Support our educational content for free when you purchase through links on our site. Learn more

9 Game-Changing Ways 3D Printing is Revolutionizing Fashion Design (2026) 👗✨

Imagine slipping on a dress that’s been printed layer by layer, perfectly tailored to your body, with intricate details no fabric could ever achieve. Sounds like sci-fi? Not anymore. Welcome to the dazzling world of 3D printing in fashion design, where technology and creativity collide to reshape how we think about clothing, accessories, and even footwear. From the runway to your closet, 3D printing is unlocking design possibilities that were once impossible — and we’re here to guide you through every twist and turn of this thrilling revolution.

In this article, we’ll unravel the history, technology, and materials behind 3D printed fashion, explore the pioneers pushing boundaries, and reveal the challenges still standing between us and a fully printed wardrobe. Curious about how Adidas’s futuristic sneakers are made or how designers are printing directly onto leather? Or maybe you want to know what flexible filaments feel like against your skin? Stick with us — the future of fashion is layered, textured, and waiting to be discovered.

Key Takeaways

- 3D printing offers unprecedented design freedom, enabling complex geometries and customizable, body-scanned garments.

- Rapid prototyping accelerates the fashion cycle, allowing designers to iterate and innovate faster than ever.

- Sustainability is a major benefit, with additive manufacturing drastically reducing fabric waste and enabling on-demand production.

- Material innovation is key, from flexible TPU filaments to experimental bioprinting and hybrid textiles.

- Challenges remain, including high costs, scalability issues, and the quest for comfort comparable to traditional fabrics.

- Industry leaders like Iris van Herpen and Adidas are pioneering new frontiers, blending art, technology, and performance.

- The future points to democratized DIY fashion printing and exciting digital-physical crossover in the metaverse.

Ready to dive deeper into the tech, trends, and trailblazers shaping 3D printed fashion? Let’s get started!

Table of Contents

- ⚡️ Quick Tips and Facts: Your Fast Track to Fashion’s Future

- 👗 The Threads of Innovation: A Brief History of 3D Printing in Fashion

- ⚙️ Unpacking the Tech: How Additive Manufacturing Weaves into Apparel Design

- 🌟 The Runway Revolution: How 3D Printing is Redefining Fashion Design

- 1. Unleashing Creativity: Design Freedom and Complex Geometries

- 2. Rapid Prototyping & Iteration: Speeding Up the Design Cycle

- 3. Customization & Personalization: Tailoring to Every Body and Style

- 4. Sustainable Fashion & On-Demand Production: A Greener Wardrobe

- 5. Wearable Technology & Smart Textiles: Fashion That Does More

- 6. Haute Couture & Avant-Garde Creations: Pushing Artistic Boundaries

- 7. Footwear Innovation: From Sneakers to Statement Heels

- 8. Accessories & Jewelry: Crafting Unique Adornments

- 9. Textile & Fabric Reinvention: Beyond Traditional Weaves

- 🌈 Materials Matter: What Can We Print Our Dreams With?

- 🚧 Roadblocks & Runways: Challenges and Limitations in Fashion 3D Printing

- 🛠️ The Designer’s Toolkit: Essential Software and Hardware for Fashionistas

- 🏆 Who’s Leading the Trend? Key Brands and Innovators in Fashion 3D Printing

- 🔮 The Crystal Ball: What’s Next for 3D Printing in the Fashion Industry?

- ✨ Conclusion: Stitching the Future of Style

- 🔗 Recommended Links: Dive Deeper into Fashion Tech

- ❓ FAQ: Your Burning Questions About 3D Printed Fashion Answered

- 📚 Reference Links: Our Sources for Fashion-Forward Insights

Here at 3D Printed™, we’ve seen it all. From tiny tabletop dragons to full-scale rocket engine parts, we live and breathe additive manufacturing. But let me tell you, few things get our gears turning like the collision of high-tech and high fashion. Forget sewing machines and pattern paper for a moment. We’re talking about garments and accessories literally materializing out of thin air, layer by intricate layer.

Is this sci-fi? Nope. It’s the electrifying reality of 3D printing in fashion design, and it’s changing the game faster than a runway model’s outfit change. So, grab your spools of filament, and let’s unravel the threads of this incredible revolution together!

⚡️ Quick Tips and Facts: Your Fast Track to Fashion’s Future

Pressed for time? Here’s the haute couture of what you need to know, served up fast.

- It’s Not Just Plastic: While plastics are common, designers are using everything from flexible, rubber-like materials (TPU) to metal powders and even biodegradable filaments. The material palette is exploding!

- Zero-Waste Potential: Traditional fashion can waste up to 30% of fabric during the cutting process. 3D printing is additive, meaning it only uses the material needed for the final product. ✅

- Hyper-Personalization is Here: Imagine a dress printed to your exact body scan. Brands like Adidas are already using 3D printing for custom-fit sneaker midsoles.

- Speedy Prototyping: A fashion house can design a complex accessory in the morning, print a prototype by lunch, and make revisions by the evening. This drastically cuts down the design-to-runway timeline.

- Key Tech Lingo: The big three technologies you’ll hear about are FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering). We’ll break these down later, don’t you worry!

- Pioneering Spirit: Designer Iris van Herpen is widely considered the godmother of 3D printed couture, showcasing her first 3D printed pieces back in 2010.

👗 The Threads of Innovation: A Brief History of 3D Printing in Fashion

To understand where we’re going, we need to see where we’ve been. 3D printing, or additive manufacturing, wasn’t born on a catwalk. It started in the 1980s with industrial prototyping. For decades, it was the secret weapon of engineers and product designers, a way to create rough models quickly. It was functional, not fashionable.

Then, something shifted. As the technology became more refined and accessible, artists and designers began to ask, “What if?”

The real turning point for fashion came in the 2010s. This is when the technology matured enough to produce objects with the detail and complexity that fashion demands. The aforementioned Iris van Herpen, in collaboration with architect Daniel Widrig, sent jaws to the floor with her “Crystallization” collection. It was the first time a fully 3D printed garment graced a Paris Haute Couture Week runway, and the industry has never been the same.

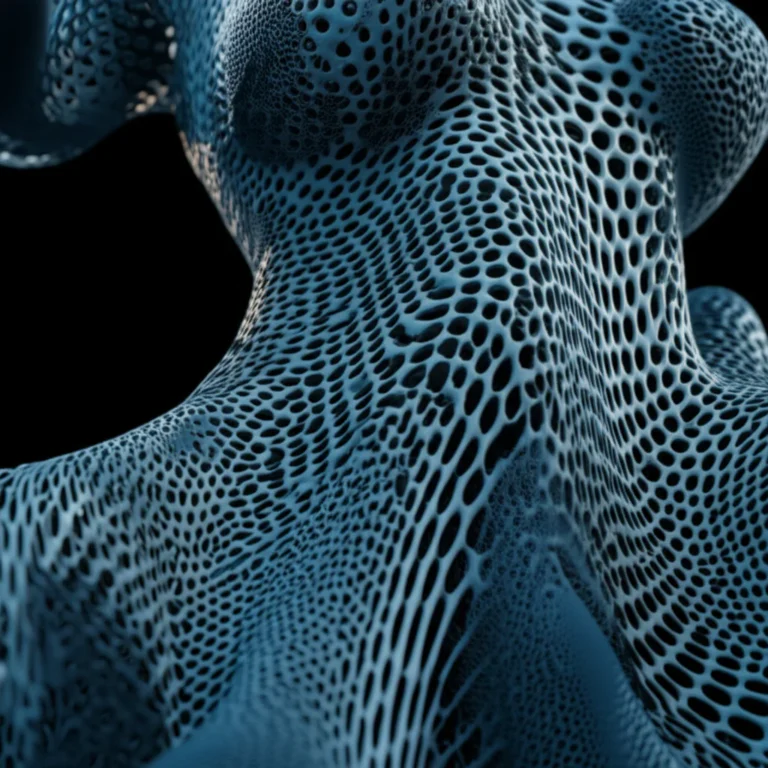

Suddenly, the rigid rules of fabric—how it drapes, how it’s cut, how it’s stitched—were thrown out the window. Designers could now create geometric structures, intricate lattices, and organic forms that looked more like sculpture than clothing. This wasn’t just a new tool; it was a whole new medium for artistic expression, a key part of the ongoing story of 3D Printing Innovations.

⚙️ Unpacking the Tech: How Additive Manufacturing Weaves into Apparel Design

Alright, let’s pop the hood. How does a digital file become a dazzling dress? It all comes down to a few core technologies. While they all build objects layer by layer, they go about it in very different ways. Think of them as different types of stitches for the digital age.

FDM, SLA, SLS: The Core Technologies Shaping Fashion

Here at the 3D Printed™ lab, we have printers of every flavor, and each one is a specialist. Choosing the right one is crucial for a fashion project.

| Technology | How it Works ⚙️ | Best for in Fashion 👠 | Pros ✅ | Cons ❌ |

|---|---|---|---|---|

| FDM (Fused Deposition Modeling) | Melts and extrudes a plastic filament (like a hot glue gun) layer by layer. | Rapid prototypes, bold accessories, printing directly onto fabric, flexible wearables using TPU. | Most affordable, wide range of colors & materials (especially flexibles). | Visible layer lines, less detail than other methods. |

| SLA (Stereolithography) | Uses a UV laser to cure liquid resin into a solid object, layer by layer. | High-detail jewelry, intricate embellishments, smooth-surfaced prototypes, transparent components. | Incredible detail and smooth finish, great for complex shapes. | Resins can be brittle, post-processing (washing & curing) required. |

| SLS (Selective Laser Sintering) | A high-powered laser fuses powdered material (like nylon) together, layer by layer. | Durable final products, complex interlocking parts (like chainmail), shoe midsoles, eyewear frames. | Strong, durable parts; no support structures needed, allowing for immense design freedom. | Expensive machinery, materials can be limited and costly. |

As the folks at Tomorrow.bio point out, FDM is great for “wearable accessories with flexible filaments,” while SLS produces “durable, lightweight parts like shoe soles.” It’s all about matching the tech to the textile dream.

From Digital Design to Tangible Textile: The Workflow Explained

So, you have an idea for a mind-bending piece of wearable art. How do you bring it to life?

- Digital Sculpting (The Dream Phase): It all starts in the computer. Using 3D Design Software like Blender, ZBrush, or fashion-specific programs like CLO3D, you create a 3D model of your design. This is where you define every curve, every texture, every impossible angle.

- Slicing (The Blueprint Phase): You then export this model as a file (usually an .STL or .OBJ). This file is fed into a “slicer” program. The slicer, true to its name, digitally cuts the model into hundreds or thousands of thin horizontal layers and generates the code (G-code) that tells the 3D printer exactly how to move.

- Printing (The Magic Phase): You load your chosen material—be it a spool of flexible TPU filament or a vat of liquid resin—and hit “print.” The printer then meticulously builds your design, one layer at a time. This can take anywhere from a few hours for a small bracelet to several days for a full bodice.

- Post-Processing (The Finishing Touch): The job isn’t done when the printer stops! This step can involve removing support structures, washing and curing resin prints, sanding, polishing, or dyeing the final piece to achieve the desired look and feel.

🌟 The Runway Revolution: How 3D Printing is Redefining Fashion Design

This isn’t just a gimmick for a few avant-garde runway shows. Additive manufacturing is fundamentally altering the DNA of the fashion industry in at least nine powerful ways.

1. Unleashing Creativity: Design Freedom and Complex Geometries

Traditional manufacturing is subtractive (cutting from a block of material) or formative (weaving, knitting). Both have limitations. 3D printing is additive, which means if you can design it on a computer, you can probably create it. Intricate lattices, impossible overhangs, interlocking spirals—designs that would give a traditional tailor nightmares are now possible. As Stratasys notes, “3D printing in fashion design offers a new realm of creative possibilities, transforming how designers approach material and form.”

2. Rapid Prototyping & Iteration: Speeding Up the Design Cycle

In the old world, creating a prototype for a complex handbag or shoe could take weeks of skilled labor. Now? A designer can print a scale model or even a full-size prototype overnight. This allows for rapid iteration. Don’t like the curve of that heel? Tweak the design and print it again tomorrow. This agility is a massive competitive advantage.

3. Customization & Personalization: Tailoring to Every Body and Style

This is one of the most exciting frontiers. Mass production gave us standardized sizes (S, M, L), which fit almost no one perfectly. 3D printing allows for true mass customization.

- Perfect Fit: By using a 3D body scan, a garment can be printed to a person’s exact measurements. Estel Vilaseca, quoted by FashionUnited, puts it perfectly: “3D fashion will allow us to create very diverse and specific designs for each body without so much work.”

- Bespoke Style: Want your name integrated into the pattern of your sunglasses? Or a specific texture on your phone case? 3D printing makes this level of personalization not just possible, but scalable.

4. Sustainable Fashion & On-Demand Production: A Greener Wardrobe

The fashion industry has a massive waste problem. 3D printing offers a powerful solution through two main avenues:

- Reduced Material Waste: As mentioned, additive manufacturing is incredibly efficient. There are no leftover scraps of fabric on the cutting room floor.

- On-Demand Production: Brands can shift from producing thousands of items in anticipation of sales to printing items only after they’ve been ordered. This eliminates overstock, which often ends up in landfills. FashionUnited highlights the vision of circularity where “recycled clothing feeding 3D printers” could become a reality.

5. Wearable Technology & Smart Textiles

3D printing is the perfect partner for wearable tech. It allows for the creation of custom housings for sensors, lights, and electronics that can be seamlessly integrated into a garment. Designer Anouk Wipprecht’s “Spider Dress” is a famous example, featuring robotic arms that react to the wearer’s personal space. This is fashion that sees, feels, and reacts.

6. Haute Couture & Avant-Garde Creations: Pushing Artistic Boundaries

For the world of high fashion, 3D printing is a playground. It’s where the most experimental and boundary-pushing ideas come to life. From the ethereal, skeletal structures of Iris van Herpen to Balenciaga’s armour-like dress made of galvanized resin, 3D printing allows designers to create wearable sculptures that challenge our very definition of clothing.

7. Footwear Innovation: From Sneakers to Statement Heels

Footwear is arguably where 3D printing has made its biggest commercial splash. The complex geometry of a supportive midsole is a perfect application for the technology.

- Adidas’s Futurecraft 4D: The lattice midsole, created with Carbon’s DLS technology, is tuned for cushioning and stability. It’s a prime example of mass-produced, high-performance 3D printing.

- Nike & New Balance: As FashionUnited reports, these giants are also heavily invested, using 3D printing for everything from rapid prototyping their Flyknit line to creating laser-sintered midsoles for a precise fit in shoes like the Zante Generate.

8. Accessories & Jewelry: Crafting Unique Adornments

Accessories are often the entry point for designers and consumers into the world of 3D printed fashion. The smaller scale and rigid material requirements are a great fit for desktop FDM and SLA printers. You can find an incredible variety of 3D printed earrings, necklaces, glasses frames, and more on platforms like Etsy. This is a fantastic category of 3D Printable Objects that you can explore right now.

9. Textile & Fabric Reinvention: Beyond Traditional Weaves

Perhaps the most mind-bending application is not just creating solid objects, but creating new fabrics. By printing tiny, interlocking structures, designers can create textiles with unique properties of drape, flexibility, and texture. It’s like weaving on a microscopic level. Some designers are even printing directly onto traditional fabrics like tulle or leather to create hybrid materials with unprecedented looks and feels.

🌈 Materials Matter: What Can We Print Our Dreams With?

A design is nothing without the right material. In the early days, options were limited to hard, brittle plastics. Not exactly comfy. But today, the material science is catching up to the design ambition.

Flexible Filaments & Resins: TPU, TPE, and Beyond

This was the game-changer. The development of flexible materials made truly wearable 3D printed fashion a reality.

| Material | Type | Key Properties | Feels Like… | Best For |

|---|---|---|---|---|

| TPU (Thermoplastic Polyurethane) | FDM Filament | Very flexible, durable, rubber-like, abrasion resistant. | A tough, flexible phone case or a watch strap. | Shoe soles, living hinges, watch bands, flexible garments. |

| TPE (Thermoplastic Elastomer) | FDM Filament | Softer and stretchier than TPU, more elastic. | A rubber band or a soft shoe insole. | Very soft, stretchy applications where comfort is key. |

| Flexible Resin | SLA Resin | Can be engineered for specific levels of flexibility and rebound. | A firm silicone or hard rubber. | Prototyping flexible parts with high detail, custom grips. |

| Nylon (PA11/PA12) | SLS Powder | Strong, durable, and has good flexibility when printed thin. | A high-quality, sturdy plastic with a slightly grainy texture. | Interlocking parts (chainmail), eyewear, durable components. |

Bioprinting & Sustainable Materials: The Future of Fabric?

The eco-friendly potential is huge. Researchers and companies are developing filaments made from recycled plastics, wood pulp, and even algae. The ultimate dream? Bioprinting fabrics from living cells, creating materials that could potentially grow, self-repair, or biodegrade on command. While still largely in the research phase, it points to a future where our clothes are as sustainable as they are stylish.

Hybrid Materials & Multi-Material Printing: Mixing it Up

Why stick to one material? Advanced 3D printers, like Stratasys’s PolyJet machines, can print with multiple materials and colors in a single job. This allows a designer to create an object with rigid sections, flexible joints, and transparent windows all in one go. This is how you can create a shoe with a tough sole, a flexible upper, and a clear logo, all printed as a single piece.

🚧 Roadblocks & Runways: Challenges and Limitations in Fashion 3D Printing

As much as we love this technology, we have to be realists. It’s not all glamour and glitz just yet. There are significant hurdles to overcome before you’re printing your Saturday night outfit at home.

Cost of Entry: Is High Fashion Always High Price?

While a hobbyist FDM printer can be surprisingly affordable, the industrial machines (especially SLS and PolyJet) used for high-end fashion cost a fortune. The materials can also be expensive. This currently keeps the most advanced techniques in the hands of luxury brands and well-funded design studios. However, as Tomorrow.bio rightly predicts, costs are “anticipated to decrease as technology advances.”

Scalability & Production Speed: From Prototype to Mass Market

3D printing a single, complex dress can take hundreds of hours. This is fine for a one-off couture piece but impossible for mass-market production. While companies like Adidas have proven scalability for smaller components, printing entire garments at the speed of traditional manufacturing is still a long way off. ❌

Material Properties & Comfort: Wearability Woes?

Let’s be honest: wearing plastic doesn’t sound appealing. While flexible materials have come a long way, they still don’t have the breathability, drape, or softness of cotton, silk, or wool. A lot of current “3D printed fashion” is more like wearable art or armor than everyday clothing. Cracking the code on comfort and feel is the holy grail for material scientists in this space.

Design Complexity & Software Learning Curve: A Designer’s Dilemma

Designing for 3D printing requires a completely different skillset than traditional pattern making. Fashion designers need to become proficient in complex CAD software, a field typically reserved for engineers and architects. This technical barrier is why collaboration is so key. Many of the most successful projects are partnerships between a fashion designer with the vision and a 3D printing expert with the technical know-how. This is a challenge that can be addressed through better 3D Printing in Education.

🛠️ The Designer’s Toolkit: Essential Software and Hardware for Fashionistas

Ready to dip your toes into the digital design pool? Here’s the gear you’ll need to get started.

CAD Software for Fashion: Blender, ZBrush, CLO3D, and More

- Blender: A powerhouse of 3D creation, and it’s completely free! It has a steep learning curve but is incredibly versatile for sculpting organic shapes and complex patterns. ✅

- ZBrush: The industry standard for digital sculpting. It’s like working with digital clay, perfect for creating detailed textures and intricate jewelry.

- CLO3D: This software is specifically for fashion design. It allows you to design patterns in 2D and see them simulated on a 3D avatar in real-time, providing a bridge between traditional and digital design.

- Rhino: Excellent for precision modeling, often used for accessories, eyewear, and the technical components of footwear.

Printer Powerhouses: From Desktop to Industrial Giants

The right printer depends entirely on your ambition and budget. Our team has run prints on just about everything, and here’s the breakdown.

- Desktop FDM Printers: For beginners and accessory designers, these are fantastic. Brands like Prusa, Bambu Lab, and Creality offer incredible value and are perfect for experimenting with flexible TPU filaments. Check out our 3D Printer Reviews for in-depth guides.

- Desktop SLA Printers: If you’re focused on high-detail jewelry or small, intricate components, a resin printer from a brand like Elegoo or Anycubic is your best bet. The level of detail is simply stunning.

- Industrial Machines: For the big leagues—full garments, high-performance footwear, and multi-material prints—you’re looking at machines from giants like Stratasys, 3D Systems, and Carbon. These are the Ferraris of the 3D printing world.

👉 Shop 3D Printers for Fashion Exploration on:

- Bambu Lab A1 Mini: Bambu Lab Official | MatterHackers

- Prusa MK4: Prusa Official Website

- Elegoo Mars 4 Ultra (SLA): Amazon | Elegoo Official Website

🏆 Who’s Leading the Trend? Key Brands and Innovators in Fashion 3D Printing

This revolution is being led by a handful of fearless pioneers. These are the names to watch.

Iris van Herpen: The Queen of Couture and Code

You can’t talk about 3D printed fashion without starting here. Her work is a breathtaking fusion of nature, technology, and art. She collaborates with architects and scientists to create collections that mimic everything from water ripples to magnetic fields. Her pieces are fixtures in museums like the Met and prove that 3D printed garments can be true works of art.

Adidas & Nike: Stepping Up Their Game with 3D Printed Footwear

These sportswear titans are using 3D printing not just for show, but for performance. By printing midsoles, they can create structures that provide cushioning and support precisely where an athlete needs it, tuned to their weight and gait. The Adidas Futurecraft 4D is the most visible example, but both companies use additive manufacturing extensively for prototyping, allowing them to test dozens of new designs in the time it used to take to create one.

Emerging Designers & Startups: The Next Generation of Fashion Tech

The most exciting work often happens on the cutting edge, away from the big brands. Designers like Julia Koerner (who has collaborated with Adidas and on costumes for the movie Black Panther) and Anouk Wipprecht are constantly pushing the boundaries.

A fantastic example of this innovative spirit is the work of Sophie Wong, whose “textile explorations” we’ve been following closely. As seen in the featured video, she’s not just printing objects to be worn; she’s printing onto and into existing materials to create entirely new hybrid textiles.

- Printing on Fabric: Sophie prints hexagonal PLA panels directly onto leather and other fabrics, sandwiching a nylon mesh inside the print to create flexible, armor-like embellishments.

- Imbuing Material with Behavior: Her “Wizards Voodoo” dress uses panels of varying sizes to control the garment’s drape and structure. As Sophie herself says, “As a designer, it’s really exciting because I get to imbue the material with behavioral qualities that wouldn’t otherwise be there. I get to completely control how that material works.”

- Integrated Tech: She seamlessly integrates RGB LEDs into her creations, using the 3D printed parts as light diffusers. On her custom leather jacket, she explains, “I wanted to take advantage of the fact that it’s a clear PLA material, so I’m using these as light diffusion. So this jacket actually lights up.”

Sophie’s iterative, hands-on approach—printing countless small samples to test flexibility and form—is exactly how this field moves forward. It’s this kind of experimentation that leads to breakthroughs. As Adam Savage reflects in the video, when designers learn to do things with tools that “you couldn’t do any other way… That’s a really exciting space.”

🔮 The Crystal Ball: What’s Next for 3D Printing in the Fashion Industry?

So, what does the future hold? Is everyone going to have a 3D printer in their closet next to their iron? Maybe not next year, but the trend lines are clear.

Democratizing Design: The Rise of DIY Fashion Printing

As printers get cheaper and software gets more user-friendly, we’ll see more and more independent creators designing and selling their own unique accessories and apparel. Imagine downloading a design file for a pair of earrings from your favorite indie designer and printing them at home in any color you want. This is the future of personalized, decentralized fashion.

Beyond the Garment: 3D Printing for Retail and Merchandising

The applications don’t stop at the clothes themselves. Retailers can use 3D printing to create stunning, custom mannequins, unique store displays, and promotional items on-demand. This allows for more dynamic and engaging retail experiences that can be changed and updated quickly.

The Metaverse & Digital Fashion: Bridging Real and Virtual Worlds

The same 3D files used to print a physical garment can be used to dress an avatar in the metaverse. This creates a fascinating link between our physical and digital identities. Brands are already exploring “phygital” items—where purchasing a real-world 3D printed sneaker also unlocks the digital version for your online avatar. This is a whole new frontier for 3D Printing Innovations and a wild ride we’re excited to be on. But what does this all mean for the clothes in your closet right now? Well, that’s the billion-dollar question…

✨ Conclusion: Stitching the Future of Style

We’ve journeyed through the dazzling world where digital dreams meet fabric and filament. From the early days of rigid plastic prototypes to the breathtakingly intricate, flexible, and sustainable garments of today, 3D printing is no longer a fringe experiment—it’s a game-changer for fashion design.

Yes, there are hurdles: the cost of industrial printers, the challenge of matching fabric comfort, and the steep learning curve for designers. But the benefits—unparalleled design freedom, rapid prototyping, hyper-personalization, and sustainability—are too compelling to ignore. As pioneers like Iris van Herpen and brands like Adidas and Nike show us, the future is already here, woven with layers of innovation.

Remember Sophie Wong’s hybrid textile experiments? They remind us that this technology is still evolving, and the most exciting breakthroughs often come from fearless experimentation. Soon, the line between art, fashion, and technology will blur even further, and maybe one day, your next outfit will print itself at home, perfectly tailored to your body and style.

So, whether you’re a designer, a tech enthusiast, or a fashion lover curious about the next big thing, 3D printing in fashion is a runway worth watching—and maybe even walking.

🔗 Recommended Links: Dive Deeper into Fashion Tech

Ready to explore or shop some of the incredible 3D printing tools and fashion innovations we talked about? Here’s your curated list:

3D Printers for Fashion Design:

-

Bambu Lab A1 Mini:

Bambu Lab Official Website | MatterHackers -

Prusa MK4:

Prusa Official Website -

Elegoo Mars 4 Ultra (SLA):

Amazon | Elegoo Official Website

Books to Deepen Your Fashion & 3D Printing Knowledge:

- 3D Printing in Fashion and Textiles: A Practical Guide by Deepak M. Kalaskar — Amazon Link

- Fabricated: The New World of 3D Printing by Hod Lipson and Melba Kurman — Amazon Link

- Digital Fabrications: Architectural and Material Techniques by Lisa Iwamoto — Amazon Link

Explore 3D Printed Fashion Accessories & Models:

- Thingiverse – 3D Printed Fashion Accessories

- MyMiniFactory – 3D Printed Jewelry

- Cults3D – 3D Printed Wearables

❓ FAQ: Your Burning Questions About 3D Printed Fashion Answered

How is 3D printing transforming fashion design?

3D printing is revolutionizing fashion by enabling designers to create complex, customized, and sustainable pieces that were previously impossible or prohibitively expensive to produce. It accelerates prototyping, reduces waste through additive manufacturing, and opens new creative avenues with intricate geometries and hybrid materials. This transformation is reshaping everything from haute couture to mass-market footwear.

What are the best materials for 3D printing in fashion?

The best materials depend on the application:

- TPU and TPE are flexible filaments ideal for wearable, comfortable parts like shoe soles or flexible accessories.

- Nylon (PA11/PA12) powders used in SLS printing offer durability and flexibility for interlocking textiles and footwear components.

- Flexible resins in SLA printers provide fine detail with some elasticity, great for jewelry and small embellishments.

- Emerging biodegradable and recycled filaments promise sustainability.

Material choice balances flexibility, durability, comfort, and aesthetic needs.

Can 3D printing be used to create wearable clothing?

✅ Yes, but with caveats. While 3D printing can produce wearable garments, most current 3D printed clothing is more like wearable art or structured pieces rather than everyday soft garments. Hybrid approaches—printing onto or integrating with traditional fabrics—are gaining traction. As materials improve, fully 3D printed, comfortable clothing will become more common.

What are the benefits of using 3D printing in fashion design?

- Design freedom: Create complex, intricate shapes impossible with traditional methods.

- Rapid prototyping: Test and iterate designs quickly.

- Customization: Tailor garments to individual body scans for perfect fit.

- Sustainability: Reduce waste and enable on-demand production.

- Innovation: Integrate wearable technology and smart textiles seamlessly.

How do designers incorporate 3D printing into their collections?

Designers typically use 3D printing for:

- Creating prototypes to refine designs rapidly.

- Producing accessories, jewelry, and footwear components.

- Crafting avant-garde or couture pieces that push artistic boundaries.

- Experimenting with hybrid textiles by printing onto fabrics.

- Collaborating with engineers and material scientists to innovate.

What are some popular 3D printed fashion accessories?

Popular 3D printed accessories include:

- Earrings, necklaces, and bracelets with intricate lattice or organic designs.

- Eyewear frames customized for fit and style.

- Shoe midsoles and decorative elements.

- Custom buttons, buckles, and embellishments.

Platforms like Thingiverse and MyMiniFactory offer thousands of downloadable designs.

Is 3D printing cost-effective for fashion designers?

It depends. For rapid prototyping and small-batch production, 3D printing can save time and reduce waste, making it cost-effective. However, industrial-grade printers and materials can be expensive, limiting large-scale production currently. As technology advances and costs drop, 3D printing will become more accessible and economical for a broader range of designers.

How does 3D printing contribute to sustainability in fashion?

3D printing reduces fabric waste by using only the material needed (additive manufacturing). It enables on-demand production, which cuts overproduction and unsold inventory. Additionally, the development of recycled and biodegradable materials supports circular fashion models, where end-of-life garments can be reprocessed into new raw materials.

What skills do fashion designers need to work with 3D printing?

Designers need proficiency in 3D modeling software such as Blender, ZBrush, or CLO3D, along with an understanding of material properties and printer capabilities. Collaboration with engineers or 3D printing specialists is common. Educational programs integrating 3D printing into fashion curricula are helping bridge this skills gap.

📚 Reference Links: Our Sources for Fashion-Forward Insights

-

Tomorrow.bio, How 3D Printing is Revolutionizing the Fashion Industry:

https://www.tomorrow.bio/post/how-3d-printing-is-revolutionizing-the-fashion-industry-2023-06-4727466168-3d-printing -

Stratasys, 3D Printing in Fashion Tech:

https://www.stratasys.com/en/guide-to-3d-printing/technologies-and-materials/3dfashion-tech-style/ -

FashionUnited, The Future of Fashion is Here: How 3D Printing is Changing the Industry:

https://fashionunited.com/news/fashion/the-future-of-fashion-is-here-how-3d-printing-is-changing-the-industry/2024120463260 -

Iris van Herpen Official Website:

https://www.irisvanherpen.com/ -

Adidas Futurecraft 4D:

https://www.adidas.com/us/4dfwd -

Carbon 3D Printing Technology:

https://www.carbon3d.com/our-story -

Anouk Wipprecht’s Spider Dress:

https://www.anoukwipprecht.nl/spider-dress-2-0 -

Stratasys PolyJet Technology:

https://www.stratasys.com/en/polyjet-technology/ -

Blender 3D Software:

https://www.blender.org/ -

CLO3D Fashion Software:

https://www.clo3d.com/ -

Prusa 3D Printers:

https://www.prusa3d.com/ -

Bambu Lab 3D Printers:

https://bambulab.com/ -

Elegoo Resin Printers:

https://www.elegoo.com/

We hope this deep dive has sparked your imagination and given you the tools to explore the thrilling intersection of 3D printing and fashion design. Stay tuned for more insights and happy printing! 🎨👗✨