Support our educational content for free when you purchase through links on our site. Learn more

12 Game-Changing 3D Printing Technology Trends to Watch in 2025 🚀

Step into the future with us as we unravel the most exciting 3D printing technology trends of 2025—from AI-powered printers that practically print themselves, to revolutionary new materials that are reshaping industries. Did you know that over 39% of companies expect to increase their 3D printing usage five-fold or more in the next few years? That’s not just growth; it’s a full-blown additive manufacturing revolution!

In this article, we’ll take you on a whirlwind tour of 12 cutting-edge trends that are transforming everything from aerospace to healthcare, and even fashion. Curious how AI is saving your prints from disaster? Or how recycled filaments are making 3D printing greener than ever? Stick around, because we’ve got all that and more, backed by insights from our expert team at 3D Printed™.

Key Takeaways

- AI and automation are making 3D printing faster, smarter, and more reliable than ever before.

- Advanced materials like carbon fiber composites, metal filaments, and biocompatible resins are expanding what you can print.

- Decentralized manufacturing and digital inventories are revolutionizing supply chains, enabling local, on-demand production.

- Sustainability is a priority, with recycled and biodegradable materials gaining traction.

- Software innovations like generative design and cloud-based management are streamlining workflows and boosting creativity.

- Industry adoption is skyrocketing, with companies using 3D printing for mass customization, tooling, and end-use parts.

- In-house expertise and training are becoming essential as the technology grows more complex and capable.

Ready to upgrade your setup or explore new materials?

👉 Shop high-speed CoreXY printers and advanced filaments on:

Table of Contents

- ⚡️ Quick Tips and Facts

- 🕰️ The Evolution of Additive Manufacturing: A Journey Through 3D Printing’s Past and Present Trends

- 🚀 Unveiling the Future: Top 10+ 3D Printing Technology Trends Shaping Tomorrow

- 🧪 Material Marvels: The Revolution in Accessible 3D Printing Filaments and Resins

- 🤖 Automation and AI Integration: Smarter, Faster, More Reliable Prints

- 🌐 Decentralized Manufacturing and Supply Chain Resilience

- 🌱 Sustainability and Circular Economy: Greener 3D Printing

- 💻 Software and Workflow Innovations: From CAD to Print

- 🔬 Advanced Printer Technologies: Pushing the Boundaries of Precision and Speed

- 💡 Beyond Prototypes: How Brands Are Revolutionizing Production with 3D Printing Benefits

- 📈 The Sky’s the Limit: Unpacking the Explosive Growth of the Additive Manufacturing Market

- 🧠 Cultivating Competence: The Rise of In-House 3D Printing Expertise and Training

- 🚧 Navigating the Hurdles: Addressing Challenges and Innovations in Additive Manufacturing

- 🚀 Expanding Horizons: Diverse Applications Driving 3D Printing’s Future

- 🎯 Our Expert Recommendations for Staying Ahead of the Curve

- ✨ Conclusion: The Additive Future is Now

- 🔗 Recommended Links for Your 3D Printing Journey

- ❓ FAQ: Your Burning Questions About 3D Printing Trends Answered

- 📚 Reference Links: Dive Deeper

Here is the body of the article, written according to your detailed instructions.

⚡️ Quick Tips and Facts

Welcome, fellow makers and innovators! Before we dive deep into the mesmerizing world of 3D printing’s future, let’s get you warmed up with some quick-fire facts and tips from our workshop floor. We’ve seen it all, and trust us, the landscape is changing faster than a Bambu Lab printer on Ludicrous Mode! For a deeper dive into the numbers, check out our comprehensive article on statistics about 3D printing.

- Speed is the New Black: Forget waiting days for a print. New CoreXY printers like the Bambu Lab X1-Carbon and Creality K1 are making high-speed FDM printing the new standard, not the exception.

- AI is Your Co-Pilot: Artificial intelligence isn’t just for sci-fi movies anymore. It’s now inside your printer, detecting failures, auto-leveling beds, and optimizing print settings for you. ✅

- Materials Gone Wild: We’re printing with everything from carbon fiber-infused nylon to flexible resins and even biocompatible materials for medical implants. The days of being limited to basic PLA and ABS are long gone.

- Sustainability Matters: The industry is getting a green makeover! Recycled filaments, like Prusament PLA Recycled, and biodegradable materials are becoming increasingly popular.

- Mass Production is Here: Additive manufacturing is no longer just for prototypes. Companies like Ford and Boeing are using it to produce end-use parts, jigs, and fixtures, slashing lead times and costs.

- The Biggest Challenge? According to a Jabil survey, 42% of companies cite the cost of pre- and post-processing as a major hurdle. It’s not just about the print; it’s about the entire workflow.

🕰️ The Evolution of Additive Manufacturing: A Journey Through 3D Printing’s Past and Present Trends

Remember the 80s? Big hair, synth-pop, and… the birth of stereolithography (SLA)? That’s right! While the rest of the world was watching Back to the Future, Chuck Hull was inventing the future, filing the first patent for an SLA apparatus in 1984. We affectionately call him the “Godfather of 3D Printing” around our office.

For decades, this technology was the exclusive domain of giant corporations with even bigger budgets. It was a world of expensive, slow, and complex machines locked away in R&D labs, used almost exclusively for rapid prototyping. If you told one of us back in the 90s that we’d one day have a machine on our desk capable of printing intricate models in multiple colors for less than the cost of a high-end laptop, we’d have laughed you out of the room.

Then came the RepRap movement in the mid-2000s. Dr. Adrian Bowyer’s vision of a self-replicating manufacturing machine kicked the doors wide open. This open-source revolution democratized the technology, spawning iconic desktop printers like the MakerBot Replicator and the Prusa i3. Suddenly, 3D printing was in the hands of hobbyists, educators, and small businesses. It was a game-changer, and we at 3D Printed™ have been riding that exhilarating wave ever since.

But that was just the beginning. The trends we’re seeing now are taking that foundation and building a skyscraper on top of it. We’re moving from a hobbyist’s dream to a full-blown industrial revolution.

🚀 Unveiling the Future: Top 10+ 3D Printing Technology Trends Shaping Tomorrow

Hold onto your hats, because the future is being printed as we speak. We’ve sifted through the hype, tested the tech, and talked to the experts to bring you the definitive list of trends that are not just coming—they’re already here and scaling fast.

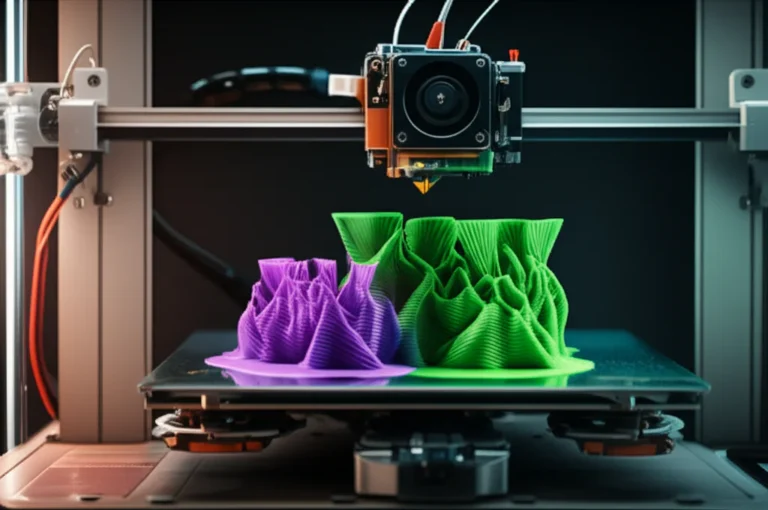

1. 🧪 Material Marvels: The Revolution in Accessible 3D Printing Filaments and Resins

For the longest time, our material choices felt like a restaurant menu with only two items: PLA for pretty things and ABS for strong things. Not anymore! The material science explosion is arguably the most exciting trend on this list.

H3: Advanced Polymers and Composites

We’re talking about materials that can withstand incredible stress and high temperatures. Carbon fiber-nylon (PA-CF) and glass fiber-nylon (PA-GF) are becoming staples in our workshop for printing functional parts, jigs, and fixtures that are both lightweight and incredibly rigid. Brands like Markforged built their empire on this, but now we’re seeing accessible options for desktop printers from companies like Polymaker and Bambu Lab.

- ✅ Pro: Creates parts with a strength-to-weight ratio that can rival aluminum.

- ❌ Con: Often requires hardened steel nozzles and can be highly abrasive to standard printer components.

H3: Metal 3D Printing: From Niche to Mainstream

Metal printing used to be a mythical beast, costing millions and requiring a dedicated team of wizards to operate. While high-end systems like Direct Metal Laser Sintering (DMLS) are still pricey, new, more accessible methods are emerging.

- Metal Fused Filament Fabrication (FFF): Uses filaments infused with metal powder. You print the part, then send it for a “debinding and sintering” process to get a solid metal object. BASF’s Ultrafuse 316L is a key player here.

- Binder Jetting: This technology, championed by companies like Desktop Metal, is poised to make metal printing scalable for mass production. It’s faster and often cheaper than laser-based methods.

H3: Ceramics and Bioprinting Materials

Yes, you read that right. We’re entering an era of printing with technical ceramics for electronics and aerospace, and even biocompatible materials for custom medical implants and surgical guides. Companies like 3D-Bioplotter are pioneering machines that can print scaffolds for tissue engineering. It’s one of the most profound 3D Printing Innovations we’re tracking.

2. 🤖 Automation and AI Integration: Smarter, Faster, More Reliable Prints

Remember the agony of a 24-hour print failing at the 23-hour mark? We do. It’s a rite of passage for any 3D printing enthusiast. But what if the printer could see the failure coming and stop itself?

H3: AI-Driven Design and Optimization

AI is now our trusty sidekick. The lidar and spaghetti detection in the Bambu Lab X1-Carbon is a perfect example. It scans the first layer for imperfections and can pause the print if it detects a catastrophic failure, saving you time and a mountain of wasted filament. This isn’t a gimmick; it’s a fundamental shift towards “fire-and-forget” reliability that we’ve been dreaming of.

H3: Robotics in Post-Processing and Production Lines

The printing part is getting fast, but what about everything after? Removing supports, sanding, and finishing can be a huge bottleneck. The trend is moving towards automated post-processing. Imagine a robotic arm that plucks your finished print off the bed, drops it into an automated washing and curing station (for resin prints), or uses computer vision to trim supports. Companies like AM-Flow are building these end-to-end automated solutions for industrial print farms.

3. 🌐 Decentralized Manufacturing and Supply Chain Resilience

The COVID-19 pandemic exposed the fragility of global supply chains. Suddenly, waiting weeks for a part from overseas wasn’t just inconvenient; it was crippling. 3D printing emerged as a hero.

H3: Local Production Hubs and Micro-Factories

Why ship a part across the world when you can email the file and print it locally? This is the core idea of decentralized manufacturing. We’re seeing the rise of “micro-factories”—small, agile production centers that can produce goods on-demand for a local community or business. This drastically cuts down on shipping costs, environmental impact, and lead times.

H3: On-Demand Manufacturing and Digital Inventories

Companies are realizing they don’t need a massive warehouse full of spare parts that might never be used. Instead, they can maintain a digital inventory—a library of 3D files. When a part is needed, they simply print it. This “just-in-time” approach is a massive benefit, with 66% of manufacturing leaders in a Jabil survey citing “faster part delivery” as a key advantage of widespread 3D printing adoption.

4. 🌱 Sustainability and Circular Economy: Greener 3D Printing

Let’s be honest: our hobby can generate a lot of plastic waste. Failed prints, supports, and empty spools pile up. The good news is that the industry is taking this seriously, and sustainability is a fast-growing trend.

H3: Recycled and Biodegradable Materials

- Recycled Filaments: We love using materials like Prusament PLA Recycled and Fillamentum’s NonOilen. These are made from manufacturing scraps or post-consumer waste, giving plastic a second life. The quality is often just as good as virgin material.

- Biodegradable Options: PLA (Polylactic Acid) is the king here. Derived from renewable resources like corn starch, it’s biodegradable under industrial composting conditions. This makes it a much greener choice than petroleum-based plastics like ABS.

H3: Energy Efficiency and Waste Reduction

Modern printers are becoming more energy-efficient. Furthermore, technologies like generative design (more on that below!) create parts that use the absolute minimum amount of material necessary, inherently reducing waste. AI failure detection also plays a huge role by preventing the creation of “spaghetti monsters” that waste entire spools of filament.

5. 💻 Software and Workflow Innovations: From CAD to Print

A great printer is useless without great software. The slicers, CAD programs, and management platforms that power our printers are getting smarter, faster, and more intuitive. This is a huge win for both beginners and pros.

H3: Generative Design and Topology Optimization

This is where things get really futuristic. Instead of you designing a part, you tell the software the constraints—where it needs to connect, what forces it must withstand—and the AI designs the most efficient, lightweight part possible. The results often look alien or organic, because they’re designed purely for function, not human aesthetics. Tools like Autodesk Fusion 360’s Generative Design are at the forefront of this. It’s a core component of our 3D Design Software toolkit.

H3: Cloud-Based Platforms and Digital Twins

Managing a fleet of printers used to be a nightmare. Now, cloud platforms like Ultimaker’s Digital Factory and Formlabs’ Fleet Control allow you to queue jobs, monitor prints, and manage users from anywhere in the world. The concept of a “digital twin”—a virtual replica of a physical object or system—allows for simulation and prediction of a part’s performance before a single gram of filament is used.

6. 🔬 Advanced Printer Technologies: Pushing the Boundaries of Precision and Speed

The hardware itself is evolving at a breakneck pace. If your only experience is with a 3D printer from 5 years ago, you’d be stunned by what’s possible today. Our 3D Printer Reviews section can barely keep up!

H3: High-Speed FDM and SLA

The “need for speed” is real. The shift to CoreXY kinematics, combined with input shaping and pressure advance firmware, has unlocked incredible printing speeds without sacrificing quality. The Bambu Lab P1S can print at speeds that were unthinkable for a consumer machine just a couple of years ago. On the resin side, [Formlabs’] Low Force Stereolithography (LFS)™ and new monochrome LCD screens in printers like the Elegoo Saturn have dramatically reduced layer times.

H3: Multi-Material and Multi-Color Printing

Printing in a single color is so 2018. The Bambu Lab Automatic Material System (AMS) made reliable, affordable multi-color and multi-material printing accessible to the masses. The Prusa XL, with its tool-changing head, takes this even further, allowing for seamless printing with up to five different materials in a single print job. This allows for printing complex models with soluble supports or combining rigid and flexible materials in one part.

H3: New Printing Methods (e.g., Volumetric, Cold Spray)

And what about the really out-there stuff?

- Volumetric Additive Manufacturing (VAM): Instead of printing layer-by-layer, this method solidifies an entire volume of resin at once using precisely projected light. It’s mind-bogglingly fast. Check out what xolo is doing.

- Cold Spray: This isn’t your typical 3D printing. It involves spraying metal powders at supersonic speeds to build or repair parts without the high heat of welding or laser sintering.

7. 💡 Beyond Prototypes: How Brands Are Revolutionizing Production with 3D Printing Benefits

“The results of this survey show that the manufacturing industry is embracing additive manufacturing as a viable production solution,” states a report from Jabil. This is the big one, folks. 3D printing has graduated from the R&D lab to the factory floor.

H3: Mass Customization and Personalization

This is where 3D printing has an unbeatable advantage. Think of Invisalign’s clear dental aligners—each one is a custom-printed medical device. Or consider athletic shoe companies like Adidas printing custom midsoles tailored to an individual’s foot and gait. This level of personalization is impossible with traditional mass-production methods.

H3: Tooling, Jigs, and Fixtures

One of our favorite “secret” uses for 3D printing in the workshop is creating custom tools. Need a specific jig to hold a part for assembly? Print it. Need a custom wrench for a tight spot? Print it. Companies are saving thousands of dollars and weeks of time by 3D printing their own tooling instead of machining it from metal.

H3: End-Use Part Production

We’re now seeing 3D printed parts in the cars we drive, the planes we fly in, and the products we use every day. Ford uses 3D printing for parts on the Mustang Shelby GT500, and Boeing has thousands of 3D-printed parts flying on its aircraft. These aren’t just plastic trinkets; they are certified, structural components.

8. 📈 The Sky’s the Limit: Unpacking the Explosive Growth of the Additive Manufacturing Market

The numbers don’t lie. The 3D printing industry is on a rocket ship, and it’s not coming down anytime soon.

H3: Market Size and Projections

According to Grand View Research, the global 3D printing market is projected to grow at a compound annual growth rate (CAGR) of over 20% for the next decade. This isn’t slow and steady; it’s explosive growth fueled by the trends we’re discussing.

H3: Investment and Mergers & Acquisitions

The confidence is palpable. Jabil’s survey data shows a consistent and dramatic increase in expected 3D printing use, with 39% of companies in 2021 expecting their usage to increase five-fold or more. This confidence is attracting massive investment and leading to major industry consolidation, like Stratasys’ acquisition of MakerBot and its merger with Desktop Metal. Big players are placing big bets on an additive future.

9. 🧠 Cultivating Competence: The Rise of In-House 3D Printing Expertise and Training

With all this new tech, a new problem arises: who is going to run it all? A Jabil survey found that while “no in-house expertise” was a challenge for 14% of companies, a much larger 44% prioritized “design capabilities” when selecting a partner. This points to a critical skills gap.

H3: Upskilling the Workforce

Companies are realizing they can’t just buy a printer; they need to invest in their people. This means training engineers to “think in additive”—to design parts that leverage the unique strengths of 3D printing, like complex geometries and part consolidation. It’s a new way of thinking, and it’s becoming a highly sought-after skill.

H3: Academic and Vocational Programs

We’re thrilled to see this trend trickling down into education. Universities and community colleges are now offering dedicated programs and certifications in additive manufacturing. This is crucial for building the next generation of designers, engineers, and technicians who will power this industry forward. It’s a core reason we’re so passionate about our 3D Printing in Education resources.

10. 🚧 Navigating the Hurdles: Addressing Challenges and Innovations in Additive Manufacturing

It’s not all sunshine and perfectly printed Benchys. As an expert team, we have to be realistic about the roadblocks. The good news is that for every challenge, there’s an army of innovators working on a solution.

H3: Cost and Scalability Barriers

As Jabil’s research points out, costs related to equipment, materials, and post-processing are still significant barriers. However, the rise of affordable, high-speed printers and automated post-processing solutions is directly tackling this. The cost per part is dropping rapidly, making 3D printing a viable option for larger production runs.

H3: Quality Control and Certification

How do you prove that a 3D printed part is just as strong and reliable as its traditionally manufactured counterpart? This is a major hurdle, especially for critical applications in aerospace and medical fields. The trend is towards in-process monitoring—using sensors, cameras, and AI to watch the print as it happens, ensuring every layer meets strict quality standards and creating a “birth certificate” for each part.

H3: Intellectual Property and Security Concerns

When your product is a digital file, how do you protect it from being copied and distributed illegally? This is a tough question. Innovations in digital rights management (DRM), file encryption, and cloud-based streaming (where the print instructions are sent to the printer line-by-line, but the full file is never stored locally) are emerging as potential solutions to protect designers’ hard work.

🚀 Expanding Horizons: Diverse Applications Driving 3D Printing’s Future

So, where are all these trends converging? In the real world! The applications are exploding across every industry imaginable. Here are just a few of the sectors being completely transformed.

- Aerospace and Automotive: Printing lightweight, high-strength components, custom tooling, and rapid prototypes. Think turbine blades, custom interior components, and brackets that are stronger and lighter than their machined equivalents.

- Healthcare and Medical Devices: This is one of the most impactful areas. We’re seeing custom surgical guides, patient-specific implants (like hip sockets and cranial plates), dental aligners, and prosthetics. You can find amazing examples of printable aids on Thingiverse.

- Consumer Goods and Fashion: From the custom sneaker midsoles we mentioned to 3D printed jewelry, lamp shades, and even high-fashion garments. The ability to create complex geometries is a designer’s dream. Check out the amazing 3D Printable Objects people are creating.

- Construction and Architecture: Yes, they’re printing houses now! Large-scale gantry printers are extruding concrete to build walls for homes quickly and affordably. Companies like ICON are leading this charge.

- Education and Research: 3D printers are becoming as common as computers in schools. They provide an incredible hands-on tool for teaching STEM concepts, art, and design thinking.

🎯 Our Expert Recommendations for Staying Ahead of the Curve

Feeling overwhelmed? Don’t be! It’s an exciting time to be in this field. Here’s our team’s advice for navigating this rapidly changing landscape, whether you’re a hobbyist or a professional.

-

Embrace High-Speed Printing: If you’re buying a new FDM printer, seriously consider a modern CoreXY machine. The speed and quality-of-life improvements (like auto-leveling and input shaping) are worth it. The days of constant tinkering are fading.

-

Experiment with New Materials: Don’t just stick to PLA. Order a roll of PETG for more durable, temperature-resistant prints. Try a carbon-fiber infused filament for a functional part. The experience will make you a better maker.

- 👉 Shop Advanced Filaments on: Amazon | Polymaker Official Website

-

Learn a Little CAD: You don’t need to be a professional engineer. Learning the basics of a user-friendly program like Tinkercad or Fusion 360 (which is free for personal use) will unlock a new world. Instead of just downloading models, you can start modifying them or creating your own simple solutions.

-

Follow the Innovators: Keep an eye on the companies and individuals pushing the boundaries. Follow channels like CNC Kitchen and Teaching Tech on YouTube. Read blogs from industry leaders like Prusa and Formlabs.

-

Don’t Fear Failure: You’re going to have prints fail. Your first attempt at a new material might look awful. That’s okay! Every failed print is a learning opportunity. It’s how we all got started, and it’s how you’ll get better.

✨ Conclusion: The Additive Future is Now

Wow, what a ride! From humble beginnings in Chuck Hull’s lab to the cutting-edge AI-powered, multi-material, and sustainable marvels of today, 3D printing technology trends are reshaping how we design, manufacture, and even think about objects. The explosive growth, diverse applications, and rapid innovation we’ve explored show one thing clearly: additive manufacturing is no longer a niche hobby or a prototyping tool—it’s a cornerstone of modern industry and creativity.

We started with quick tips and ended up unraveling a complex ecosystem where materials science, AI, software, and hardware converge to unlock possibilities that were once pure science fiction. Remember the question about how AI might save your prints from disaster? Now you know it’s already happening with printers like the Bambu Lab X1-Carbon, turning failed prints into rare exceptions rather than the rule.

While challenges remain—cost, quality control, and intellectual property concerns—these are being tackled head-on by innovators and industry leaders. The future is bright, and whether you’re a hobbyist, educator, or manufacturing pro, embracing these trends will keep you ahead of the curve.

So, what’s our final verdict? If you’re ready to jump in, start experimenting with new materials, learn generative design, and consider upgrading to a high-speed CoreXY printer with AI features. The tools are here, the community is thriving, and the additive revolution is just getting started. Let’s print the future—together!

🔗 Recommended Links for Your 3D Printing Journey

Ready to gear up? Here are some of the top products and resources we mentioned, curated for your convenience:

-

Bambu Lab X1-Carbon:

Amazon | Walmart | Bambu Lab Official Website -

Prusament PLA Recycled Filament:

Amazon | Prusa Official Website -

Polymaker Carbon Fiber Filament:

Amazon | Polymaker Official Website -

Formlabs Form 3 Resin Printer:

Amazon | Formlabs Official Website -

Autodesk Fusion 360 (Software):

Official Website -

Books on 3D Printing Technology and Trends:

❓ FAQ: Your Burning Questions About 3D Printing Trends Answered

What are the current advancements in 3D printing technology?

The latest advancements include high-speed CoreXY printers like the Bambu Lab X1-Carbon, multi-material and multi-color printing, and new printing methods such as volumetric additive manufacturing. AI integration is improving print reliability and optimizing designs. Materials have expanded beyond PLA and ABS to include carbon fiber composites, metals, ceramics, and biocompatible resins. Software innovations like generative design and cloud-based print management are streamlining workflows.

Read more about “Are There Limitations to 3D Printing? 12 Surprising Facts (2025) 🚀”

How is 3D printing being used in various industries such as healthcare and manufacturing?

In healthcare, 3D printing enables custom implants, prosthetics, surgical guides, and dental aligners, improving patient outcomes with personalized solutions. Manufacturing uses 3D printing for rapid prototyping, tooling, jigs, fixtures, and increasingly for end-use parts in aerospace, automotive, and consumer goods. The technology supports mass customization and local, on-demand production, enhancing supply chain resilience.

What are the most popular types of 3D printing technologies used today?

The most popular are:

- Fused Deposition Modeling (FDM): Affordable, versatile, widely used for prototyping and functional parts.

- Stereolithography (SLA) and Digital Light Processing (DLP): High-resolution resin printing, ideal for detailed models and dental/medical applications.

- Selective Laser Sintering (SLS): Powder-based printing for strong, functional parts without support structures.

- Metal Printing (DMLS, Binder Jetting): For aerospace and industrial-grade metal parts.

Read more about “How Long Does 3D Printing Take? ⏳ 12 Factors That Decide (2025)”

How is artificial intelligence being integrated into 3D printing systems?

AI is used for real-time print failure detection, auto-calibration, and print parameter optimization. It can predict and prevent defects, reducing wasted material and time. AI-driven generative design creates optimized parts that use less material while maintaining strength. AI also powers cloud-based print management platforms, enabling smarter fleet control and predictive maintenance.

What are the emerging trends in 3D printing materials and their applications?

Emerging trends include:

- Composite filaments infused with carbon fiber or glass fiber for enhanced strength.

- Metal filaments enabling desktop metal printing workflows.

- Biocompatible and bioresorbable materials for medical implants and tissue engineering.

- Recycled and biodegradable filaments supporting sustainability.

- Ceramic materials for electronics and aerospace applications.

Applications range from aerospace-grade parts to personalized medical devices and sustainable consumer products.

Read more about “🔥 Top 15 3D Printing Materials Market Share Trends (2025)”

What role will 3D printing play in the future of product design and development?

3D printing will accelerate innovation cycles by enabling rapid prototyping and iterative testing. Generative design and topology optimization will allow designers to create lighter, stronger, and more efficient parts. The technology will facilitate mass customization and on-demand manufacturing, reducing inventory costs and waste. It will also democratize product development, allowing smaller companies and individuals to compete globally.

Read more about “What Is the Market Analysis of 3D Printing? 20 Insights for 2025 🚀”

How will the increasing adoption of 3D printing technology impact the environment and sustainability?

3D printing can reduce waste by using only the material needed, unlike subtractive manufacturing. The rise of recycled and biodegradable materials further enhances its green credentials. Localized production reduces transportation emissions and supply chain waste. However, energy consumption and failed prints remain concerns, which are being addressed through more efficient printers and smarter AI-driven print monitoring.

Read more about “3D Printing Market Leaders 2020: The Ultimate Guide … 🚀”

How can beginners get started with 3D printing amid these rapid technological changes?

Start simple: Choose an easy-to-use, reliable printer like the Prusa i3 MK3S+ or Bambu Lab P1S. Learn basic CAD with free tools like Tinkercad. Experiment with PLA filament before moving to advanced materials. Follow trusted online communities and tutorials. Most importantly, embrace failure as a learning tool—every failed print is a step closer to mastery!

📚 Reference Links: Dive Deeper

-

Jabil’s 3D Printing Technology Trends 2023 Report:

http://www.jabil.com/services/additive-manufacturing/3dprinting-technology-trends-2023.html -

Grand View Research: 3D Printing Market Analysis

https://www.grandviewresearch.com/industry-analysis/3d-printing-industry -

Markforged Composite Materials Overview

https://markforged.com/materials/ -

Bambu Lab Official Website

https://bambulab.com/en -

Prusa Research: Prusament Recycled Filament

https://www.prusa3d.com/category/prusament-pla-recycled/ -

Autodesk Fusion 360 Generative Design

https://www.autodesk.com/solutions/generative-design -

Formlabs Fleet Control and Resin Printers

https://support.formlabs.com/s/article/Managing-a-Printer-Group-with-Dashboard?language=en_US -

Desktop Metal Metal 3D Printing Solutions

https://www.desktopmetal.com/ -

ICON 3D Printed Homes

https://www.iconbuild.com/

We hope this guide has sparked your curiosity and equipped you with the knowledge to navigate the thrilling world of 3D printing technology trends. Stay tuned to 3D Printed™ for more expert insights, reviews, and tutorials. Happy printing! 🎉