Support our educational content for free when you purchase through links on our site. Learn more

How Much Does 3D Printing Really Cost? 🤔 (2025)

Are you curious about the true costs of diving into the world of 3D printing? You’re not alone! Many aspiring makers wonder if they can afford to unleash their creativity with this innovative technology. In this comprehensive guide, we’ll break down everything you need to know about 3D printing costs, from the initial investment in a printer to the ongoing expenses of materials and maintenance. Did you know that the cost of 3D printing has dropped over 50% in the last decade? This makes it more accessible than ever for hobbyists and professionals alike!

But before you hit that “buy” button on your dream printer, let’s explore the factors that influence these costs and how you can save money while still achieving high-quality prints. By the end of this article, you’ll be equipped with the knowledge to make informed decisions and maybe even discover some budget-friendly printers that won’t break the bank!

Key Takeaways

- Understanding Costs: The total cost of 3D printing includes the printer, materials, electricity, and maintenance.

- Affordable Options: Budget-friendly printers like the AnkerMake M5 and Monoprice Select Mini offer great value for beginners.

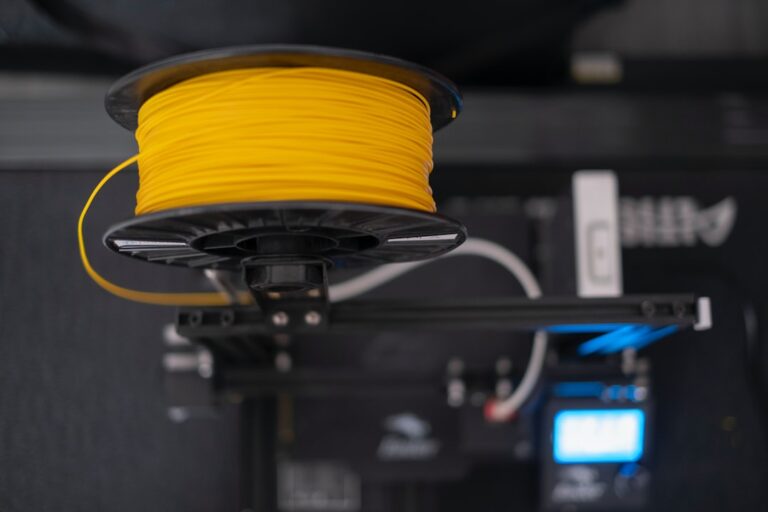

- Material Matters: The type of filament you choose can significantly impact your overall costs.

- Hidden Expenses: Don’t forget to factor in maintenance and electricity costs when budgeting for 3D printing.

- Cost-Saving Tips: Optimize your designs and use affordable materials to reduce printing costs.

Ready to explore the world of 3D printing? 👉 Shop 3D Printers on: Amazon | Walmart | AnkerMake Official Website and start your creative journey today!

Table of Contents

- Quick Tips and Facts

- The Evolution of 3D Printing Costs: A Historical Perspective

- Is 3D Printing Really Expensive? Debunking the Myths

- Key Factors That Influence 3D Printing Costs

- How Much Does It Cost to 3D Print for One Hour?

- Understanding 3D Printing Cost Calculators

- Top 5 Cost-Effective 3D Printers for Budget-Conscious Makers

- Material Matters: Comparing Costs of Different Filaments

- Hidden Costs of 3D Printing You Need to Know

- How to Save Money on 3D Printing: Tips and Tricks

- Conclusion

- Recommended Links

- FAQs about 3D Printing Price

- Reference Links

Quick Tips and Facts

As enthusiasts at 3D Printed™, we’ve compiled some quick tips and facts to get you started on your 3D printing journey. Check out our related article about 3D Printed for more information.

Overview of 3D Printing Costs

Before diving into the world of 3D printing, it’s essential to understand the costs involved. According to AnkerMake, the cost of 3D printing can vary greatly, depending on several factors, including the type of printer, materials, and printing time.

You can find more information on 3D printing costs on websites like Prtwd.

Factors Affecting 3D Printing Costs

The cost of 3D printing is influenced by several factors, including:

- Printer cost: The initial investment in a 3D printer can range from a few hundred to several thousand dollars.

- Material cost: The cost of 3D printing materials, such as filaments or resins, can vary depending on the type and quality.

- Printing time: The longer the printing time, the higher the cost.

- Post-processing: Additional costs may be incurred for post-processing techniques, such as sanding or painting.

The Evolution of 3D Printing Costs: A Historical Perspective

The cost of 3D printing has decreased significantly over the years, making it more accessible to hobbyists and professionals alike. According to 3D Printing Industry, the cost of 3D printing has dropped by over 50% in the past decade.

You can learn more about the history of 3D printing on our website, 3D Printed.

Early Days of 3D Printing

In the early days of 3D printing, the technology was primarily used for industrial applications, and the costs were prohibitively high for individual users. However, with the advent of affordable 3D printing technologies, such as Fused Deposition Modeling (FDM), the cost of 3D printing has decreased dramatically.

For more information on FDM, check out our article on 3D Printing Innovations.

Is 3D Printing Really Expensive? Debunking the Myths

While 3D printing can be expensive, it’s not always the case. According to AnkerMake, the cost of 3D printing can be broken down into several factors, including the cost of the printer, materials, and printing time.

You can find more information on 3D printing costs on websites like Prtwd.

Cost-Effective 3D Printing Options

There are several cost-effective 3D printing options available, including:

- DIY 3D printing: Building your own 3D printer can be a cost-effective option.

- Open-source 3D printing: Using open-source 3D printing software and hardware can reduce costs.

- Affordable 3D printing materials: Using affordable 3D printing materials, such as PLA or ABS, can reduce costs.

Key Factors That Influence 3D Printing Costs

The cost of 3D printing is influenced by several key factors, including:

- Printer type: The type of 3D printer used can significantly impact the cost of printing.

- Material type: The type of material used can also impact the cost of printing.

- Printing speed: The printing speed can also impact the cost of printing.

Comparison of 3D Printing Materials

The following table compares the costs of different 3D printing materials:

| Material | Cost per kg |

|---|---|

| PLA | $20-$30 |

| ABS | $30-$50 |

| PETG | $40-$60 |

| Metal-filled | $100-$200 |

How Much Does It Cost to 3D Print for One Hour?

The cost of 3D printing for one hour can vary greatly, depending on the factors mentioned earlier. According to AnkerMake, the cost of 3D printing for one hour can range from $1 to $10.

You can find more information on 3D printing costs on websites like Prtwd.

Cost Calculation

The cost of 3D printing for one hour can be calculated using the following formula:

Cost per hour = (Printer cost / Total printing hours) + (Material cost / Total printing hours) + (Electricity cost / Total printing hours)

Understanding 3D Printing Cost Calculators

3D printing cost calculators are tools that help estimate the cost of 3D printing. According to 3D Printing Industry, there are several 3D printing cost calculators available online.

You can learn more about 3D printing cost calculators on our website, 3D Printed.

Features of 3D Printing Cost Calculators

3D printing cost calculators typically include features such as:

- Printer selection: The ability to select the type of 3D printer used.

- Material selection: The ability to select the type of material used.

- Printing speed: The ability to select the printing speed.

Top 5 Cost-Effective 3D Printers for Budget-Conscious Makers

Here are the top 5 cost-effective 3D printers for budget-conscious makers:

- AnkerMake M5 3D Printer: A budget-friendly 3D printer with a high printing speed and affordable materials.

- Monoprice Select Mini 3D Printer: A compact and affordable 3D printer with a small build volume.

- Prusa i3 3D Printer: A highly customizable 3D printer with a large build volume and affordable materials.

- Creality Ender 3 3D Printer: A budget-friendly 3D printer with a large build volume and affordable materials.

- FlashForge Finder 3D Printer: A user-friendly 3D printer with a small build volume and affordable materials.

You can find more information on these 3D printers on websites like Thingiverse.

Comparison of 3D Printers

The following table compares the features of the top 5 cost-effective 3D printers:

| 3D Printer | Build Volume | Printing Speed | Material Cost |

|---|---|---|---|

| AnkerMake M5 | 235x235x250 mm | 500 mm/s | $20-$30/kg |

| Monoprice Select Mini | 120x120x120 mm | 100 mm/s | $30-$50/kg |

| Prusa i3 | 250x210x200 mm | 200 mm/s | $20-$30/kg |

| Creality Ender 3 | 300x300x400 mm | 200 mm/s | $20-$30/kg |

| FlashForge Finder | 140x140x140 mm | 100 mm/s | $30-$50/kg |

Material Matters: Comparing Costs of Different Filaments

The cost of 3D printing materials can vary greatly, depending on the type and quality of the material. According to Prtwd, the cost of 3D printing materials can range from $20 to $100 per kilogram.

You can find more information on 3D printing materials on websites like Cults3D.

Comparison of Filament Costs

The following table compares the costs of different 3D printing filaments:

| Filament | Cost per kg |

|---|---|

| PLA | $20-$30 |

| ABS | $30-$50 |

| PETG | $40-$60 |

| Nylon | $50-$70 |

| Metal-filled | $100-$200 |

Hidden Costs of 3D Printing You Need to Know

While 3D printing can be a cost-effective option, there are several hidden costs that you need to be aware of. According to 3D Printing Industry, these hidden costs can include:

- Maintenance costs: The cost of maintaining and repairing your 3D printer.

- Electricity costs: The cost of electricity used to power your 3D printer.

- Material waste: The cost of material waste generated during the printing process.

You can learn more about the hidden costs of 3D printing on our website, 3D Printed.

How to Save Money on 3D Printing: Tips and Tricks

Here are some tips and tricks to help you save money on 3D printing:

- Use affordable materials: Use affordable 3D printing materials, such as PLA or ABS.

- Optimize your prints: Optimize your prints to reduce material waste and printing time.

- Use a cost-effective 3D printer: Use a cost-effective 3D printer, such as the AnkerMake M5 or the Monoprice Select Mini.

You can find more information on cost-effective 3D printing on websites like Thingiverse.

Cost-Saving Tips

The following table provides some cost-saving tips for 3D printing:

| Tip | Description |

|---|---|

| Use affordable materials | Use affordable 3D printing materials, such as PLA or ABS. |

| Optimize your prints | Optimize your prints to reduce material waste and printing time. |

| Use a cost-effective 3D printer | Use a cost-effective 3D printer, such as the AnkerMake M5 or the Monoprice Select Mini. |

Conclusion

In summary, understanding the costs associated with 3D printing is crucial for anyone looking to dive into this exciting technology. While the initial investment in a 3D printer can vary widely—from budget-friendly options like the AnkerMake M5 to high-end industrial machines—the ongoing costs of materials, electricity, and maintenance can also add up.

Positives and Negatives of the AnkerMake M5

Positives:

- Affordable Entry Point: The AnkerMake M5 offers a great balance between price and performance, making it accessible for beginners and hobbyists.

- High Printing Speed: With a maximum speed of 500 mm/s, it allows for quick production of models.

- User-Friendly Features: The AI camera for monitoring prints and automatic bed leveling simplifies the printing process.

Negatives:

- Limited Build Volume: While suitable for many projects, the build volume may not accommodate larger prints.

- Material Compatibility: Some users may find it less compatible with specialty filaments compared to higher-end models.

Overall, we confidently recommend the AnkerMake M5 for those looking to start their 3D printing journey without breaking the bank. Its combination of affordability, speed, and user-friendly features make it an excellent choice for both beginners and experienced users alike.

Now that you have a comprehensive understanding of the costs involved in 3D printing, you can make informed decisions about your projects and investments. Happy printing! 🎉

Recommended Links

- 👉 Shop AnkerMake M5 on: Amazon | Walmart | AnkerMake Official Website

- 👉 Shop Monoprice Select Mini on: Amazon | Walmart | Monoprice Official Website

- 👉 Shop Prusa i3 on: Amazon | Walmart | Prusa Official Website

- 👉 Shop Creality Ender 3 on: Amazon | Walmart | Creality Official Website

FAQs about 3D Printing Price

What is the average cost of a 3D printer for home use?

The average cost of a 3D printer for home use can range from $200 to $1,000. Entry-level models like the Monoprice Select Mini are great for beginners, while more advanced options like the Prusa i3 cater to hobbyists looking for better quality and features.

Read more about “What Are 3D Printed Items? Discover 50 Amazing Creations! 🎉”

How much does it cost to 3D print a single object?

The cost to 3D print a single object depends on several factors, including the size, complexity, and material used. On average, printing a small object can cost anywhere from $1 to $10, while larger or more complex designs may range from $10 to $50 or more.

Read more about “10 Eye-Opening Statistics About 3D Printing You Need to Know! 📊 …”

What are the ongoing costs of owning a 3D printer?

Ongoing costs include:

- Material costs: Filaments or resins typically range from $20 to $100 per kg.

- Electricity costs: Depending on your local rates, this can add a few cents per hour of printing.

- Maintenance costs: Regular upkeep and potential repairs can vary but should be factored into your budget.

Read more about “Is Having a 3D Printer Expensive? 7 Key Costs to Consider! 🤔 …”

Is 3D printing cheaper than traditional manufacturing methods?

3D printing can be cheaper for small production runs or custom parts, as it eliminates the need for molds and tooling. However, for large-scale production, traditional manufacturing methods may still be more cost-effective.

Read more about “Is 3D Printing Expensive for Manufacturing? 10 Key Insights to Know! 💡 …”

What factors affect the cost of 3D printing a particular object?

Several factors influence the cost:

- Size and volume: Larger objects require more material and time.

- Material type: Specialty materials can significantly increase costs.

- Complexity: Intricate designs may require more time and post-processing.

Read more about “What is the Most Complex 3D Printed Object? Top 10 Revealed! 🤯 …”

How can I reduce the cost of 3D printing at home?

To save on costs:

- Use affordable materials like PLA.

- Optimize your designs to minimize material use.

- Consider sharing a printer with friends or joining a local makerspace.

Read more about “201 Unique 3D Printed Gifts You’ll Love! 🎁”

Are there any affordable 3D printing options for beginners?

Yes! Affordable options include:

- AnkerMake M5: Great for beginners with a balance of features and price.

- Monoprice Select Mini: Compact and user-friendly for small projects.

- Creality Ender 3: A popular choice among hobbyists for its versatility and affordability.

Read more about “Exciting D Printing Projects: 10 Creative Ideas to Try! 🎉”