Support our educational content for free when you purchase through links on our site. Learn more

Unlocking 3D Printing ROI: 7 Secrets to Skyrocket Your Investment 🚀 (2025)

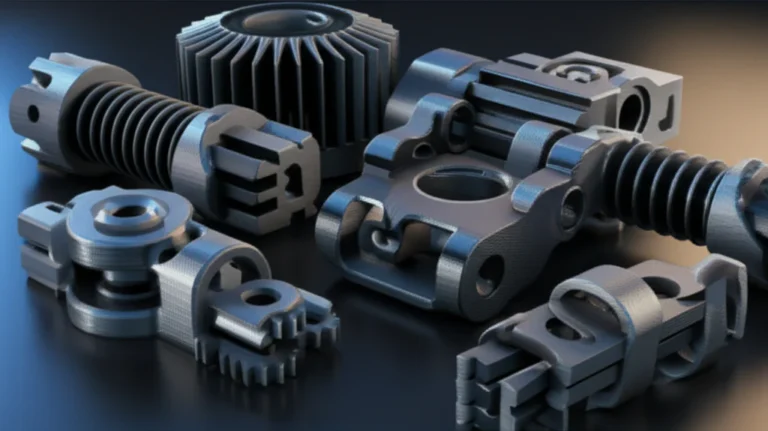

Imagine turning a plastic spool and a desktop machine into a money-making powerhouse that pays for itself in weeks—not years. Sounds like sci-fi? Not anymore. At 3D Printed™, we’ve crunched the numbers, tested the gear, and lived the highs and lows of 3D printing investments. From slashing prototyping costs by over 97% to accelerating product launches from weeks to hours, the ROI story is nothing short of revolutionary.

But here’s the kicker: the secret to unlocking this goldmine isn’t just buying any printer. It’s about choosing the right machine, integrating it smartly, and avoiding common pitfalls that silently drain your budget. Stick around, because later we’ll reveal a real-life case study where a company’s printer paid for itself in just two weeks—and how you can replicate that success.

Key Takeaways

- 3D printing ROI goes beyond cost savings: it’s about time saved, innovation unlocked, and agility gained.

- In-house 3D printing beats outsourcing for speed, flexibility, and long-term savings—especially for frequent or functional parts.

- Choosing a reliable, professional-grade printer like the UltiMaker S7 or Bambu Lab X1-Carbon is critical to maximizing ROI.

- Maintenance, training, and workflow integration are essential factors that impact your investment’s success.

- Real-world case studies prove that rapid prototyping and on-demand production can pay off in weeks, not years.

Ready to start your 3D printing journey?

- Shop professional 3D printers: UltiMaker | Bambu Lab | Prusa

- Explore 3D printable objects to test your new machine: Thingiverse | MyMiniFactory

Table of Contents

- ⚡️ Quick Tips and Facts About 3D Printing ROI

- 🔍 The Evolution of 3D Printing and Its Impact on Investment Returns

- 💡 Why Investing in 3D Printing Technology Makes Financial Sense

- 💸 Outsourcing vs. In-House 3D Printing: A Cost Comparison Breakdown

- 📊 How to Calculate and Maximize Your 3D Printing ROI Like a Pro

- 🛠️ 7 Key Factors Influencing 3D Printing Return on Investment

- 📈 Real-World Success: Snow Business Case Study on 3D Printing ROI

- 🚀 Building a Rock-Solid Business Case for 3D Printing Investment

- 🔧 Maintenance, Upgrades, and Hidden Costs: What You Need to Know

- 🧩 Integrating 3D Printing into Your Workflow for Maximum Profitability

- 📉 Common Pitfalls That Can Sink Your 3D Printing ROI and How to Avoid Them

- 🌍 Environmental and Sustainability Benefits Impacting ROI

- 🔮 Future Trends in 3D Printing ROI: What to Expect Next

- ✅ Conclusion: Is 3D Printing a Worthwhile Investment for You?

- 🔗 Recommended Links for Deep Diving into 3D Printing ROI

- ❓ Frequently Asked Questions About 3D Printing ROI

- 📚 Reference Links and Resources for 3D Printing Investment Insights

Here at 3D Printed™, we live and breathe melted plastic, cured resin, and sintered powder. We’ve seen it all: the triumphs, the spaghetti-monster failures, and the jaw-dropping moment when a custom part, printed for pennies, saves a project worth thousands. You’re probably wondering, “Is a 3D printer really a good investment for me or my business?” You’ve heard the hype, but you want the real numbers, the nitty-gritty details.

Well, grab a coffee, because we’re about to pull back the curtain on the Return on Investment (ROI) of 3D printing. We’ll go beyond the marketing fluff and give you the straight-up, experience-backed truth. Let’s get into it!

⚡️ Quick Tips and Facts About 3D Printing ROI

Before we dive deep, let’s get you up to speed with some rapid-fire insights. Think of this as your cheat sheet to sounding like a pro at your next budget meeting.

- It’s Not Just About Money: ROI in 3D printing is a three-headed beast: Time Savings, Cost Reduction, and Innovation Unlocked. Ignoring any one of these gives you an incomplete picture.

- Speed is a Superpower: The ability to go from a digital design to a physical object in hours, not weeks, is arguably the biggest ROI driver. This is a core theme you’ll see again and again.

- Break-Even Can Be FAST: For businesses that frequently outsource prototypes, the break-even point can be surprisingly quick. The case study we’ll discuss later shows a company whose printer paid for itself in just two weeks!

- Failures are Part of the Budget: Don’t forget to factor in the cost of failed prints. It happens to everyone! A reliable machine minimizes this, directly boosting your ROI.

- The Power of a Spare Part: Printing a single, out-of-production plastic bracket for a critical piece of machinery can save you from having to replace the entire unit. That’s an ROI of thousands of percent right there.

- Staggering Savings: According to research cited by 3DGence, automotive giant BMW achieved a whopping 58% cost savings by using 3D printed tools and fixtures.

- Market Growth is Explosive: The 3D printing market is booming, with some sectors projecting a Compound Annual Growth Rate (CAGR) of over 20%. This growth is fueled by proven, tangible returns. For more data, check out our deep dive into the latest statistics about 3D printing.

🔍 The Evolution of 3D Printing and Its Impact on Investment Returns

Remember the early days of personal computing? Giant, beige boxes that cost a fortune and did very little? The early days of 3D printing were kind of like that. The machines were colossal, eye-wateringly expensive, and required a PhD to operate. The ROI was a concept reserved for aerospace companies and Formula 1 teams.

Then, everything changed. Key patents for Fused Deposition Modeling (FDM) technology expired in 2009, unleashing a tidal wave of innovation. Suddenly, brilliant minds in sheds and garages all over the world could build and sell their own printers. This was the “Big Bang” of desktop 3D printing.

From Clunky Prototypes to Functional Parts

Initially, the ROI was simple: could you print a rough-looking prototype cheaper than getting it machined? Yes. ✅

But as the technology matured, so did the investment equation. Printers like the original MakerBot Replicator or the first Prusa i3 models showed us what was possible on a desk. Now, we have machines like the Bambu Lab X1-Carbon that can print with multiple colors and materials, or the UltiMaker S7 that offers industrial-grade reliability.

This evolution shifted the conversation from “rapid prototyping” to “rapid production.” As the experts at 3DGence note, this is a fundamental change in how industries, especially automotive, view the technology. The focus is no longer just on making a sample; it’s on making the final product, the custom tool, or the essential manufacturing jig. This leap in capability has sent the potential for ROI into the stratosphere, a key part of the story of 3D Printing Innovations.

💡 Why Investing in 3D Printing Technology Makes Financial Sense

So, why should you divert funds from other parts of your budget to a machine that, essentially, melts plastic? Because it’s a strategic tool that pays dividends in ways you might not expect.

H3: Accelerate Your Ideas into Reality

Traditional prototyping is a slow, painful dance. You send a design out, wait a week (or more), pay a hefty invoice, and get a part back. What if it’s not quite right? Rinse and repeat. With an in-house 3D printer, you can iterate multiple times in a single day. We once designed a custom enclosure for an electronics project; the first version had the USB port off by 2mm. With outsourcing, that would have been a one-week, costly delay. In-house? We adjusted the model in Fusion 360, and had a perfect-fit version printing 15 minutes later. That speed is money.

H3: Become a “Just-in-Time” Production Powerhouse

Warehouses are expensive. Storing mountains of spare parts or products “just in case” ties up capital and space. As UltiMaker points out, “in-house production allows for a ‘just in time’ approach to your inventory, eliminating costly storage.” Need a specific jig for a one-off job? Print it. A customer wants a custom-colored version of your product? Print it on demand. You transform from a mass-producer to an agile creator.

H3: Unleash Unprecedented Customization

From custom ergonomic grips for tools to personalized phone cases, 3D printing makes one-of-a-kind items economically viable. This opens up entirely new business models. You can offer a level of personalization that’s impossible with traditional manufacturing, creating high-value 3D Printable Objects that customers love.

H3: Lock Down Your Intellectual Property (IP)

Every time you send a design file to an external service, you’re creating a potential point of failure for your IP. While most services are reputable, keeping your sensitive, proprietary designs within your own four walls is the only way to be 100% certain they stay yours. For a new invention, this peace of mind is priceless.

💸 Outsourcing vs. In-House 3D Printing: A Cost Comparison Breakdown

The classic dilemma: Do you buy the cow or just get milk delivered? Both have their place. Let’s break down the real-world differences between owning a 3D printer and using a service like Craftcloud or Shapeways.

| Factor | In-House 3D Printing | Outsourcing Service |

|---|---|---|

| Upfront Cost | 💰💰💰 High initial investment in hardware. | ✅ Zero upfront cost. Pay as you go. |

| Per-Part Cost | ✅ Extremely low. You only pay for material and a tiny bit of electricity. | ❌ High. You’re paying for their machine time, labor, and profit margin. |

| Lead Time | 🚀 Blazing fast. Hours from design to part-in-hand. | 🐌 Slow. Typically days to weeks, including shipping. |

| Flexibility | ✅ Infinite. Print what you want, when you want. Make changes on the fly. | ❌ Limited. You’re bound by their processes and schedules. |

| Material Variety | 🛠️ Good, but limited to the capabilities of your specific machine(s). | ✅ Massive. Access to industrial materials like metal, nylon, and more. |

| Expertise Required | 🧠 Requires learning and maintenance. Someone has to run the machine. | ✅ None. You just upload a file and they handle the rest. |

| IP Security | ✅ Maximum security. Your files never leave your network. | ⚠️ Potential risk. You’re trusting a third party with your designs. |

The bottom line? Outsourcing is great for one-off projects, parts that require exotic materials your desktop machine can’t handle, or if you have absolutely zero time or interest in learning the process.

In-house printing is the clear winner for anyone who needs to iterate, produce parts regularly, or requires speed and control. The high upfront cost is amortized over every single print, and as Ultimaker’s analysis shows, the break-even point can arrive much sooner than you think.

📊 How to Calculate and Maximize Your 3D Printing ROI Like a Pro

Alright, let’s get down to brass tacks. How do you actually put a number on this? The basic formula is simple, but the devil is in the details.

The Basic Formula:

ROI (%) = [ (Net Gain from Investment - Cost of Investment) / Cost of Investment ] * 100

Let’s break down those two big components:

H3: Tallying the “Cost of Investment”

This isn’t just the sticker price of the printer! A true calculation includes:

- Hardware: The printer itself. This could be a workhorse like a Prusa MK4, a speed demon like a Bambu Lab P1S, or a professional unit like an UltiMaker Method X. Check out our 3D Printer Reviews for help choosing.

- Software: While slicers like UltiMaker Cura and PrusaSlicer are free, your design process might require paid 3D Design Software like SolidWorks or a premium TinkerCAD plan.

- Materials: Your initial stock of filament or resin. Don’t just buy one spool!

- Labor & Training: The time it takes for you or your team to learn the machine and software.

- Maintenance & Consumables: Budget for spare nozzles, build plates, cleaning supplies, etc.

H3: Quantifying the “Net Gain”

This is the fun part. Your “gain” comes from several places:

- Direct Cost Savings: This is the easiest to measure. Take 10 parts you’ve outsourced in the past year. Add up what you paid. Now, calculate the material cost to print them yourself. The difference is your direct saving.

- Example: You paid an outsourcing service $80 for a prototype. The filament to print it in-house costs $2.50. That’s a $77.50 saving on one part.

- Time Savings (The Hidden Multiplier): This is harder to quantify but often more valuable. How much is a week of your engineering team’s time worth? If printing in-house saves you a 5-day wait, that’s a full week of development time you’ve gained on a project. This accelerates your time-to-market, which has a massive financial impact.

- New Revenue & Opportunities: Did you create a new product line of customizable goods? Did you land a client because you could produce a physical sample overnight? This is new revenue that wouldn’t exist without the printer.

To maximize ROI, focus on high-value prints. Don’t just print keychains from Thingiverse. Print jigs, fixtures, functional prototypes, and custom parts that solve expensive problems.

🛠️ 7 Key Factors Influencing 3D Printing Return on Investment

Thinking of pulling the trigger? Your final ROI will hinge on these seven critical factors. Get these right, and you’ll be swimming in savings.

- Printer Choice & Reliability: This is number one for a reason. A cheap, unreliable printer that’s constantly down for repairs or producing failed prints will destroy your ROI. A professional, reliable machine, as Ultimaker emphasizes, “is capable of running continuously with high uptime and print success rates.” This maximizes throughput and minimizes wasted material and time.

- Material Selection: Printing everything in expensive carbon-fiber-infused nylon when a simple PLA or PETG would do the job is like filling a commuter car with rocket fuel. Match the material to the application’s needs to control costs. Research material properties on sites like MatterHackers or Polymaker.

- Print Volume & Frequency: A 3D printer sitting idle is a wasted investment. The more you use it to offset outsourcing costs or generate value, the faster it pays for itself. Before buying, have a list of at least 10-20 things you know you need to print.

- Labor and Skill Level: A printer with a steep learning curve will cost you in training time. Machines known for their ease of use, like those from Bambu Lab or Prusa, lower this barrier, meaning your team can get productive faster.

- Application Type: The value of what you print matters immensely.

- Low ROI: Trinkets, toys, things you could buy cheaply.

- Medium ROI: Prototypes, aesthetic models.

- High ROI: Functional end-use parts, custom jigs and fixtures, replacement parts for expensive equipment.

- Post-Processing Requirements: A print isn’t always “done” when it comes off the build plate. Sanding, painting, support removal, or resin curing all take time and materials. Complex parts that need lots of finishing will have a lower net ROI than parts that are usable right off the printer.

- Workflow Integration: How easily does the printer fit into your existing process? Does the software talk to your CAD program? Can you manage it remotely? A smooth workflow, like the one proposed by 3DGence CLOUD, saves time at every step, which directly translates to a better ROI.

📈 Real-World Success: Snow Business Case Study on 3D Printing ROI

Theory is great, but what about the real world? Let’s look at one of the most compelling case studies out there, detailed by UltiMaker, featuring a company called Snow Business. No, they don’t sell snow cones; they create the incredible snow effects you see in blockbuster movies.

The Challenge:

The team at Snow Business, led by Head of Research Paul Denney, constantly needed to design and test new nozzles to create different types of cinematic snow. Their process was to outsource these prototypes using SLS (Selective Laser Sintering). This came with two massive headaches:

- Cost: A minimum order of around $150 per design iteration.

- Time: A lead time of up to 7 days.

Imagine trying to be creative and innovative with that kind of friction. It’s like trying to paint a masterpiece while waiting a week for each new color to dry.

The Solution:

They decided to take the plunge and invested in three UltiMaker 3D printers. They brought the entire process in-house.

The Jaw-Dropping Results:

The impact was immediate and staggering.

- Cost per iteration plummeted from ~$150 to just ~$3.25. That’s a cost reduction of over 97%!

- Lead time collapsed from 7 days to a mere 7 hours. They could design a nozzle in the morning, print it over lunch, and be testing it in the afternoon.

The ROI was so massive and so fast that Paul Denney estimated their first printer paid for itself within two weeks. This isn’t a typo. Two. Weeks.

This case perfectly illustrates the trifecta of 3D printing ROI: drastic cost reduction, exponential speed increase, and the resulting explosion in innovation and creative freedom.

🚀 Building a Rock-Solid Business Case for 3D Printing Investment

So, you’re convinced. But your boss, the accounting department, or your spouse still needs some persuading. How do you build a case so compelling they can’t say no? Follow this battle-tested plan.

- Identify and Quantify the Pain: Don’t start by talking about the printer. Start by talking about the problems. “Last quarter, we spent X amount on outsourcing prototypes.” “Project Y was delayed by three weeks waiting for parts.” “We couldn’t take on Client Z because we couldn’t produce a custom sample fast enough.” Use real data and real examples.

- Gather Competitive Quotes: This is your secret weapon. Pick 5-10 parts your company has recently outsourced or would need in the future. Get fresh quotes for them from services like Xometry or local machine shops. This gives you a hard, undeniable “Cost of Doing Nothing.”

- Do the Math (and Show Your Work): Now, choose a specific printer you’re proposing (e.g., a Creality K1 Max). Use a slicer to calculate the exact material cost and print time for those same 5-10 parts. Create a simple table:

Part Name Outsourced Cost In-House Cost Savings Bracket A $120 $4.50 $115.50 Enclosure B $250 $12.00 $238.00 Total … … … - Calculate the Payback Period: Add up the total savings. Now, divide the total cost of your proposed printer setup (hardware, initial materials) by the savings per month or per quarter. This will give you a tangible payback period. “Based on our average usage, this printer will pay for itself in 7 months.”

- Highlight the “Soft” ROI: Now you hit them with the value-adds: increased speed to market, protecting our IP, enabling our engineers to be more innovative, the ability to repair our own equipment, etc.

- Present a Turnkey Solution: Don’t just ask for a printer. Present a full package: “We need the [Printer Model], 5 spools of this material, and this small workspace. The total investment is X, and the payback period is Y.” This shows you’ve done your homework and makes it an easy “yes.”

🔧 Maintenance, Upgrades, and Hidden Costs: What You Need to Know

We believe in being honest brokers of information. A 3D printer is not a magical black box. It’s a piece of machinery, and like any machine, it has running costs and requires care. Ignoring these is a surefire way to get a nasty surprise.

H3: The Reality of Routine Maintenance

Your printer is not an office inkjet. It has hot moving parts. You’ll need to perform regular tasks like:

- Cleaning the build plate: To ensure good adhesion.

- Changing nozzles: They are a consumable item and will wear out or clog.

- Lubricating rods and lead screws: To keep things moving smoothly.

- Tensioning belts: To maintain accuracy.

This isn’t difficult, but it is time that needs to be factored in.

H3: Consumables Beyond the Spool

Your shopping list doesn’t end with filament or resin. Be prepared to budget for:

- For FDM: Isopropyl alcohol (IPA) for cleaning, glue sticks or special bed adhesives, spare nozzles, and potentially replacement build surfaces like PEI sheets.

- For Resin: Gallons of IPA for washing parts, nitrile gloves (lots of them!), replacement FEP or nFEP films for the vat, and paper towels. These costs add up!

H3: The Price of Failure

Every failed print is a double loss: wasted material and wasted time. A 12-hour print that fails at the 11-hour mark is a painful lesson in ROI reduction. This is why investing in a reliable printer is so critical. The higher upfront cost of a machine from a brand known for quality, like LulzBot or Raise3D, can easily be recouped by having a much lower failure rate than a cheaper, less-proven alternative.

H3: The Inevitable Upgrade Itch

The world of 3D Printing Innovations moves at lightning speed. A year after you buy your printer, a new model will come out that’s faster, bigger, or has some new killer feature. Resisting the urge to constantly upgrade is key to letting your initial investment mature and deliver its full ROI.

🧩 Integrating 3D Printing into Your Workflow for Maximum Profitability

Owning a 3D printer is one thing. Making it a seamless, profit-generating part of your daily operations is another. True ROI comes from deep integration, not just having a machine in the corner for odd jobs.

H3: Think in 3D: Design for Additive Manufacturing (DfAM)

You can’t just take a design meant for injection molding and expect it to print perfectly. To get the most out of your machine, your team needs to learn the principles of Design for Additive Manufacturing (DfAM). This means designing parts that leverage the strengths of 3D printing—like creating complex internal geometries, consolidating multiple parts into one, and minimizing the need for supports. It’s a shift in thinking that can be taught and is a fantastic use case for 3D Printing in Education within a company.

H3: Create a “Mission Control” for Your Prints

For a business, managing print jobs can get chaotic. Who gets to print next? Which file is the latest version? This is where print management software becomes essential. Solutions like OctoPrint (a free, open-source marvel) or professional cloud-based platforms like the ones offered by 3DGence or UltiMaker allow you to:

- Queue jobs remotely.

- Monitor prints via webcam.

- Track material usage.

- Manage a whole farm of printers from a single dashboard.

This organization turns a hobbyist tool into a professional manufacturing system.

H3: Establish a Clear “Use Case” Protocol

To avoid the printer becoming a toy for printing knick-knacks from MyMiniFactory, establish a clear protocol. Create a simple request form: What problem does this part solve? What is the estimated cost/time saving? This forces everyone to think in terms of value and ensures the printer’s time is dedicated to tasks that boost your bottom line.

📉 Common Pitfalls That Can Sink Your 3D Printing ROI and How to Avoid Them

We’ve helped countless people and businesses get started, and we’ve seen the same mistakes pop up time and again. Here are the biggest ROI-killers and how you can sidestep them like a pro.

-

❌ The Mistake: Buying a cheap hobbyist printer for a demanding professional workload. You’ll spend more time tinkering and fixing it than actually printing.

-

✅ The Solution: Match the machine to the mission. Be honest about your needs. If you need high uptime and precision parts for your business, invest in a professional-grade machine. Read our 3D Printer Reviews to understand the differences.

-

❌ The Mistake: Underestimating the learning curve. You hand a complex engineering-grade printer to a team with no experience and expect perfect results on day one.

-

✅ The Solution: Invest in training. Start with simple projects. Designate one or two “champions” to become the in-house experts and then train others. Patience in the beginning pays off exponentially.

-

❌ The Mistake: Forgetting about “Total Cost of Ownership.” You only budget for the printer, then get shocked by the cost of materials, consumables, and maintenance.

-

✅ The Solution: Create a real budget. When calculating ROI, include a realistic annual budget for filament/resin, spare parts, and cleaning supplies.

-

❌ The Mistake: The “Solution in Search of a Problem.” You buy a printer because it’s cool, but have no clear plan for how it will add value. It ends up gathering dust or just printing Yoda heads.

-

✅ The Solution: Strategy before spending. Before you even browse for printers, complete the “Building a Business Case” steps. Know exactly what you’re going to use it for and how it will save or make you money.

🌍 Environmental and Sustainability Benefits Impacting ROI

In today’s world, ROI isn’t just measured in dollars. A company’s environmental impact is a critical metric for customers, employees, and investors. 3D printing offers some surprisingly powerful sustainability benefits that contribute to a “green ROI.”

H3: Additive, Not Subtractive

Traditional manufacturing is often subtractive—you start with a big block of material and cut away everything you don’t need, creating immense waste. 3D printing is additive. It builds an object layer by layer, using only the material required. This fundamental difference, as highlighted by institutions like MIT, can lead to a massive reduction in material waste.

H3: The End of Overproduction

By enabling on-demand production, 3D printing fights the wasteful model of mass-producing goods that may never be sold. You print what you need, when you need it. This reduces the energy, materials, and carbon footprint associated with manufacturing and warehousing excess inventory.

H3: Reshoring and Localized Manufacturing

Why outsource a part to be made on the other side of the world and then ship it back? 3D printing empowers local manufacturing. This drastically cuts down on transportation emissions and strengthens local economies. Printing a replacement part in-house instead of having it flown in from a central warehouse is a huge environmental win.

H3: A Circular Economy in the Making

The materials themselves are getting greener. You can now buy high-quality filament made from recycled plastics from innovative companies like Filamentive. Furthermore, common materials like PLA (Polylactic Acid), derived from corn starch, are biodegradable under industrial composting conditions. This opens the door to a more circular and sustainable production lifecycle. While this “green ROI” might not show up on a traditional balance sheet, it’s invaluable for brand reputation and corporate responsibility.

🔮 Future Trends in 3D Printing ROI: What to Expect Next

If you think the ROI is good now, just wait. The technology is accelerating, and the next wave of innovations will make the investment even more compelling. Here’s what we at 3D Printed™ are most excited about:

- Smarter, AI-Driven Software: Slicers are getting scary smart. We’re seeing the emergence of AI-powered software that can analyze a model and automatically optimize the print settings—not just for speed, but for strength, cost, and material usage. This will reduce the need for user expertise and minimize failed prints, directly boosting ROI.

- Accessible Multi-Material and Metal Printing: Systems like Bambu Lab’s AMS have made multi-color/multi-material printing mainstream. This trend will continue, allowing for the creation of complex parts with both rigid and flexible elements in a single print. Meanwhile, the cost of metal 3D printing, while still high, is steadily decreasing. When desktop metal printing becomes widely accessible, the ROI for manufacturing and repair applications will be astronomical.

- Full Automation and “Lights-Out” Manufacturing: We’re moving towards fully automated print farms. Imagine a system that can automatically start prints, remove finished parts from the build plate, and begin the next job without any human intervention. This “lights-out” manufacturing will allow businesses to run their printers 24/7, maximizing throughput and ROI.

- Integration with Virtual and Augmented Reality: Imagine a technician wearing AR glasses, looking at a broken machine. The glasses identify the broken part, pull up the 3D model, and send it directly to the in-house 3D printer. This seamless integration of digital and physical worlds will make repair and maintenance incredibly efficient, saving immense time and money.

The future of 3D printing is one where the machines are smarter, more capable, and more integrated into our lives, making the return on investment better with each passing year. The question is quickly changing from “Should I invest?” to “Can I afford not to?”

✅ Conclusion: Is 3D Printing a Worthwhile Investment for You?

After our deep dive into the world of 3D printing ROI, the verdict is crystal clear: 3D printing is not just a cool gadget; it’s a strategic business asset that can pay for itself quickly and open doors to innovation and efficiency you never thought possible.

From the blistering speed gains and jaw-dropping cost savings seen in Snow Business’s case study, to the staggering 58% tooling cost reduction achieved by BMW, the evidence is overwhelming. But—and this is a big but—your ROI depends heavily on choosing the right printer for your needs, integrating it smartly into your workflow, and having a clear plan for how it will add value.

We’ve seen that in-house 3D printing beats outsourcing hands down for speed, flexibility, and long-term cost savings, especially when you print frequently and for functional parts. However, don’t underestimate the learning curve, maintenance, and hidden costs. A reliable, professional-grade printer like the UltiMaker S7 or the Bambu Lab X1-Carbon is worth every penny for businesses serious about ROI.

If you’re a hobbyist or a business dipping your toes in, start small but plan big. Build your business case with real data, focus on high-impact prints, and invest in training. The payoff? Faster innovation cycles, lower costs, and the freedom to create without limits.

So, is 3D printing a worthwhile investment? Absolutely yes—if you approach it with eyes wide open and a strategy in hand. Ready to join the ranks of those turning plastic into profit? We thought so!

🔗 Recommended Links for Deep Diving into 3D Printing ROI

Ready to take the plunge? Here are some top picks for printers and resources to get you started:

-

UltiMaker S7:

Thingiverse Search | Ultimaker Official Website | Amazon Search -

Bambu Lab X1-Carbon:

Thingiverse Search | Bambu Lab Official Website | Amazon Search -

Prusa MK4:

Thingiverse Search | Prusa Official Website | Amazon Search -

Creality K1 Max:

Thingiverse Search | Creality Official Website | Amazon Search -

Books to Boost Your 3D Printing ROI Knowledge:

- 3D Printing Failures: How to Diagnose and Repair All 3D Printing Issues by Sean Aranda

Amazon Link - Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing by Ian Gibson, David Rosen, Brent Stucker

Amazon Link - Design for Additive Manufacturing: Concepts and Applications by Martin Leary

Amazon Link

- 3D Printing Failures: How to Diagnose and Repair All 3D Printing Issues by Sean Aranda

❓ Frequently Asked Questions About 3D Printing ROI

How long does it take to see a return on investment with 3D printing?

The payback period varies widely depending on usage, printer choice, and application. For businesses that frequently outsource prototypes or parts, ROI can be seen in as little as two weeks, as demonstrated by Snow Business’s experience with UltiMaker printers. For less frequent users, it might take several months to a year. The key is high utilization and printing parts that replace costly outsourcing or accelerate time-to-market. Remember to factor in training and maintenance time as well.

What are the most cost-effective things to 3D print for a high ROI?

Functional parts, jigs, fixtures, and replacement components offer the highest ROI because they directly reduce costs or downtime. Printing prototypes in-house to accelerate design cycles also yields great returns. Avoid printing purely decorative or low-value items unless they serve marketing or customer engagement purposes. Focus on prints that solve real problems or generate revenue.

Can I make money selling 3D printed items, and if so, how?

Absolutely! Many entrepreneurs have built businesses selling customized products, miniatures, jewelry, and functional gadgets. Platforms like Etsy, eBay, and Amazon Handmade are great places to start. Success hinges on finding a niche, offering unique or personalized products, and maintaining high quality. Keep in mind that production speed, material costs, and post-processing time affect profitability.

How does the cost of 3D printing materials impact my return on investment?

Material costs are a significant part of the total cost per print. Filaments like PLA or PETG are relatively inexpensive, while specialty materials (carbon fiber composites, flexible TPU, resins) cost more. Using the right material for the job prevents overpaying and ensures part performance. Bulk purchasing and recycling failed prints can reduce material expenses, improving ROI.

What are the benefits of 3D printing for businesses looking to increase ROI?

3D printing offers rapid prototyping, on-demand manufacturing, customization, and inventory reduction. It accelerates product development cycles, reduces outsourcing costs, and enables innovation. Additionally, it enhances IP security and supports sustainability initiatives by reducing waste and transportation emissions.

Are there any tax benefits to investing in 3D printing equipment and supplies?

In many jurisdictions, 3D printers and related equipment qualify as capital expenditures and may be eligible for tax deductions or depreciation benefits. Some regions offer incentives for investing in manufacturing technology or green initiatives. Consult a tax professional to understand local laws and maximize your tax advantages.

How can I calculate the return on investment for a specific 3D printing project or product?

Start by calculating all costs involved: printer depreciation, materials, labor, energy, and post-processing. Then, estimate the savings compared to outsourcing or traditional manufacturing, including reduced lead times and increased revenue opportunities. Use the formula:

ROI (%) = [(Savings - Costs) / Costs] * 100

Tools like the SprintRay ROI Calculator can help dental professionals and others model their specific scenarios. Always include intangible benefits like innovation speed and IP security for a full picture.

📚 Reference Links and Resources for 3D Printing Investment Insights

- Ultimaker: The ROI of 3D Printing

- 3DGence Automotive 3D Printing ROI

- SprintRay Return on Investment Calculator

- BMW 3D Printing Case Study

- Bambu Lab Official Website

- Prusa Research Official Website

- Ultimaker Official Website

- Creality Official Website

- MatterHackers Material Guide

- Polymaker Material Profiles

- OctoPrint Open Source Software

- MyMiniFactory 3D Printable Models

We hope this comprehensive guide has armed you with the knowledge and confidence to make your 3D printing investment a roaring success. Remember, the best ROI comes from smart choices, consistent use, and a passion for turning ideas into reality. Happy printing! 🚀