Support our educational content for free when you purchase through links on our site. Learn more

What Is 3D Print Plastic Called? 16 Must-Know Filaments in 2025 🎨

Ever stared at that colorful spool of filament and wondered, “What exactly is this 3D print plastic called?” You’re not alone! The world of 3D printing plastics is a vibrant jungle of acronyms, chemical names, and exotic materials — from PLA and ABS to TPU and PEEK. But don’t worry, we’re here to cut through the jargon and unravel the mystery behind these magical filaments that bring your digital dreams to life.

Did you know that the choice of filament can make or break your print? Imagine spending hours on a design only to have it warp, crack, or fail because you picked the wrong plastic. In this guide, we’ll introduce you to 16 essential 3D printing plastics, explain their unique properties, and help you pick the perfect one for your next project. Ready to become a filament wizard? Let’s dive in!

Key Takeaways

- 3D print plastics are commonly called “filaments” and come in many types, each with unique strengths and quirks.

- PLA is the easiest and most popular filament for beginners, while ABS and PETG offer more durability and heat resistance.

- Specialty filaments like TPU (flexible), Nylon (strong), and PC (heat resistant) expand your creative possibilities.

- Proper filament choice is crucial for successful prints — consider strength, flexibility, heat resistance, and environmental factors.

- Storage and printer settings matter: keep filaments dry and experiment with temperatures for best results.

- Explore trusted brands like Hatchbox, eSUN, NinjaFlex, and Polymaker for quality filament options.

👉 Shop Filaments on:

- PLA Filaments on Amazon | Thingiverse PLA Models

- ABS Filaments on Amazon | Thingiverse ABS Models

- TPU Filaments on Amazon | NinjaFlex Official Site

Table of Contents

- ⚡️ Quick Tips and Facts: Your Filament Fast-Track!

- 📜 The Polymer Playground: A Brief History of 3D Printing Filaments

- 🤔 So, What Are These Plastics Called? Unraveling the Filament Names

- 🔬 The Big Players: 16+ Common 3D Printing Plastics You’ll Encounter

- 1. The Everyday Hero: PLA (Polylactic Acid) 🌿

- 2. The Workhorse: ABS (Acrylonitrile Butadiene Styrene) 🧱

- 3. The Best of Both Worlds: PETG (Polyethylene Terephthalate Glycol-modified) ✨

- 4. The Flexible Friend: TPU (Thermoplastic Polyurethane) & TPE (Thermoplastic Elastomer) 🤸

- 5. The Tough Guy: Nylon (Polyamide) 💪

- 6. The Clear Contender: PC (Polycarbonate) 💎

- 7. The Outdoor Champion: ASA (Acrylonitrile Styrene Acrylate) ☀️

- 8. The Support Stars: HIPS (High Impact Polystyrene) & PVA (Polyvinyl Alcohol) 💧

- 9. The Chemical Resistant: PP (Polypropylene) 🧪

- 10. The High-Performance Powerhouses: PEEK, PEI (ULTEM), & PPSU 🔥

- 11. The Aesthetic Enhancers: Wood, Metal, & Silk Filaments 🎨

- 12. The Super Strong: Carbon Fiber & Glass Fiber Composites 🚀

- 13. The Electrically Charged: Conductive & ESD Filaments ⚡

- 14. The Glow-Getters: Glow-in-the-Dark & UV Reactive Filaments 🌟

- 15. The Eco-Warriors: Recycled & Biodegradable Filaments ♻️

- 16. The Niche Navigators: Medical Grade, Food Safe, & Flame Retardant Filaments 🏥

- 💡 Beyond the Basics: Understanding Filament Properties and Applications

- 🎯 Choosing Your Weapon: Selecting the Right 3D Printing Filament for Your Project

- 🏭 The Science Behind the Spool: How 3D Printer Filaments are Made

- 🛠️ Troubleshooting Common Filament Foes: When Your Plastic Misbehaves

- 🔮 The Future of 3D Print Plastics: Innovations on the Horizon

- 🎉 Conclusion: The Wonderful World of 3D Print Plastics!

- 🔗 Recommended Links: Dive Deeper!

- ❓ FAQ: Your Burning Questions About 3D Print Plastics Answered

- 📚 Reference Links: Our Sources

⚡️ Quick Tips and Facts: Your Filament Fast-Track!

You’re ready to dive into the world of 3D printing plastics, but where do you even begin? Don’t worry, we’ve got you covered! Here’s a quick rundown of the essentials:

- Is 3D printed stuff plastic? Well, it’s often made of plastic, but not always! We’ve got a whole article on that, check it out: Is 3D printed stuff plastic?

- 3D printing plastics are called “filaments” when they’re in the form you use in your printer. Think of them like long, thin strands of plastic that get melted and extruded layer by layer.

- PLA is the most popular beginner filament. It’s easy to print with, relatively inexpensive, and comes in a wide range of colors.

- ABS is another common filament. It’s known for its strength and durability, but it can be a bit trickier to print with than PLA.

- There are tons of different 3D printing plastics out there! Each one has its own unique properties and applications.

- Choosing the right filament is crucial for a successful print. Consider the strength, flexibility, heat resistance, and other properties you need for your project.

3D Printing Plastics: A Quick Comparison

| Filament Type | Strength | Flexibility | Heat Resistance | Other Properties |

|---|---|---|---|---|

| PLA | Medium | Low | Low | Biodegradable, easy to print |

| ABS | High | Medium | Medium | Strong, durable, requires heated bed |

| PETG | High | Medium | High | Tough, impact resistant, good for outdoor use |

| TPU | Medium | High | Medium | Flexible, elastic, good for making rubber-like parts |

| Nylon | High | Medium | High | Strong, durable, good for making functional parts |

📜 The Polymer Playground: A Brief History of 3D Printing Filaments

The story of 3D printing filaments is a fascinating journey through innovation and evolution. It all started with the invention of fused deposition modeling (FDM), a process that uses a heated nozzle to extrude thermoplastic filaments layer by layer.

The first 3D printing filaments were primarily ABS (Acrylonitrile Butadiene Styrene), a material known for its strength and durability. ABS was a natural choice because it was already widely used in other manufacturing processes.

As 3D printing technology advanced, new filaments emerged, each with its own unique properties and applications. PLA (Polylactic Acid), a biodegradable and eco-friendly filament, quickly gained popularity due to its ease of printing and affordability.

Today, the world of 3D printing filaments is a vibrant and diverse landscape. From flexible TPU (Thermoplastic Polyurethane) to high-performance PEEK (Polyetheretherketone), there’s a filament for every need and application.

🤔 So, What Are These Plastics Called? Unraveling the Filament Names

You’ve probably heard terms like “PLA,” “ABS,” and “PETG” thrown around, but what do they actually mean? Let’s break it down:

- PLA (Polylactic Acid): PLA is a biodegradable thermoplastic made from renewable resources like cornstarch. It’s known for its ease of printing, affordability, and wide range of colors.

- ABS (Acrylonitrile Butadiene Styrene): ABS is a strong and durable thermoplastic that’s commonly used for making toys, appliances, and other everyday items. It’s a bit trickier to print with than PLA, but it offers excellent strength and impact resistance.

- PETG (Polyethylene Terephthalate Glycol-modified): PETG is a tough and impact-resistant thermoplastic that’s often used for making bottles, food containers, and other items that need to be durable and clear. It’s a good choice for outdoor applications because it’s resistant to UV light and weathering.

- TPU (Thermoplastic Polyurethane): TPU is a flexible and elastic thermoplastic that’s often used for making rubber-like parts. It’s a good choice for applications that require flexibility, such as seals, gaskets, and wearable devices.

- Nylon (Polyamide): Nylon is a strong and durable thermoplastic that’s often used for making gears, bearings, and other functional parts. It’s known for its high strength-to-weight ratio and its resistance to wear and tear.

These are just a few of the many 3D printing plastics available. We’ll explore more of them in the next section!

🔬 The Big Players: 16+ Common 3D Printing Plastics You’ll Encounter

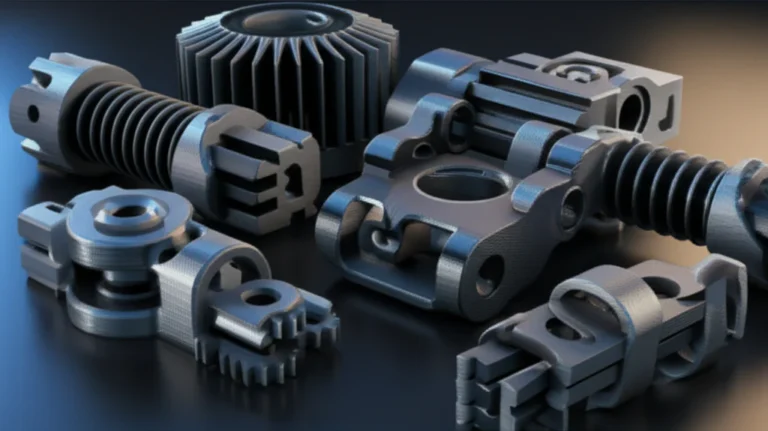

The world of 3D printing plastics is vast and exciting, with a filament for every project and purpose. Let’s take a closer look at some of the most common and popular 3D printing plastics you’ll encounter:

1. The Everyday Hero: PLA (Polylactic Acid) 🌿

PLA is the go-to filament for beginners and a popular choice for many experienced 3D printing enthusiasts. It’s easy to print with, relatively inexpensive, and comes in a wide range of colors. PLA is also biodegradable, making it an eco-friendly choice.

PLA Filament Rating:

| Feature | Rating |

|---|---|

| Ease of Printing | 9 |

| Strength | 7 |

| Flexibility | 5 |

| Heat Resistance | 6 |

| Cost | 8 |

PLA Filament Pros:

- Easy to print: PLA is known for its ease of use, making it a great choice for beginners. It doesn’t require a heated bed and has a lower melting temperature than other filaments, making it less likely to warp or clog your nozzle.

- Biodegradable: PLA is made from renewable resources like cornstarch, making it an eco-friendly choice.

- Wide range of colors: PLA is available in a wide variety of colors, allowing you to create vibrant and eye-catching prints.

- Affordable: PLA is one of the most affordable 3D printing filaments available.

PLA Filament Cons:

- Not as strong as ABS: PLA is not as strong as ABS, so it’s not the best choice for applications that require high strength or impact resistance.

- Not as heat resistant as ABS: PLA is not as heat resistant as ABS, so it’s not the best choice for applications that will be exposed to high temperatures.

- Can be brittle: PLA can be brittle, so it’s not the best choice for applications that require flexibility.

PLA Filament Applications:

- Prototypes: PLA is a great choice for making prototypes because it’s easy to print and relatively inexpensive.

- Decorative objects: PLA is a good choice for making decorative objects because it comes in a wide range of colors and can be printed with intricate details.

- Functional parts: PLA can be used for making functional parts, but it’s important to consider its limitations in terms of strength and heat resistance.

PLA Filament Brands:

- Hatchbox PLA: Thingiverse | Amazon | Hatchbox Official Website

- eSUN PLA: Thingiverse | Amazon | eSUN Official Website

- Sunlu PLA: Thingiverse | Amazon | Sunlu Official Website

PLA Filament Tips:

- Store PLA filament in a dry place: PLA is hygroscopic, meaning it absorbs moisture from the air. Storing it in a dry place will help prevent warping and other printing problems.

- Use a heated bed for large prints: A heated bed can help prevent warping, especially for large prints.

- Experiment with different printing temperatures: The optimal printing temperature for PLA can vary depending on the brand and type of filament. Experiment with different temperatures to find the best settings for your printer.

2. The Workhorse: ABS (Acrylonitrile Butadiene Styrene) 🧱

ABS is a tough and durable thermoplastic that’s been a staple in 3D printing for years. It’s known for its strength, impact resistance, and heat resistance. ABS is a good choice for making functional parts, prototypes, and other items that need to be durable.

ABS Filament Rating:

| Feature | Rating |

|---|---|

| Ease of Printing | 7 |

| Strength | 9 |

| Flexibility | 6 |

| Heat Resistance | 8 |

| Cost | 7 |

ABS Filament Pros:

- Strong and durable: ABS is a strong and durable thermoplastic that can withstand high impact forces.

- Heat resistant: ABS is more heat resistant than PLA, making it a good choice for applications that will be exposed to high temperatures.

- Good chemical resistance: ABS is resistant to a variety of chemicals, making it a good choice for applications that will be exposed to harsh environments.

- Widely available: ABS is one of the most widely available 3D printing filaments, making it easy to find.

ABS Filament Cons:

- Can be tricky to print: ABS can be more difficult to print with than PLA because it requires a heated bed and can be prone to warping.

- Can release fumes: ABS can release fumes during printing, so it’s important to use a well-ventilated area or a 3D printer enclosure.

- Not as smooth as PLA: ABS prints can have a slightly rougher surface finish than PLA prints.

ABS Filament Applications:

- Functional parts: ABS is a good choice for making functional parts because it’s strong, durable, and heat resistant.

- Prototypes: ABS is a good choice for making prototypes because it’s strong and durable, and it can be easily sanded and painted.

- Toys: ABS is a popular choice for making toys because it’s strong, durable, and safe for children.

ABS Filament Brands:

- Hatchbox ABS: Thingiverse | Amazon | Hatchbox Official Website

- eSUN ABS: Thingiverse | Amazon | eSUN Official Website

- Sunlu ABS: Thingiverse | Amazon | Sunlu Official Website

ABS Filament Tips:

- Use a heated bed: A heated bed is essential for printing with ABS to prevent warping.

- Use a 3D printer enclosure: A 3D printer enclosure can help to reduce warping and improve print quality.

- Experiment with different printing temperatures: The optimal printing temperature for ABS can vary depending on the brand and type of filament. Experiment with different temperatures to find the best settings for your printer.

3. The Best of Both Worlds: PETG (Polyethylene Terephthalate Glycol-modified) ✨

PETG is a versatile and popular filament that combines the ease of printing of PLA with the strength and durability of ABS. It’s known for its toughness, impact resistance, and good chemical resistance. PETG is a good choice for making functional parts, prototypes, and other items that need to be durable and resistant to weathering.

PETG Filament Rating:

| Feature | Rating |

|---|---|

| Ease of Printing | 8 |

| Strength | 8 |

| Flexibility | 6 |

| Heat Resistance | 8 |

| Cost | 7 |

PETG Filament Pros:

- Tough and impact resistant: PETG is a tough and impact-resistant thermoplastic that can withstand high impact forces.

- Good chemical resistance: PETG is resistant to a variety of chemicals, making it a good choice for applications that will be exposed to harsh environments.

- Good weather resistance: PETG is resistant to UV light and weathering, making it a good choice for outdoor applications.

- Easy to print: PETG is relatively easy to print with, and it doesn’t require a heated bed.

PETG Filament Cons:

- Can be prone to stringing: PETG can be prone to stringing, which is when thin strands of filament are left behind on the print.

- Can be difficult to remove from the print bed: PETG can stick to the print bed, making it difficult to remove.

- Not as strong as ABS: PETG is not as strong as ABS, so it’s not the best choice for applications that require high strength or impact resistance.

PETG Filament Applications:

- Functional parts: PETG is a good choice for making functional parts because it’s tough, impact resistant, and weather resistant.

- Prototypes: PETG is a good choice for making prototypes because it’s easy to print and can be easily sanded and painted.

- Outdoor applications: PETG is a good choice for outdoor applications because it’s resistant to UV light and weathering.

PETG Filament Brands:

- Hatchbox PETG: Thingiverse | Amazon | Hatchbox Official Website

- eSUN PETG: Thingiverse | Amazon | eSUN Official Website

- Sunlu PETG: Thingiverse | Amazon | Sunlu Official Website

PETG Filament Tips:

- Use a brim or raft: A brim or raft can help to prevent PETG from warping.

- Use a good quality print bed: A good quality print bed can help to prevent PETG from sticking.

- Experiment with different printing temperatures: The optimal printing temperature for PETG can vary depending on the brand and type of filament. Experiment with different temperatures to find the best settings for your printer.

4. The Flexible Friend: TPU (Thermoplastic Polyurethane) & TPE (Thermoplastic Elastomer) 🤸

TPU and TPE are flexible and elastic thermoplastics that are often used for making rubber-like parts. They’re a good choice for applications that require flexibility, such as seals, gaskets, and wearable devices.

TPU/TPE Filament Rating:

| Feature | Rating |

|---|---|

| Ease of Printing | 6 |

| Strength | 7 |

| Flexibility | 9 |

| Heat Resistance | 7 |

| Cost | 8 |

TPU/TPE Filament Pros:

- Flexible and elastic: TPU and TPE are flexible and elastic thermoplastics that can be stretched and bent without breaking.

- Good impact resistance: TPU and TPE have good impact resistance, making them a good choice for applications that will be exposed to shocks and vibrations.

- Good chemical resistance: TPU and TPE are resistant to a variety of chemicals, making them a good choice for applications that will be exposed to harsh environments.

TPU/TPE Filament Cons:

- Can be difficult to print: TPU and TPE can be more difficult to print with than other filaments because they can be prone to clogging and stringing.

- Can be expensive: TPU and TPE can be more expensive than other filaments.

- Limited color availability: TPU and TPE are not available in as many colors as other filaments.

TPU/TPE Filament Applications:

- Seals and gaskets: TPU and TPE are a good choice for making seals and gaskets because they’re flexible and can conform to irregular shapes.

- Wearable devices: TPU and TPE are a good choice for making wearable devices because they’re flexible and comfortable to wear.

- Toys: TPU and TPE are a good choice for making toys because they’re flexible and durable.

TPU/TPE Filament Brands:

- NinjaFlex TPU: Thingiverse | Amazon | NinjaFlex Official Website

- SainSmart TPU: Thingiverse | Amazon | SainSmart Official Website

- Polymaker TPU: Thingiverse | Amazon | Polymaker Official Website

TPU/TPE Filament Tips:

- Use a good quality extruder: A good quality extruder is essential for printing with TPU and TPE to prevent clogging.

- Use a heated bed: A heated bed can help to prevent warping and improve print quality.

- Experiment with different printing temperatures: The optimal printing temperature for TPU and TPE can vary depending on the brand and type of filament. Experiment with different temperatures to find the best settings for your printer.

5. The Tough Guy: Nylon (Polyamide) 💪

Nylon is a strong and durable thermoplastic that’s often used for making gears, bearings, and other functional parts. It’s known for its high strength-to-weight ratio and its resistance to wear and tear. Nylon is a good choice for applications that require strength, durability, and resistance to abrasion.

Nylon Filament Rating:

| Feature | Rating |

|---|---|

| Ease of Printing | 5 |

| Strength | 9 |

| Flexibility | 6 |

| Heat Resistance | 8 |

| Cost | 7 |

Nylon Filament Pros:

- High strength-to-weight ratio: Nylon is a strong and lightweight thermoplastic, making it a good choice for applications where weight is a concern.

- Good wear resistance: Nylon is resistant to wear and tear, making it a good choice for applications that will be exposed to friction.

- Good chemical resistance: Nylon is resistant to a variety of chemicals, making it a good choice for applications that will be exposed to harsh environments.

- Good heat resistance: Nylon is more heat resistant than PLA and PETG, making it a good choice for applications that will be exposed to high temperatures.

Nylon Filament Cons:

- Can be difficult to print: Nylon can be more difficult to print with than other filaments because it requires a heated bed and can be prone to warping.

- Can be expensive: Nylon can be more expensive than other filaments.

- Limited color availability: Nylon is not available in as many colors as other filaments.

Nylon Filament Applications:

- Gears and bearings: Nylon is a good choice for making gears and bearings because it’s strong, durable, and wear resistant.

- Functional parts: Nylon is a good choice for making functional parts because it’s strong, durable, and resistant to abrasion.

- Prototypes: Nylon is a good choice for making prototypes because it’s strong and durable, and it can be easily sanded and painted.

Nylon Filament Brands:

- Taulman 3D Nylon: Thingiverse | Amazon | Taulman 3D Official Website

- Polymaker Nylon: Thingiverse | Amazon | Polymaker Official Website

- Hatchbox Nylon: Thingiverse | Amazon | Hatchbox Official Website

Nylon Filament Tips:

- Use a heated bed: A heated bed is essential for printing with nylon to prevent warping.

- Use a 3D printer enclosure: A 3D printer enclosure can help to reduce warping and improve print quality.

- Experiment with different printing temperatures: The optimal printing temperature for nylon can vary depending on the brand and type of filament. Experiment with different temperatures to find the best settings for your printer.

6. The Clear Contender: PC (Polycarbonate) 💎

PC is a strong, rigid, and heat-resistant thermoplastic known for its high impact resistance and excellent optical clarity. It’s often used for making lenses, windows, and other items that need to be clear and durable.

PC Filament Rating:

| Feature | Rating |

|---|---|

| Ease of Printing | 4 |

| Strength | 9 |

| Flexibility | 5 |

| Heat Resistance | 9 |

| Cost | 8 |

PC Filament Pros:

- High impact resistance: PC is a very strong and impact-resistant thermoplastic, making it a good choice for applications that will be exposed to high impact forces.

- Excellent optical clarity: PC is a clear thermoplastic that can be used for making lenses, windows, and other items that need to be transparent.

- Good heat resistance: PC is more heat resistant than PLA, ABS, and PETG, making it a good choice for applications that will be exposed to high temperatures.

- Good chemical resistance: PC is resistant to a variety of chemicals, making it a good choice for applications that will be exposed to harsh environments.

PC Filament Cons:

- Can be difficult to print: PC can be more difficult to print with than other filaments because it requires a heated bed and can be prone to warping.

- Can be expensive: PC can be more expensive than other filaments.

- Can be brittle: PC can be brittle, so it’s not the best choice for applications that require flexibility.

PC Filament Applications:

- Lenses and windows: PC is a good choice for making lenses and windows because it’s clear and durable.

- Functional parts: PC is a good choice for making functional parts because it’s strong, rigid, and heat resistant.

- Prototypes: PC is a good choice for making prototypes because it’s strong and durable, and it can be easily sanded and painted.

PC Filament Brands:

- Polymaker PC: Thingiverse | Amazon | Polymaker Official Website

- Hatchbox PC: Thingiverse | Amazon | Hatchbox Official Website

- eSUN PC: Thingiverse | Amazon | eSUN Official Website

PC Filament Tips:

- Use a heated bed: A heated bed is essential for printing with PC to prevent warping.

- Use a 3D printer enclosure: A 3D printer enclosure can help to reduce warping and improve print quality.

- Experiment with different printing temperatures: The optimal printing temperature for PC can vary depending on the brand and type of filament. Experiment with different temperatures to find the best settings for your printer.

7. The Outdoor Champion: ASA (Acrylonitrile Styrene Acrylate) ☀️

ASA is a tough and durable thermoplastic that’s similar to ABS but with better UV resistance. It’s often used for making outdoor applications, such as signage, automotive parts, and other items that need to be resistant to weathering.

ASA Filament Rating:

| Feature | Rating |

|---|---|

| Ease of Printing | 6 |

| Strength | 8 |

| Flexibility | 6 |

| Heat Resistance | 8 |

| Cost | 8 |

ASA Filament Pros:

- Good UV resistance: ASA is resistant to UV light, making it a good choice for outdoor applications.

- Good weather resistance: ASA is resistant to weathering, making it a good choice for applications that will be exposed to the elements.

- Strong and durable: ASA is a strong and durable thermoplastic that can withstand high impact forces.

- Good chemical resistance: ASA is resistant to a variety of chemicals, making it a good choice for applications that will be exposed to harsh environments.

ASA Filament Cons:

- Can be difficult to print: ASA can be more difficult to print with than other filaments because it requires a heated bed and can be prone to warping.

- Can be expensive: ASA can be more expensive than other filaments.

- Limited color availability: ASA is not available in as many colors as other filaments.

ASA Filament Applications:

- Outdoor signage: ASA is a good choice for making outdoor signage because it’s resistant to UV light and weathering.

- Automotive parts: ASA is a good choice for making automotive parts because it’s strong, durable, and weather resistant.

- Prototypes: ASA is a good choice for making prototypes because it’s strong and durable, and it can be easily sanded and painted.

ASA Filament Brands:

- Proto-Pasta ASA: Thingiverse | Amazon | Proto-Pasta Official Website

- Hatchbox ASA: Thingiverse | Amazon | Hatchbox Official Website

- eSUN ASA: Thingiverse | Amazon | eSUN Official Website

ASA Filament Tips:

- Use a heated bed: A heated bed is essential for printing with ASA to prevent warping.

- Use a 3D printer enclosure: A 3D printer enclosure can help to reduce warping and improve print quality.

- Experiment with different printing temperatures: The optimal printing temperature for ASA can vary depending on the brand and type of filament. Experiment with different temperatures to find the best settings for your printer.

8. The Support Stars: HIPS (High Impact Polystyrene) & PVA (Polyvinyl Alcohol) 💧

HIPS and PVA are water-soluble support materials that are often used in 3D printing to create complex geometries that would otherwise be impossible to print. They’re dissolved after printing, leaving behind a clean and finished print.

HIPS/PVA Filament Rating:

| Feature | Rating |

|---|---|

| Ease of Printing | 7 |

| Strength | 6 |

| Flexibility | 5 |

| Heat Resistance | 6 |

| Cost | 7 |

HIPS/PVA Filament Pros:

- Water-soluble: HIPS and PVA are water-soluble, making it easy to remove them from your prints.

- Easy to print: HIPS and PVA are relatively easy to print with, and they don’t require a heated bed.

- Affordable: HIPS and PVA are relatively affordable, making them a good choice for budget-conscious 3D printing enthusiasts.

HIPS/PVA Filament Cons:

- Not as strong as other filaments: HIPS and PVA are not as strong as other filaments, so they’re not the best choice for applications that require high strength or impact resistance.

- Can be brittle: HIPS and PVA can be brittle, so they’re not the best choice for applications that require flexibility.

- Can be difficult to dissolve: HIPS and PVA can be difficult to dissolve completely, especially if they’re printed with a high infill density.

HIPS/PVA Filament Applications:

- Support structures: HIPS and PVA are primarily used as support structures for 3D prints.

- Prototypes: HIPS and PVA can be used for making prototypes, but it’s important to consider their limitations in terms of strength and heat resistance.

HIPS/PVA Filament Brands:

- Hatchbox HIPS: Thingiverse | Amazon | Hatchbox Official Website

- eSUN HIPS: Thingiverse | Amazon | eSUN Official Website

- Sunlu HIPS: Thingiverse | Amazon | Sunlu Official Website

- Hatchbox PVA: Thingiverse | Amazon | Hatchbox Official Website

- eSUN PVA: Thingiverse | Amazon | eSUN Official Website

- Sunlu PVA: Thingiverse | Amazon | Sunlu Official Website

HIPS/PVA Filament Tips:

- Use a separate extruder: It’s best to use a separate extruder for HIPS and PVA to prevent contamination.

- Print support structures with a low infill density: Printing support structures with a low infill density will make them easier to dissolve.

- Use a warm water bath to dissolve HIPS and PVA: A warm water bath will help to dissolve HIPS and PVA more quickly.

9. The Chemical Resistant: PP (Polypropylene) 🧪

PP is a versatile and durable thermoplastic that’s known for its chemical resistance, good impact resistance, and low density. It’s often used for making containers, bottles, and other items that need to be resistant to chemicals and impact.

PP Filament Rating:

| Feature | Rating |

|---|---|

| Ease of Printing | 6 |

| Strength | 7 |

| Flexibility | 6 |

| Heat Resistance | 7 |

| Cost | 7 |

PP Filament Pros:

- Good chemical resistance: PP is resistant to a variety of chemicals, making it a good choice for applications that will be exposed to harsh environments.

- Good impact resistance: PP has good impact resistance, making it a good choice for applications that will be exposed to shocks and vibrations.

- Low density: PP is a lightweight thermoplastic, making it a good choice for applications where weight is a concern.

- Good heat resistance: PP is more heat resistant than PLA and PETG, making it a good choice for applications that will be exposed to high temperatures.

PP Filament Cons:

- Can be difficult to print: PP can be more difficult to print with than other filaments because it requires a heated bed and can be prone to warping.

- Can be expensive: PP can be more expensive than other filaments.

- Limited color availability: PP is not available in as many colors as other filaments.

PP Filament Applications:

- Containers and bottles: PP is a good choice for making containers and bottles because it’s chemical resistant and impact resistant.

- **Functional

🎉 Conclusion: The Wonderful World of 3D Print Plastics!

Wow, what a journey through the colorful, flexible, and sometimes downright quirky universe of 3D print plastics! From the beginner-friendly PLA to the tough-as-nails Nylon and the flexible TPU, each filament brings its own personality and superpowers to your 3D printing adventures. Remember, the magic of 3D printing lies not just in the printer itself but in choosing the right filament for your project’s needs — whether it’s strength, flexibility, heat resistance, or eco-friendliness.

We opened the loop on whether 3D printed stuff is plastic — and yes, most FDM prints are made from thermoplastic filaments, but the world of 3D printing also includes resins, powders, and composites. Knowing the names and properties of these plastics empowers you to pick the perfect material and avoid common pitfalls like warping, brittleness, or poor adhesion.

Our expert team at 3D Printed™ confidently recommends starting your filament journey with PLA for its ease and versatility, then experimenting with PETG or ABS as you get more comfortable. For specialized needs, TPU, Nylon, and PC offer exciting options, but be prepared for a learning curve.

Ready to spool up and print your next masterpiece? Dive into the filament world with confidence — and remember, every failed print is just a step closer to perfection! 🚀

🔗 Recommended Links: Dive Deeper!

Ready to grab some filament or learn more? Check out these trusted sources and brands:

-

Hatchbox Filaments:

PLA on Thingiverse | Amazon | Hatchbox Official Website

ABS on Thingiverse | Amazon

PETG on Thingiverse | Amazon -

eSUN Filaments:

PLA on Thingiverse | Amazon | eSUN Official Website

ABS on Thingiverse | Amazon

PETG on Thingiverse | Amazon -

NinjaFlex TPU:

Thingiverse | Amazon | NinjaFlex Official Website -

Polymaker Filaments:

Nylon on Thingiverse | Amazon | Polymaker Official Website -

Books for 3D Printing Enthusiasts:

- 3D Printing Failures: How to Diagnose and Repair All Desktop 3D Printing Issues by Sean Aranda — Amazon Link

- 3D Printing: The Next Industrial Revolution by Christopher Barnatt — Amazon Link

- Make: 3D Printing: The Essential Guide to 3D Printers by Anna Kaziunas France — Amazon Link

❓ FAQ: Your Burning Questions About 3D Print Plastics Answered

What types of 3D printing plastics are available for beginners?

For beginners, PLA (Polylactic Acid) is the top pick. It’s easy to print, doesn’t require a heated bed, and produces good-quality prints with minimal warping. PETG is also beginner-friendly, offering a nice balance between strength and ease of use. Avoid ABS at first—it’s more challenging due to warping and fumes.

Why PLA is beginner-friendly:

- Low printing temperature (~190-220°C)

- Minimal odor and no toxic fumes

- Prints well on most consumer-grade FDM printers

- Biodegradable and widely available

Read more about “25 Must-Know 3D Printing Tutorials to Master in 2025 🖨️”

How do I choose the right 3D print plastic for my project?

Choosing the right filament depends on your project’s needs:

- Strength & durability: ABS, PETG, Nylon, PC

- Flexibility: TPU, TPE

- Heat resistance: PC, ABS, Nylon

- Ease of printing: PLA, PETG

- Eco-friendliness: PLA, recycled filaments

- Special applications: Medical-grade resins, conductive filaments, composites

Ask yourself: Will the part be functional or decorative? Indoor or outdoor? Flexible or rigid? Your answers guide your filament choice.

Read more about “What Gets 3D Printed? 10 Surprising Things You Can Create in 2025 🎉”

What are the differences between ABS and PLA 3D printing plastics?

ABS is stronger, more heat resistant, and more durable than PLA, but it’s harder to print and emits fumes that require ventilation. PLA is easier to print, biodegradable, and less prone to warping, but it’s more brittle and less heat resistant. ABS is great for functional parts; PLA is perfect for prototypes and decorative items.

Can I recycle 3D print plastic filament and reuse it for new prints?

✅ Yes, but with caveats! Many filaments, especially thermoplastics like PLA and ABS, can be recycled and re-extruded into new filament. However, repeated recycling can degrade the material’s properties, leading to weaker prints. Specialized filament recyclers like the Filabot or ProtoCycler make this possible at home, but commercial recycling remains more efficient.

❌ Avoid recycling resin prints or composite filaments at home—they require industrial processes.

How do environmental factors affect 3D print plastics?

Humidity is the nemesis of many filaments, especially Nylon, PVA, and TPU, which are hygroscopic and absorb moisture from the air. This causes bubbling, stringing, and poor layer adhesion. Store filaments in airtight containers with desiccants to keep them dry.

Temperature fluctuations can cause warping, especially with ABS and PC. Using a heated bed and printer enclosure helps maintain stable printing conditions.

Are there any health or safety concerns with 3D printing plastics?

Some filaments like ABS emit ultrafine particles (UFPs) and volatile organic compounds (VOCs) during printing, which can be harmful if inhaled in large quantities. Always print in a well-ventilated area or use an enclosure with filtration. PLA is generally considered safer and emits fewer fumes.

Read more about “Is 3D Printed Stuff Plastic? Discover 7 Fascinating Facts! 🖨️”

📚 Reference Links: Our Sources

- Types of Plastic Used in 3D Printing – Thongguan

- 3D Printing Materials Guide – Formlabs

- 3D Printing Plastics: The Ultimate Guide – 3Dnatives

- Hatchbox Official Website

- eSUN Official Website

- NinjaFlex Official Website

- Polymaker Official Website

- 3D Printed™ – Is 3D Printed Stuff Plastic?

- Filabot Home Recycling System

- ProtoCycler Filament Recycler

Ready to spool up your next project? With this guide, you’re armed with the knowledge to pick the perfect 3D print plastic and create amazing prints that wow and last. Happy printing! 🎉