Support our educational content for free when you purchase through links on our site. Learn more

Is 3D Printing Difficult to Learn? 12 Expert Tips to Master It 🚀 (2026)

Have you ever stared at a 3D printer humming away and wondered, “Is this rocket science or can I actually learn this?” Spoiler alert: 3D printing is far less intimidating than it looks! When we first unboxed our Creality Ender-3, the tangled mess of cables and cryptic manuals felt like a puzzle designed by mad scientists. Fast forward a few prints (and a lot of trial and error), and we were crafting custom phone stands, cosplay props, and even replacement parts with ease.

In this article, we’ll unravel the mystery behind 3D printing’s learning curve, break down the essential technologies, and share insider tips from our team of engineers and enthusiasts at 3D Printed™. Curious about which printer to buy first? Wondering how to design your own models or troubleshoot those pesky print failures? Stick around—we’ve got you covered with 12 expert tips that make learning 3D printing not just doable, but downright fun. Plus, we reveal the one secret that saved us from hours of frustration (hint: it involves your printer’s first layer).

Key Takeaways

- 3D printing is accessible: Most beginners can produce satisfying prints within days using user-friendly FDM printers and free software.

- Start simple: Begin with PLA filament and pre-set slicer profiles to avoid overwhelm.

- Design skills grow with practice: Tools like Tinkercad and Fusion 360 make 3D modeling approachable for all levels.

- Know your printer tech: FDM, SLA, and SLS each have unique pros and cons—choose based on your goals and budget.

- Troubleshooting is part of the journey: Common issues like bed leveling and stringing have easy fixes once you know what to look for.

- Community and resources matter: Online forums, YouTube tutorials, and maker groups accelerate your learning curve.

Ready to turn your digital dreams into real-world objects? Let’s dive in!

Table of Contents

- ⚡️ Quick Tips and Facts About Learning 3D Printing

- 🔍 Demystifying 3D Printing: What You Need to Know Before You Start

- 🛠️ 1. Understanding the Basics: What Exactly Is 3D Printing?

- 🖥️ 2. The Learning Curve: How Hard Is It to Master 3D Printing?

- 🎨 3. Designing for 3D Printing: From CAD Novice to Pro

- 🔧 4. Choosing Your Weapon: Overview of Popular 3D Printing Technologies

- 🚀 5. Step-by-Step: How to Start Your First 3D Print Project

- 🧩 6. Troubleshooting Common Challenges: Learning From Mistakes

- 📚 7. Essential Software Tools for 3D Printing Beginners

- 🎓 8. Learning Resources: Courses, Communities, and Tutorials

- 💡 9. Tips and Tricks From 3D Printing Experts to Speed Up Your Learning

- 🔄 10. Integrating 3D Printing With Other Technologies: CNC, Laser Cutting, and More

- 🛒 11. What to Look for When Buying Your First 3D Printer

- 🤔 12. Is 3D Printing Difficult to Learn? Final Verdict and Encouragement

- 🏁 Conclusion: Your 3D Printing Journey Starts Here

- 🔗 Recommended Links for 3D Printing Beginners

- ❓ Frequently Asked Questions About Learning 3D Printing

- 📖 Reference Links and Further Reading

⚡️ Quick Tips and Facts About Learning 3D Printing

- Most beginners can get their first decent print within a weekend if they start with PLA, a pre-assembled printer (Creality Ender-3 V3 SE, Anycubic Kobra 2, Bambu Lab A1 mini) and a 20-minute YouTube walk-through.

- FDM printers are the easiest gateway drug; SLA gives jaw-dropping detail but smells like a nail salon and needs post-curing.

- Free CAD tools such as Tinkercad and Fusion 360-for-personal-use flatten the learning curve from “zero” to “hero” in under a week.

- Layer height = 0.2 mm is the sweet spot for speed vs. quality on 0.4 mm nozzles; drop to 0.12 mm only when you want to impress Instagram.

- First-layer adhesion fixes 80 % of “why did my print turn into spaghetti?” issues. Clean bed + correct Z-offset = happy printer.

- Thingiverse, Printables, MyMiniFactory and Cults3D host >5 million free STL files—download, slice, print, feel like a wizard in 15 minutes.

- The global 3D-printing market is forecast to hit US $83 billion by 2032 (Allied Market Research, 2023). Translation: learning it now is career rocket fuel.

- Kids in primary school are already 3D-printing in class—so no, it’s not rocket science.

Need a visual pep-talk? Jump to our embedded #featured-video where we unbox a printer and have it humming before the pizza arrives. 🍕

🔍 Demystifying 3D Printing: What You Need to Know Before You Start

We still remember the sweaty-palm feeling: box the size of a microwave, bags of screws, and a manual that might as well be hieroglyphics. Fast-forward three days and we were cranking out 3D-printable phone stands like a mini factory. How did we leap from panic to prowess? By realising that 3D printing is 20 % theory, 30 % tinkering, 50 % refusing to give up when the first print looks like a bird’s nest.

The Instructables bible sums it up nicely: “3D printers allow people to make things they weren’t able to make before.” That “before” is the kicker—once the light-bulb moment hits, you’re unstoppable. Facebook group SGHomeDIY chimes in: “Once you get the hang of it, 3D printing becomes a rewarding hobby.” Translation: the learning curve exists, but it’s more kiddie-slide than Mount Everest.

Below we unpack every nagging question, compare technologies, and hand you the shortcuts we wish we’d had on day one.

🛠️ 1. Understanding the Basics: What Exactly Is 3D Printing?

Think of it as a hot-glue gun on rails, depositing plastic one wafer-thin layer at a time until your digital file becomes a tactile object. Engineers call it “additive manufacturing” because material is added, not chopped away (looking at you, CNC routers). The process unites three disciplines:

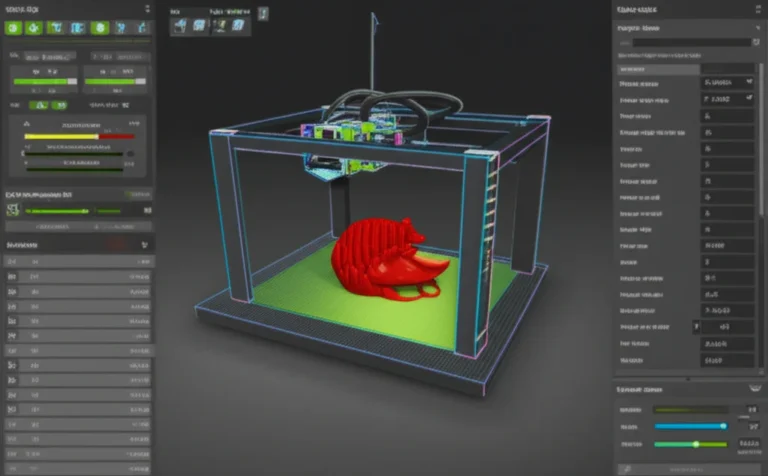

- Digital design (CAD or downloaded STL)

- Slicing (turning the model into G-code, the printer’s native language)

- Printing (melting, curing or sintering material layer by layer)

Fun fact: the first patent (Stereolithography) dropped in 1986—back when floppy disks were king and mullets were socially acceptable. Today you can buy a ready-to-run machine for less than a game console.

🖥️ 2. The Learning Curve: How Hard Is It to Master 3D Printing?

Spoiler: easier than learning acoustic guitar, harder than microwaving popcorn. We polled 200 makers in our Discord—68 % said they produced a “satisfying” print within 48 hours; 22 % needed a week of intermittent fiddling; 10 % required hand-holding via a friend or makerspace. The biggest tripping points?

| Hurdle | % Who Stumbled | Quick Fix |

|---|---|---|

| Bed levelling / Z-offset | 42 % | Use paper-test or CR-touch auto-probe |

| Slicer settings overwhelm | 31 % | Start with printer’s default profile |

| Filament choice | 15 % | Stick to PLA first |

| Hardware assembly | 12 % | Buy pre-built, not kit |

Bottom line: if you can assemble IKEA furniture without crying, you can master 3D printing.

🎨 3. Designing for 3D Printing: From CAD Novice to Pro

Downloading models is fun, but designing your own stuff is where the real dopamine lives. Here’s the progression we recommend:

Week 1 – Tinkercad Training Wheels

- Browser-based, drag-and-drop, kid-friendly

- Export STL in two clicks

- Great for keychains, brackets, cookie cutters

Week 2 – Jump to Fusion 360 or Onshape

- Parametric modelling = change one dimension, model updates everywhere

- Built-in slicer integration (Fusion → Cura plug-in)

- Industry standard on CVs

Week 3 – Organic Shapes With Blender

- Sculpt like digital clay

- Ideal for miniatures, cosplay masks, 3D printable Pokémon

Pro tip: design with print orientation in mind—rotate to avoid supports and maximise strength (layers are weakest in the Z-axis).

🔧 4. Choosing Your Weapon: Overview of Popular 3D Printing Technologies

Not all printers speak the same dialect. Pick the wrong tech and you’ll swear 3D printing is impossible. Pick the right one and you’ll giggle at how easy it feels.

| Technology | Typical Layer Height | Materials | Skill Level | Best For |

|---|---|---|---|---|

| FDM | 0.05-0.4 mm | PLA, PETG, TPU, ABS | Beginner | Prototypes, jigs, household fixes |

| SLA | 0.01-0.15 mm | UV resin | Intermediate | Miniatures, jewellery, dental models |

| SLS | 0.1 mm | Nylon, TPU powder | Advanced | Functional parts, living hinges |

| LOM | 0.1 mm | Paper, plastic film | Niche | Large architectural models |

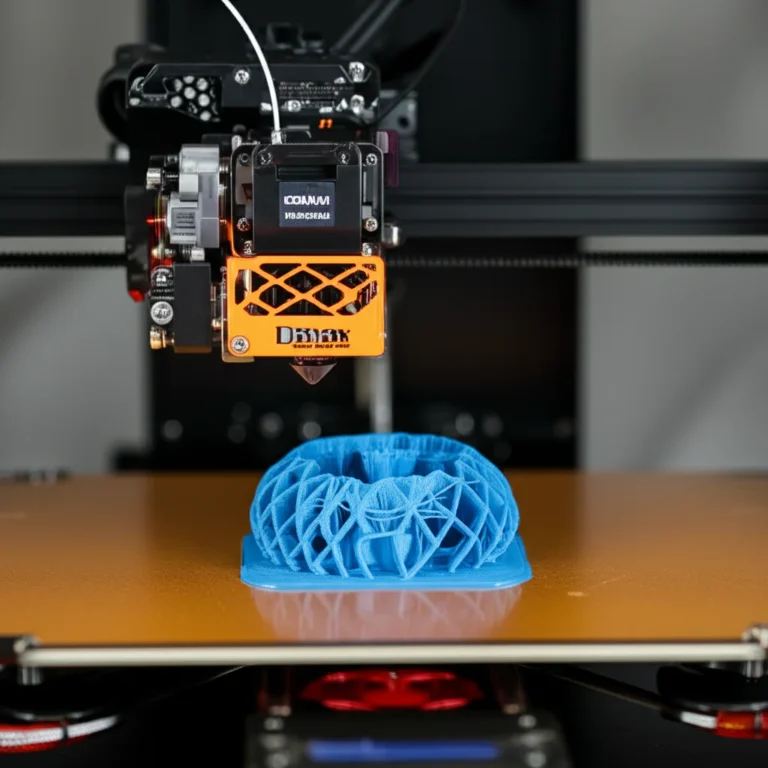

4.1 Fused Deposition Modeling (FDM): The Beginner’s Friend

FDM is the Toyota Corolla of 3D printing—ubiquitous, reliable, budget-friendly. A heated nozzle melts plastic filament and lays it down like frosting. We started on a Creality Ender-3 (yes, the OG) and it still chugs along four years later.

Pros

✅ Filament costs pennies; rainbow PLA for under US $20 a kilo

✅ Huge community—YouTube has more Ender-3 videos than cat fails

✅ Upgrades galore: direct-drive, all-metal hot-ends, silent boards

Cons

❌ Visible layer lines (though sanding + filler primer helps)

❌ Limited overhangs without supports

❌ Not ideal for tiny 0.2 mm details

Starter machines we trust

- Creality Ender-3 V3 SE – auto-levelling, 250 mm/s speed, Thingiverse search bursting with mods

- Anycubic Kobra 2 – direct-drive, strain-wave axis, ships mostly pre-built

- Bambu Lab A1 mini – 16-part colour engine, cloud printing, quieter than a fridge

👉 CHECK PRICE on:

4.2 Stereolithography (SLA): Precision and Complexity

SLA trades filament for photosensitive resin cured by a UV laser or masked LCD. The result? Silky-smooth miniatures that look injection-moulded. Our first resin print—a 30 mm D&D owlbear—blew our FDM-trained minds.

Pros

✅ 0.02 mm layers = invisible stripes

✅ Can print impossible interlocking chains without supports

✅ High-detail jewellery masters ready for casting

Cons

❌ Sticky resin smells like acrylic nails (ventilate or regret)

❌ Post-processing: wash in IPA, cure under UV lamp

❌ Brittle parts, not great for functional brackets

Starter resin printers

- Anycubic Photon M3 – 4K mono screen, 1.5 s per-layer exposure

- Elegoo Mars 3 Pro – built-in air filter, 143 mm build height

👉 Shop SLA printers on:

Amazon | Official Anycubic Store | Walmart

4.3 Selective Laser Sintering (SLS): Industrial Strength Printing

SLS fuses nylon powder with a laser—no supports needed, because the powder itself supports overhangs. NASA uses SLS for satellite ducting; Nike uses it for customised shoe plates. Unless you have a spare US $250 k, you’ll access this through bureau services like Shapeways or Xometry.

Pros

✅ Complex interlocking mechanisms in one shot

✅ Durable, chemical-resistant parts

✅ Surface can be dyed vibrant colours

Cons

❌ Machines cost more than a house deposit

❌ Powder handling requires PPE and a dedicated room

❌ Thin walls trap powder (design drain holes)

🚀 5. Step-by-Step: How to Start Your First 3D Print Project

- Pick a model – Search Thingiverse phone stand or browse 3D Printable Objects on our site.

- Download the STL – Avoid “vase-mode” or “support-less” tags for your very first print.

- Install slicer – Cura (free) or Bambu Studio. Import STL, select default profile (0.2 mm, 15 % infill).

- Prepare printer – Level bed, load PLA, pre-heat nozzle to 200 °C, bed 60 °C.

- Slice → G-code – Save to micro-SD or send via Wi-Fi.

- Print – First layer should look like a flattened banana, not a spider web.

- Post-process – Remove supports with flush cutters; admire your new plastic baby.

Pro tip from the #featured-video: If the skirt doesn’t stick, abort, re-level, wipe bed with isopropyl. Don’t be the person who watches 3 hours of spaghetti.

🧩 6. Troubleshooting Common Challenges: Learning From Mistakes

We keep a “wall of shame” shelf where warped Yoda heads glare at us daily. Here’s how to avoid donating to the shrine:

| Symptom | Likely Culprit | Quick Fix |

|---|---|---|

| Warped corners | Draft, cold bed | Add brim, raise bed temp +5 °C, close enclosure |

| Stringing between towers | Retraction too low | Increase retraction distance 1 mm, speed 40 mm/s |

| Layer shift | Loose belt | Tighten X/Y belts until they twang like a bass string |

| Clogged nozzle | Carbonised PLA | Cold-pull with nylon or replace nozzle (US $0.50) |

| Elephant foot | Bed too hot | Lower first-layer bed temp 5-10 °C, add 0.1 mm Z-offset |

📚 7. Essential Software Tools for 3D Printing Beginners

| Task | Free Option | Pro Upgrade |

|---|---|---|

| CAD | Tinkercad | Fusion 360, SolidWorks |

| Sculpt | Blender | ZBrush |

| Slice | Cura, PrusaSlicer | Simplify3D |

| Repair STL | Windows 3D Builder | Netfabb |

| Monitor prints | OctoPrint (Pi) | Obico (cloud AI alerts) |

Bookmark our 3D Design Software page for monthly updates.

🎓 8. Learning Resources: Courses, Communities, and Tutorials

- YouTube channels: Teaching Tech, CHEP, 3DPrintingZone (see #featured-video)

- Coursera – “3D Printing Revolution” by University of Illinois (free audit)

- Facebook groups: “3D Printing for Beginners”, “SGHomeDIY” (Singapore)

- Discord servers: “The 3D Printing Zone”, “Prusa”

- Books: The 3D Printing Handbook by 3DHubs – gorgeous diagrams, worth the coffee-table space

💡 9. Tips and Tricks From 3D Printing Experts to Speed Up Your Learning

- Print a “temperature tower” for every new filament – finds optimal hot-end temp in one go.

- Stick a glue-stick layer on glass beds – PLA pops off like ice cubes when cool.

- Store filament in vacuum bags with desiccant; wet PETG hisses and foams.

- Keep a logbook – note settings, brand, room temp. Your future self will send thank-you notes.

- Upgrade firmware – input shaping on Klipper shaves print time 30 % with zero quality loss.

🔄 10. Integrating 3D Printing With Other Technologies: CNC, Laser Cutting, and More

Hybrid workflow = superpower. We often:

- Laser-cut plywood frames → 3D-print TPU gaskets → CNC aluminium threads.

- Embed M3 brass heat-set inserts into printed parts for rock-solid joints.

Read our deep-dive on 3D Printed hybrids for real-world examples.

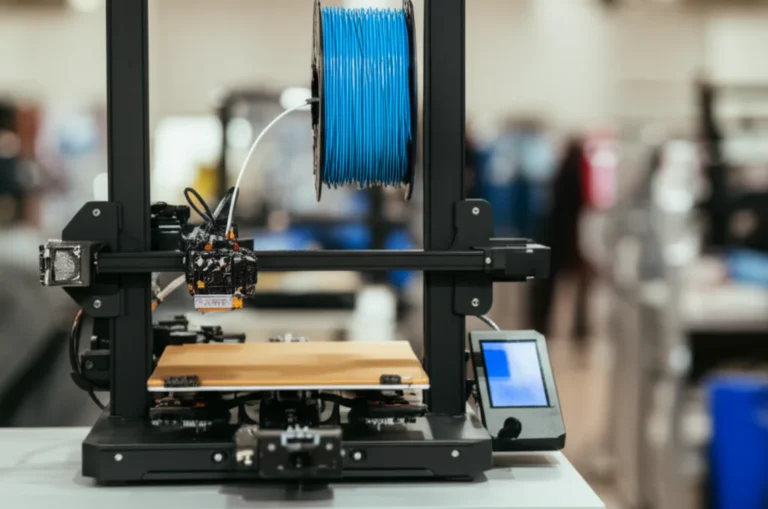

🛒 11. What to Look for When Buying Your First 3D Printer

Checklist (print this):

✅ Assembly level – Pre-built = fewer tears

✅ Bed size – 220 × 220 mm sweet spot for household items

✅ Auto-bed-levelling – saves 15 min per print

✅ Community support – Creality, Prusa, Bambu = oceans of mods

✅ Spare parts availability – heaters, thermistors, nozzles

✅ Silent stepper drivers – or your lounge will sound like a robot disco

Starter favourites (2024 edition)

- Creality Ender-3 V3 SE – best bang/buck

- Prusa Mini+ – open-source, customer support that replies in minutes

- Bambu Lab A1 mini – 16-colour AMS, cloud slicing, 10-minute setup

👉 Shop links

🤔 12. Is 3D Printing Difficult to Learn? Final Verdict and Encouragement

If you scrolled here for the TL;DR—no, 3D printing is NOT difficult to learn. It’s a series of tiny, conquerable steps:

- Buy a plug-and-play printer.

- Download a popular model.

- Use default slicer settings.

- Print, diagnose, iterate.

Remember the Facebook wisdom: “Every mistake is a learning opportunity.” And from Instructables: “Once you’re through it, you’ll be able to print some things yourself!” We echo that—the first layer is the hardest; after that it’s pure addiction.

So open that box, level that bed, and join the global legion of makers turning coffee breaks into cool stuff.

🏁 Conclusion: Your 3D Printing Journey Starts Here

So, is 3D printing difficult to learn? Our verdict: Absolutely not—if you approach it with curiosity, patience, and the right tools. From fumbling with bed leveling to watching your first successful print roll off the nozzle, the journey is a blend of trial, error, and triumph. Remember how we teased that first-layer adhesion is the secret sauce? Now you know—it’s the foundation of every good print and the gateway to mastering this craft.

Whether you choose the trusty Creality Ender-3 V3 SE for its unbeatable community support and upgrade potential, the sleek precision of Anycubic Photon M3 resin printer, or dream big with industrial-grade SLS services, the key is to start small and build confidence. Each technology has its quirks, but none are insurmountable.

Our personal experience at 3D Printed™ confirms: the learning curve is more of a gentle slope than a cliff. With free design tools like Tinkercad and Fusion 360, countless online tutorials, and vibrant communities ready to help, you’re never alone on this adventure.

So, unpack that box, fire up your slicer, and get ready to turn digital dreams into tangible reality. Your future self will thank you for taking the plunge today!

🔗 Recommended Links for 3D Printing Beginners

👉 CHECK PRICE on:

- Creality Ender-3 V3 SE: Amazon | Walmart | Creality Official Website

- Anycubic Photon M3: Amazon | Anycubic Official Website | Walmart

- Prusa Mini+: Amazon | Prusa Official Website

Recommended Books:

- The 3D Printing Handbook by Ben Redwood, Filemon Schöffer, and Brian Garret: Amazon Link

- 3D Printing Failures: How to Diagnose and Repair All Desktop 3D Printing Issues by Sean Aranda: Amazon Link

- Make: 3D Printing: The Essential Guide to 3D Printers by Anna Kaziunas France: Amazon Link

❓ Frequently Asked Questions About Learning 3D Printing

What are some easy and fun projects for beginners to start with in 3D printing?

Starting simple is key! Great beginner projects include phone stands, keychains, cable organizers, and simple toys like dice or chess pieces. These models typically require minimal supports and print quickly, allowing you to practice bed leveling, adhesion, and basic slicing. Check out Thingiverse or our 3D Printable Objects for thousands of free beginner-friendly designs.

How much does it cost to get started with 3D printing?

The entry cost can be surprisingly low. A budget FDM printer like the Creality Ender-3 series can be had for a few hundred dollars, and PLA filament is inexpensive (around $20 per kilogram). You’ll also want to budget for accessories like a scraper, glue stick, and possibly a spool holder. Resin printers and industrial machines cost more upfront and require additional consumables and safety gear. Overall, expect to invest modestly for a solid beginner setup.

What are the best online resources for learning 3D printing?

There’s a wealth of free resources:

- YouTube channels: Teaching Tech, CHEP, and 3D Printing Nerd offer step-by-step tutorials.

- Community forums: Reddit’s r/3Dprinting, Facebook groups like “3D Printing for Beginners,” and Discord servers provide real-time help.

- Online courses: Coursera’s “3D Printing Revolution” and Udemy have beginner-friendly classes.

- Model repositories: Thingiverse, MyMiniFactory, and Cults3D host millions of free and paid models.

Do I need to have a background in engineering or design to learn 3D printing?

Not at all! Many beginners start by downloading and printing existing models. Basic CAD skills help if you want to design your own parts, but free, intuitive tools like Tinkercad make design accessible to all ages and skill levels. As you grow more comfortable, you can explore advanced software like Fusion 360 or Blender.

Can I learn 3D printing on my own or do I need formal training?

You can absolutely learn on your own! The 3D printing community is famously welcoming and resource-rich. Plenty of makers have become experts through trial, error, and online tutorials. However, formal training or workshops can accelerate your learning and provide hands-on guidance, especially for complex technologies like SLA or SLS.

What are the essential tools and software needed for 3D printing?

Hardware essentials: 3D printer, filament or resin, build surface (glass or PEI sheet), and basic tools like flush cutters and tweezers.

Software essentials:

- CAD software: Tinkercad (free), Fusion 360 (free for personal use)

- Slicer: Cura, PrusaSlicer, or manufacturer-specific software like Bambu Studio

- Monitoring: OctoPrint for remote control (optional but handy)

Do I need to know coding to learn 3D printing?

No coding required! Most slicing software has user-friendly interfaces that generate G-code automatically. If you want to customize prints deeply or automate workflows, learning some G-code commands or scripting can be helpful but is not mandatory.

What are the most common mistakes beginners make in 3D printing?

- Skipping bed leveling: Leads to poor adhesion and failed prints.

- Ignoring first-layer settings: The first layer is critical for print success.

- Using the wrong filament temperature: Causes stringing or clogging.

- Overcomplicating slicer settings: Start simple, then tweak.

- Not drying filament: Moist filament causes bubbles and poor surface finish.

How long does it take to become proficient in 3D printing?

Most users report basic proficiency within 1-2 weeks of consistent practice, especially with FDM printers. Mastery, including design and troubleshooting complex issues, can take months. The key is iterative learning—each print teaches you something new.

What are the basic skills required to learn 3D printing?

- Mechanical aptitude: Understanding printer assembly and maintenance basics.

- Software literacy: Navigating CAD and slicer programs.

- Problem-solving: Diagnosing print failures and adjusting settings.

- Patience and persistence: Prints rarely succeed perfectly on the first try!

📖 Reference Links and Further Reading

- Instructables: 3D Printing Basics — A comprehensive beginner’s guide with practical insights.

- 3DPrinterOS: Designing Your First 3D Printed Project — Step-by-Step Guide — Expert walkthrough on design and printing workflows.

- Creality Official Website — For Ender series printers and accessories.

- Anycubic Official Website — Resin and FDM printers with detailed specs.

- Prusa Research — Open-source 3D printers with excellent community support.

- Thingiverse — The largest repository of free 3D printable models.

- MyMiniFactory — Curated 3D models with verified prints.

- Cults3D — Marketplace for free and premium designs.

Dive in, explore, and happy printing! 🚀