers or particles to improve strength, stiffness, or aesthetics.

| Composite Type | Base Material | Benefits | Drawbacks |

|---|---|---|---|

| Carbon Fiber | Nylon, PLA | High strength, stiffness | Abrasive on nozzles, costly |

| Wood-Filled | PLA | Wood-like finish, aesthetic | Brittle, less durable |

| Glass Fiber | Nylon, PETG | Improved strength | Abrasive, requires hardened nozzle |

Our Favorite: ColorFabb XT-CF20 (carbon fiber nylon) for drone frames.

9. 🎨 Exotic & Specialty Filaments: Beyond the Ordinary

From glow-in-the-dark PLA to conductive filaments and metal-infused blends, the market is bursting with novelty materials.

Examples:

- Conductive PLA: For simple electronics projects.

- Glow-in-the-Dark: Fun for toys and decorations.

- Metallic PLA: For shiny, metal-like finishes.

10. 🍽️ Food-Safe & Biocompatible Materials: Eating and Healing with 3D Prints

3D printing is making inroads into food and medical fields with materials that are safe for ingestion or implantation.

- Food-safe PLA and PETG: Used for custom cookie cutters, molds, and containers.

- Biocompatible resins: Used in dental and surgical guides.

- Medical-grade titanium: For implants.

11. 🧱 Ceramics & Concrete: Artistic and Architectural Innovations

Ceramic 3D printing is growing in art and industry, allowing intricate pottery and heat-resistant parts. Concrete printing is revolutionizing construction with rapid, customizable building components.

Choosing Your Weapon: Factors Influencing 3D Printing Material Selection

Picking the right filament or resin is like choosing the perfect tool for a job. Consider:

- Purpose: Prototype, functional part, artistic model?

- Strength & Flexibility: Will it bear load or bend?

- Printer Compatibility: Does your printer support the material?

- Ease of Printing: Are you ready for tricky materials?

- Environmental Impact: Want eco-friendly?

- Post-Processing Needs: Sanding, acetone smoothing, curing?

The Future is Now: Emerging Trends in 3D Printing Materials

The horizon is bright with innovations:

- Bioinks for tissue engineering (source)

- Recyclable and biodegradable composites

- Smart materials: Shape-memory polymers, self-healing filaments

- Multi-material printing: Combining flexible and rigid parts in one print

Common Misconceptions About 3D Printed Objects and Their Materials

- “3D prints are always fragile.” ❌ Not true—materials like ABS, Nylon, and composites can be very strong.

- “PLA is always better because it’s eco-friendly.” ❌ Depends on use case; PLA is brittle and heat-sensitive.

- “Resin prints are toxic.” ✅ Some resins are, but many are now formulated to be safer.

- “Metal printing is only for industry.” ❌ Desktop metal printers are becoming more accessible.

Keeping Your Filaments Fresh: Storage and Maintenance Tips for 3D Printing Materials

Humidity is the enemy! Here’s how to keep your filaments happy:

- Store in airtight containers with desiccants (silica gel).

- Use filament dryers or ovens for moisture-sensitive materials like Nylon and TPU.

- Avoid sunlight and extreme temperatures.

- Label your spools with purchase date and material type.

When Things Go Wrong: Troubleshooting Material-Related 3D Printing Issues

- Warping: Common with ABS and Nylon; use heated bed and enclosure.

- Stringing: PETG and TPU prone; adjust retraction settings.

- Layer adhesion problems: Check temperature and print speed.

- Brittle prints: Could be old or moisture-logged filament.

- Resin curing issues: Ensure proper UV exposure and clean prints thoroughly.

Conclusion: The Ever-Evolving World of 3D Printing Materials

Wow, what a journey through the vibrant landscape of 3D printing materials! From the eco-friendly PLA that’s perfect for beginners and decorative prints, to the industrial-strength metals powering aerospace and medical breakthroughs, the diversity of materials available today is nothing short of mind-blowing.

We’ve seen how ABS stands strong for functional parts, PETG offers a sweet spot between ease and durability, and resins bring ultra-fine detail to miniatures and dental models. Not to mention the exciting rise of composites, flexible filaments, and even biocompatible materials that are changing how we think about manufacturing and healthcare.

If you’re just starting out, we confidently recommend PLA for its ease of use and environmental benefits. For more demanding projects, PETG or ABS are excellent next steps, while adventurous makers can explore nylon, TPU, or resins depending on their printer and needs.

Remember, the right material is not just about strength or finish—it’s about matching your project’s purpose, your printer’s capabilities, and your own patience for post-processing. And as we hinted earlier, don’t underestimate the power of proper filament storage and troubleshooting to keep your prints flawless.

The future? It’s glowing bright with smart materials, bioinks, and multi-material printing that will push the boundaries of creativity and function even further. So keep experimenting, stay curious, and happy printing! 🎉

Recommended Links for Your 3D Printing Journey

Ready to stock up or dive deeper? Check out these top-quality materials and resources:

-

Prusament PLA Filament:

Thingiverse | Amazon | Prusa Official Website -

MatterHackers PRO Series ABS:

Thingiverse | Amazon | MatterHackers Official Website -

eSun PETG Filament:

Thingiverse | Amazon | eSun Official Website -

Taulman3D Nylon 645:

Thingiverse | Amazon | Taulman3D Official Website -

NinjaTek Cheetah TPU:

Thingiverse | Amazon | NinjaTek Official Website -

Formlabs Resin:

Amazon | Formlabs Official Website -

ColorFabb XT-CF20 Carbon Fiber Nylon:

Thingiverse | Amazon | ColorFabb Official Website

Books to Level Up Your 3D Printing Game

-

3D Printing Failures: How to Diagnose and Repair All 3D Printing Issues by Sean Aranda

Amazon Link -

3D Printing: The Next Industrial Revolution by Christopher Barnatt

Amazon Link -

Make: 3D Printing: The Essential Guide to 3D Printers by Anna Kaziunas France

Amazon Link

FAQ: Your Burning Questions About 3D Printing Materials Answered

What are the most common materials used in 3D printing for beginners?

For beginners, PLA (Polylactic Acid) is the most popular choice. It’s easy to print with, requires no heated bed (though it helps), and is environmentally friendly since it’s biodegradable. PLA prints with minimal warping and emits a sweet smell rather than harsh fumes. It’s ideal for prototypes, toys, and decorative objects.

ABS is another common filament but is better suited for users with some experience due to its higher printing temperature and warping tendencies. PETG is gaining popularity as a beginner-friendly alternative with better durability than PLA.

Read more about “50+ Must-Have 3D Printing Resources for Makers in 2025 🚀”

What are the differences between PLA and ABS filament in 3D printing?

PLA is derived from renewable resources like corn starch, making it biodegradable and eco-friendly. It prints at lower temperatures (180-220°C), has minimal warping, and is great for detailed prints. However, PLA is more brittle and less heat-resistant, so it’s not ideal for functional parts exposed to stress or heat.

ABS is petroleum-based, stronger, and more heat-resistant, making it suitable for mechanical parts and functional prototypes. It prints at higher temperatures (215-250°C), requires a heated bed, and emits fumes that necessitate good ventilation. ABS can be smoothed with acetone vapor, which PLA cannot.

Read more about “8 Types of 3D Printing Technology You Need to Know in 2025 🔥”

How do I choose the right 3D printing material for my project?

Choosing the right material depends on several factors:

- Purpose: Decorative vs. functional parts.

- Strength & Flexibility: Does your part need to bend or bear weight?

- Printer Compatibility: Some materials require specific printer features (heated bed, enclosure).

- Post-Processing: Are you willing to sand, acetone-smooth, or cure your prints?

- Environmental Concerns: Do you prefer biodegradable materials?

- Budget: Some specialty filaments and resins cost more.

Start with PLA for simple projects, then explore PETG or ABS for durability, Nylon for strength, TPU for flexibility, and resin for detail.

Read more about “🧵 33 Types of D Printing Filaments You Need to Try (2025)”

What are some of the safest and most durable materials for 3D printing at home?

PLA is the safest for home use due to its low printing temperature and non-toxic nature. For durability, PETG offers a good balance of strength and ease of printing without toxic fumes. ABS is durable but requires ventilation due to fumes.

If you want flexibility, TPU is safe but needs careful printing. For detailed, small prints, resins offer precision but require safety precautions like gloves and masks due to toxicity.

Reference Links: Dive Deeper into 3D Printing Material Science

- National Institutes of Health: Medical Applications for 3D Printing: Current and Projected Uses

- Make: Magazine – Finishing and Post-Processing 3D Printed Objects

- Prusa Research – Prusament PLA Filament

- MatterHackers – PRO Series ABS Filament

- eSun – PETG Filament

- Taulman3D – Nylon 645

- NinjaTek – TPU Filaments

- Formlabs – Resins for SLA Printing

- ColorFabb – Composite Filaments

Ready to dive into your next 3D printing adventure? Explore our 3D Printable Objects and stay tuned for more tips and innovations at 3D Printed™!