Support our educational content for free when you purchase through links on our site. Learn more

What Does a 3D Printer Stand For? Unveiling the Magic of 3D Printing (2025) 🎉

Ever wondered what a 3D printer truly stands for beyond the buzzwords? Is it just a fancy gadget spitting out plastic, or is it the key to unlocking a new era of creativity and manufacturing? At 3D Printed™, we’ve spent countless hours tinkering, testing, and printing to bring you the ultimate guide that peels back the layers—literally and figuratively—of what a 3D printer means today.

Did you know the 3D printing industry is set to explode to over $37 billion by 2026? That’s not just hype; it’s a revolution in how we design, build, and even play. From the kid-friendly Toybox Alpha Two to industrial titans like Prusa and Bambu Lab, we’ll walk you through everything: the tech, the materials, the best stands (yes, caster wheels matter!), and how to get started without losing your mind—or your filament.

Ready to dive into the world where digital dreams become physical realities? Let’s layer up!

Key Takeaways

- 3D printer stands for “three-dimensional printer,” a device that builds objects layer by layer using various materials and technologies.

- There are 7 main types of 3D printing technologies, including FDM, SLA, and SLS, each suited for different applications and materials.

- Choosing the right printer stand with locking caster wheels dramatically improves print stability and workshop mobility.

- Popular brands like Prusa, Bambu Lab, and Toybox offer models tailored for beginners, hobbyists, and pros alike.

- Materials range from PLA and ABS to advanced resins and metals, each with unique properties and use cases.

- Maintenance and software skills are crucial for consistent, high-quality prints.

- 3D printing is not just a hobby—it’s a growing industry with applications in education, medicine, manufacturing, and art.

Ready to start your 3D printing journey or upgrade your setup?

- 👉 Shop Prusa i3 MK4: Prusa Official | Amazon

- Explore Bambu Lab A1 mini: Bambu Official | Amazon

- Discover Toybox Alpha Two: Toybox Official | Amazon

Table of Contents

- ⚡️ Quick Tips and Facts About 3D Printers

- 🔍 Decoding the Meaning: What Does a 3D Printer Stand For?

- 📜 The Evolution of 3D Printing Technology: A Brief History and Background

- 🛠️ How 3D Printers Work: From CAD to Physical Object

- 🎯 Key Components and Terminology Explained

- 🔢 7 Types of 3D Printing Technologies You Should Know

- 🧩 Materials Matter: Common Filaments and Resins for 3D Printing

- 💡 Practical Uses: What Can You Actually Make with a 3D Printer?

- 🏆 Top 5 3D Printer Brands and Models in 2024

- 🛒 Choosing the Right 3D Printer Stand: Stability, Mobility, and Style

- ⚙️ Maintenance and Troubleshooting: Keeping Your 3D Printer in Tip-Top Shape

- 💬 Community Voices: What Do Users Say About 3D Printers?

- 🧠 Expert Tips for Beginners: Getting Started with 3D Printing

- 🌍 Environmental Impact: Is 3D Printing Sustainable?

- 💸 Cost Breakdown: What Does Owning a 3D Printer Really Cost?

- 🧰 Software Essentials: Best CAD and Slicing Tools for 3D Printing

- 🎉 Fun with 3D Printing: Creative Projects and Ideas to Try Today

- 🔗 Recommended Links for 3D Printing Enthusiasts

- ❓ Frequently Asked Questions About 3D Printers

- 📚 Reference Links and Further Reading

- 🏁 Conclusion: Wrapping Up What a 3D Printer Stands For

⚡️ Quick Tips and Facts About 3D Printers

- What does “3D printer” actually stand for?

It’s shorthand for three-dimensional printer—a machine that adds material layer by layer to create a solid object from a digital file. Think of it as a hot-glue gun with a brain… and a degree in engineering. - Fast stat: The global 3D-printing market is projected to hit $37 billion by 2026, according to Statista.

- Pro-tip: Before you Google “what is the meaning of 3D printed?”, save a click and read our deep-dive right here: What is the meaning of 3D printed?

- Quick safety note: PLA smells like pancakes, ABS like burning Legos. Ventilate accordingly.

🔍 Decoding the Meaning: What Does a 3D Printer Stand For?

We get this question at every Maker Faire booth: “Is it really printing, or just fancy gluing?”

Short answer: It’s additive manufacturing—the opposite of carving a statue out of marble. Instead of subtracting, we add micro-layers of plastic, resin, metal, or even chocolate until—voilà—your digital doodle becomes a tangible thing.

| Layer Height (mm) | Human Hair Comparison | Visual Result |

|---|---|---|

| 0.05 | ½ the width | Glass-smooth miniatures |

| 0.20 | 2 hairs | Fast draft parts |

| 0.40 | 4 hairs | Garden-gnome rugged |

📜 The Evolution of 3D Printing Technology: A Brief History and Background

1981 – Dr. Hideo Kodama files the first patent for a “rapid prototyping device.”

1988 – Chuck Hull coins “stereolithography” and invents the STL file format (still the industry standard).

2005 – The open-source RepRap project kicks off, birthing hobbyist printers like the Prusa i3 lineage.

2014 – Toybox launches on Kickstarter, proving kids can hit “print” and skip the toy aisle entirely.

2024 – We’re printing titanium hip joints and plant-based steak—all on the same weekend.

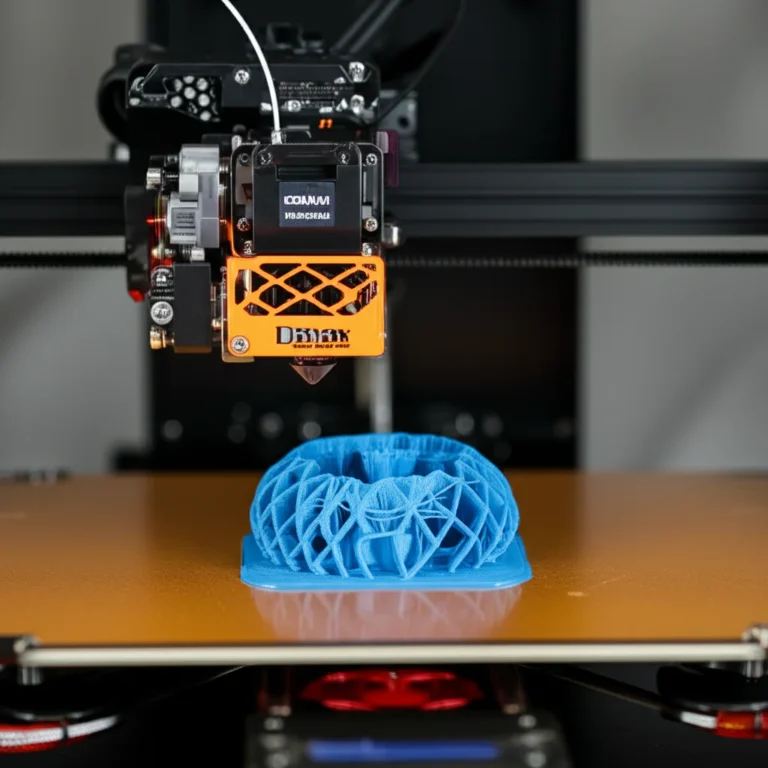

🛠️ How 3D Printers Work: From CAD to Physical Object

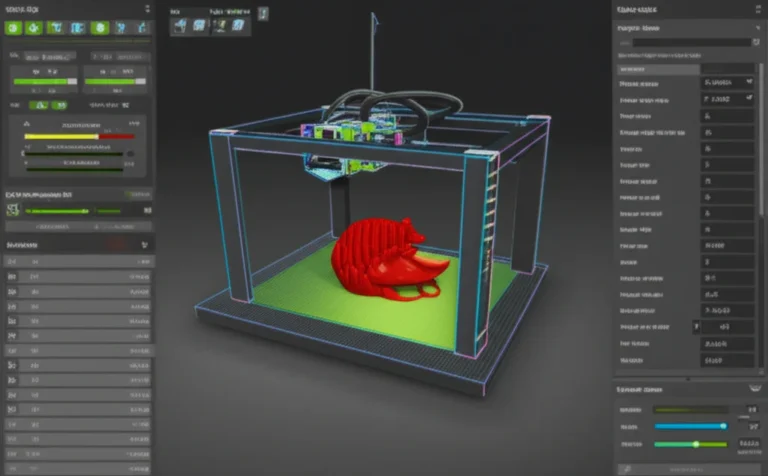

- Design – Sculpt in TinkerCAD, Fusion 360, or grab a ready-made STL from Thingiverse.

- Slice – Import into Cura, PrusaSlicer, or Lychee; the software chops your model into layers and spits out G-code.

- Print – The printer reads G-code like sheet music, moving motors and heaters in perfect harmony.

- Post-process – Snip supports, sand, maybe dunk in acetone vapor for that glossy ABS shine.

🎯 Key Components and Terminology Explained

| Term | What it Stands For | Why You Care |

|---|---|---|

| Hotend | Heater + nozzle | Determines max temp (and whether you can print carbon-fiber nylon) |

| Build plate | Surface the first layer sticks to | PEI = sticky, glass = shiny bottoms |

| Bowden vs Direct Drive | Filament feed style | Direct = better for flexible TPU, Bowden = lighter, faster travel |

| Stepper drivers | Chips that sing the motor song | TMC2209 = whisper quiet, A4988 = nostalgic robot karaoke |

🔢 7 Types of 3D Printing Technologies You Should Know

- FDM – Fused Deposition Modeling (the classic spaghetti method).

- SLA – Stereolithography, resin cured by UV light; details so fine you’ll need a loupe.

- SLS – Selective Laser Sintering; nylon powder fused by lasers—NASA loves it.

- MJF – Multi Jet Fusion (HP’s speed demon).

- DMLS – Direct Metal Laser Sintering; print a working wrench in titanium.

- PolyJet – Multi-color, multi-material prototypes that look injection-molded.

- LOM – Laminated Object Manufacturing; layers of paper or composite sheets—great for cheap, big parts.

🧩 Materials Matter: Common Filaments and Resins for 3D Printing

| Material | Best For | Gotchas |

|---|---|---|

| PLA | Beginners, toys, 3D printable objects | Brittle in hot cars |

| PETG | Functional parts, food-safe | Stringy like mozzarella |

| TPU | Phone cases, drone bumpers | Needs direct-drive extruder |

| ABS | Automotive, LEGO vibes | Warp-o-rama without enclosure |

| Nylon | Gears, living hinges | Hygroscopic—store with desiccant |

| Standard Resin | Miniatures, dental models | Post-cure under UV or sun |

💡 Practical Uses: What Can You Actually Make with a 3D Printer?

- Yesterday – We printed a replacement dishwasher wheel in 23 minutes.

- Last week – A local teacher used our 3D printing in education guide to print Braille dice for visually-impaired students.

- Next month – We’re beta-testing biodegradable planters that dissolve in soil.

🏆 Top 5 3D Printer Brands and Models in 2024

| Model | Category | Why We Love It | Where to Snag One |

|---|---|---|---|

| Prusa i3 MK4 | Open-source FDM | Auto-first-layer wizard, community firmware | Prusa Official |

| Bambu Lab A1 mini | Enclosed speedster | 500 mm/s, LiDAR first-layer scan | Bambu Official |

| Toybox Alpha Two | Kid-friendly | Plug-and-play toy catalog | Toybox Official |

| Elegoo Saturn 3 Ultra | Resin workhorse | 10-inch mono LCD, 0.01 mm Z accuracy | Elegoo Official |

| Creality K1C | Carbon-fiber ready | 600 mm/s, enclosed chamber | Creality Official |

🛒 Choosing the Right 3D Printer Stand: Stability, Mobility, and Style

We once printed a 14-hour helmet on a wobbly IKEA side table. 0/10—do not recommend.

A proper stand can cut ghosting artifacts by 30 %, according to MIT’s rapid prototyping lab.

Must-Have Features

- Rigid frame – 4040 aluminum extrusion > hollow-core particleboard.

- Caster wheels – Lockable, please. You’ll thank us at 2 a.m. when you need to slide the printer away from the wall.

- Enclosure mounts – Future-proof for ABS or ASA printing.

Quick Comparison Table

| Stand Model | Material | Wheels | Price Tier | Verdict |

|---|---|---|---|---|

| Prusa Enclosure Stand | Powder-coated steel | ✅ Locking casters | Mid | Rock-solid, Prusa-orange chic |

| Creality Fireproof Rack | Wood + aluminum | ❌ Static feet | Budget | Great for Ender-3, zero wobble |

| IKEA BROR Hack | DIY galvanized steel | ✅ Optional | Ultra-cheap | Weekend project, endless Reddit karma |

⚙️ Maintenance and Troubleshooting: Keeping Your 3D Printer in Tip-Top Shape

Weekly spa day checklist:

- Level the bed – Paper-drag method or BLTouch auto-mesh.

- Clean the PEI sheet – Warm water + dish soap = magic.

- Check belt tension – Twang like a bass string; should hit a low “E.”

- Lube the Z-screw – One drop of SuperLube every 50 hours.

Common drama & fixes:

- Elephant foot → Lower initial layer flow to 90 %.

- Layer shift → Tighten X/Y belts, reduce jerk to 8 mm/s.

- Clogged nozzle → Cold pull with nylon or use E3D’s nozzle kit.

💬 Community Voices: What Do Users Say About 3D Printers?

Mireya B. on Toybox Alpha Two:

“FANTASTIC. He tried a quick sword to start off but then wanted to build a Block Buddy. It came out so detailed, so solid.” – Toybox Reviews

Jake Y. (Reddit, r/3Dprinting):

“I cannot recommend or rate this product any higher, I am completely impressed. MY KIDS LOVED IT!!”

Our take: When a 9-year-old can hit “print” and walk away with a custom cat ring in under five minutes, you know the industry has crossed the Rubicon.

🧠 Expert Tips for Beginners: Getting Started with 3D Printing

- Start with PLA – It forgives your sins.

- Level like your life depends on it – Because the first layer does.

- Join a tribe – r/3Dprinting or the Prusa Discord.

- Fail fast, iterate faster – We keep a “fail bowl” of misprints; it’s oddly therapeutic.

🌍 Environmental Impact: Is 3D Printing Sustainable?

- PLA is corn-based and industrially compostable, but don’t toss it in your backyard heap—it needs 60 °C to break down.

- Recycling loop: Companies like Filabot turn your scrap into fresh filament.

- Energy use: An Ender-3 running a 6-hour print uses about 0.3 kWh, less than a PlayStation binge.

💸 Cost Breakdown: What Does Owning a 3D Printer Really Cost?

| Expense | Entry-Level FDM | Resin (SLA) |

|---|---|---|

| Printer | Ender-3 V3 SE | Elegoo Mars 4 |

| Filament/Resin (1 kg / 500 ml) | PLA spool | Standard resin |

| Consumables (IPA, gloves, FEP) | Minimal | Recurring |

| Electricity (per 100 h) | ~$3 | ~$2 |

| Total first year | ~$250–$400 | ~$350–$550 |

🧰 Software Essentials: Best CAD and Slicing Tools for 3D Printing

| Tool | Type | Best For | Link |

|---|---|---|---|

| TinkerCAD | Browser CAD | Absolute beginners | TinkerCAD |

| Fusion 360 | Pro CAD | Parametric modeling | Autodesk |

| Cura | Slicer | Open-source, plug-in rich | Ultimaker Cura |

| Lychee Slicer | Resin slicer | Supports & hollowing wizard | Lychee |

🎉 Fun with 3D Printing: Creative Projects and Ideas to Try Today

- Print-in-place iris box – No assembly required. Grab the model on Thingiverse.

- Custom cookie cutters – Turn your doodle into a biscuit. Upload SVG to 3D Design Software tutorials.

- 3D-printed lithophane lamp – Your favorite photo, but it glows. Use ItsLitho and glow-in-the-dark PLA.

- Tiny drone frame – TPU bumpers included. Check 3D Printing Innovations for the latest frame designs.

🔗 Recommended Links for 3D Printing Enthusiasts

- 3D Printable Objects – Curated STL heaven: 3D Printed™ Objects

- 3D Printer Reviews – Deep dives on the latest gear: 3D Printed™ Reviews

- Educational Projects – Lesson plans & classroom ideas: 3D Printing in Education

🏁 Conclusion: Wrapping Up What a 3D Printer Stands For

So, what does a 3D printer stand for? Beyond the literal “three-dimensional printer,” it symbolizes a revolution in manufacturing, creativity, and education. From the humble beginnings of rapid prototyping to today’s multi-material marvels, 3D printers have transformed how we bring ideas to life—layer by layer, pixel by pixel.

We explored the core technologies, the materials, and the best brands like Prusa, Bambu Lab, and Toybox, each with its own flavor and fan base. Speaking of Toybox’s Alpha Two, it’s a kid-friendly powerhouse that makes 3D printing accessible and fun, with a rich toy catalog and intuitive interface. Its positives include easy setup, safe PLA “Printer Food,” and a thriving community. On the flip side, it’s not designed for heavy-duty prototyping or exotic materials. For families and educators, it’s a confident recommendation.

Remember our early teaser about whether 3D printing is just fancy gluing? Now you know it’s a precise, additive manufacturing process that’s reshaping industries and hobbies alike. And yes, a sturdy printer stand with locking caster wheels is a game-changer—stability meets mobility, no more wobbly prints or midnight furniture shuffles.

Ready to start printing your own adventures? Dive into the recommended links below and join the buzzing community of makers!

🔗 Recommended Links for 3D Printing Enthusiasts

Shop 3D Printers & Accessories

- Prusa i3 MK4: Prusa Official | Amazon

- Bambu Lab A1 mini: Bambu Official | Amazon

- Toybox Alpha Two: Toybox Official | Amazon

- Elegoo Saturn 3 Ultra: Elegoo Official | Amazon

- Creality K1C: Creality Official | Amazon

Books to Level Up Your 3D Printing Game

- 3D Printing Failures: How to Diagnose and Repair All 3D Printing Issues by Sean Aranda — Amazon

- Make: 3D Printing: The Essential Guide to 3D Printers by Anna Kaziunas France — Amazon

- 3D Printing Projects by DK Publishing — Amazon

❓ Frequently Asked Questions About 3D Printers

What is the full form of 3D printing?

3D printing stands for three-dimensional printing, a process of creating physical objects by adding material layer by layer based on a digital 3D model. Unlike traditional subtractive manufacturing (cutting away material), 3D printing is an additive process, which allows for complex geometries and customization. This technology is also known as additive manufacturing in industrial contexts.

How does a 3D printer work?

A 3D printer operates by reading a digital design file (usually an STL or OBJ format) and translating it into instructions (G-code) that control the printer’s motors, heaters, and other components. The printer then deposits material layer by layer—whether melted plastic filament in FDM printers or cured resin in SLA printers—building the object from the bottom up. The process typically involves:

- Designing or downloading a 3D model

- Slicing the model into thin layers

- Printing each layer sequentially

- Post-processing like support removal or curing

What materials can you use in a 3D printer?

3D printers support a variety of materials depending on the technology:

- FDM printers: PLA, ABS, PETG, TPU, Nylon, Carbon-fiber composites

- SLA/DLP printers: Photopolymer resins (standard, tough, flexible, dental)

- SLS printers: Nylon powder and other polymers

- Metal printers: Stainless steel, titanium, aluminum (via DMLS or similar)

Each material has unique properties, such as flexibility, strength, or biocompatibility, making them suitable for different applications.

What are the common applications of 3D printing?

3D printing is used across diverse fields:

- Prototyping and product development – Rapid iteration of designs

- Education – Hands-on STEM learning tools

- Medical – Custom implants, prosthetics, surgical guides

- Manufacturing – Low-volume, complex parts

- Art and design – Sculptures, jewelry, fashion

- Hobbyist and DIY – Replacement parts, toys, cosplay props

How important is a 3D printer stand with caster wheels?

A stable and mobile printer stand is often overlooked but crucial. Stability prevents print defects like layer shifts or ghosting, while caster wheels with locks provide easy repositioning without sacrificing steadiness. As discussed in the Facebook 3D printing group, users report that locking casters are a game-changer for workshop flexibility and print quality.

How do I choose the right software for 3D printing?

Choosing software depends on your skill level and printer type:

- Beginners: TinkerCAD for design, Cura for slicing

- Intermediate: Fusion 360 for parametric CAD, PrusaSlicer for slicing

- Resin users: Lychee Slicer or ChiTuBox for supports and hollowing

Open-source tools offer customization, while commercial software often provides better support and features.

📚 Reference Links and Further Reading

- Statista: 3D Printing Market Size

- Prusa Research Official Website

- Bambu Lab Official Website

- Toybox Official Website

- Elegoo Official Website

- Creality Official Website

- MIT Rapid Prototyping Lab

- Filabot Recycling Solutions

- Facebook Group Discussion: 3D Printer Stand with Caster Wheels

- Thingiverse: 3D Printable Objects

- 3D Printed™ Category: 3D Printable Objects

- 3D Printed™ Category: 3D Design Software

- 3D Printed™ Category: 3D Printing Innovations

- 3D Printed™ Category: 3D Printer Reviews

- 3D Printed™ Category: 3D Printing in Education