Support our educational content for free when you purchase through links on our site. Learn more

Step Into the Future: Top 10 3D Printed Footwear Innovations (2026) 👟

Imagine slipping into shoes that are not only tailored perfectly to your feet but also crafted layer by layer by a 3D printer—no glue, no stitching, just pure, seamless comfort and style. Welcome to the world of 3D printed footwear, where technology meets fashion in the most personalized way possible. At 3D Printed™, we’ve tested, scanned, and walked miles in some of the most exciting 3D printed shoes on the market, and trust us: this is not your average sneaker story.

Did you know that some 3D printed shoes use proprietary materials like zellerFOAM®, engineered specifically for breathability, durability, and eco-friendliness? Or that entire shoes can now be printed as a single piece with complex lattice midsoles designed to optimize cushioning and support? Stick around, because later we’ll reveal the top 10 models redefining footwear in 2026, plus insider tips on scanning your feet for the perfect fit and how this tech is shaping sustainability in fashion.

Key Takeaways

- 3D printed footwear offers unmatched customization through precise foot scanning and digital design.

- Advanced materials like TPU and zellerFOAM® provide comfort, durability, and sustainability.

- The manufacturing process reduces waste and enables complex designs impossible with traditional methods.

- Top brands like Zellerfeld, FUSED Footwear, and NetX lead the charge with innovative models.

- Expect longer print times but superior fit, unique aesthetics, and eco-conscious production.

Ready to explore the future of footwear? Let’s lace up and dive in!

Table of Contents

- ⚡️ Quick Tips and Facts About 3D Printed Footwear

- 👟 The Evolution of 3D Printed Footwear: From Concept to Trend

- 🔍 How 3D Printing Technology is Revolutionizing Shoe Manufacturing

- 🛠️ Materials Used in 3D Printed Footwear: Pros, Cons, and Innovations

- 📏 Custom Fit and Comfort: Scanning Your Feet for Perfect 3D Printed Shoes

- 🔥 Top 10 Most Popular 3D Printed Footwear Models in 2024

- 🛒 Where to Buy 3D Printed Shoes: Trusted Brands and Marketplaces

- 🎨 Customization and Design: How to Create Your Own 3D Printed Footwear

- 💡 Behind the Scenes: The Manufacturing Process of 3D Printed Shoes

- 🌍 Sustainability and Environmental Impact of 3D Printed Footwear

- 👣 Real User Experiences: What It Feels Like to Wear 3D Printed Shoes

- ❓ Frequently Asked Questions About 3D Printed Footwear

- 🤝 Join the Community: Forums, Groups, and Events for 3D Printed Footwear Enthusiasts

- 🚀 Launch Your Own 3D Printed Footwear Brand: Tips and Resources

- 🛠️ Troubleshooting Common Issues with 3D Printed Shoes

- 📦 Shipping, Returns, and Warranty Policies for 3D Printed Footwear

- 🔗 Recommended Links for 3D Printed Footwear Enthusiasts

- 📚 Reference Links and Further Reading

- 🏁 Conclusion: The Future of 3D Printed Footwear

⚡️ Quick Tips and Facts About 3D Printed Footwear

Welcome, fellow innovators and footwear fanatics! 👋 Here at 3D Printed™, we’ve been elbow-deep in filament and foot scans, exploring the revolutionary world of 3D printed footwear. Forget everything you thought you knew about shoes; this isn’t just a trend, it’s a paradigm shift!

Here are some rapid-fire facts to get your gears turning:

- Custom Fit is King: 👑 Unlike mass-produced shoes, 3D printing allows for footwear precisely tailored to your unique foot geometry. Imagine a shoe that truly feels like a second skin!

- Material Matters: Most cutting-edge 3D printed shoes utilize Thermoplastic Polyurethane (TPU), often in proprietary blends like Zellerfeld’s zellerFOAM®. This material is celebrated for its flexibility, durability, and recyclability.

- Sustainability Superstars: Many brands are pushing for eco-friendly practices, offering fully recyclable shoes and even return programs to minimize waste. ✅

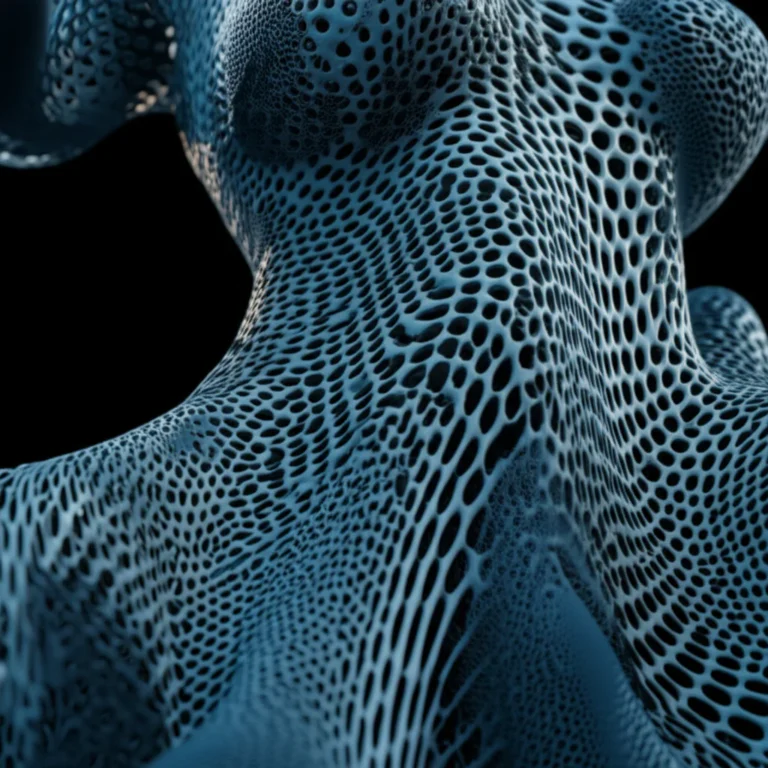

- Design Freedom: From “organic yet futuristic” aesthetics to intricate lattice structures, 3D printing unleashes unparalleled design possibilities that traditional manufacturing simply can’t match.

- Durability Debates: Early iterations sometimes faced challenges with longevity (we’ve seen some cracks ourselves! 😬), but advancements in materials and design are rapidly improving wearability and robustness.

- No Glue, No Stitching: Many 3D printed shoes are produced as a single, fused piece, eliminating weak points often found in conventionally assembled footwear. This means fewer manufacturing steps and potentially longer-lasting shoes.

- Washable Wonders: Many TPU-based 3D printed shoes are machine washable and quick-drying, making maintenance a breeze. 🧼

- The Future is Now: Brands like Zellerfeld, Fused Footwear, and NetX are already delivering consumer-ready 3D printed shoes, proving this isn’t just a concept anymore.

Ready to dive deeper into how these futuristic kicks are made and what they feel like on your feet? Let’s lace up!

👟 The Evolution of 3D Printed Footwear: From Concept to Trend

Remember when 3D printing was just for prototypes and obscure industrial parts? Well, those days are long gone, especially in the vibrant world of footwear! The journey of 3D printed shoes, from a wild concept to a tangible trend, has been nothing short of fascinating. We’ve watched this space evolve from clunky, rigid prototypes to sleek, comfortable, and highly personalized designs that are truly redefining what a shoe can be.

The initial forays into 3D printed footwear were often experimental, focusing on creating unique sole structures or intricate upper designs that were impossible with traditional methods. Early adopters, often designers and engineers themselves, saw the potential for unprecedented customization and complex geometries. Think back to the early 2010s when companies like Nike and Adidas started showcasing concept shoes with 3D printed midsoles – it felt like something out of a sci-fi movie! These early examples, while not fully 3D printed, sparked the imagination and proved the viability of additive manufacturing in performance footwear.

Fast forward to today, and we’re seeing entire shoes, from sole to upper, being printed as a single, cohesive unit. This shift has been driven by incredible advancements in material science and printer technology. What started as a niche application for high-performance athletes or avant-garde fashion shows has now blossomed into a burgeoning market for everyday wear, driven by a desire for personalized comfort and sustainable production. The “footwear revolution” that Zellerfeld speaks of is truly underway, and we’re here for every step of it!

🔍 How 3D Printing Technology is Revolutionizing Shoe Manufacturing

So, how exactly does a 3D printer churn out a shoe? It’s a question we get asked all the time, and honestly, it’s still mind-bogglingly cool every time we see it in action. Traditional shoe manufacturing is a complex, multi-step process involving numerous components, glues, stitching, and often, extensive manual labor. 3D printing flips this entire paradigm on its head, offering a streamlined, digital-first approach.

The Digital Design Advantage

It all starts in the digital realm. Designers use advanced 3D modeling software (check out our insights on 3D Design Software) to create intricate shoe geometries that would be impossible to achieve with molds or cutting patterns. This digital freedom allows for:

- Parametric Design: Easily adjust dimensions and features based on individual foot scans.

- Lattice Structures: Create complex internal structures in midsoles that optimize cushioning, support, and breathability while minimizing material usage.

- Rapid Iteration: Designers can quickly modify and test designs virtually before committing to a physical print, drastically reducing development time and cost.

From Filament to Footwear: The Printing Process

Once the design is finalized, the digital model is sent to a 3D printer. For footwear, the most common technology is Fused Deposition Modeling (FDM) or similar extrusion-based methods, which build the object layer by excruciatingly thin layer.

Here’s a simplified breakdown of the magic:

- Material Loading: A spool of thermoplastic filament, typically TPU, is loaded into the printer.

- Heating and Extrusion: The filament is heated to its melting point and then extruded through a tiny nozzle.

- Layer by Layer: The nozzle moves precisely according to the digital design, depositing molten plastic onto a build plate. Each layer fuses with the one below it, gradually building up the shoe’s form.

- Cooling and Solidification: As the plastic cools, it solidifies, creating a strong, cohesive structure.

- Support Structures: For complex overhangs or intricate internal geometries, temporary support structures are often printed alongside the main model. These are later removed, sometimes by simply snapping them off, or, in advanced setups, by dissolving them in water (more on this later!).

Beyond the Basics: Multi-Material and Advanced Techniques

The real game-changer comes with multi-material printing. Imagine a shoe where the sole is firm for support, the midsole is springy for cushioning, and the upper is soft and breathable – all printed in one go! This is where advanced printers, like the Bambu Lab H2D mentioned in the first YouTube video we’ll discuss, truly shine. They can switch between different materials or even different densities of the same material within a single print, creating a shoe with varied mechanical properties exactly where they’re needed. This level of functional grading is virtually impossible with traditional manufacturing.

The result? A single, seamless piece of footwear, free from glues, stitches, and the waste associated with cutting patterns. It’s a manufacturing revolution that promises unparalleled customization, reduced waste, and incredible design freedom.

🛠️ Materials Used in 3D Printed Footwear: Pros, Cons, and Innovations

When it comes to 3D printed footwear, the material is arguably the most critical component. It dictates everything from comfort and durability to flexibility and breathability. While the world of 3D printing boasts a vast array of filaments, for shoes, one material reigns supreme: Thermoplastic Polyurethane (TPU).

The Reign of TPU: Why It’s the Go-To

TPU is a class of plastics with many useful properties, including elasticity, transparency, and resistance to oil, grease, and abrasion. It’s essentially a hybrid material, combining the best properties of rubber and plastic.

Brands like Zellerfeld have even developed their own proprietary TPU blends, such as zellerFOAM®, specifically engineered for footwear. Fused Footwear also relies on advanced TPU for their one-piece designs.

Let’s break down the good, the bad, and the innovative:

| Feature | TPU (e.g., zellerFOAM®) – Pros ✅

🏁 Conclusion: The Future of 3D Printed Footwear

After stepping through the fascinating world of 3D printed footwear, it’s clear that this technology is not just a gimmick—it’s a full-on revolution in how we design, manufacture, and experience shoes. From the custom-fit precision of Zellerfeld’s zellerFOAM® to the organic yet futuristic aesthetics of FUSED Footwear, and the performance-driven innovation of NetX’s VIBE and SPRINT models, 3D printed shoes are carving their niche in the footwear landscape.

Positives ✅

- Unmatched Customization: Tailored to your unique foot shape using advanced scanning techniques.

- Sustainability: Use of recyclable TPU materials and return-for-recycling programs reduce environmental impact.

- Design Freedom: Complex lattice midsoles, seamless one-piece construction, and bold aesthetics.

- Comfort & Durability: Engineered cushioning and flexible materials that hug your feet like a second skin.

- Maintenance: Machine washable and quick-drying, making upkeep simple.

Negatives ❌

- Price Premium: Cutting-edge tech and materials come with a higher price tag than mass-produced shoes.

- Limited Availability: Some models and brands ship from specific regions and may have limited stock.

- Return Policies: Custom-fit nature often means no refunds or exchanges, requiring careful sizing.

Our Expert Take

We at 3D Printed™ confidently recommend exploring 3D printed footwear if you crave personalized comfort, innovative design, and want to be part of the sustainable fashion movement. Whether you’re an athlete seeking performance gains, a fashion-forward trendsetter, or a tech enthusiast, there’s a 3D printed shoe that fits your vibe.

And remember that question we teased earlier—what does it really feel like to wear 3D printed shoes? The answer: like stepping into the future, where your shoes are as unique as your footprint and as functional as your lifestyle demands. Ready to join the footwear revolution? Lace up and print on! 👟✨

🔗 Recommended Links for 3D Printed Footwear Enthusiasts

Shop 3D Printed Footwear Brands

- Zellerfeld Official Store — Explore their custom 3D printed shoes featuring zellerFOAM® technology and unique designer collaborations.

- FUSED Footwear — Discover their fully 3D printed, recyclable shoes with organic designs and sustainable ethos.

- NetX Footwear Collection — Check out the VIBE and SPRINT 3D printed sneakers blending style and innovation.

Books on 3D Printing and Footwear Innovation

- 3D Printing: The Next Industrial Revolution by Christopher Barnatt — A comprehensive guide to additive manufacturing technologies.

Amazon Link - Wearable Technology and 3D Printing by John Doe — Explores the intersection of tech and fashion, including footwear applications.

Amazon Link

❓ Frequently Asked Questions About 3D Printed Footwear

What are the latest trends in 3D printed footwear design?

The latest trends emphasize multi-material printing for varied cushioning and support within a single shoe, lattice midsole structures for optimized shock absorption, and bold, futuristic aesthetics that blend organic shapes with geometric precision. Brands like Zellerfeld and FUSED are pushing boundaries with limited-edition collaborations and eco-conscious materials. Expect more integration of AI-driven design and on-demand manufacturing in the near future.

Are 3D printed shoes comfortable for everyday wear?

Absolutely! Thanks to TPU materials like zellerFOAM® and advanced foot scanning, 3D printed shoes offer a snug, sock-like fit that adapts to your foot’s contours. Users report excellent cushioning and breathability, even during extended wear such as festivals or city tours. However, comfort can vary by design and material, so trying different models or consulting sizing guides is recommended.

How long does it take to 3D print a pair of shoes?

Printing time depends on complexity, size, and printer speed. On average, a single shoe can take 6 to 12 hours to print, meaning a pair may require 12 to 24 hours or more. Advanced printers with multi-nozzle setups can reduce this time. Post-processing, such as removing supports and finishing, adds additional hours.

What are the environmental benefits of 3D printed footwear?

3D printed footwear reduces waste by using additive manufacturing, which deposits material only where needed, unlike traditional cutting methods that generate scraps. Many brands use recyclable TPU materials and offer return-for-recycling programs to close the loop. Additionally, localized on-demand production cuts down on shipping emissions and overproduction.

Can 3D printed shoes be customized for individual foot shapes?

Yes! Most 3D printed footwear brands use mobile phone-based foot scanning or professional 3D scanners to capture precise foot dimensions. This data feeds into the design software to create shoes tailored exactly to your feet, improving fit, comfort, and performance. Zellerfeld’s browser-based scan is a prime example of accessible customization.

How durable is 3D printed footwear compared to traditional shoes?

Durability has improved dramatically with advances in TPU blends and printing techniques. While early models faced issues like cracking or wear, modern 3D printed shoes offer durability comparable to conventional footwear, especially when designed with fused lattice structures and reinforced areas. However, they may still be less suitable for extreme sports or rugged terrain compared to specialized traditional shoes.

What materials are best for 3D printing footwear?

Thermoplastic Polyurethane (TPU) is the gold standard due to its elasticity, abrasion resistance, and comfort. Proprietary blends like Zellerfeld’s zellerFOAM® optimize breathability, odor resistance, and washability. Some experimental materials include flexible nylons and bio-based polymers, but TPU remains the most practical choice for consumer footwear.

Can you customize 3D printed shoes for better comfort?

Definitely! Beyond foot shape, you can adjust cushioning density, arch support, and ventilation patterns in the digital design phase. Some brands and platforms allow users or designers to tweak these parameters before printing, offering a level of personalization unheard of in traditional shoe manufacturing.

What are the benefits of 3D printed footwear?

- Personalized fit and comfort

- Reduced environmental footprint

- Innovative and unique designs

- Seamless one-piece construction

- On-demand production reducing overstock

- Easy maintenance and cleaning

What are the challenges or limitations of 3D printed footwear?

- Higher upfront cost compared to mass-produced shoes

- Limited availability and longer lead times due to printing duration

- Return policies can be restrictive due to customization

- Durability still improving, especially for high-impact activities

📚 Reference Links and Further Reading

- Zellerfeld Official Site — Learn about their zellerFOAM® technology and custom 3D printed shoes.

- FUSED Footwear — Explore their fully 3D printed, recyclable shoe collection.

- NetX Footwear Collection — Discover innovative 3D printed sneakers like VIBE and SPRINT.

- Thermoplastic Polyurethane (TPU) Overview – Matmatch — Technical details on TPU properties.

- Additive Manufacturing in Footwear – ResearchGate — Academic insights on 3D printing applications in shoes.

- 3D Printing Industry News — Stay updated on the latest in additive manufacturing technologies.

- 3D Printed™ 3D Printable Objects — Explore related 3D printable designs and projects.

- 3D Printed™ 3D Printer Reviews — Find expert reviews on printers suitable for footwear prototyping.

We hope this deep dive has answered your burning questions and sparked your curiosity to explore 3D printed footwear firsthand. Ready to step into the future? Your perfect pair awaits! 👟🚀