Support our educational content for free when you purchase through links on our site. Learn more

What’s the Difference Between Normal Printing and 3D Printing? Discover 10 Surprising Insights! [2024] 🖨️

Ever wondered why your printer can only churn out flat pieces of paper while 3D printers can create everything from intricate jewelry to functional prototypes? 🤔 It’s a fascinating world where dimensions collide, and understanding the differences between these two printing methods can unlock a treasure trove of possibilities for creators and innovators alike.

Imagine this: you’re in a workshop, surrounded by tools and materials. You’re tasked with bringing a unique design to life. With traditional printing, you can only produce beautiful images, but with 3D printing, you can literally hold your creation in your hands! In this article, we’ll dive deep into the 10 surprising insights that set normal printing apart from the magic of 3D printing. From design freedom to material waste, we’ll explore how these technologies complement each other and revolutionize industries.

So, whether you’re a hobbyist, an entrepreneur, or just curious about the future of manufacturing, buckle up! You’re about to embark on a journey that could change the way you think about printing forever. 🌟

Key Takeaways

- Design Flexibility: 3D printing allows for complex geometries and customization that traditional printing cannot achieve.

- Production Volume: Traditional printing excels in mass production, while 3D printing is ideal for prototyping and small batches.

- Cost Efficiency: 3D printing can be more cost-effective for low-volume production due to lower setup costs.

- Material Waste: 3D printing generates less waste compared to traditional methods, making it more eco-friendly.

- Future Innovations: Technologies like 4D printing and bioprinting are paving the way for even more exciting applications.

Ready to explore the world of 3D printing? 👉 Shop 3D Printers today:

- Creality Ender 3: Amazon | Official Site

- Prusa i3 MK3S: Amazon | Official Site

Dive into the article to discover more! 🚀

Table of Contents

- Quick Tips and Facts

- The Evolution of Printing: From Traditional to 3D

- Understanding 3D Printing: What Sets It Apart?

- Traditional Printing: The Old Guard of Manufacturing

- 3D Printing vs. Traditional Printing: A Detailed Comparison

- Comparison Table: 3D Printing vs. Traditional Printing

- Exploring Alternatives: What Can Replace 3D and Traditional Printing?

- The Future of Printing: Trends and Innovations

- Real-World Applications: Where 3D Printing Shines

- Common Misconceptions: Debunking Myths about 3D Printing

- Conclusion

- Recommended Links

- FAQ

- Reference Links

Quick Tips and Facts

- 🤯 Mind-blowing fact: The first 3D printer was invented way back in 1983! Crazy, right?

- 🚀 Speed demons: 3D printing can be faster than traditional methods, especially for complex designs. No more waiting weeks for prototypes!

- 💰 Cost-effective: For smaller batches and intricate designs, 3D printing can be easier on the wallet.

- 🌎 Eco-friendly: 3D printing often generates less waste than traditional manufacturing. Mother Earth approves!

- 🤯 Limitless potential: From medical implants to rocket parts, 3D printing is revolutionizing industries. The future is now!

The Evolution of Printing: From Traditional to 3D

Remember the days of clunky dot matrix printers and blurry photocopies? Traditional printing has come a long way, but 3D printing? That’s a whole different ball game! Let’s dive into the fascinating history of printing:

Gutenberg’s Legacy: The Birth of Mass Communication

Johannes Gutenberg’s printing press in the 15th century was a game-changer. Suddenly, information could be spread faster and wider than ever before. This invention paved the way for mass production and consumption, shaping the world as we know it.

From Gutenberg to Offset: Refining Traditional Printing

Over the centuries, traditional printing evolved through various methods like lithography and offset printing. These techniques, while effective for mass production, still relied on transferring ink onto a flat surface, limiting creative possibilities.

The 3D Printing Revolution: Breaking Free from Two Dimensions

Enter 3D printing! This revolutionary technology, also known as additive manufacturing, bursts out of the two-dimensional limitations of traditional printing. Instead of ink, it uses materials like plastics, metals, and even ceramics to build objects layer by layer from a digital design.

Think of it like this: Traditional printing is like making a pizza by spreading toppings on dough. 3D printing is like building a pizza from scratch, layer by layer, with each layer representing a different ingredient. 🍕

This paradigm shift opens up a world of possibilities, allowing us to create complex geometries and customized designs that were previously unimaginable with traditional methods.

Understanding 3D Printing: What Sets It Apart?

3D printing, also known as additive manufacturing, is a transformative technology that creates three-dimensional objects from digital models. Unlike traditional manufacturing, which often involves removing material (subtractive manufacturing), 3D printing builds objects layer by layer.

How Does 3D Printing Work?

- Design: It all starts with a digital 3D model, created using 3D design software. You can either design your own models or download pre-existing ones from online platforms like Thingiverse.

- Slicing: The 3D model is then sliced into thin, horizontal layers by a slicing software. Think of it like slicing a loaf of bread – each slice represents a layer of the final object.

- Printing: The 3D printer reads the sliced data and deposits material layer by layer, following the precise instructions of the sliced model. This process continues until the entire object is built.

Types of 3D Printing Technologies:

There are various 3D printing technologies, each using different materials and methods:

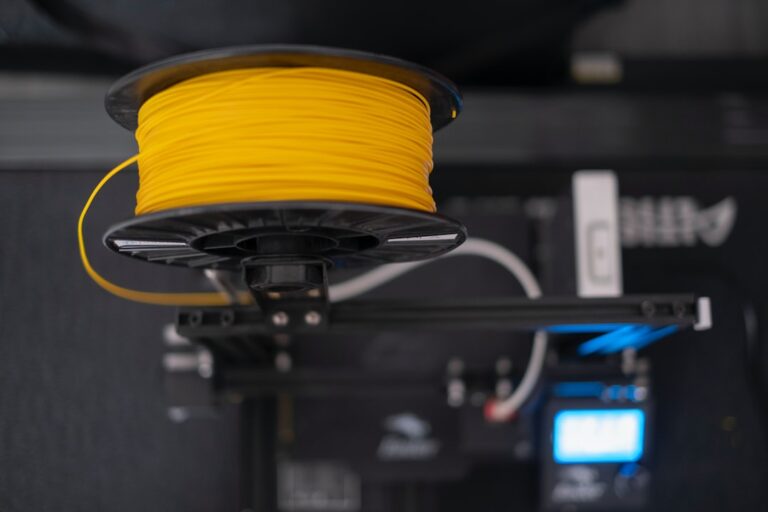

- Fused Deposition Modeling (FDM): This popular and affordable method extrudes thermoplastic filament through a heated nozzle, building the object layer by layer.

- Stereolithography (SLA): SLA uses a UV laser to cure liquid resin, creating highly detailed and smooth-surfaced objects.

- Selective Laser Sintering (SLS): SLS uses a laser to fuse powdered material (typically nylon or metal) together, creating strong and durable parts.

Benefits of 3D Printing:

- Design Freedom: 3D printing allows for intricate and complex geometries that are impossible to achieve with traditional manufacturing.

- Customization: Create personalized objects tailored to specific needs and preferences.

- Rapid Prototyping: Quickly produce prototypes to test and refine designs before mass production.

- On-Demand Manufacturing: Print parts only when needed, reducing waste and inventory costs.

- Decentralized Production: 3D printing enables distributed manufacturing, bringing production closer to the point of need.

Traditional Printing: The Old Guard of Manufacturing

Traditional printing, often referred to as subtractive manufacturing, encompasses a range of methods that have been the backbone of industrial production for centuries. These methods typically involve removing material from a larger workpiece to achieve the desired shape.

Common Traditional Manufacturing Processes:

- Machining: Using cutting tools to shape metal, plastic, or other materials. CNC machining (Computer Numerical Control) provides high precision and automation.

- Molding: Creating a cavity (mold) and injecting molten material into it to create identical parts. Injection molding is a common example.

- Forming: Applying force to shape materials like sheet metal into desired forms.

- Casting: Pouring molten material into a mold and allowing it to solidify.

Advantages of Traditional Manufacturing:

- High Volume Production: Ideal for mass-producing identical parts efficiently.

- Established Processes: Decades of refinement have led to reliable and predictable outcomes.

- Wide Material Selection: A vast range of materials can be used, including metals, plastics, composites, and more.

Limitations of Traditional Manufacturing:

- Design Constraints: Complex geometries and intricate designs can be challenging and costly to produce.

- Tooling Costs: Creating molds and tooling can be expensive, making it less cost-effective for small production runs or prototyping.

- Material Waste: Subtractive processes often generate significant material waste, especially when machining from solid blocks.

3D Printing vs. Traditional Printing: A Detailed Comparison

Now that we’ve explored both 3D printing and traditional printing, let’s put them head-to-head in a detailed comparison:

Design Flexibility:

- 3D Printing: ✅ Excels in creating complex geometries, intricate details, and customized designs.

- Traditional Printing: ❌ Limited by tooling and machining constraints, making complex designs challenging and costly.

Production Volume:

- 3D Printing: ✅ Cost-effective for prototyping, small batch production, and personalized items.

- Traditional Printing: ✅ Ideal for mass production of identical parts, achieving economies of scale.

Cost:

- 3D Printing: ✅ Lower setup costs, making it suitable for low-volume production and prototyping.

- Traditional Printing: ❌ Higher initial tooling costs, but lower cost per unit for large production runs.

Speed:

- 3D Printing: ✅ Generally faster for prototyping and small batches, as it eliminates tooling creation.

- Traditional Printing: ✅ Can be faster for mass production once tooling is in place.

Material Selection:

- 3D Printing: ❌ Material options are rapidly expanding but still limited compared to traditional methods.

- Traditional Printing: ✅ Offers a wider range of materials, including metals, plastics, composites, and more.

Waste Generation:

- 3D Printing: ✅ Additive nature generally results in less material waste, especially for complex designs.

- Traditional Printing: ❌ Subtractive processes can generate significant waste material, particularly during machining.

Comparison Table: 3D Printing vs. Traditional Printing

| Feature | 3D Printing | Traditional Printing |

|---|---|---|

| Design Flexibility | High | Limited |

| Production Volume | Low to Medium | High |

| Cost | Lower setup, higher per unit | Higher setup, lower per unit |

| Speed | Faster for prototypes, small batches | Faster for mass production |

| Material Selection | Expanding, but limited | Wide range |

| Waste Generation | Low | High |

| Customization | High | Low |

Exploring Alternatives: What Can Replace 3D and Traditional Printing?

While 3D printing and traditional printing dominate the manufacturing landscape, alternative technologies are emerging and evolving:

1. Rapid Tooling: Bridging the Gap

Rapid tooling combines the speed of 3D printing with the advantages of traditional molding or casting. It involves using 3D printing to create molds or tooling quickly and cost-effectively, enabling short-run production using traditional methods.

2. Laser Cutting: Precision Cutting and Engraving

Laser cutting uses a high-powered laser to cut or engrave materials like wood, acrylic, metal, and fabric. It offers high precision and intricate detail, making it suitable for various applications, from signage to electronics.

3. Smart Manufacturing: The Digital Transformation

Smart manufacturing leverages data, automation, and connectivity to optimize traditional manufacturing processes. It involves integrating sensors, robotics, and data analytics to improve efficiency, reduce waste, and enable flexible production.

The Future of Printing: Trends and Innovations

The world of printing is in constant flux, with exciting advancements shaping its future:

1. 4D Printing: Objects That Transform Over Time

Imagine objects that can change their shape or properties in response to external stimuli like heat, light, or moisture. That’s the promise of 4D printing, which adds the dimension of time to 3D printing.

2. Bioprinting: Printing Functional Organs and Tissues

Bioprinting is pushing the boundaries of medicine by using 3D printing techniques to create living tissues and organs for transplantation. This groundbreaking technology has the potential to revolutionize healthcare and address organ shortages.

3. Metal 3D Printing: Revolutionizing Manufacturing

Metal 3D printing is transforming industries like aerospace, automotive, and medical by enabling the creation of complex metal parts with high strength and lightweight designs.

Real-World Applications: Where 3D Printing Shines

3D printing is no longer a futuristic fantasy; it’s making waves across industries:

1. Healthcare: Personalized Medicine and Prosthetics

- Surgical Guides and Implants: 3D printed models assist surgeons in planning and executing complex procedures. Patient-specific implants improve fit and outcomes.

- Prosthetics and Orthotics: Customized prosthetics and orthotics enhance comfort and functionality for amputees and individuals with mobility impairments.

2. Aerospace: Lightweighting and On-Demand Parts

- Lightweight Components: 3D printing enables the creation of strong yet lightweight aerospace components, reducing fuel consumption and emissions.

- On-Demand Manufacturing: Printing parts on demand reduces lead times and inventory costs for specialized aerospace components.

3. Automotive: Prototyping and Customized Parts

- Rapid Prototyping: Accelerates the design process by enabling quick iterations and testing of automotive components.

- Customized Parts: Create personalized car interiors, specialized parts, and aftermarket accessories.

4. Consumer Goods: From Toys to Jewelry

- Personalized Products: 3D printing allows consumers to create customized phone cases, jewelry, toys, and other personalized items.

- On-Demand Manufacturing: Products can be printed on demand, reducing waste and inventory costs for niche markets.

Common Misconceptions: Debunking Myths about 3D Printing

Despite its growing popularity, 3D printing is often surrounded by misconceptions:

Myth 1: 3D Printing Will Replace Traditional Manufacturing

Reality: 3D printing and traditional manufacturing are complementary technologies, each with strengths and limitations. They are more likely to coexist and collaborate rather than one replacing the other entirely.

Myth 2: 3D Printing is Only for Prototyping

Reality: While 3D printing excels in rapid prototyping, it’s increasingly used for end-use part production, especially for customized, low-volume, or complex designs.

Myth 3: 3D Printing is Too Expensive

Reality: The cost of 3D printing has decreased significantly, making it accessible for hobbyists, small businesses, and large enterprises alike. The cost-effectiveness depends on factors like production volume, material, and technology used.

Myth 4: 3D Printing is Difficult to Learn

Reality: While designing complex 3D models requires specialized skills, operating a 3D printer and using pre-designed models is becoming increasingly user-friendly, thanks to intuitive software and plug-and-play devices. We recommend checking out 10 Free 3D Printing Software Powerhouses for Your Ender 3 2024 💡 to get started.

Conclusion

In this deep dive into the world of printing, we’ve uncovered the stark differences between traditional printing methods and the revolutionary realm of 3D printing. While traditional printing has been the stalwart of manufacturing for centuries, 3D printing is shaking things up with its design flexibility, cost-effectiveness for small runs, and rapid prototyping capabilities.

Summary of Positives and Negatives:

Positives of 3D Printing:

- Design Freedom: Create complex and customized shapes that traditional methods struggle with.

- Reduced Waste: The additive process minimizes material waste compared to subtractive methods.

- Speed: Rapid prototyping and on-demand production significantly shorten lead times.

Negatives of 3D Printing:

- Material Limitations: The range of materials is still expanding but not as extensive as traditional manufacturing.

- Surface Finish: Some methods may require post-processing for a smooth finish.

- Initial Costs: While operating costs can be lower, high-quality 3D printers can have a steep initial price.

In conclusion, 3D printing is a game-changer that complements traditional manufacturing rather than replacing it. For anyone looking to innovate, prototype, or create intricate designs, embracing this technology is a no-brainer! So, what are you waiting for? Dive into the world of 3D printing and unleash your creativity! 🚀

Recommended Links

-

👉 Shop 3D Printers:

- Creality Ender 3: Amazon | Official Site

- Prusa i3 MK3S: Amazon | Official Site

-

Books on 3D Printing:

FAQ

What is the difference between 3D printing and printing?

3D Printing vs. Traditional Printing

3D printing creates three-dimensional objects by layering materials based on digital models. In contrast, traditional printing (like inkjet or laser printing) produces two-dimensional images by applying ink onto surfaces like paper. Think of it this way: 3D printing builds up while traditional printing prints flat.

Read more about “Discover the 25 Best 3D Printing Software of 2024! 🖨️✨”

How is 3D printing different than traditional printing?

Key Differences

The fundamental difference lies in their processes:

- 3D Printing: Utilizes additive manufacturing techniques to construct objects layer by layer, allowing for complex designs and customization.

- Traditional Printing: Involves subtractive methods, where material is removed from a larger block or surface to create a desired shape or image.

Read more about “75 Most Useful 3D Printed Objects You Need to Try in 2024! 🚀”

What makes 3D printing different?

Unique Features of 3D Printing

3D printing stands out due to:

- Material Variety: While still expanding, 3D printing can use plastics, metals, ceramics, and even biological materials.

- Customization: Each print can be unique, allowing for personalized products tailored to individual needs.

- Prototyping Speed: Rapidly create prototypes without the lengthy setup times associated with traditional manufacturing.

What is 3D printing not good for?

Limitations of 3D Printing

While 3D printing is revolutionary, it does have its drawbacks:

- High Volume Production: For mass production of identical parts, traditional manufacturing methods often remain more efficient and cost-effective.

- Material Properties: Some 3D printed materials may not possess the same strength or durability as those produced through traditional methods.

- Surface Finish: Certain 3D printing processes can result in a rougher finish, requiring post-processing for a polished look.

Read more about “Can I 3D Print ANYTHING? The Ultimate Guide to 3D Printing in … 🤯”

Reference Links

- Xometry: 3D Printing vs. Traditional Manufacturing

- Mastercam: What’s the Difference Between CAD/CAM and 3D Printing?

- Science Museum: The History of 3D Printing

- 3D Printing Industry: The Latest Trends and Innovations

With all this information, you’re now equipped to navigate the exciting world of 3D printing vs. traditional printing! Happy printing! 🎉