Support our educational content for free when you purchase through links on our site. Learn more

The 15 Best 3D Printing Materials You Need to Know in 2026 🎯

Ever wondered why your 3D prints sometimes crack, warp, or just don’t look as slick as those jaw-dropping prototypes on Instagram? The secret sauce isn’t just your printer settings—it’s the material you choose. From the humble PLA that’s as easy as Sunday morning pancakes to high-tech metal powders used in aerospace, the world of 3D printing materials is a wild ride of chemistry, engineering, and a dash of magic.

Did you know that the global 3D printing materials market is projected to hit over $3 billion by 2026? That means more options, better performance, and yes—more confusion. But don’t sweat it. We’ve distilled decades of hands-on experience and the latest industry insights into this ultimate guide. Stick around, and you’ll discover how to pick the perfect filament, resin, or powder for your next masterpiece—even if you’re just starting out.

Spoiler alert: We’ll reveal why PETG might just be the Goldilocks material you didn’t know you needed, and how flexible TPU can turn your prints into bendy works of art without a meltdown.

Key Takeaways

- No one-size-fits-all: Choose materials based on your project’s strength, flexibility, and heat requirements.

- PLA is perfect for beginners—easy, clean, and colorful.

- ABS and Nylon offer toughness and heat resistance but demand more printer finesse.

- Resins deliver ultra-fine detail but require careful handling and post-processing.

- Metal powders unlock industrial-grade strength for serious applications.

- Drying filaments and calibrating your printer can make or break print quality.

- Sustainability is growing: recycled PETG and biodegradable PLA are eco-friendly options.

Ready to level up your 3D printing game? Dive in and discover the materials that will transform your prints from meh to magnificent!

Table of Contents

- ⚡️ Quick Tips and Facts About 3D Printing Materials

- 🔍 The Evolution and Science Behind 3D Printing Materials

- 🌈 Exploring Plastic 3D Printing Materials: Types, Properties & Uses

- ⚔️ Comparing Plastic 3D Printing Materials: Strength, Flexibility, and Finish

- 🔩 Metal 3D Printing Materials: From Titanium to Stainless Steel

- 🧠 How to Choose the Perfect 3D Printing Material for Your Project

- 🛠️ Specialty and Emerging 3D Printing Materials: Wood, Ceramic, and Conductive Filaments

- 💡 Insider Tips: Maximizing Material Performance and Print Quality

- 🌍 Sustainability in 3D Printing Materials: Biodegradable and Recycled Options

- 🧩 Troubleshooting Common Material Issues: Warping, Layer Adhesion, and More

- 🔗 Recommended Links for 3D Printing Materials and Resources

- ❓ Frequently Asked Questions About 3D Printing Materials

- 📚 Reference Links and Further Reading

- 🏁 Conclusion: Mastering Your 3D Printing Material Choices

⚡️ Quick Tips and Facts About 3D Printing Materials

- PLA is the gateway drug 🌱—easy to print, smells like pancakes, and perfect for 75 % of weekend projects.

- ABS stinks (literally) but survives 90 °C dashboards and acetone-vapor spa days.

- PETG is the over-achiever: food-safe, UV-stable, and almost as forgiving as PLA—once you tame the stringies.

- Nylon will absorb more water than your houseplant; keep it in a dry box or suffer the pops and cracks.

- Resin prints look injection-moulded straight off the build plate, but post-cure under UV or they’ll snap like crisps.

- TPU can print on a Bowden—but only if you slow it down to “sloth on sedatives” speeds.

- Carbon-fiber filaments eat brass nozzles for breakfast; swap to hardened steel before you cry.

- Wood-infused PLA can be sanded, stained, and even “grain”-brushed for faux-Walnut glory—just don’t exceed 210 °C or you’ll cook the sawdust.

- PVA support dissolves in tap water while you binge Netflix; just don’t leave it on the radiator or it’ll turn into a gummy bear.

- There is no “best” material—only the right one for the job. We’ll show you how to pick it in under five minutes.

New to the game? Dip your toes with our 3D-printed beginner projects before you splurge on exotic powders.

🔍 The Evolution and Science Behind 3D Printing Materials

Once upon a 1983, Chuck Hull printed a humble cup in UV-curable acrylic. Fast-forward four decades and we now juggle thermoplastics, thermosets, photopolymers, metal alloys, and even chocolate on the same lab bench. How did we get here?

A 60-Second History Lesson

| Year | Milestone | Material Star |

|---|---|---|

| 1983 | SLA invented | Acrylic-based photopolymer |

| 1988 | SLS patents | Nylon-12 powder |

| 1989 | FDM patents | ABS filament |

| 2005 | RepRap born | PLA enters chat |

| 2012 | Formlabs Kickstarter | Tough resin |

| 2020 | Desktop metal | 17-4 PH stainless |

| 2023 | Recycled ocean PET | Coca-Cola bottle to gear in 6 h |

“Ultimately, it’ll be largely up to the materials to enable you to create parts with the desired characteristics.” — Formlabs Materials Team

Thermoplastics vs. Thermosets: The Chemistry You Forgot

- Thermoplastics (PLA, ABS, PETG, Nylon) melt, cool, remelt—think cheese fondue.

- Thermosets (SLA resins, epoxy) cross-link once and lock forever—think birthday cake.

Why care? You can recycle thermoplastics into new filament; thermosets go to landfill unless you like toxic bonfires.

🌈 Exploring Plastic 3D Printing Materials: Types, Properties & Uses

1. FDM 3D Printing Filaments: PLA, ABS, PETG, and Beyond

PLA (Polylactic Acid) – The Crowd-Pleaser

- Print temp: 190-220 °C

- Bed: 50-60 °C (or cold on PEI)

- Pros: Biodegradable, low-warp, 300+ colourways, smells like maple syrup.

- Cons: Softens at 55 °C, brittle like autumn leaves.

- Best for: 3D-printed board-game pieces, plant pots, classroom demos.

Pro-tip from the trenches: We once printed 120 PLA keychains for a Maker-Faire giveaway—zero bed adhesion fails on a $220 printer. Zero.

ABS (Acrylonitrile Butadiene Styrene) – The Tough Guy

- Print temp: 230-250 °C

- Bed: 90-110 °C (enclosure strongly advised)

- Pros: Impact-tough, acetone-smoothable, survives under-hood temps.

- Cons: Warps like a vinyl record in a sauna; fumes can pickle your brain.

“ABS offers a good balance of impact resistance, toughness, and rigidity… and allows for vapor smoothing.” — #featured-video

PETG (Polyethylene Terephthalate Glycol) – The Goldilocks

- Print temp: 220-245 °C

- Bed: 70-80 °C

- Pros: Food-safe, crystal-clear, UV-stable, almost no warp.

- Cons: Stringier than a 90’s garage band; needs 0.2 mm Z-hop or you’ll rip chunks off your print.

Nylon (PA6, PA12, PA66) – The Engineering Workhorse

- Print temp: 240-260 °C (all-metal hot-end mandatory)

- Pros: Self-lubricating, 140 MPa tensile, survives under 120 °C.

- Cons: Hygroscopic—leave it on the counter overnight and it’ll sound like microwave popcorn.

Dry-box hack: We toss a $5 rechargeable silica-gel canister in a 20 L gasket box; humidity stays <15 % for weeks.

TPU/TPE – The Yoga Instructor

- Print temp: 210-230 °C

- Print speed: 20 mm/s for Bowden, 40 mm/s for direct-drive.

- Pros: Shore 85A–98A, perfect for drone bumpers, flexible phone stands.

- Cons: Loves to tangle; keep slack to zero.

PC (Polycarbonate) – The Bullet-Proof Choice

- Print temp: 280-310 °C

- Bed: 110-120 °C (enclosure + borosilicate glass)

- Pros: 110 °C heat deflection, clear as aquarium glass when polished.

- Cons: Needs volcano-style heater; brass nozzles glow like Chernobyl.

Composite Blends – When Plain Plastic Isn’t Enough

| Blend | Feel | Use-Case |

|---|---|---|

| Wood-PLA | Sawdust scent | Decorative vases |

| Copper-PLA | Cold metallic heft | Jewellery |

| Carbon-fiber Nylon | 30 % lighter, 2× stiffer | Racing drone arms |

👉 CHECK PRICE on:

- PLA: Amazon | Walmart | Overture Official

- ABS: Amazon | eBay | eSUN Official

- PETG: Amazon | Cults3D | Prusa Official

2. SLA Resin Materials: Standard, Tough, Flexible, and Specialty Resins

Standard Resin – The Detail Diva

- Layer height: 0.01 mm achievable

- Tensile: 38 MPa

- Pros: Glass-smooth, captures fingerprints.

- Cons: Brittle—drop it and it’s toast.

Tough / Durable Resin – The ABS Impersonator

- Impact: 38 J/m notched Izod (comparable to ABS)

- Pros: Living hinges, snap-fits, miniature gears.

- Cons: Still stiffer than TPU; don’t expect skateboard wheels.

Flexible 80A Resin – The Silicone Wannabe

- Shore: 80A

- Elongation: 25 %

- Pros: Gaskets, watch straps.

- Cons: Feels tacky until you dust it with corn-starch.

Specialty Resins

| Type | Cert | Ideal For |

|---|---|---|

| Biocompatible | USP Class VI | Dental guides |

| High-temp | 238 °C HDT | Mold inserts |

| Castable | Zero ash | Jewellery investment casting |

👉 Shop Resin on:

3. SLS Powder Materials: Nylon, TPU, and Composite Powders

Nylon-12 (PA12) – The Benchmark

- Tensile: 48 MPa XY, 42 MPa Z

- Pros: No supports = insane overhangs; dyeable in fabric dye.

- Cons: Slightly rough surface (Ra 8–12 µm); needs media-blasting for cosmetics.

TPU Powder – The Rubber Biscuit

- Shore: 75–90A depending on supplier

- Pros: 250 % elongation; perfect for midsoles.

- Cons: $$$ and requires nitrogen-purged chamber.

Glass-Filled Nylon – The Stiff Upper Lip

- Stiffness: 2.8 GPa (vs 1.5 GPa neat PA12)

- Pros: Motor mounts, UAV arms.

- Cons: Abrades nozzles; send your recoater blade to therapy.

👉 CHECK PRICE on:

- PA12 Powder (Formlabs Fuse): Official

⚔️ Comparing Plastic 3D Printing Materials: Strength, Flexibility, and Finish

| Material | Tensile (MPa) | Elongation (%) | HDT (°C) | Surface Finish | Ease | Cost |

|---|---|---|---|---|---|---|

| PLA | 55 | 6 | 55 | Glossy | ★★★★★ | $ |

| ABS | 35 | 25 | 95 | Matte → Vapor-gloss | ★★★ | $$ |

| PETG | 50 | 20 | 75 | Satin | ★★★★ | $$ |

| Nylon | 70 | 30 | 100 | Slight grain | ★★ | $$$ |

| TPU | 30 | 400 | 60 | Matte rubber | ★★ | $$$ |

| Standard Resin | 38 | 8 | 70 | Glassy | ★★★ | $$ |

| Tough Resin | 40 | 24 | 75 | Glassy | ★★★ | $$$ |

Takeaway: Need stiffness on a budget? PLA wins. Need snap-fit living hinges? Tough resin or TPU. Need 120 °C under-hood? Nylon or PC.

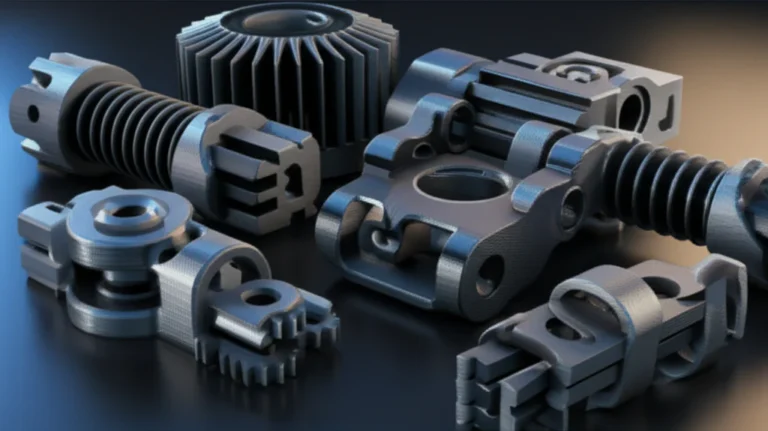

🔩 Metal 3D Printing Materials: From Titanium to Stainless Steel

We’re not talking cheesy “metal-filled” PLA. Real metal 3D printing uses:

Powder-Bed Fusion (DMLS/SLM)

- Titanium Ti6Al4V – Aerospace bones; 900 MPa UTS; $$$$ but weight-saving nirvana.

- 316L Stainless – Surgical shiny; corrosion-proof; perfect for custom bike pedals.

- Tool Steel H13 – 45 HRC after heat-treat; injection-mould inserts that outrun aluminium.

Bound-Metal FDM (Desktop Metal, Markforged)

- 17-4 PH – Prints like plastic, debinds, sinters to 96 % density; tolerances ±0.2 mm.

- Copper – 85 % IACS conductivity; rocket nozzles & heat sinks.

Design Rules

- Over-sinter allowance: +1 % XY, +2 % Z

- Min wall: 0.4 mm (metal), 1 mm (bound-metal)

- Support removal: EDM or CNC; budget accordingly.

👉 Shop Metal 3D Printing Services:

🧠 How to Choose the Perfect 3D Printing Material for Your Project

- List the job’s must-haves: load, temp, UV, chemical, food, skin, look.

- Translate into specs: tensile, HDT, elongation, surface Ra.

- Shortlist 2-3 candidates using the table above.

- Prototype cheapest first (usually PLA or standard resin).

- Iterate upward (PETG → Nylon → Metal).

- Document settings in Cura LulzBot Edition or PrusaSlicer for repeatability.

Still stuck? Use Formlabs’ interactive material wizard or Simplify3D’s properties table linked earlier.

🛠️ Specialty and Emerging 3D Printing Materials: Wood, Ceramic, and Conductive Filaments

- Wood-PLA: Sand at 200 grit, stain with water-based dye, finish with beeswax.

- Ceramic Resin: Debind & kiln-fire to 99.8 % alumina; perfect for custom espresso cups.

- Conductive PLA: 0.3 Ω·cm resistivity; great for touch-sensor prototypes—check our 3D-printed electronics guide.

- Glow-in-the-Dark: Strontium-aluminate pigments; abrasive—hardened nozzle mandatory.

- Color-Changing: Leuco dyes shift at 31 °C; ideal for mood rings.

💡 Insider Tips: Maximizing Material Performance and Print Quality

- Dry like your life depends on it: 4 h at 55 °C for PLA, 70 °C for PETG, 80 °C for Nylon.

- Calibrate extruder steps/mm every 500 h; 2 % under-extrusion kills strength 10 %.

- Use 0.25 mm nozzle for miniatures, 0.6 mm for chunky mechanical parts—halves print time.

- For PETG stringing: 3 mm retraction, 40 mm/s, Z-hop 0.2 mm, fan 30 %.

- For ABS warping: 110 °C bed, brim 10 mm, enclosure 45 °C ambient, no part-cooling fan.

- For resin layer lines: Angle model 15°, post-cure 10 min at 405 nm, then 2 min ultrasonic bath in 99 % IPA.

🌍 Sustainability in 3D Printing Materials: Biodegradable and Recycled Options

- PLA is industrially compostable (EN 13432) but not in your backyard bin.

- Recycled PET-G (ReForm rPET) uses 90 % less energy than virgin PET.

- ASA lasts 10 years outdoors—better to print once than reprint five times.

- Filabot lets you shred failed PLA prints and re-extrude into new filament—closed-loop crafting.

- Metal powders can be recycled 95 %; most service providers sieve and reuse.

🧩 Troubleshooting Common Material Issues: Warping, Layer Adhesion, and More

| Symptom | Likely Culprit | Quick Fix |

|---|---|---|

| Corners lifting | Draft, low bed temp | Brim + enclosure + 10 °C bed bump |

| Layer splitting | Moisture, low temp | Dry filament + 5 °C hotter |

| Resin stickiness | Under-cure | Post-cure 2× longer under 405 nm |

| TPU jams | Retraction too high | Disable retraction, print slower |

| Nylon pops | Wet | Dry 8 h @ 80 °C, store with desiccant |

Still scratching your head? Drop us a line in the comments—we’ve probably melted that exact mistake before.

Ready to level-up? Browse our curated 3D printer reviews or dive into 3D design software to model your next masterpiece.

🏁 Conclusion: Mastering Your 3D Printing Material Choices

Phew! That was quite the material journey, wasn’t it? From the sweet-smelling PLA that’s perfect for your first prints, to the aerospace-grade titanium powders that rocket engineers drool over, the world of 3D printing materials is vast, nuanced, and endlessly fascinating.

Here’s the bottom line:

There is no one-size-fits-all “best” material. Instead, it’s about matching your project’s needs with the right material’s strengths and quirks. Want ease and color variety? PLA’s your buddy. Need toughness and heat resistance? ABS or Nylon steps up. Craving ultra-fine detail? SLA resins deliver. Looking for flexibility? TPU flexes with you. Dreaming of metal parts? Powder-bed fusion has your back.

Remember our teaser about choosing the right material in under five minutes? Now you can confidently list your project’s requirements, check the specs, and pick a winner without second-guessing. And if you ever hit a snag—whether it’s warping, stringing, or sticky resin—you know where to find the fix.

At 3D Printed™, we’ve tested, tweaked, and tuned these materials on real printers, and we recommend starting simple and scaling up your material game as your skills grow. Keep your filament dry, your nozzle clean, and your curiosity alive.

Happy printing! 🚀

🔗 Recommended Links for 3D Printing Materials and Resources

👉 Shop Popular Filaments and Resins:

- PLA Filament: Amazon | Walmart | Overture Official Website

- ABS Filament: Amazon | eBay | eSUN Official Website

- PETG Filament: Amazon | Cults3D | Prusa Official Website

- SLA Resins (Elegoo, Siraya Tech): Amazon | Elegoo Official Website | Siraya Tech Official Website

- Nylon Powder (Formlabs Fuse PA12): Formlabs Official Store

- Metal 3D Printing Services: Shapeways | Xometry

Recommended Books for Deep Dives:

- 3D Printing Failures: How to Diagnose and Repair All 3D Printing Problems by Sean Aranda — Amazon

- Fabricated: The New World of 3D Printing by Hod Lipson and Melba Kurman — Amazon

- Additive Manufacturing Technologies by Ian Gibson, David Rosen, Brent Stucker — Amazon

❓ Frequently Asked Questions About 3D Printing Materials

What are the safety precautions I should take when working with 3D printing materials?

Safety first! For thermoplastics like PLA and PETG, ventilation is generally sufficient as they emit minimal fumes. ABS and Nylon, however, release styrene and caprolactam vapors, which can irritate your respiratory system. Always print in a well-ventilated area or use an enclosure with a HEPA filter. When handling resins, wear nitrile gloves and eye protection, as uncured resin is toxic and can cause skin sensitization. Post-processing with isopropyl alcohol requires caution—keep away from flames and use gloves. For metal powders, avoid inhalation and skin contact; use proper PPE and handle powders in controlled environments.

Can I use recycled materials for 3D printing?

✅ Yes, but with caveats. Thermoplastics like PLA and PETG can be recycled into filament using filament extruders such as the Filabot or the Lyman Filament Maker. However, recycled filament may have inconsistent diameter and mechanical properties unless carefully processed. Some companies offer recycled PETG filaments made from post-consumer bottles, reducing environmental impact. Thermoset resins and metal powders are not recyclable at home but can be recycled industrially. Always dry recycled filament thoroughly to avoid print failures.

What is the difference between PLA and ABS 3D printing materials?

PLA is a biodegradable thermoplastic derived from renewable resources like cornstarch. It prints at lower temperatures, has minimal warping, and produces a glossy finish. However, it softens at around 55 °C and is brittle under mechanical stress. ABS is a petroleum-based thermoplastic known for toughness, heat resistance (up to ~95 °C), and impact strength. It requires higher print temperatures, a heated bed, and preferably an enclosure to prevent warping and cracking. ABS can be post-processed with acetone vapor for a smooth finish, which PLA cannot.

What are the best 3D printing materials for beginners?

PLA is the undisputed champion for beginners. It’s easy to print, forgiving with bed adhesion, and emits a pleasant smell. PETG is a great next step, offering more durability and chemical resistance with slightly more challenging print settings. Avoid ABS initially due to warping and fumes. Resin printing is beginner-friendly for detail but requires post-processing and safety precautions.

How do different 3D printing materials affect print quality?

Material properties like melting temperature, viscosity, and shrinkage directly impact print quality. PLA offers crisp details and smooth surfaces but is brittle. ABS can warp and crack if not printed in an enclosure, affecting dimensional accuracy. PETG bridges well but can string. Resins provide the highest resolution and surface finish but are brittle. Flexible filaments require slow speeds and special settings to avoid blobs and jams. Material choice dictates layer adhesion, surface finish, and mechanical strength.

What are the most durable materials for 3D printing?

Nylon and carbon-fiber reinforced filaments top the durability charts for FDM printing, offering excellent tensile strength, abrasion resistance, and flexibility. For SLA, tough and durable resins mimic ABS-like properties. Metal powders such as titanium alloys and stainless steel provide unmatched strength and heat resistance but require industrial processes. TPU offers durability in flexible applications.

Can you use flexible materials for 3D printing?

✅ Absolutely! TPU and TPE are popular flexible filaments. They require slower print speeds (20–30 mm/s), direct-drive extruders for best results, and careful retraction settings to avoid jams. Flexible resins exist too, offering Shore hardness around 80A, suitable for gaskets and wearable parts. Flexible materials open doors to functional prints like phone cases, seals, and living hinges.

What are eco-friendly 3D printing materials available?

PLA is biodegradable under industrial composting conditions. Recycled PETG filaments reduce plastic waste. Some companies offer bio-based resins with lower VOC emissions. Additionally, using recycled filament or reprocessing failed prints reduces landfill. Avoid toxic solvents and opt for water-soluble supports like PVA to minimize environmental impact.

How to choose the right 3D printing material for your project?

Start by defining your project’s requirements: mechanical strength, flexibility, temperature resistance, surface finish, and environmental exposure. Consult datasheets for tensile strength, elongation, and heat deflection temperature. Consider printer compatibility and post-processing needs. Prototype with affordable materials like PLA or standard resin before moving to specialty filaments or powders. Use interactive tools like Formlabs’ material wizard or Simplify3D’s properties table for tailored recommendations.

What are the common issues with various 3D printing materials?

| Material | Common Issues | Solutions |

|---|---|---|

| PLA | Brittleness, low heat resistance | Use for decorative parts; avoid high-temp use |

| ABS | Warping, fumes | Use enclosure, ventilate, acetone vapor smoothing |

| PETG | Stringing, poor bed adhesion | Adjust retraction, clean bed with isopropyl alcohol |

| Nylon | Moisture absorption, warping | Dry filament, use enclosure, slow print speed |

| TPU | Jamming, stringing | Slow speed, direct-drive extruder, disable retraction |

| Resin | Sticky prints, brittle parts | Proper post-curing, handle with gloves, avoid overexposure |

📚 Reference Links and Further Reading

- Formlabs 3D Printing Materials Overview

- LulzBot 3D Printing Materials Guide

- Simplify3D Ultimate 3D Printing Materials Guide

- Overture Filament Official Website

- eSUN Filament Official Website

- Prusa Research Official Website

- Elegoo Resin Official Website

- Siraya Tech Resin Official Website

- Formlabs Fuse PA12 Nylon Powder

- Shapeways Metal 3D Printing Services

- Xometry Metal 3D Printing Services

For more expert insights and printable models, visit 3D Printed™.