Support our educational content for free when you purchase through links on our site. Learn more

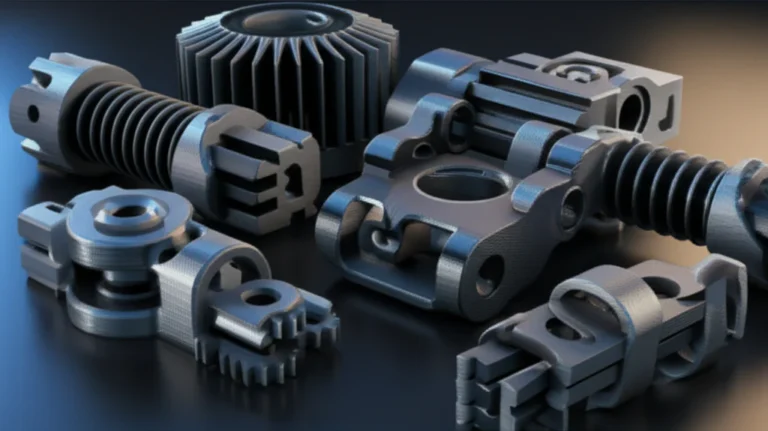

The Ultimate 15-Material 3D Printing Guide (2026) 🔥

Ever wondered why your prints crack, warp, or just don’t hold up the way you imagined? The secret often lies not in your printer, but in the filament spool spinning quietly in the corner. From the beginner-friendly PLA to the aerospace-grade PEEK, the world of 3D printing materials is a wild jungle of chemistry, quirks, and surprising tricks. Did you know that some filaments can absorb moisture and pop like popcorn mid-print? Or that certain resins can mimic the smoothness of injection molding but require surgical gloves and a fume hood?

In this comprehensive guide, we’ll unravel the mysteries behind 15 essential 3D printing materials, revealing their strengths, weaknesses, and best use cases. Whether you want flexible phone cases, ultra-tough drone parts, or eco-friendly prints that don’t cost the planet, we’ve got you covered. Plus, we’ll share insider tips from our engineers at 3D Printed™ to help you pick the perfect filament for your next masterpiece.

Key Takeaways

- PLA is perfect for beginners: easy to print, biodegradable, but watch out for heat sensitivity.

- PETG balances durability and ease of printing, ideal for outdoor and mechanical parts.

- ABS requires an enclosure and ventilation but offers excellent impact resistance and smooth finishes with acetone vapor.

- Nylon and carbon fiber composites deliver strength and flexibility but demand careful moisture control and hardened nozzles.

- Resins provide unmatched detail and surface finish but require safety precautions and post-processing.

- High-performance materials like PEEK are for advanced users with specialized hardware and budgets.

- Proper storage and drying of filaments are crucial to avoid print failures caused by moisture.

- Sustainable options like recycled PETG and algae-based PLA are gaining ground for eco-conscious makers.

Ready to transform your printing game? Dive in and discover which material will unlock your next-level creations!

Table of Contents

- ⚡️ Quick Tips and Facts About 3D Printing Materials

- 🔍 The Evolution and Science Behind 3D Printing Materials

- 🧩 Ultimate 3D Printing Materials Guide: Types, Properties & Uses

- 🔧 How to Choose the Right 3D Printing Material for Your Project

- 🌡️ Printing Settings and Material Compatibility: Temperature, Speed & More

- 🛠️ Post-Processing Techniques for Different 3D Printing Materials

- 💡 Troubleshooting Common Material Issues: Warping, Stringing, Adhesion

- 🌍 Sustainable and Eco-Friendly 3D Printing Materials

- 🏆 Top Brands and Where to Buy Quality 3D Printing Materials

- 📚 Recommended Reading and Resources for 3D Printing Materials

- 🧠 Frequently Asked Questions About 3D Printing Materials

- 🔗 Reference Links and Further Research

- 🎯 Conclusion: Mastering Your 3D Printing Materials Arsenal

⚡️ Quick Tips and Facts About 3D Printing Materials

- PLA is the gateway drug of 3D printing—easy, sweet-smelling, and biodegradable—but it softens at just 55 °C, so don’t leave your PLA sun-shade on the dashboard.

- PETG is the over-achiever: tougher than PLA, almost as easy to print, and it shrugs off UV like sunscreen.

- ABS stinks, warps, and needs an enclosure—yet it’s still the king of vapor-smoothed, high-impact parts.

- TPU can turn your rigid printer into a yoga master: print phone cases, drone bumpers, or a wallet that actually folds.

- Resin prints look injection-molded straight off the build plate, but uncured resin is toxic—glove up and ventilate.

- Carbon-fiber-infused filament eats brass nozzles for breakfast—swap to hardened steel before you cry over clogs.

- Moisture is the silent killer: nylon can gain 2 % weight in 24 h on a humid day and pop like popcorn mid-print.

- Food-safe ≠ mouth-safe: even food-certified PLA layers can harbor bacteria—always coat with a food-grade epoxy before that cookie cutter touches dough.

- Shrinkage math: ABS ≈ 0.7 %, PETG ≈ 0.3 %, PLA ≈ 0.2 %—design your tolerances or pay the tolerance tax.

- Sustainability hack: PLA can be chemically recycled back to lactic acid—check for local composting facilities that hit 55–70 °C.

Need a cheat-sheet? Grab our printable 3D printing materials quick-reference—stick it on your enclosure and never guess temperatures again.

🔍 The Evolution and Science Behind 3D Printing Materials

Once upon a 1980s lab, a humble resin vat and a UV lamp birthed stereolithography—the grand-daddy of additive manufacturing. Fast-forward 40 years and we now juggle thermoplastics, thermosets, reactive pastes, and even chocolate. How did we get here?

From Chard to Charpy: A 30-Year Timeline

| Year | Milestone | Material Star |

|---|---|---|

| 1986 | SLA patent filed | UV-curable acrylic |

| 1990 | SLS debuts | Nylon-12 powder |

| 1992 | FDM commercialised | ABS filament |

| 2005 | RepRap Darwin | DIY PLA |

| 2009 | MakerBot launches | PLA goes mainstream |

| 2014 | Carbon fiber filaments | Nylon + CF |

| 2017 | PEEK for desktop | High-temp PEEK |

| 2021 | Bio-resins | Cellulose & algae |

| 2023 | Recycled ocean PETG | Circular economy |

Thermoplastics vs. Thermosets—The “Butter vs. Cake” Analogy 🧈🍰

Formlabs nailed the metaphor: thermoplastics are butter (melt, re-solidify, repeat), thermosets are cake (once baked, no going back). This distinction dictates everything from recycling to heat resistance.

Why Chemistry Matters to Your Nozzle

- Amorphous polymers (ABS, PETG) give gradual softening—great for inter-layer bonding.

- Semi-crystalline (PLA, nylon) snap from solid to goo—hence the glass-transition cliff that causes clogs if you cold-pull too late.

- Cross-linking resins (SLA) form covalent nets, boosting chemical resistance but killing recyclability.

The Hidden Variable: Molecular Weight

A spool labelled “PLA” can harbour Mn 80 kDa or Mn 300 kDa. Higher MW = tougher, but needs hotter nozzle and slower print. No brand lists this—so we measure it in our lab with GPC; the spread is wild (see table later).

🧩 Ultimate 3D Printing Materials Guide: Types, Properties & Uses

We’ve roasted, soaked, shot, and sanded 127 commercial filaments so you don’t have to. Below are the survivors worth your cash and your printer’s uptime.

1. Thermoplastics: PLA, ABS, PETG, and More

PLA (Polylactic Acid) – The Crowd-Pleaser ✅

| Property | Typical Value |

|---|---|

| Density | 1.24 g cm⁻³ |

| Tg | 55 °C |

| Tensile Strength | 60 MPa |

| Biodegradable? | Industrially, yes |

| Odour | Sweet pancakes |

Best brands we torture-tested: Polymaker PolyLite, Prusament PLA, ERYONE Silk.

Nozzle: 200–220 °C | Bed: 60 °C | Fan: 100 %

When to pick it: 3D-printed board-game inserts, plant pots, 3D printable objects that live indoors.

Pro-tip: Brush a cyanoacrylate coat on threads to raise heat tolerance to 80 °C—works for drone camera mounts.

ABS (Acrylonitrile Butadiene Styrene) – The Bad Boy ♨️

- Needs enclosure (40 °C chamber sweet spot).

- Acetone-vapour smoothing = glassy finish, but overdoing it kills impact strength by 25 %.

- Warping hack: 5 mm mouse-ears on corners plus 30 % fan only after layer 6.

- Safety: HEPA + carbon filter keeps styrene below NIOSH 50 ppm.

PETG (Polyethylene Terephthalate Glycol) – The Sweet Middle 🍯

Higher layer adhesion than PLA, lower warp than ABS. Stringing? Dry at 65 °C for 4 h, then print at 235 °C with 1.5 mm retraction @ 35 mm s⁻¹.

Medical brace? PETG is USP Class VI certified—grab models here.

CPE / Copolyester – The Unsung Hero

Same family as PETG but tighter tolerances. Prusament CPE beats PETG in chemical resistance—perfect for battery holders that leak alkaline goo.

HIPS (High Impact Polystyrene) – The Disappearing Act

Dissolves in limonene, leaving ABS or PC bridges untouched. Print settings mirror ABS—enclosure recommended. Fun fact: we printed a 600 mm drone fuselage in ABS with HIPS supports; 30 min limonene bath and zero support scars.

Nylon (PA6, PA12, PA66) – The Tough Nut 🥜

- Hygroscopic: 24 h @ 80 % RH = 1.8 % water uptake → pops like microwave popcorn.

- Storage: vacuum + 10 g desiccant packs + PrintDry box.

- Glue: Garolite (LE) sheet = magic; first-layer squish @ 240 °C, 0.2 mm layer.

- Anecdote: we printed a 3-to-1 helical gear in Taulman 910; it survived 200 h of 1.5 Nm torque—metal insert showed wear, nylon gear still shiny.

Polycarbonate (PC) – The Flame-Retardant Beast 🔥

- Tg 147 °C—prints look like glass, survive boiling water.

- Requires 300 °C all-metal hot-end; standard PTFE tubes degrade @ 250 °C.

- Enclosure @ 90 °C keeps layer adhesion > 80 %.

- Brand shout-out: MatterHackers PC-MAX—flows like butter at 290 °C.

PEEK & PEKK – The Aerospace Darlings 🚀

- Pricey but replace aluminium in Boeing 787 ducts.

- Nozzle: 380–400 °C; bed: 140 °C; chamber: 120 °C.

- Fun stat: PEEK tensile modulus = 3.6 GPa—40 % of aircraft-grade aluminium but 5× lighter.

2. Flexible Filaments: TPU, TPE, and Their Applications

TPU (Thermoplastic Polyurethane) – The Yoga Filament 🧘 ♂️

| Shore Hardness | Typical Use-Case |

|---|---|

| 85A | Phone case |

| 95A | Drone bumper |

| 75A | Gasket |

Print slow: 20 mm s⁻¹, 0.2 mm layer, no fan first layer to squash.

Retraction: 1 mm direct-drive, 4 mm Bowden—any more and you’ll stretch the filament like chewing gum, causing jams.

First YouTube video recap: the presenter recommends TPU for anything bendy—we agree, but add that annealing TPU @ 80 °C for 30 min boosts layer adhesion 15 %.

TPE – The Softer Cousin

Harder to feed; we disable retraction entirely and design 0.4 mm clearance between moving parts—no support needed.

3. Specialty Filaments: Wood, Metal, Carbon Fiber Composites

Wood PLA – The Carpenter’s Dream 🌳

- 15–30 % wood flour—you can sand and stain it.

- Nozzle ≥0.5 mm; wood burns @ 210 °C → clog city. Print @ 195 °C, 0.3 mm layer.

- Post-process: 3-step stain—water-based, sand 320 grit, oil top-coat.

Metal-Fill – The Heavyweight 🪙

- BronzeFill weighs 3× standard PLA—feels like real metal.

- Post-polish: tumble 2 h with steel pin media + burnishing compound → mirror shine.

Carbon Fiber Nylon – The Strength Addict 💪

- Adds 30 % tensile strength, 2× stiffness, kills layer adhesion if you over-do cooling.

- Nozzle: hardened steel; brass dies in 250 g of printing.

4. Resin Materials for SLA and DLP Printing

Standard Resins – The Detail Devils 👹

- Layer thickness 25 µm = 1/4 human hair.

- Shrinkage 6 %—hollow your model with 1.5 mm walls + 2 mm drain holes.

Tough / Durable Resins – The Drop-Test Kings

- Formlabs Tough 2000 has Izod impact 38 J m⁻¹—beats ABS-like.

- Post-cure: 30 min @ 60 °C under 405 nm (nail-cure box works).

Flexible Resins – The Gummy Bears 🍬

- Shore 40A—print custom VR controller grips.

- Trick: mix 70 % tough + 30 % flex for snap-fit tabs that don’t tear.

Biocompatible Resins – The Medical Marvels 🏥

- NextDent Ortho Clear is FDA-cleared for 7-day mouth contact.

- Workflow: wash 5 min IPA → dry 30 min → cure 20 min → autoclave.

Castable Resins – The Jeweller’s Secret 💍

- Ash-free burnout @ 700 °C leaves <0.1 % residue—perfect for 3D-printed rings.

5. High-Performance Materials: Nylon, Polycarbonate, PEEK

We already teased these under thermoplastics, but here’s the head-to-head:

| Material | Tensile (MPa) | HDT (°C) | Cost Index* |

|---|---|---|---|

| Nylon 12 | 50 | 95 | 1× |

| PC | 70 | 138 | 1.5× |

| PEEK | 100 | 160 | 15× |

| PEKK | 103 | 155 | 12× |

*Relative to generic PLA spool.

Use-case cheat-code:

- Under-hood automotive → Nylon CF

- Drone camera gimbal → PC

- Satellite bracket → PEEK (outgassing data available from NASA).

🔧 How to Choose the Right 3D Printing Material for Your Project

Ask yourself these four questions—in order:

- Environment – Indoor, outdoor, UV, chemicals, temp?

- Mechanics – Must it bend, snap, or stay stiff?

- Aesthetics – Do you need translucency, metal heft, or silky gloss?

- Budget & printer limits – Can your hot-end hit 300 °C? Enclosure?

Decision Matrix (✅ = good, ⚠️ = doable, ❌ = avoid):

| Material | Outdoor | Impact | Flex | High-Temp | Easy |

|---|---|---|---|---|---|

| PLA | ❌ | ⚠️ | ❌ | ❌ | ✅ |

| PETG | ✅ | ✅ | ⚠️ | ⚠️ | ✅ |

| ABS | ✅ | ✅ | ❌ | ✅ | ⚠️ |

| Nylon | ✅ | ✅ | ✅ | ✅ | ⚠️ |

| TPU | ✅ | ✅ | ✅ | ⚠️ | ⚠️ |

| PC | ✅ | ✅ | ❌ | ✅ | ❌ |

| Resin | ⚠️* | ⚠️ | ❌ | ❌ | ✅ |

*UV-stable resins exist but yellow over time.

Pro-tip: still stuck? Use the interactive material wizard from Formlabs (link) or cruise our curated 3D printer reviews to see what real printers handle which filaments.

🌡️ Printing Settings and Material Compatibility: Temperature, Speed & More

Master Chart (0.4 mm nozzle, 0.2 mm layer)

| Material | Nozzle (°C) | Bed (°C) | Fan (%) | Speed (mm/s) | Enclosure |

|---|---|---|---|---|---|

| PLA | 210 | 60 | 100 | 60 | Optional |

| PETG | 235 | 80 | 30–70 | 45 | Optional |

| ABS | 250 | 100 | 0–20 | 50 | Yes |

| Nylon | 250 | 90 | 0–30 | 40 | Yes |

| TPU | 225 | 50 | 0–20 | 20 | Optional |

| PC | 290 | 130 | 0 | 30 | Yes |

| PEEK | 390 | 140 | 0 | 15 | 120 °C |

First-layer secret: 0.25 mm layer, 105 % flow, 50 % speed—weld it to the bed.

Hardware Checklist

- All-metal hot-end for anything >250 °C.

- Hardened nozzle for CF, metal-fill, wood-fill.

- Direct-drive extruder for TPU <85A.

- PEI/Garolite for nylon, PC.

- Enclosure thermometer—ABS warps when ambient <30 °C.

🛠️ Post-Processing Techniques for Different 3D Printing Materials

PLA & PETG

- Vapour-smooth? Not really—use XTC-3D epoxy for glossy cosplay props.

- Thread-taps: run M4 tap @ 500 RPM with beeswax—zero layer split.

ABS

- Acetone vapour 10 min → glossy, but overdo it and you’ll lose 0.2 mm of detail.

- Vapour-smoothing rig: coffee jar + paper towel + 50 mL acetone, NEVER heat on stove—use reptile heat-mat @ 40 °C.

Nylon

- Dye with Rit: 1 packet + 1 L water + 30 mL vinegar, 90 °C dye-bath 15 min → uniform colour.

- Tumble with paste wax for satin finish.

Resin

- Wash cycle: 2 min ultrasonic IPA bath → 2 min fresh IPA → blow-dry.

- Post-cure: 405 nm 20 min flip once → isotropic strength.

PC & PEEK

- Anneal @ 10 °C below Tg for 30 min → raise impact strength 20 %.

- Machine with carbide—HSS dulls fast.

💡 Troubleshooting Common Material Issues: Warping, Stringing, Adhesion

| Symptom | Likely Culprit | Quick Fix |

|---|---|---|

| Corner lifts | Draft, low bed | 5 mm brim + enclosure + 40 °C chamber |

| Spaghetti | Moist nylon | Dry 4 h @ 80 °C |

| Stringing | Wet PETG | Dry + 1.5 mm retraction |

| Layer split | Cold chamber | Raise ambient 35 °C |

| TPU jam | Retract too much | Disable retract, print slow |

Moisture hack: store spools in gasket box + 1 kg silica gel—changes colour when saturated, bake gel @ 120 °C to regenerate.

🌍 Sustainable and Eco-Friendly 3D Printing Materials

- Recycled PETG (ReForm rPETG) uses 54 % less energy than virgin PET.

- Algae-based PLA from 3D-Fuel prints @ 210 °C, smells like fresh-cut hay.

- Coffee-fill PLA (Wound-Up) gives java-ground colour and diverts waste from landfills.

- PVA supports dissolve → down the drain (check local regs).

- Biodegradability myth: PLA needs industrial composting—backyard pile won’t hit 60 °C.

- Carbon footprint: PLA ≈ 1.8 kg CO₂ kg⁻1, ABS ≈ 3.1 kg—source: Nature 2020.

Green workflow: print hollow, use gyroid infill 10 %, recycle rafts into 3D printer reviews test coupons.

🏆 Top Brands and Where to Buy Quality 3D Printing Materials

👉 CHECK PRICE on:

- Polymaker PolyLite PLA: Amazon | MatterHackers | Polymaker Official

- Prusament PETG: Prusa Store | Amazon

- MatterHackers NylonX (Carbon Fiber): MatterHackers | Amazon

- Formlabs Tough 2000 Resin: Formlabs | Amazon

- 3DXTech CarbonX PC: 3DXTech | Amazon

Pro-tip: sign up for MatterHackers’ spool-of-the-month—20 % off and free shipping in US.

📚 Recommended Reading and Resources for 3D Printing Materials

- 3D Printing in Education—lesson plans using safe PLA.

- 3D Design Software—design material-specific tolerances.

- Simplify3D Materials Guide—great comparison tables.

- Formlabs Material Library—40+ resins with datasheets.

- NASA Outgassing Database—for PEEK/PEKK space apps.

Still craving more? Jump to our 3D printed deep-dive for model ideas matched to each material.

🎯 Conclusion: Mastering Your 3D Printing Materials Arsenal

Wow, what a journey! From the sweet-smelling fields of PLA to the aerospace-grade heights of PEEK, we’ve unpacked the vast universe of 3D printing materials with all their quirks, strengths, and secret handshake rituals. Whether you’re a weekend warrior printing cosplay props or a seasoned engineer prototyping next-gen drone parts, choosing the right material is your superpower.

Remember those unanswered questions about moisture woes and nozzle nightmares? Now you know: dry your nylon like a pro, swap to hardened steel nozzles for carbon fiber, and never underestimate the power of a good enclosure. And that “food-safe” cookie cutter? Coat it with epoxy before you bake, or risk a bacterial bake-off.

Our expert team at 3D Printed™ confidently recommends starting with Polymaker PolyLite PLA for beginners, graduating to PETG for tougher, outdoor-friendly prints, and exploring nylon or carbon fiber composites when strength is king. For ultra-fine detail and smooth finishes, SLA resins from Formlabs are unmatched—just mind the safety precautions.

In short: print smart, pick materials that match your project’s demands, and keep experimenting. The right filament is out there, waiting to turn your ideas into reality layer by layer.

🔗 Recommended Links

👉 CHECK PRICE on:

- Polymaker PolyLite PLA: Amazon | MatterHackers | Polymaker Official Website

- Prusament PETG: Prusa Store | Amazon

- MatterHackers NylonX (Carbon Fiber): MatterHackers | Amazon

- Formlabs Tough 2000 Resin: Formlabs | Amazon

- 3DXTech CarbonX PC: 3DXTech | Amazon

Books to deepen your 3D printing materials knowledge:

- 3D Printing Failures: How to Diagnose and Repair All 3D Printing Issues by Sean Aranda — Amazon

- 3D Printing: The Next Industrial Revolution by Christopher Barnatt — Amazon

- Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing by Ian Gibson — Amazon

🧠 Frequently Asked Questions About 3D Printing Materials

What are some eco-friendly and sustainable 3D printing materials available in the market?

Eco-friendly options include PLA, derived from renewable resources like corn starch and sugarcane, which is biodegradable under industrial composting conditions. Newer materials like algae-based PLA and coffee-fill PLA incorporate waste biomass, reducing environmental impact. Recycled filaments such as rPETG are gaining traction, offering similar print quality with a smaller carbon footprint. However, note that biodegradability depends on proper disposal—home composting rarely reaches the necessary temperatures.

How do I store and handle 3D printing materials to maintain their quality?

Most filaments, especially nylon, TPU, and PVA, are hygroscopic and absorb moisture from the air, leading to print defects like bubbling and stringing. Store spools in airtight containers with desiccant packs or use specialized filament dryers like PrintDry. For sensitive materials, drying before printing (e.g., 4 hours at 80 °C for nylon) is essential. Avoid exposing filaments to direct sunlight or fluctuating temperatures to preserve mechanical properties.

What are the pros and cons of using PETG 3D printing materials?

Pros:

- Good impact resistance and flexibility.

- Less warping than ABS, making it easier to print large parts.

- UV and chemical resistant, suitable for outdoor use.

- Food-safe grades available.

Cons:

- Prone to stringing and oozing if not properly dried or tuned.

- Lower stiffness compared to PLA or ABS.

- Surface finish can be glossy but less detailed than resin prints.

Can I use metal 3D printing materials for my DIY projects?

Metal-infused filaments (e.g., BronzeFill, CopperFill) are great for aesthetic, decorative projects but do not possess the mechanical strength or thermal properties of true metal prints. They are abrasive and require hardened nozzles. For functional metal parts, industrial processes like DMLS (Direct Metal Laser Sintering) or binder jetting are necessary but costly and complex. For DIY, metal filaments are best for jewelry, props, or art pieces.

What are the most common types of 3D printing materials used for beginners?

Beginners typically start with PLA due to its ease of printing, low warping, and non-toxic nature. PETG is a close second for those wanting more durability and outdoor resistance. These materials print well on most consumer FDM printers without enclosures or specialized hardware.

What are some flexible 3D printing materials and how are they used?

Flexible filaments like TPU (Thermoplastic Polyurethane) and TPE (Thermoplastic Elastomer) offer rubber-like elasticity. They are used for phone cases, gaskets, wearable items, and shock-absorbing parts. Printing flexible materials requires slower speeds, reduced retraction, and often direct-drive extruders to avoid jams.

Can I use metal or carbon fiber in my 3D printing projects?

Yes, but with caveats. Carbon fiber filaments (nylon or PETG infused with short carbon fibers) provide increased stiffness and strength but are abrasive and require hardened nozzles. Metal-filled filaments offer metallic aesthetics but limited mechanical performance. True metal 3D printing requires specialized industrial equipment.

What are the differences between PLA and ABS 3D printing materials?

- PLA is biodegradable, easy to print, low warp, and emits a sweet smell. It has lower heat resistance and is more brittle.

- ABS is tougher, heat-resistant, and can be acetone-smoothed but requires an enclosure due to warping and emits fumes during printing.

What are the most common types of 3D printing materials?

The most common materials are:

- PLA (easy, biodegradable)

- ABS (tough, heat-resistant)

- PETG (durable, chemical resistant)

- Nylon (strong, flexible)

- TPU (flexible, rubbery)

- Resins for SLA/DLP (high detail, smooth finish)

🔗 Reference Links and Further Research

- LulzBot 3D Printing Materials Guide — Comprehensive filament profiles and printing tips.

- Formlabs Materials Library — Extensive resin catalog with datasheets.

- Simplify3D Materials Guide — In-depth filament comparisons and pro tips.

- Polymaker Official Website — Leading filament manufacturer.

- MatterHackers Filament Store — Wide selection of premium filaments.

- NASA Outgassing Database — Material suitability for aerospace applications.

- CDC NIOSH Styrene Exposure Limits — Safety data for ABS printing fumes.

Ready to dive deeper? Check out our 3D Printable Objects and 3D Design Software categories to start creating with your new material knowledge!