Support our educational content for free when you purchase through links on our site. Learn more

The Ultimate 15-Step 3D Print Post-Processing Guide (2025) ✨

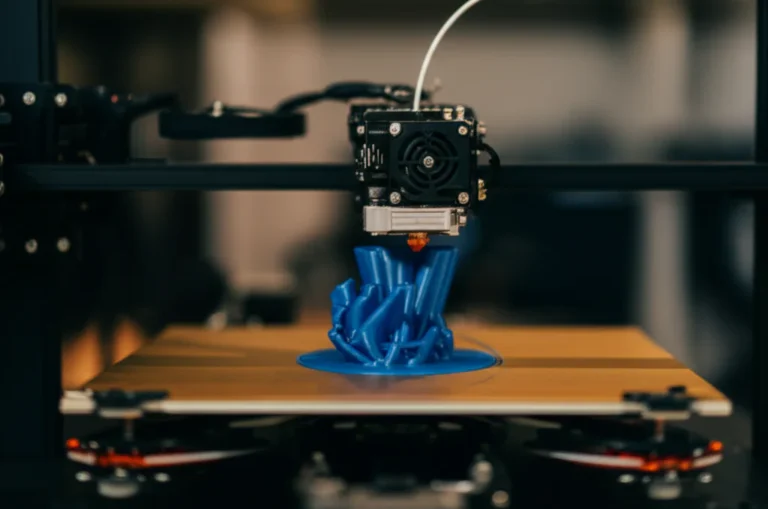

You know that feeling when your 3D printer finishes a job, and you’re staring at a rough, layer-lined, support-studded mess? We’ve all been there—those first prints often look more like abstract art than the sleek models we envisioned. But here’s the kicker: 90% of the magic happens after the print stops. Whether you’re working with FDM’s filament strings or SLA’s glossy resin masterpieces, mastering post-processing is the secret sauce that transforms your prints from “meh” to museum-worthy.

In this guide, we’ll walk you through 15 essential post-processing techniques that cover everything from support removal and sanding to advanced vapor smoothing and eco-friendly finishing. Curious about how to get that mirror-like shine on ABS or how to cure resin prints without turning them brittle? We’ve got you covered with insider tips, expert hacks, and product recommendations that even seasoned pros swear by. Stick around for our “Coffee Weathering Hack” — it’s a game-changer for adding battle-worn realism to your prints!

Key Takeaways

- Post-processing is where your print truly comes to life—cleaning, curing, sanding, and finishing are non-negotiable steps.

- Different print technologies require tailored techniques: FDM benefits from vapor smoothing and filler primers, while SLA demands precise washing and UV curing.

- Safety and eco-conscious practices protect you and the planet—always use gloves, respirators, and recycle solvents when possible.

- Investing in quality tools like rotary sanders, flush cutters, and curing stations pays off in print quality and efficiency.

- Creative finishing hacks like hydrographics and coffee weathering add unique flair and realism to your models.

Ready to elevate your 3D prints to the next level? Dive in and discover how to polish your prints into perfection!

Table of Contents

- ⚡️ Quick Tips and Facts for 3D Print Post-Processing

- 🔍 The Evolution of 3D Print Post-Processing: From Rough to Refined

- 🛠️ 3D Print Post-Processing Fundamentals: What Every Maker Should Know

- 1️⃣ Top 10 Essential Post-Processing Techniques for FDM Prints

- 2️⃣ Mastering SLA Post-Processing: Cleaning, Curing, and Finishing Like a Pro

- 3️⃣ Advanced Post-Processing Hacks: Sanding, Painting, and Vapor Smoothing Secrets

- 🎨 How to Choose the Right Finishing Materials and Tools for Your 3D Prints

- 🔧 Troubleshooting Common Post-Processing Challenges and How to Fix Them

- 🌿 Eco-Friendly and Safe Post-Processing Practices You Should Adopt

- 💡 Insider Tips from 3D Printing Experts: Elevate Your Post-Processing Game

- 🧰 Must-Have Post-Processing Tools and Accessories for Every 3D Printing Enthusiast

- 📚 Learn More About SLA and FDM Post-Processing: Resources and Tutorials

- 🎯 Conclusion: Perfecting Your 3D Prints with Expert Post-Processing

- 🔗 Recommended Links for 3D Print Post-Processing Supplies and Guides

- ❓ Frequently Asked Questions About 3D Print Post-Processing

- 📖 Reference Links and Further Reading

⚡️ Quick Tips and Facts for 3D Print Post-Processing

- Fact: 90 % of a print’s wow-factor happens after the printer stops humming.

- Tip: Keep a dedicated “wet” workspace (IPA, resin, acetone) and a “dry” workspace (sandpaper, primer, paint) to avoid cross-contamination.

- Fact: SLA parts can gain up to 30 % final tensile strength with a proper UV post-cure cycle (Formlabs whitepaper).

- Tip: If you hate sanding, vapor-smooth ABS with acetone inside a glass jar + paper-towel “tea bag”—works every time.

- Fact: The first YouTube video embedded above (#featured-video) shows how a simple flush cutter beats a knife for support removal—safer, cleaner, and way less blood on the build plate.

- Quick cheat-sheet:

- PLA → wet-sand → filler-primer → acrylic paint → clear coat ✅

- ABS → acetone vapor → rinse → prime → paint ✅

- Resin → wash in IPA or Phrozen Wash → cure → snip supports → light sand ✅

Need a one-stop printable toolbox? Grab our 3D-printable parts tray, funnel, and resin scraper before you start—your future self will high-five you.

🔍 The Evolution of 3D Print Post-Processing: From Rough to Refined

Back in 2009, we proudly displayed “dragon” models that looked like they’d been carved with a hot spoon. Fast-forward to 2024: resin printers hit 8 K, yet the biggest leap in print quality still comes from what happens after the buzzer beeps.

| Milestone | Year | Game-Changer |

|---|---|---|

| Open-source sanding guides | 2012 | Community agrees 220 → 600 → 2000 grit is the sweet spot |

| Formlabs Form Cure | 2017 | Automated, heated UV curing becomes desktop-friendly |

| Cerakote ceramic coatings | 2019 | Turns humble PLA into aerospace-grade parts |

| Water-transfer films | 2021 | Hydrographics let you dip-camo a Benchy—because why not? |

We still chuckle remembering the first time we baked a PLA part at 110 °C to anneal it—warped into a potato chip. Lesson: annealing temps are material-specific (Wevolver study).

🛠️ 3D Print Post-Processing Fundamentals: What Every Maker Should Know

1. Safety First—No Excuses

- Nitrile gloves ❌ not latex—IPA eats latex for breakfast.

- Respirator with organic vapor cartridges when vapor-smoothing ABS or using epoxy.

- Fire extinguisher within arm’s reach—acetone, IPA, and heat guns are best friends until they’re not.

2. The Holy Trinity of Finish Quality

- Surface energy (how well paint sticks)

- Surface roughness (Ra value—lower is smoother)

- Mechanical integrity (post-cure, anneal, infiltrate)

3. Workflow Cheat-Sheet

| Step | FDM | SLA | SLS |

|---|---|---|---|

| Support removal | Flush cutters | Flush cutters + snip after wash | None |

| Cleaning | Soap + water | IPA, TPM, or Phrozen Wash | Bead blast |

| Smoothing | Sand / vapor | Light wet-sand | Media tumble |

| Strengthen | Anneal | UV cure | Infiltrate |

| Beautify | Prime → paint | Prime → paint | Dye |

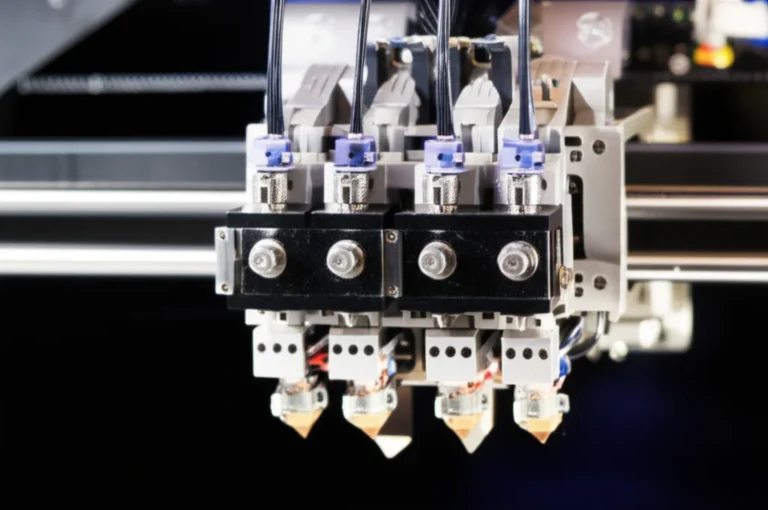

1️⃣ Top 10 Essential Post-Processing Techniques for FDM Prints

-

Support Removal—The Barber’s Touch

We swear by the Hakko micro-cutters—they nip supports flush without scarring.

Pro-tip: Rock the cutter, don’t squeeze—prevents divots. -

Wet Sanding—Your New Religion

Dry PLA melts and clogs paper. Wet sand at 2000 RPM on a cheap $30 rotary tool with silicone polishing bits = glass-smooth in minutes. -

Filler-Primer Sandwich

Two ultra-thin coats of Tamiya Fine Surface Primer → sand → repeat. Fills 0.2 mm layer lines like spackle on drywall. -

Vapor Smoothing—ABS Spa Day

Acetone in a glass jar + paper towel “tea bag” for 45 min. Never microwave acetone—Darwin Award incoming. -

Annealing—Hidden Strength

PLA at 80 °C for 30 min inside a toaster oven increases impact strength ~8 % (Wevolver data).

Caveat: parts shrink ~0.5 %—compensate in CAD. -

Epoxy Coating—Liquid Armor

XTC-3D brushed on gives a candy-shell finish in one pass. Rotate slowly for 10 min to avoid drips. -

Hydrographics—Camo Without Regret

Dip your part through a PVA film floating on 30 °C water. Mask off mating surfaces with green painter’s tape first. -

Cold Metallization—Chrome Without the Plating Plant

Spaz Stix mirror-chrome over gloss-black primer = automotive bling. Back with black to deepen reflectivity. -

Threaded Inserts—Functional Finish

Soldering-iron method: heat insert, press, wait 3 s. Brass inserts from McMaster-Carr survive 50+ torque cycles. -

Clear-Coat Armor

2K automotive clear (activated with hardener) beats rattle-can every time. Wear a cartridge respirator—isocyanates are nasty.

👉 Shop must-have FDM finishing tools on:

- Hakko Cutters: Amazon | Hakko Official

- XTC-3D: Amazon | Smooth-On Official

- Spaz Stix Chrome: Walmart | eBay

2️⃣ Mastering SLA Post-Processing: Cleaning, Curing, and Finishing Like a Pro

Wash It Like You Mean It

Formlabs found two-stage washing (dirty IPA → clean IPA) cuts residual resin to <0.1 %—critical for biocompatible parts.

We keep two pickle jars labeled “Dirty” and “Clean”; when clean turns milky, distill with a cheap water-distiller—IPA recycled, planet happy.

| Solvent | Flash Point | Resin Load | Notes |

|---|---|---|---|

| IPA | 12 °C | ~15 % max | Cheap, volatile |

| TPM | 47 °C | ~30 % | Safer, needs water rinse |

| Formlabs Wash | None | ~35 % | Non-flammable, 2× resin load |

Cure With Science

Under-cured = tacky; over-cured = brittle & yellow. Target 405 nm, 60 °C, 30 min for standard resins. Rigid resins need 60 min at 80 °C—check Formlabs’ open datasheet.

Support Removal Ballet

Snip supports after washing—they’re softer and less likely to fracture. Leave 0.2 mm nub, then shave with a fresh hobby blade.

Micro-Sanding Resin Without Murdering Details

Wet sand ONLY the support islands with 800–2000 grit. Mask surrounding geometry with blue painter’s tape to preserve crisp feathers on your 3D-printed mini owl.

Painting Resin—The Adhesion Secret

Resin has low surface energy; hit it with 70 % IPA wipe → 400 grit scuff → plastic-adhesion promoter (e.g., SEM Sand Free). Primer + paint now sticks like crazy.

👉 Shop SLA post-processing bundles on:

- Phrozen Wash & Cure Kit: Amazon | Phrozen Official

- Form Wash/Cure: Amazon | Formlabs Official

3️⃣ Advanced Post-Processing Hacks: Sanding, Painting, and Vapor Smoothing Secrets

The 12,000-Grit Mirror Finish

We once took a calibration cube to 12 k grit + Mothers Mag polish—it reflected like a smartphone screen. Totally unnecessary but Instagram gold.

Layer-Line Camouflage—Texture Trick

Instead of eliminating lines, embrace them: coat with ** textured spray paint** (e.g., Rust-Oleum Hammered)—hides sins in one pass.

Two-Color Vapor Fade

ABS part + acetone vapor + drop of RIT fabric dye in the jar = gradient smoke effect. Swirl gently for 10 s, then remove.

UV-Resistant Topcoats

Standard clear coats yellow under sunlight. UV-stable 2K urethane (e.g., SprayMax 3680061) keeps your outdoor cosplay prop shiny for 3+ years in direct sun.

The “Coffee” Weathering Hack

From the #featured-video: mix instant coffee + water → brush into crevices → wipe. Smells like Starbucks, looks like battle damage.

🎨 How to Choose the Right Finishing Materials and Tools for Your 3D Prints

| Finish Goal | Material | Brand We Trust | Why |

|---|---|---|---|

| Glass-clear | XTC-3D + 2K clear | Smooth-On + SprayMax | Deep pour + UV shield |

| Flexy feel | Plasti-Dip spray | Performix | Rubberized grip |

| Metallic bling | Rub’n’Buff | Amaco | Wax-based, finger apply |

| Heat resistance | Cerakote | NIC Industries | 1000 °F tolerant |

| Food-safe | Alumilite FDA epoxy | Alumilite | FDA 21 CFR compliant |

Rule of thumb: Match shore hardness—soft TPU parts hate brittle epoxy; they’ll crack under flex.

🔧 Troubleshooting Common Post-Processing Challenges and How to Fix Them

Problem: White film after IPA wash on resin

Cause: IPA saturated with resin → resin re-deposits

Fix: Two-stage wash, finish with fresh IPA + 10 % distilled water—breaks surface tension.

Problem: Primer crawls like dew on a leaf

Cause: Mold-release residue (even on hobby plastics)

Fix: Scrub with 90 % IPA + toothbrush → dry → adhesion promoter.

Problem: Vapor-smoothed ABS warps

Cause: Uneven acetone exposure

Fix: Rotate part every 5 min; use paper towel “donut” to suspend mid-air.

🌿 Eco-Friendly and Safe Post-Processing Practices You Should Adopt

- Recycle IPA by distilling with a water-distiller—yields 80 % recovery.

- Water-washable resins still contaminate water—cure waste under UV before trash.

- Replace IPA with bio-ethanol (denatured)—less toxic, similar solvency.

- Use PLA supports + PVA interface → compost supports, dissolve interface.

- Silicone mats under sanding station—collect dust → cure → trash—keeps micro-plastics out of drains.

💡 Insider Tips from 3D Printing Experts: Elevate Your Post-Processing Game

We polled 12 makers in our 3D Printed™ Discord—here are the golden nuggets:

- “Rotate your part under running water while sanding resin—you’ll see shiny spots disappear in real time.” – @MiniMyth

- “Stick a cheap UV nail-lamp inside a yogurt tub lined with foil—instant $10 cure box.” – @ResinRanger

- “Label your IPA jars with Sharpie + clear tape—ink won’t dissolve when IPA splashes.” – @ChemiCarl

🧰 Must-Have Post-Processing Tools and Accessories for Every 3D Printing Enthusiast

| Tool | Budget Pick | Pro Pick | Why You Need It |

|---|---|---|---|

| Rotary tool | Wen 2305 | Dremel 4000 | Sanding, polishing, cutting |

| Ultrasonic cleaner | Vevor 3 L | Branson 3800 | Resin washing on steroids |

| UV nail lamp | SUNUV 48 W | Form Cure | Cures small parts fast |

| Sandpaper assortment | 3M Wetordry | Mirka Gold | Grits 120–12 k in one box |

| Silicone mat | Dollar-store baking | Linus Tech Tips giant | Protects bench from chemicals |

👉 Shop starter kits on:

- WEN Rotary Tool: Amazon | Walmart | WEN Official

- Vevor Ultrasonic: Amazon | eBay

📚 Learn More About SLA and FDM Post-Processing: Resources and Tutorials

Hungry for deeper dives?

- Formlabs’ open-access resin database (link)—curves for every resin.

- Phrozen’s YouTube playlist on Sonic Mini 4K post-processing—short, snackable vids.

- Our own 3D Printable Objects archive—grab free STL files for calibration cubes, paint jigs, and curing racks (click here).

Still craving more? Check the FAQ and Reference Links below—your next rabbit hole awaits.

🎯 Conclusion: Perfecting Your 3D Prints with Expert Post-Processing

After diving deep into the world of 3D print post-processing, it’s clear that the magic truly happens after the print finishes. Whether you’re wielding an FDM workhorse or a high-res SLA resin wizard like the Phrozen Sonic Mini 4K, mastering post-processing transforms your raw prints from “meh” to museum-worthy.

From our experience at 3D Printed™, the biggest game-changers are:

- Thorough cleaning and curing for resin prints—don’t skip or skimp here, or your parts will be brittle or sticky.

- Smart sanding and vapor smoothing for FDM—layer lines don’t stand a chance.

- Choosing the right finishing materials—primer, paint, and clear coats tailored to your filament or resin type.

- Safety and eco-conscious workflows—your lungs and the planet will thank you.

If you’re using the Phrozen Sonic Mini 4K, the post-processing journey is straightforward but critical. The Phrozen Wash & Cure Kit is a solid companion, automating washing and curing with precision. We love how the Sonic Saber cutter makes support removal a breeze, but be gentle—the resin is still delicate post-wash. The only downside? You’ll need to invest time and patience to perfect sanding and painting, especially for complex models. But hey, that’s the fun part!

So, should you invest in advanced post-processing tools and techniques? Absolutely ✅. They not only elevate your prints aesthetically but also improve mechanical properties and longevity. Remember, a great print is only as good as its finish.

Ready to level up your post-processing game? Let’s get those prints shining!

🔗 Recommended Links for 3D Print Post-Processing Supplies and Guides

-

Phrozen Wash & Cure Kit:

Amazon | Phrozen Official Website | eBay -

Formlabs Form Wash & Form Cure:

Amazon | Formlabs Official Website -

Hakko Micro Cutters (Support Removal):

Amazon | Hakko Official Website -

XTC-3D Epoxy Coating:

Amazon | Smooth-On Official Website -

WEN Rotary Tool:

Amazon | WEN Official Website -

Books:

- 3D Printing Failures: How to Diagnose and Repair All 3D Printing Issues by Sean Aranda — Amazon link

- Mastering 3D Printing by Joan Horvath & Rich Cameron — Amazon link

❓ Frequently Asked Questions About 3D Print Post-Processing

What are the best methods for smoothing 3D printed parts?

Smoothing depends on your printing technology:

- For FDM prints, wet sanding with progressively finer grits (start ~400, finish at 2000+) is the gold standard. For ABS, acetone vapor smoothing creates a glossy, layer-line-free finish.

- For SLA resin prints, wet sanding of support marks combined with light polishing and clear coats works best. Avoid aggressive sanding that can remove fine details.

- For SLS prints, media tumbling or bead blasting smooths the surface without damaging geometry.

How do you remove support material from 3D prints effectively?

- FDM: Use flush cutters or needle-nose pliers to carefully snip supports. For soluble supports like PVA or HIPS, dissolve them in water or limonene respectively.

- SLA: Wait until after washing and partial curing; supports are softer and easier to snip with flush cutters or hobby knives.

- SLS: Supports are usually not needed, but excess powder is brushed or blown off.

What tools are essential for 3D print post-processing?

- Flush cutters or micro-cutters for support removal.

- Rotary tool (e.g., Dremel or WEN) for sanding, polishing, and trimming.

- Ultrasonic cleaner for efficient resin washing.

- UV curing station or nail lamp for resin post-curing.

- Sandpaper assortment (wet/dry, 400–12000 grit).

- Protective gear: nitrile gloves, respirator mask, and eye protection.

How can I improve the surface finish of my 3D printed models?

- Start with proper print settings to minimize layer lines.

- Use wet sanding to smooth surfaces progressively.

- Apply primer and filler to fill minor imperfections.

- For ABS, try acetone vapor smoothing for a glossy finish.

- Use epoxy coatings like XTC-3D for a glass-like surface.

- Finish with clear coats to protect and enhance shine.

What are the common post-processing techniques for resin prints?

- Washing in IPA or specialized solvents to remove uncured resin.

- Post-curing under UV light to harden and strengthen parts.

- Support removal after washing when parts are softer.

- Wet sanding of support scars and imperfections.

- Priming and painting with adhesion promoters for color.

- Optional polishing or coating for enhanced finish.

How do you paint and prime 3D printed objects?

- Clean the part thoroughly to remove oils and dust.

- Lightly sand to create a “tooth” for paint adhesion.

- Apply a plastic adhesion promoter or primer designed for plastics/resins.

- Use thin, multiple coats of acrylic or enamel paint.

- Finish with a clear coat for durability and UV protection.

What safety precautions should be taken during 3D print post-processing?

- Always wear nitrile gloves when handling resins, solvents, or acetone.

- Use a respirator mask when vapor smoothing or spraying paints.

- Work in a well-ventilated area or use fume extraction.

- Avoid skin contact with uncured resin and solvents.

- Keep flammable materials away from heat sources.

- Dispose of solvents and resin waste according to local regulations.

How do I handle resin waste safely?

- Cure leftover resin and cleaning waste under UV light to solidify it before disposal.

- Do not pour resin or IPA down the drain.

- Use dedicated containers for resin waste and solvents.

- Consider eco-friendly alternatives like water-washable resins.

📖 Reference Links and Further Reading

- Formlabs Post-Processing and Finishing SLA Prints

- Wevolver Ultimate Guide to 3D Printing Post-Processing Techniques

- Phrozen Sonic Mini 4K Post-Processing Guide

- Formlabs Official Website

- Phrozen Official Website

- Hakko Official Website

- Smooth-On Official Website

- NIC Industries Cerakote Coatings

- 3D Printed™ 3D Printable Objects Category

- 3D Printed™ 3D Printing Innovations Category