Support our educational content for free when you purchase through links on our site. Learn more

How Long Does It Take to 3D Print an Object? ⏳ (2026)

Ever stared at your 3D printer humming away and wondered, “When will this masterpiece finally be done?” You’re not alone. Whether you’re printing a tiny keychain or a full-sized cosplay helmet, the time it takes to 3D print an object can vary wildly—from minutes to days! In this deep dive, we unravel the mystery behind those ticking hours and reveal the surprising factors that can speed up or slow down your print job. Spoiler alert: it’s not just about size!

Stick around, because later we’ll share insider tips on how to slash your print times without sacrificing quality, and even reveal which printers are the Usain Bolts of the 3D world. Ready to become a time-savvy 3D printing pro? Let’s get started!

Key Takeaways

- Print time depends on multiple factors including object size, layer height, printer type, and material choice.

- Layer height is the biggest time influencer—thinner layers mean longer prints but finer detail.

- Printer mechanics matter: CoreXY and direct drive systems can print faster and more reliably.

- Material affects speed: PLA prints faster than flexible or high-temp filaments.

- Post-processing adds extra time beyond the print itself, so factor that in when planning.

- Multi-color and complex models significantly increase print duration.

Curious about which printer can turbocharge your workflow? Check out our expert picks for the fastest and most reliable 3D printers in our 3D Printer Reviews section!

Table of Contents

- ⚡️ Quick Tips and Facts About 3D Printing Time

- 🕰️ The Evolution of 3D Printing: How We Got Here

- 🔍 What Is 3D Printing and How Does It Actually Work?

- 🎯 How Precise and Detailed Can 3D Printing Be?

- 💻 Software Essentials: Creating 3D Models for Printing

- 📏 Does Printer Size Limit the Size of Your 3D Prints?

- ⚙️ Printing Moving Parts: Is It Possible?

- ⏳ How Long Does It Really Take to 3D Print an Object?

- 1. Factors Affecting 3D Printing Time: Size, Complexity, and More

- 2. Printer Type and Speed: Which Machines Are Faster?

- 3. Layer Height and Resolution: Trade-offs Between Quality and Time

- 4. Material Choice Impact on Printing Duration

- 5. Post-Processing Time: Beyond the Print Bed

- 🏭 Common Applications: Where 3D Printing Saves Time and Money

- 🔧 Printing Replacement Parts for Everyday Items: Quick Fixes at Home

- 🌈 Multi-Color 3D Printing: How Does It Affect Time and Complexity?

- 🧩 Printing Flexible and Transparent Objects: Challenges and Solutions

- 🧵 How Filament Type Influences Print Quality and Speed

- 🏗️ Large-Scale Printing on Desktop 3D Printers: What’s Possible?

- 🧪 Functional Prototypes: Printing for Testing and Iteration

- ♻️ Using Recycled Materials in 3D Printing: Eco-Friendly or Not?

- 🛠️ Choosing the Right 3D Printer: Speed, Quality, and Budget Considerations

- 💪 Printing Objects with Different Hardness Levels: How to Do It

- 🔩 Ensuring Structural Integrity in Your 3D Prints

- 🔬 Printing Intricate Details: Tips for High-Resolution Success

- 📚 Recommended Resources for 3D Printing Enthusiasts

- 🤔 Frequently Asked Questions About 3D Printing Time

- 📖 Reference Links and Further Reading

- 🏁 Conclusion: Mastering Your 3D Printing Time Expectations

⚡️ Quick Tips and Facts About 3D Printing Time

Before we dive into the nitty-gritty of why your printer might be taking longer than a slow cooker on a Sunday, here is the “cheat sheet” from our engineering lab at 3D Printed™.

| Feature | Typical Time Estimate | Pro Tip |

|---|---|---|

| Small Keychain | 20 – 45 Minutes | Use a 0.6mm nozzle to shave off 30% of the time! |

| Standard #3DBenchy | 30 Minutes – 2 Hours | High-speed printers like the Bambu Lab X1-Carbon can crush this in under 20 mins. |

| Full-Sized Cosplay Helmet | 48 – 120 Hours | Print in parts to avoid a total failure at hour 90. 😱 |

| Dental Crown (SLA) | 1 – 2 Hours | Resin printing speed depends on height, not the number of objects. |

| Industrial Prototype (SLS) | 12 – 24 Hours | Requires a “cool down” period that can double the total turnaround. |

- Fact: Doubling the size of an object doesn’t double the time; it can increase it by 8x because you are increasing volume (Length x Width x Height)!

- Fact: Layer height is the single biggest “time thief.” Cutting layer height in half (e.g., from 0.2mm to 0.1mm) roughly doubles your print time.

- Check this out: If you’re curious about the magic behind the machine, read more about 3D Printed at 3D Printed™.

🕰️ The Evolution of 3D Printing: How We Got Here

We didn’t just wake up and start printing 3D houses. The journey began in the 1980s when Chuck Hull invented Stereolithography (SLA). Back then, “fast” meant finishing a small part before the weekend started.

In the early days, 3D printing was strictly for “Rapid Prototyping”—which, ironically, wasn’t very rapid by today’s standards. It wasn’t until the RepRap project in the mid-2000s that desktop 3D Printable Objects became a reality for us mere mortals. Today, we’ve moved from clunky machines that required constant babysitting to high-speed beasts that can print at 500mm/s.

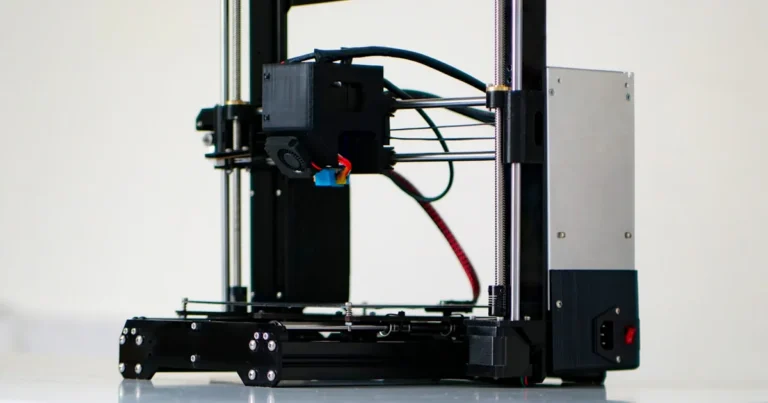

🔍 What Is 3D Printing and How Does It Actually Work?

At its core, 3D printing (or Additive Manufacturing) is the process of joining materials to make objects from 3D model data, usually layer upon layer. Think of it like building a LEGO castle, but instead of clicking bricks, you’re melting plastic or curing resin.

The Three Big Players:

- FDM (Fused Deposition Modeling): The most common. It melts a plastic string (filament) and draws layers. Brands like Creality and Prusa Research dominate this space.

- SLA (Stereolithography): Uses a UV laser to harden liquid resin. It’s messy but incredibly detailed.

- SLS (Selective Laser Sintering): Uses a laser to fuse powdered material. This is the “big leagues” of industrial manufacturing.

🎯 How Precise and Detailed Can 3D Printing Be?

Precision is the name of the game. When we talk about precision, we’re looking at XY resolution (the horizontal detail) and Z resolution (the layer thickness).

- FDM Printers: Usually accurate within +/- 0.1mm.

- Resin (SLA) Printers: Can reach resolutions of 25 microns (that’s 0.025mm!). For context, a human hair is about 70 microns thick.

Does precision affect time? Absolutely. As noted in our 3D Printer Reviews, the more “precise” you want the finish, the thinner the layers must be, and the longer you’ll be waiting.

💻 Software Essentials: Creating 3D Models for Printing

You can’t just tell a printer to “make a dragon.” You need a digital blueprint. This involves two types of software:

- CAD Software: Where you design the object. Beginners love Tinkercad, while pros use Autodesk Fusion 360.

- Slicer Software: This translates your 3D model into G-code (the language printers speak). Popular slicers include Ultimaker Cura and PrusaSlicer.

If you’re a teacher looking to bring this into the classroom, check out our guide on 3D Printing in Education.

👉 Shop 3D Design Software on:

- Autodesk: Official Website

- Adobe Substance 3D: Amazon | Official Website

📏 Does Printer Size Limit the Size of Your 3D Prints?

Yes and no. Every printer has a Build Volume (the maximum X, Y, and Z dimensions it can print).

- The “Small” Problem: If you have a Bambu Lab A1 Mini, you’re limited to 180mm cubed.

- The “Big” Solution: You can slice a large model into smaller chunks and glue them together. This is how people print life-sized Iron Man suits on standard desktop printers!

⚙️ Printing Moving Parts: Is It Possible?

One of the coolest things we do at 3D Printed™ is “Print-in-Place” (PiP) models. These are objects with hinges, gears, or joints that come off the printer already assembled and moving!

How it works: The designer leaves a tiny gap (usually 0.2mm to 0.4mm) between the moving parts. As long as your printer is calibrated, the plastic won’t fuse together.

- Example: The famous Articulated Dragon on Cults3D.

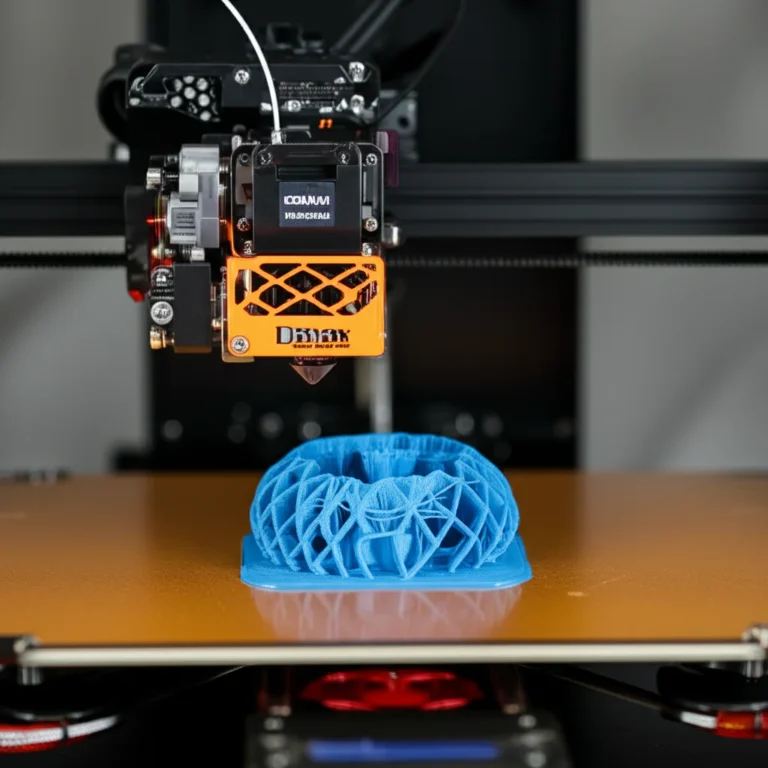

⏳ How Long Does It Really Take to 3D Print an Object?

This is the million-dollar question. As the featured video suggests, “Print time is affected by a number of things… The bigger the object, the longer it’s going to take.”

But it’s not just size. According to Raise3D, a simple 1-inch cube can take anywhere from 20 minutes to over an hour. Why the discrepancy? It’s all in the settings.

Bambu Lab X1-Carbon Review & Rating

| Category | Rating (1-10) | Notes |

|---|---|---|

| Speed | 10 | The current gold standard for consumer speed. |

| Ease of Use | 9 | Almost “plug and play” with AI spaghetti detection. |

| Print Quality | 9 | Exceptional detail even at high speeds. |

| Price Value | 8 | It’s an investment, but saves hundreds of hours. |

👉 CHECK PRICE on:

- Bambu Lab X1-Carbon: Bambu Lab Official | MatterHackers

- Creality Ender 3 V3: Amazon | Creality Official

1. Factors Affecting 3D Printing Time: Size, Complexity, and More

Complexity doesn’t always mean “more time” in FDM printing, but it does in SLA.

- Volume: A solid sphere takes much longer than a hollow one.

- Surface Area: More intricate outer shells require the nozzle to slow down for detail.

- Supports: If your model has “overhangs” (parts floating in mid-air), the printer must build temporary scaffolding. This can add 20-50% to your print time!

2. Printer Type and Speed: Which Machines Are Faster?

Not all printers are created equal.

- Bed Slingers: (e.g., Ender 3) The build plate moves back and forth. If you go too fast, the weight of the print causes “ghosting” or vibrations.

- CoreXY: (e.g., Voron or Bambu Lab) The bed only moves up and down, allowing the print head to fly at insane speeds.

Conflict Resolution: While Snapmaker suggests 100mm/s is “fast,” modern engineering has pushed this. We now consider 100mm/s “standard” and 300-500mm/s “fast.” Trust the newer benchmarks if you own a printer released after 2023.

3. Layer Height and Resolution: Trade-offs Between Quality and Time

This is the most powerful lever you can pull.

- 0.1mm (High Detail): Looks amazing, takes forever.

- 0.2mm (Standard): The “sweet spot” for most hobbyists.

- 0.3mm+ (Draft): Looks like a topographical map, but it’s done in a flash.

Engineer’s Tip: Use Adaptive Layer Height in Cura. It uses thin layers for curves and thick layers for vertical walls. It’s like magic for your schedule!

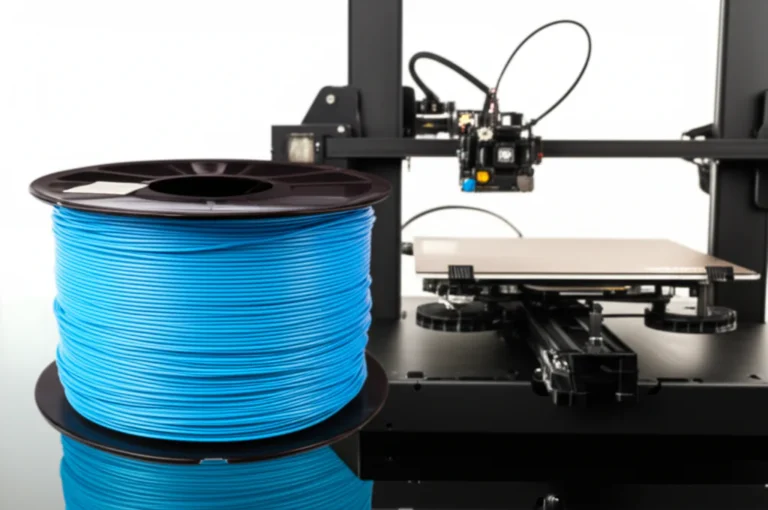

4. Material Choice Impact on Printing Duration

Believe it or not, what you print with dictates how fast you can go.

- PLA: The speed king. It cools quickly and flows easily.

- TPU (Flexible): You have to print this slowly (20-30mm/s), or it will tangle like wet spaghetti in your extruder.

- ABS/ASA: Requires a heated chamber and slower speeds to prevent warping.

5. Post-Processing Time: Beyond the Print Bed

The timer on your printer lies! It only tells you when the printing stops.

- Support Removal: 5 – 30 minutes.

- Sanding/Priming: Hours to days.

- Resin Washing/Curing: 15 – 30 minutes in a Formlabs Wash & Cure station.

🏭 Common Applications: Where 3D Printing Saves Time and Money

From 3D Design Software to the factory floor, 3D printing is a time-saver.

- Medical: Custom prosthetics printed in 24 hours vs. weeks of manual labor.

- Aerospace: Reducing part weight by printing complex geometries that traditional milling can’t touch.

- Education: Students can visualize geometry or history by holding a 3D-printed artifact.

🔧 Printing Replacement Parts for Everyday Items: Quick Fixes at Home

Broken dishwasher knob? Snapped battery cover?

We once saved a $500 espresso machine by printing a $0.50 plastic gear that took 45 minutes to print.

- Where to find parts: Search Thingiverse or Printables for your appliance model number.

🌈 Multi-Color 3D Printing: How Does It Affect Time and Complexity?

Multi-color printing is beautiful but brutally slow.

Systems like the Bambu Lab AMS or Prusa MMU3 have to swap the filament for every single color change on every single layer.

- The “Poop” Factor: Every swap requires “purging” the old color, which adds time and waste material.

- Time Impact: A 4-hour single-color print can easily become a 15-hour multi-color print.

🧩 Printing Flexible and Transparent Objects: Challenges and Solutions

- Transparent: To get “glass-like” results, you need to print with 100% infill and very slow speeds to avoid air bubbles. It’s a test of patience.

- Flexible: Use a Direct Drive extruder (like the one on the Prusa MK4) to handle soft filaments like NinjaTek NinjaFlex.

🧵 How Filament Type Influences Print Quality and Speed

| Filament | Max Speed | Difficulty | Best Use |

|---|---|---|---|

| PLA | Very High | 1/10 | Models, Toys |

| PETG | Medium | 4/10 | Outdoor parts, Water bottles |

| TPU | Very Low | 7/10 | Phone cases, Gaskets |

| Nylon | Low | 9/10 | High-strength gears |

🏗️ Large-Scale Printing on Desktop 3D Printers: What’s Possible?

Can you print a chair on a Creality Ender 3? Technically, yes—if you’re willing to glue 50 pieces together.

However, if you want to print large items in one go, you’ll need a “Large Format” printer like the Anycubic Kobra 2 Max or the Elegoo OrangeStorm Giga.

- Warning: A full-volume print on these machines can take 7 to 10 days. Make sure you have a UPS (Uninterruptible Power Supply)!

🧪 Functional Prototypes: Printing for Testing and Iteration

Engineers use 3D printing to fail fast. Instead of waiting 6 weeks for an injection mold, we print a prototype in 6 hours, test it, tweak the design, and print again. This “Iterative Design” process is the heartbeat of modern innovation.

♻️ Using Recycled Materials in 3D Printing: Eco-Friendly or Not?

You can buy “Recycled PLA” from brands like Reflow or Proto-pasta.

- Pros: Better for the planet.

- Cons: Sometimes less consistent diameter, which can lead to clogs (and more wasted time!).

- DIY: Some enthusiasts use a “Filastruder” to turn old failed prints back into usable filament. It’s a labor of love!

🛠️ Choosing the Right 3D Printer: Speed, Quality, and Budget Considerations

If you value your time, buy a printer with Auto-Bed Leveling and Input Shaping.

- Budget King: Creality Ender 3 V3 SE

- Speed King: Bambu Lab P1P

- Reliability King: Original Prusa MK4

💪 Printing Objects with Different Hardness Levels: How to Do It

You can’t change the hardness of the plastic itself mid-print, but you can change the Perceived Hardness.

- Infill Density: 100% infill makes a part feel like a rock. 5% infill makes it feel “squishy” or brittle.

- Wall Loops: Adding more “walls” (perimeters) increases structural rigidity more effectively than increasing infill.

🔩 Ensuring Structural Integrity in Your 3D Prints

Ever had a print snap in your hands?

- Orientation is Key: 3D prints are weakest along the layer lines (like wood grain). Never print a long peg standing straight up if it needs to take a load!

- Temperature: Printing slightly hotter improves “Layer Adhesion,” making the bond between layers stronger.

🔬 Printing Intricate Details: Tips for High-Resolution Success

To get those tiny details on a Dungeons & Dragons miniature:

- Swap to a 0.2mm nozzle. It’s like switching from a Sharpie to a fine-liner pen.

- Lower your speed. Give the plastic time to settle.

- Check your cooling. If the plastic stays hot, the tiny details will melt into a blob.

👉 Shop 3D Printing Accessories on:

- Nozzle Kits: Amazon | E3D-Online

- Dry Boxes: Amazon | Sunlu Official

But wait… if you’ve done everything right and the print still takes 20 hours, is it safe to leave it running while you sleep? We’ll tackle the “Overnight Printing” debate in the FAQ!

🏁 Conclusion: Mastering Your 3D Printing Time Expectations

So, how long does it take to 3D print an object? The answer is a deliciously complex stew of printer type, object size, layer height, material choice, and post-processing. From our experience at 3D Printed™, the best way to master your print times is to understand these variables and optimize them according to your project’s needs.

If you’re after speed without sacrificing quality, the Bambu Lab X1-Carbon remains our top pick — it’s a turbocharged, reliable workhorse that can print stunning models in a fraction of the time of traditional FDM printers. Its auto-calibration, high-speed CoreXY mechanics, and multi-material capabilities make it a standout for both hobbyists and pros. Downsides? It’s an investment and requires some space, but the time saved and quality gained justify it hands down.

Remember our earlier question about leaving your printer on overnight? With modern printers equipped with safety features like thermal runaway protection and remote monitoring, it’s possible — but always keep safety protocols in place. Your printer is a powerful tool, but not a babysitter.

In the end, 3D printing is as much an art as a science. The more you experiment with settings, materials, and designs, the better you’ll get at predicting and controlling print times. And when you finally hit that sweet spot, watching your creation emerge layer by layer is pure magic.

🔗 Recommended Links

👉 Shop 3D Printers and Accessories:

-

Bambu Lab X1-Carbon:

Bambu Lab Official Website | MatterHackers | Amazon Search -

Creality Ender 3 V3 SE:

Creality Official | Amazon | MatterHackers -

Prusa MK4:

Prusa Official | Amazon

3D Design Software:

3D Printing Accessories:

Books:

-

3D Printing Failures: How to Diagnose and Repair All 3D Printing Issues by Sean Aranda

Amazon Link -

Mastering 3D Printing by Joan Horvath and Rich Cameron

Amazon Link

🤔 Frequently Asked Questions About 3D Printing Time

Can complex designs increase the time required for 3D printing?

Absolutely! Complex designs often have intricate details, overhangs, and require support structures, all of which add layers and print time. For example, a simple cube might take 30 minutes, but a detailed figurine with many overhangs and supports can take several hours or even days. Supports especially increase print time because the printer has to lay down extra material that will be removed later.

What materials print faster in 3D printers?

PLA is the fastest and easiest material to print due to its low melting temperature and quick cooling. Flexible filaments like TPU print much slower because they require slower extrusion speeds to avoid jams. Materials like ABS or Nylon also print slower due to higher temperature requirements and warping concerns.

How does print resolution influence 3D printing speed?

Print resolution is directly tied to layer height. Lower layer heights (e.g., 0.1mm) mean more layers and longer print times but finer detail. Higher layer heights (e.g., 0.3mm) print faster but with visible layer lines and less detail. Adaptive slicing can help balance speed and quality by varying layer height depending on the model’s geometry.

Does the size of the object impact 3D printing duration?

Yes, the larger the object, the longer it takes, but it’s not a linear relationship. Since printing is volumetric, doubling the size in all dimensions increases the volume—and thus print time—by roughly eight times. Also, taller objects take longer because printers build layer by layer vertically.

What are the fastest 3D printing methods available?

FDM printers with CoreXY or Delta mechanics can print at speeds up to 300-500mm/s. SLA printers are generally slower but can produce high-detail parts quickly for small objects. HP Multi Jet Fusion and Carbon DLS are industrial methods that can print faster but are expensive and less accessible to hobbyists.

How can I reduce the time it takes to 3D print a model?

- Increase layer height (within acceptable quality limits).

- Use larger nozzle sizes (e.g., 0.6mm instead of 0.4mm).

- Reduce infill density or use faster infill patterns like lines or grids.

- Optimize model orientation to minimize Z height.

- Avoid or minimize supports by redesigning the model.

- Use faster printing materials like PLA.

- Batch print multiple small parts simultaneously.

What factors affect the 3D printing time of an object?

- Object size and volume

- Layer height and resolution

- Infill density and pattern

- Printer type and mechanics

- Material properties and extrusion speed

- Use of supports and model complexity

- Post-processing requirements

Are there any 3D printing techniques that can significantly reduce printing time for complex objects?

Yes! Techniques like variable layer height slicing, vase mode printing (single continuous outer wall), and printing hollow models with thin walls can drastically reduce print time. Also, multi-nozzle printers can print multiple parts simultaneously.

What are some ways to speed up the 3D printing process without sacrificing quality?

- Use adaptive layer height slicing.

- Print with a larger nozzle but slow down speed slightly to maintain detail.

- Optimize cooling settings to allow faster printing without defects.

- Use high-quality filament with consistent diameter to avoid jams.

- Calibrate your printer regularly for optimal extrusion.

How does the level of detail in a 3D printed object affect its printing time?

Higher detail means thinner layers and slower print speeds to ensure accuracy, which increases print time. Fine details require the printer to slow down and carefully deposit material, especially on curves and small features.

Can the type of 3D printing material used change the printing time?

Yes. Materials like PLA print faster due to easy extrusion and cooling, while flexible or high-temperature materials require slower speeds to avoid print failures, increasing print time.

What is the difference in printing time between FFF and SLA 3D printing technologies?

FFF (Fused Filament Fabrication) typically prints larger objects faster but with less detail. SLA (Stereolithography) prints smaller, highly detailed objects but takes longer per layer due to resin curing times. For small parts requiring fine detail, SLA can be faster overall.

How does the size of the object impact 3D printing time?

As mentioned, larger objects exponentially increase print time due to volume. Taller prints increase the number of layers, while wider prints increase the time per layer.

What factors affect the speed of 3D printing an object?

Printer mechanics, nozzle size, layer height, infill, material type, model complexity, and support structures all play critical roles in print speed.

📖 Reference Links and Further Reading

- Raise3D Blog: How Long Does 3D Printing Take?

- Snapmaker Blog: How Long Does It Take To 3D Print Something?

- Bambu Lab Official Website

- Creality Official Website

- Prusa Research Official Website

- Formlabs Wash & Cure Station

- Thingiverse 3D Models

- Cults3D Multi-Color Models

- Autodesk Fusion 360

- E3D Online Nozzle Kits

We hope this comprehensive guide helps you master your 3D printing time expectations and get the most out of your printer — whether you’re printing a tiny keychain or a full-scale cosplay helmet! Happy printing! 🚀