Support our educational content for free when you purchase through links on our site. Learn more

How Much Does It Really Cost to 3D Print for 1 Hour? 💸 (2025)

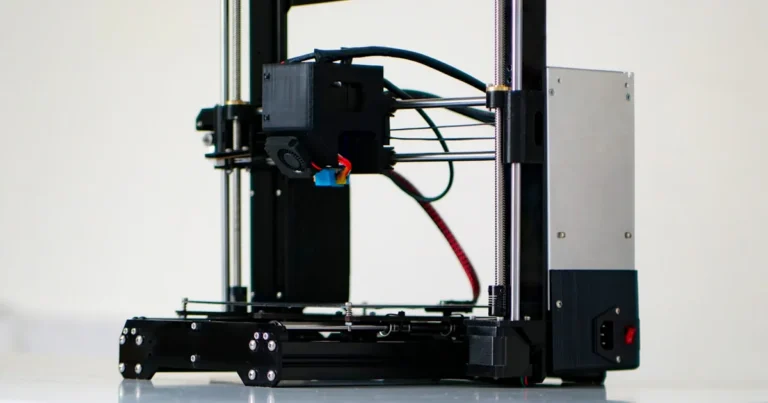

Ever stared at your 3D printer humming away and wondered, “What’s this actually costing me per hour?” You’re not alone. Whether you’re a hobbyist printing quirky figurines or a pro cranking out prototypes, understanding the true hourly cost of 3D printing is like unlocking a secret level in your maker journey. Spoiler alert: it’s not just about filament or electricity — there’s a whole ecosystem of factors that sneak into your bill.

In this article, we’ll peel back the layers on every cost component — from material and power consumption to printer depreciation, labor, and even those pesky failed prints that make you want to toss your spool out the window. Plus, we’ll share insider tips on how to slash your hourly expenses without sacrificing quality. Ready to become a savvy 3D printing cost ninja? Let’s dive in!

Key Takeaways

- Material costs dominate your hourly expenses, with filament or resin choice making a huge difference.

- Electricity is surprisingly minor, often just a few cents per hour on desktop printers.

- Printer depreciation and maintenance add real value to your cost per hour—don’t overlook them!

- Labor and post-processing time can double or triple your effective hourly cost, especially for beginners.

- Failed prints and waste inflate costs but can be minimized with experience and good slicer settings.

- Choosing the right printer technology (FDM vs. Resin) impacts your hourly rate significantly.

- Outsourcing to service bureaus can sometimes be more cost-effective than DIY for complex or low-volume prints.

Ready to optimize your 3D printing budget? Check out these top picks and resources:

- 👉 Shop Prusa i3 MK3S Filaments & Printers: Thingiverse | Prusa Official Website

- Explore Resin Printing with Formlabs Form 3: Formlabs Official

- Get Quality Filaments: Prusament PLA | Hatchbox on Amazon

- Download Free Slicer Software: Ultimaker Cura | PrusaSlicer

Table of Contents

- ⚡️ Quick Tips and Facts

- 🤔 Unraveling the Mystery: Why “Per Hour” 3D Printing Costs Are Tricky

- 💸 The Core Components of Your 3D Printing Bill: What Goes Into That Hour?

- 1. 🧵 Filament Follies: The Material Cost Breakdown

- 2. ⚡ Powering Up: Your Electricity Bill’s Contribution

- 3. 💰 The Machine’s Worth: Printer Depreciation & Initial Investment

- 4. 🛠️ Keeping It Running: Maintenance & Spare Parts

- 5. 🧑💻 The Human Touch: Labor & Design Time

- 6. 🗑️ The Oops Factor: Failed Prints & Waste

- 🕵️♀️ Beyond the Basics: Hidden Costs and Unexpected Surprises

- 🔬 FDM vs. Resin: How Printer Technology Impacts Hourly Rates

- ⚙️ Optimizing Your Prints: Slicing Settings That Save You Money

- 🏡 vs. 🏢 Hobbyist vs. Professional: Different Goals, Different Costs

- 📊 Calculating Your True Hourly 3D Printing Cost: A Step-by-Step Guide

- 🤝 When to DIY vs. When to Outsource: 3D Printing Service Bureaus

- 💡 Smart Strategies: How to Reduce Your 3D Printing Costs Per Hour

- ❌ Common Misconceptions About 3D Printing Costs

- ✅ Conclusion: Demystifying the Hourly 3D Print Cost

- 🔗 Recommended Links

- ❓ FAQ

- 📚 Reference Links

⚡️ Quick Tips and Facts

Welcome to the wild world of 3D printing costs! If you’ve ever wondered how much it really costs to 3D print for 1 hour, you’re in the right place. We at 3D Printed™ have crunched the numbers, tested printers, and chatted with fellow enthusiasts to bring you the juiciest, most practical insights.

Here’s a quick cheat sheet before we dive deeper:

- Material cost dominates your hourly expense — filament or resin can range from budget-friendly PLA to pricey specialty composites.

- Electricity costs? Surprisingly low, often just a few cents per hour for desktop printers.

- Printer depreciation matters — your machine’s wear and tear adds up over time.

- Labor and prep time can be a hidden cost, especially for complex prints or professional setups.

- Failed prints and waste can sneakily inflate your costs.

- Post-processing (sanding, painting, curing) adds time and materials, so factor that in!

For a more detailed look at cost per print, check out our related article: How much does it cost per 3D print?.

Ready to unravel the mystery? Let’s go! 🚀

🤔 Unraveling the Mystery: Why “Per Hour” 3D Printing Costs Are Tricky

You might think it’s as simple as multiplying printer power by electricity rates, but oh no — the cost to 3D print for 1 hour is a multi-layered beast. Here’s why:

- Print complexity varies wildly: A simple cube prints faster and uses less material than a detailed figurine.

- Material consumption fluctuates: Some prints use dense infills, others are mostly hollow.

- Printer models differ: A Prusa i3 MK3S and a Formlabs Form 3 resin printer have very different operating costs.

- Human factors: Setup, monitoring, and troubleshooting time can vary by user skill and project.

So, the hourly cost is more of a range than a fixed number. But don’t fret — we’ll break down each cost factor so you can calculate your own personalized hourly rate.

💸 The Core Components of Your 3D Printing Bill: What Goes Into That Hour?

Let’s dissect the anatomy of your 3D printing cost per hour. Spoiler: it’s not just filament and electricity!

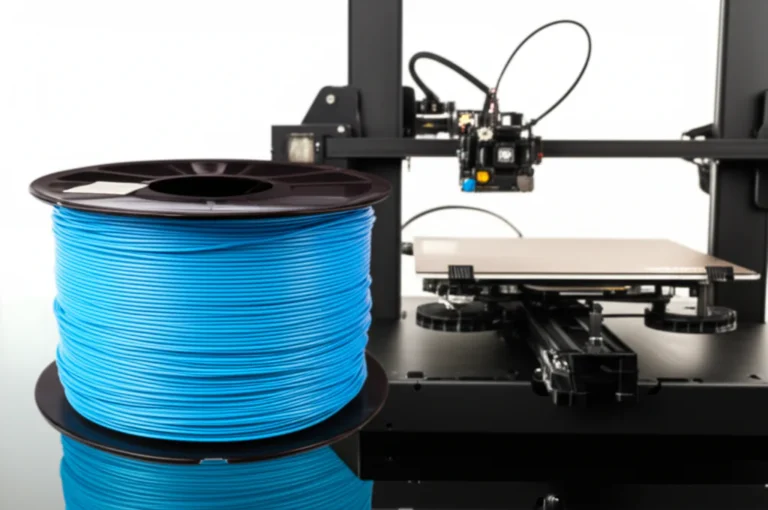

1. 🧵 Filament Follies: The Material Cost Breakdown

Material is king 👑 when it comes to 3D printing costs. Here’s the lowdown:

- PLA and ABS filaments: Typically around $20–$30 per kilogram.

- Specialty filaments: Carbon fiber composites, flexible TPU, or metal-infused filaments can run upwards of $50–$100/kg.

- Resins: SLA/DLP resins vary widely, from $50 to $300+ per liter depending on type and brand.

How to calculate material cost per hour?

Estimate how many grams or milliliters your print consumes in one hour, then multiply by the cost per gram/ml.

| Material Type | Cost per Kg/Liter | Typical Consumption per Hour | Estimated Cost per Hour |

|---|---|---|---|

| PLA Filament | $20 – $30 | 10 – 20 grams | $0.20 – $0.60 |

| Carbon Fiber Filament | $50 – $100 | 10 – 20 grams | $0.50 – $2.00 |

| Standard Resin | $100 – $300 | 10 – 30 ml | $1.00 – $9.00 |

Pro tip: Use slicer software like PrusaSlicer or Cura to estimate filament usage before printing. It’s a game-changer for budgeting!

2. ⚡ Powering Up: Your Electricity Bill’s Contribution

Electricity costs are often the unsung hero of 3D printing expenses — or rather, the unsung negligible. Here’s why:

- Desktop FDM printers like the Prusa i3 MK3S consume around 50-120 watts during printing.

- SLA printers like the Formlabs Form 3 use similar or slightly higher power due to lasers and resin vats.

- Average electricity cost in the US is about $0.13 per kWh (varies by region).

Example calculation:

A 100W printer running for 1 hour uses 0.1 kWh. At $0.13/kWh, that’s 13 cents per hour.

Electricity is rarely a deal-breaker but adds up over months of printing.

3. 💰 The Machine’s Worth: Printer Depreciation & Initial Investment

Your printer isn’t free — it’s an investment that depreciates over time. Here’s how to factor it in:

- Assume your printer costs $1,000 and has a useful life of 2,500 hours (typical for desktop printers).

- Depreciation per hour = $1,000 / 2,500 = $0.40 per hour.

This cost covers wear and tear, potential repairs, and eventual replacement.

Pro tip: Higher-end printers like the Ultimaker S5 or Prusa SL1 have different lifespans and depreciation rates. Adjust accordingly!

4. 🛠️ Keeping It Running: Maintenance & Spare Parts

Maintenance is the silent cost that keeps your printer humming:

- Replacement nozzles, belts, and build plates wear out and need periodic swapping.

- Lubricants, cleaning supplies, and occasional repairs add to expenses.

- Some users budget around 5-10% of printer cost per year for maintenance.

If you print heavily, maintenance costs can add up to $0.05–$0.15 per hour.

5. 🧑💻 The Human Touch: Labor & Design Time

Don’t forget the time you or your operator spends:

- Preparing the model and slicing: 5–15 minutes per print.

- Monitoring the print and troubleshooting: variable, but can be 10–30 minutes or more.

- Post-processing: sanding, curing, painting — can take hours depending on complexity.

If you value your time at $15/hour, even 15 minutes of prep adds $3.75 to the cost.

6. 🗑️ The Oops Factor: Failed Prints & Waste

Ah, the bane of every 3D printer’s existence — failed prints! They cost you:

- Material wasted.

- Time lost.

- Additional electricity and wear on your printer.

A 30% failure rate is not uncommon for beginners. Professionals aim for under 5%.

Tip: Factor in a “failure margin” of 10–30% of your material cost to cover these mishaps.

🕵️♀️ Beyond the Basics: Hidden Costs and Unexpected Surprises

There’s more lurking beneath the surface of your hourly 3D printing cost. Let’s uncover these sneaky expenses.

💻 Software Subscriptions & Licensing Fees

- Some slicers are free (Ultimaker Cura, PrusaSlicer), but professional CAD and design software like SolidWorks or Fusion 360 may require subscriptions.

- Cloud-based services and print farm management tools can add monthly fees.

If you use paid software, amortize the cost over your printing hours.

✨ Post-Processing Materials & Tools

Post-processing isn’t just elbow grease:

- Sandpaper, primers, paints, resin curing stations, and gloves all add to costs.

- SLA prints require isopropyl alcohol baths and UV curing — both consumables.

Estimate post-processing costs per hour or per print to get a full picture.

🧠 Learning Curve & Time Investment

3D printing is a skill. Early on, you’ll spend more time troubleshooting and experimenting, which adds to your effective hourly cost.

- Beginners might spend hours per print fixing issues.

- Experienced users streamline workflows, reducing labor costs.

Patience pays off — your hourly cost drops as you gain experience!

🌬️ Environmental Control & Safety Gear

Some materials and printers require:

- Ventilation systems or air purifiers (especially for resin printing).

- Safety gloves, masks, and eye protection.

These setup and operating costs should be factored in, especially in professional or educational settings.

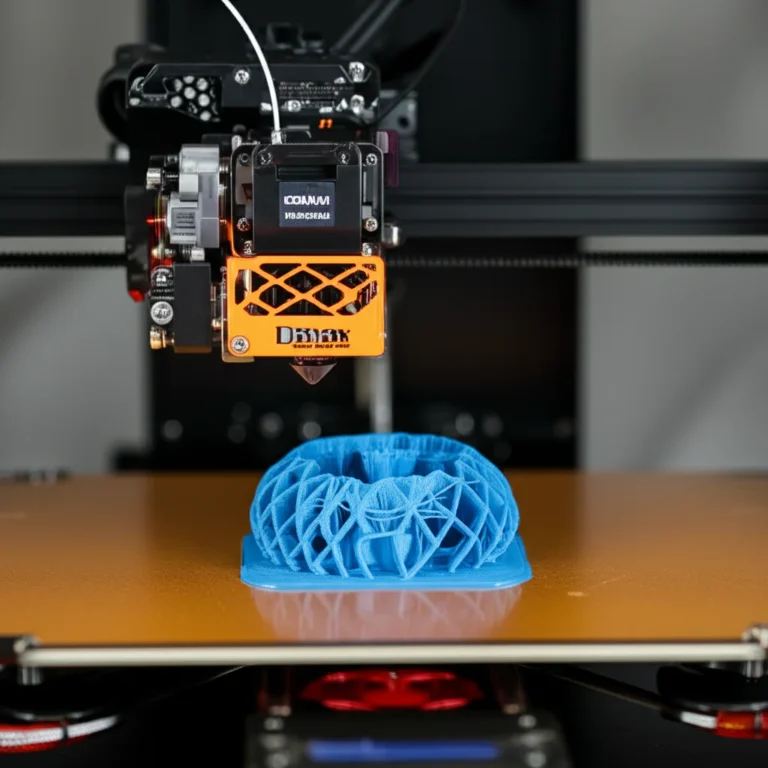

🔬 FDM vs. Resin: How Printer Technology Impacts Hourly Rates

The technology you choose makes a huge difference:

| Aspect | FDM (Fused Deposition Modeling) | Resin (SLA/DLP) |

|---|---|---|

| Material Cost | $20–$50/kg filament | $100–$300/liter resin |

| Print Speed | Moderate (hours for medium parts) | Slower for large parts, but high detail |

| Printer Cost | $200–$2,500 desktop models | $500–$5,000+ (higher-end models) |

| Maintenance | Nozzle clogs, bed leveling | Resin vat replacement, cleaning |

| Post-Processing | Minimal (removal, sanding) | Extensive (washing, curing) |

| Typical Hourly Cost | $0.50–$2.00 | $2.00–$10.00+ |

Example: Josef from Prusa’s blog found resin prints cost about 3x more per hour than FDM prints, mainly due to material and post-processing.

⚙️ Optimizing Your Prints: Slicing Settings That Save You Money

Want to stretch your dollar? Tweaking slicer settings can lower your hourly cost:

- Layer height: Thicker layers print faster but reduce detail.

- Infill density: Lower infill saves material and time.

- Print speed: Faster speeds reduce time but may affect quality.

- Supports: Minimize supports to save material and post-processing time.

Experiment with settings in PrusaSlicer or Ultimaker Cura to find your sweet spot.

🏡 vs. 🏢 Hobbyist vs. Professional: Different Goals, Different Costs

Your printing context shapes your cost structure:

| Factor | Hobbyist | Professional / Business |

|---|---|---|

| Labor Cost | Usually DIY, low or no labor cost | Paid operators, designers, and post-processors |

| Volume | Low to moderate | High volume, batch production |

| Quality Standards | Variable, often forgiving | Strict, consistent quality control |

| Equipment | Consumer-grade printers | Industrial-grade, high-end machines |

| Cost per Hour | Lower, but less optimized | Higher, but with economies of scale |

Professionals often factor in profit margins and overhead, pushing hourly costs higher but justifying it with quality and reliability.

📊 Calculating Your True Hourly 3D Printing Cost: A Step-by-Step Guide

Ready to crunch your own numbers? Here’s our stepwise formula:

-

Calculate Material Cost per Hour:

Use slicer estimates for filament/resin consumption × material price per gram/ml. -

Add Electricity Cost:

(Printer wattage ÷ 1000) × print time (hours) × electricity rate per kWh. -

Add Printer Depreciation:

Printer cost ÷ expected lifespan in hours. -

Add Maintenance Cost:

Estimate annual maintenance cost ÷ annual printing hours. -

Add Labor Cost:

Time spent on prep, monitoring, and post-processing × your hourly rate. -

Add Failure Margin:

Add 10–30% of material cost to cover failed prints. -

Sum All Components:

This gives your true hourly cost.

Example:

- Material: $0.50/hour

- Electricity: $0.10/hour

- Depreciation: $0.40/hour

- Maintenance: $0.10/hour

- Labor: $2.00/hour (15 minutes prep + 15 minutes post-processing)

- Failure margin: $0.15/hour

Total: $3.25 per hour

🤝 When to DIY vs. When to Outsource: 3D Printing Service Bureaus

Sometimes, printing yourself isn’t the cheapest or fastest option.

- DIY printing is great for prototyping, learning, and small runs.

- Service bureaus like Shapeways, Sculpteo, or 3D Hubs offer professional quality and materials you might not own.

- Outsourcing saves you time and hassle but adds markup and shipping costs.

If your hourly cost DIY is creeping too high, consider a quote from a service bureau — sometimes it’s surprisingly economical!

💡 Smart Strategies: How to Reduce Your 3D Printing Costs Per Hour

Want to slash your hourly costs without sacrificing quality? Here’s how:

- Buy filament in bulk from trusted brands like Prusament or Hatchbox.

- Optimize print settings to reduce material and time.

- Maintain your printer regularly to avoid costly repairs.

- Use open-source slicers to avoid software fees.

- Batch print multiple parts to maximize printer uptime.

- Learn from failures to reduce waste.

At 3D Printed™, we swear by these tactics — they’ve saved us hundreds of dollars and countless headaches!

❌ Common Misconceptions About 3D Printing Costs

Let’s bust some myths:

-

Myth: Electricity is the biggest cost.

Fact: Material and labor usually outweigh electricity by a large margin. -

Myth: Faster printing always saves money.

Fact: Speed can reduce quality and increase failure rates, costing more in the long run. -

Myth: All filaments cost the same.

Fact: Specialty filaments can be 5x or more expensive than basic PLA. -

Myth: Post-processing is negligible.

Fact: It can double your total print time and costs if you’re not careful.

Understanding these helps you budget realistically and avoid surprises.

✅ Conclusion: Demystifying the Hourly 3D Print Cost

Phew! We’ve journeyed through the tangled web of 3D printing costs per hour, and hopefully, you’re feeling like a cost-calculating wizard now. Remember, there’s no one-size-fits-all hourly rate because your costs depend on your printer, materials, skills, and how much elbow grease you’re willing to invest.

Here’s the bottom line from 3D Printed™:

- Material costs dominate — choose your filament or resin wisely.

- Electricity is a minor player but still worth tracking.

- Printer depreciation and maintenance add up — don’t ignore them.

- Labor and post-processing time can surprise you if you’re new or tackling complex projects.

- Failed prints are costly but inevitable at first — learn and improve!

If you’re a hobbyist, expect to pay roughly $1–$5 per hour depending on your setup and materials. Professionals with industrial-grade machines and high labor costs will see higher numbers but also higher quality and throughput.

By mastering your slicer settings, buying quality materials in bulk, and maintaining your printer, you can significantly reduce your hourly costs without sacrificing print quality.

So, next time someone asks, “How much does it cost to 3D print for 1 hour?” you can confidently say: “It depends — but here’s how you can calculate it yourself!”

🔗 Recommended Links

Ready to shop or learn more? Here are some top picks and resources:

- Prusa i3 MK3S:

Thingiverse Search for Prusa i3 MK3S | Prusa Official Website - Formlabs Form 3 Resin Printer:

Formlabs Official Website | Thingiverse Search for Formlabs Prints - Prusament PLA Filament:

Prusa Official Store - Hatchbox Filament:

Amazon Hatchbox PLA Filament - Ultimaker Cura Slicer:

Ultimaker Cura Download - Books on 3D Printing Costs and Techniques:

- 3D Printing Failures: How to Diagnose and Repair All 3D Printing Issues by Sean Aranda

- The 3D Printing Handbook by Ben Redwood, Filemon Schöffer, and Brian Garret

❓ FAQ

What is the average cost of 3D printing per hour for beginners?

For beginners, hourly costs typically range from $1 to $5, depending on printer type, filament, and how much time you spend on setup and post-processing. Beginners often experience higher failure rates, which inflate material and labor costs. As you gain experience and optimize settings, your effective hourly cost will decrease significantly.

How does the cost of 3D printing vary depending on the type of filament used?

Filament type is a major cost driver. Basic PLA or ABS filaments usually cost between $20 and $30 per kilogram, making them the most budget-friendly. Specialty filaments like carbon fiber composites, flexible TPU, or metal-infused filaments can cost $50 to $100+ per kilogram, increasing your material cost per hour. Resin materials for SLA printers are generally more expensive, ranging from $100 to $300+ per liter. Choosing the right filament for your project’s needs and budget is crucial.

What are the factors that affect the hourly cost of 3D printing, such as printer model and print speed?

Several factors influence hourly cost:

- Printer model: Higher-end printers have higher depreciation costs but may reduce failures and post-processing time.

- Print speed: Faster printing reduces time but can compromise quality or increase failure risk, potentially raising costs.

- Material consumption: Denser infills and supports increase material use and time.

- Labor: Time spent on preparation, monitoring, and finishing affects your effective hourly rate.

- Electricity and maintenance: Though minor, these add up over time.

Balancing these factors is key to optimizing costs.

Are there any ways to reduce the hourly cost of 3D printing, such as using recycled filament or optimizing print settings?

Absolutely! Here are some proven strategies:

- Use recycled or budget-friendly filaments from reputable brands to lower material costs without sacrificing quality.

- Optimize slicing settings — reduce infill, increase layer height, and minimize supports to save time and filament.

- Batch print multiple parts to maximize printer uptime.

- Maintain your printer regularly to avoid costly repairs and failures.

- Use free slicer software like Ultimaker Cura or PrusaSlicer to avoid subscription fees.

- Learn from failed prints to improve success rates and reduce waste.

Implementing these tips can significantly reduce your hourly printing costs.

How do post-processing and labor costs impact the total hourly cost of 3D printing?

Post-processing (sanding, painting, curing) and labor (design, setup, monitoring) can sometimes double or triple your effective hourly cost. For example, a 30-minute post-processing session adds $7.50 if you value your time at $15/hour. Ignoring these costs leads to underestimating your true expenses. Factor them in carefully for accurate budgeting.

What role does printer depreciation play in calculating hourly 3D printing costs?

Printer depreciation spreads the initial purchase cost over the printer’s useful life, reflecting wear and tear. For example, a $1,000 printer with a 2,500-hour lifespan adds $0.40 per hour to your cost. This cost is often overlooked but critical for understanding your real expenses and planning replacements.

📚 Reference Links

- Prusa3D: How to Calculate Printing Costs

- EUFYMake: How Much Do 3D Prints Cost?

- SolidPrint3D: How Much Does 3D Printing Cost Per Hour?

- Ultimaker Cura: Official Website

- Prusa Official: Prusa i3 MK3S

- Formlabs Official: Form 3 Resin Printer

- Shapeways: 3D Printing Services

- Sculpteo: 3D Printing Services