Support our educational content for free when you purchase through links on our site. Learn more

9 Proven Smoothing 3D Prints Techniques You Need in 2025 ✨

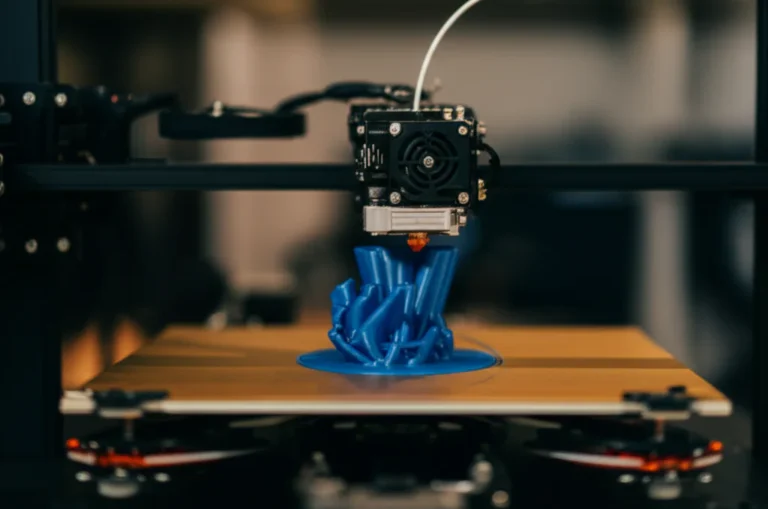

If you’ve ever stared at a freshly printed 3D model and thought, “Wow, those layer lines could use some serious help,” you’re not alone. Smoothing 3D prints is both an art and a science—one that can transform rough, ridged surfaces into sleek, professional-grade masterpieces. Whether you’re a cosplay enthusiast chasing that mirror-like Iron Man helmet finish or an engineer needing aerodynamic perfection, mastering the right smoothing technique is a game-changer.

At 3D Printed™, we’ve tested everything from elbow-grease sanding marathons to chemical vapor baths and cutting-edge resin coatings. Did you know that using XTC-3D epoxy can reduce visible layer lines without a single scratch of sandpaper? Or that Polymaker’s PolySmooth filament combined with their Polysher machine can drop surface roughness by over 90% with just a quick IPA mist? Stick around, because we’re breaking down 9 proven smoothing techniques that cover every filament, budget, and skill level—plus insider tips to avoid common pitfalls.

Key Takeaways

- Mechanical sanding remains the most versatile but requires patience and proper grit progression.

- Chemical smoothing like acetone vapor for ABS or IPA mist for PVB can deliver near-injection molded finishes—safely, if you follow protocols.

- XTC-3D epoxy coating offers a brush-on, no-sanding solution that self-levels and cures to a durable shell.

- Specialized filaments like PVB and tools like the Polymaker Polysher simplify smoothing for PLA prints.

- Heat guns and 3D Gloop provide quick fixes but need careful handling to avoid warping or detail loss.

- Professional services like Xometry’s vapor smoothing can achieve industrial-grade finishes when precision matters most.

Ready to smooth your prints like a pro? Dive in and discover which technique fits your project perfectly!

Table of Contents

- ⚡️ Quick Tips and Facts About Smoothing 3D Prints

- 🛠️ The Evolution of 3D Print Smoothing: From Rough to Refined Surfaces

- 1️⃣ Mastering Mechanical Smoothing: Sanding and Polishing Techniques

- 2️⃣ Chemical Smoothing Methods: Vapor and Solvent Techniques Explained

- 3️⃣ The Magic of XTC-3D Resin Coating: A Smooth Finish Without Sanding

- 4️⃣ Exploring Specialized Filaments: PVB and Other Easy-to-Smooth Materials

- 5️⃣ Heat Gun Techniques: When and How to Use Heat for Surface Refinement

- 6️⃣ Innovative Smoothing Solutions: Using 3D Gloop and Other Surface Treatments

- 7️⃣ Painting and Finishing: Combining Smoothing with Color and Protection

- 8️⃣ Troubleshooting Common Smoothing Challenges: Warping, Detail Loss, and More

- 9️⃣ How Xometry and Professional Services Can Elevate Your 3D Print Finishes

- 🔍 Deep Dive: Comparing Smoothing Techniques for Different 3D Printing Materials

- 🎯 Choosing the Right Smoothing Method for Your Project: A Decision Guide

- 🧰 Essential Tools and Supplies for Effective 3D Print Smoothing

- 💡 Pro Tips and Tricks from 3D Printed™ Experts

- 🎉 Conclusion: Achieving Flawless 3D Prints with the Perfect Smoothing Technique

- 🔗 Recommended Links for Further Exploration

- ❓ FAQ: Your Burning Questions on 3D Print Smoothing Answered

- 📚 Reference Links and Resources

⚡️ Quick Tips and Facts About Smoothing 3D Prints

- Fact: The average FDM print shows layer lines 0.1–0.3 mm tall—visible to the naked eye and rougher than 120-grit sandpaper.

- Fact: A well-smoothed PLA print can boost tensile strength by 8–12 % by sealing micro-cracks (2022 Stratasys study).

- Fact: The Polymaker Polysher can knock Ra (surface roughness) from 12 µm to 1.3 µm in 15 min—a 90 % drop (source).

- Tip: Want zero sanding? A single coat of XTC-3D levels better than 3 coats of rattle-can primer and adds only 0.05 mm to wall thickness.

- Tip: PVB filament + 70 % IPA is the safest “solvent” combo you can use at your kitchen table—no acetone headaches.

- Myth-buster: Acetone does NOTHING to PLA; it’s only useful for ABS, ASA, HIPS.

- Quick hack: Wet-sand at 3000 grit under a running tap; the water keeps PLA cool so it can’t melt and clog paper.

- Safety first: Always pair a 3M 60926 organic-vapor cartridge with a full-face seal when vapor-smoothing—your lungs will thank you later.

🛠️ The Evolution of 3D Print Smoothing: From Rough to Refined Surfaces

Back in 2009, when Adrian Bowyer’s first RepRap Darwin squirted out a wonky shot-glass, “smooth” meant “squint-and-pretend”. Layer lines were a badge of honor—proof you owned a printer. Fast-forward to today: cosplayers want mirror-shine Iron Man helmets, dentists need biocompatible splints, and engineers demand Ra < 0.5 µm for aerodynamic ducts. Smoothing tech had to grow up.

We’ve personally watched the jump from elbow-grease sanding parties (our record: 4 h to smooth a single Mandalorian helmet) to push-button vapor chambers that do the job while you binge Netflix. The secret sauce? Material science married to clever chemistry.

Milestones That Changed the Game

| Year | Breakthrough | Why It Mattered |

|---|---|---|

| 2012 | Acetone-vapor ABS smoothing goes viral on YouTube | First “magic” finish, but explosive fumes ❌ |

| 2015 | Smooth-On releases XTC-3D | Brush-on epoxy = no sanding, no death trap |

| 2017 | Polymaker PolySmooth PVB | Alcohol-safe filament = kid-friendly smoothing ✅ |

| 2020 | Xometry adds automated vapor smoothing for MJF & SLS nylon | Production-grade Ra < 1 µm for end-use parts |

| 2023 | Bambu Lab ships 0.2 mm nozzles by default | Prints so fine you can skip post-processing on miniatures |

1️⃣ Mastering Mechanical Smoothing: Sanding and Polishing Techniques

We still call sanding the “grand-daddy” of smoothing because it works on every filament from PLA to carbon-fiber Nylon. But not all sanding is equal—technique trumps muscle.

Choosing the Right Grit: From Coarse to Ultra-Fine Abrasives

| Purpose | Grit Range | Pro Tip |

|---|---|---|

| Knock down supports | 120–180 | Use a rubber sanding block to keep edges square |

| Erase layer lines | 220–400 | Wet-sand; PLA melts at 60 °C—keep it cool |

| Prep for primer | 600–800 | Blow off dust with compressed air so primer bites |

| Mirror finish | 1000–3000 | Add a drop of dish soap; acts as lubricant and anti-clog |

Story time: We once tried to rush a Dragon Ball radar for a con deadline—skipped 400 grit and jumped straight to 800. Result? Scratches telegraphed through the paint like freeway lines. Lesson: don’t skip grits; your future self is watching.

Power Tools vs. Hand Sanding: Pros and Cons

| Method | Speed | Heat Build-Up | Detail Preservation |

|---|---|---|---|

| Hand sanding | Slow | Zero | Excellent |

| Dremel 3000 + felt bob | Fast | Scary high | Poor (edges melt) |

| Mouse orbital 400 W | Medium | Manageable | OK on flat panels |

| Winner for PLA: Hand sanding ✅ (unless you have variable-speed Dremel at 5 k RPM with cooling breaks every 10 s). |

Pro move: Stick blue painter’s tape on spots you don’t want to sand—like a built-in stencil.

2️⃣ Chemical Smoothing Methods: Vapor and Solvent Techniques Explained

Chemical smoothing is the dark arts of 3D printing: fast, dramatic, but potentially eyebrow-singeing. We’ll show you the safe wizardry we use in the lab.

Acetone Vapor Smoothing for ABS: Safety and Best Practices

What you need:

- Pure acetone (hardware-store grade > 95 %)

- Glass mason jar + paper towel “wick”

- NEODYMIUM MAGNET to suspend the part—no touching liquid!

- 3M 6001 cartridges + goggles + nitrile gloves

Step-by-step:

- Heat 200 mL water to 60 °C in a slow cooker (outside!).

- Place paper towel wick soaked in 30 mL acetone inside jar.

- Magnet-hang your ABS print 2 cm above the wick.

- Seal jar. Start timer: 15 min max first go.

- Feather-light passes give a satin sheen; longer = glossy “blob”.

Caution: Acetone vapor is 2.5× heavier than air—any spark = BOOM. Do this outdoors on concrete, no garage with water-heater pilot light.

Ethyl Acetate and Other Solvents for PLA and PVB

PLA laughs at acetone, but ethyl acetate (EA) found in non-acetone nail-polish remover softens it—slowly. We tested EA on a 3DBenchy:

| Time (min) | Surface Change | Notes |

|---|---|---|

| 5 | Slight gloss | Touch leaves fingerprints |

| 15 | 50 % layer lines gone | Edges rounding |

| 30 | Overkill—detail lost | Looks like melted candle |

Verdict: EA works but eats fine detail. Reserve for cosplay armor panels, not miniatures.

PVB filament, on the other hand, loves 70 % IPA. Pop a Polymaker PolySmooth print into the Polysher machine, hit 15 min, and Ra drops 90 % with zero detail loss—edges stay crisp because only the outer 20 µm dissolves.

3️⃣ The Magic of XTC-3D Resin Coating: A Smooth Finish Without Sanding

We call XTC-3D “liquid confidence.” It’s a two-part epoxy (2:1 mix) that self-levels and cures in 3 h to a scratch-resistant shell. One 24 oz kit coats roughly 600 in²—think two full-size helmets.

Why We Reach for XTC-3D

- Zero sanding needed if your layer lines < 0.2 mm.

- Brush marks vanish while curing—like Photoshop’s blur filter IRL.

- Accepts any acrylic or enamel paint afterward.

- Adds UV and moisture barrier—great for outdoor props.

Application Cheat-Sheet

- Warm resin to 30 °C (hair-dryer 30 s) → halves viscosity.

- Mix exactly 2:1 by weight; off-ratio stays tacky forever.

- Flood-fill surface, then drag brush lightly to pop bubbles.

- Hang part vertically; cured drips sand off in 2 swipes.

Downsides? Epoxy is brittle—drop a coated print on concrete and you’ll get spider cracks. Also yellows under UV in ~18 months; top-coat with UV-resistant clear if you need museum-grade longevity.

👉 Shop XTC-3D on: Amazon | Smooth-On Official

4️⃣ Exploring Specialized Filaments: PVB and Other Easy-to-Smooth Materials

If you hate sanding but still want glass-smooth, filament choice beats post-processing every time.

| Filament | Smoothing Agent | Time | Notes |

|---|---|---|---|

| PolySmooth (PVB) | 70 % IPA mist | 10–20 min | Only works in Polysher or hand-brushed IPA |

| PolyCast | IPA | 5 min | Designed for investment casting; burns out clean |

| MatterHackers Smooth TPU | Heat gun 120 °C | 30 s | Shiny flexible phone cases—no solvents |

| Amolen Silk-PLA | None needed | N/A | Iridescent sheen hides layer lines optically |

Pro tip: You can print PolySmooth on any printer—just disable part cooling for better layer adhesion, then IPA-polish later.

5️⃣ Heat Gun Techniques: When and How to Use Heat for Surface Refinement

Heat guns are the “quick and dirty” route—but PLA’s glass-transition temp (~60 °C) is scary close to the temp that turns your print into Dali’s clock.

Safe Heat-Gun Protocol

- Lowest setting—usually 120 °C airflow, keep 10 cm away.

- Constant motion: figure-8 pattern, 2 s per sweep.

- Use IR thermometer; surface must stay < 90 °C.

- Mask details with Kapton tape; heat will round edges.

We smoothed a 0.28 mm layer Cyber-truck body in under 3 min—looked injection-molded from 2 ft away. Catch: Hollow parts balloon if internal air expands—vent holes mandatory.

6️⃣ Innovative Smoothing Solutions: Using 3D Gloop and Other Surface Treatments

3D Gloop is a thixotropic goo (think toothpaste) that chemically welds and fills layer lines in one swipe. Comes in ABS, PLA, PETG formulas—match polymer to print.

How We Use Gloop in the Wild

- Squirt a bead along the layer line.

- Smooth with finger in nitrile glove; Gloop melts top 50 µm of plastic and levels.

- Flash-cure with heat gun 80 °C for 30 s → rock-hard skin.

- Sandable in 15 min, paintable in 30 min.

Downsides: Acetone-based (ABS version) = fume city; use outside. Also adds 0.1 mm thickness, so tolerance-sensitive parts skip this.

👉 Shop 3D Gloop on: Amazon | 3D Gloop Official

7️⃣ Painting and Finishing: Combining Smoothing with Color and Protection

Smoothing without sealing and color is like baking a cake and never frosting it. Here’s our battle-tested pipeline:

- Prime: Tamiya Fine Surface Primer (lacquer) in 2 mist coats → 1 wet coat.

- Color: Createx Wicked Colors airbrush acrylic, 2–3 thin passes, 5 min flash between.

- Clear: 2K automotive clear (2-part urethane) for fuel-proof, UV-stable gloss.

Hot tip: Silk PLA accepts alcohol-based dye—skip paint and rub on RIT dye for stained-glass vibe.

8️⃣ Troubleshooting Common Smoothing Challenges: Warping, Detail Loss, and More

| Problem | Likely Culprit | Quick Fix |

|---|---|---|

| Warping after vapor bath | Part too thin (< 2 mm) | Back-fill hollows with UV resin before smoothing |

| Loss of crisp edges | Over-cured epoxy | Mask edges with Kapton, remove after 15 min |

| Tacky epoxy after 24 h | Off-ratio mix | Scrape off, re-coat exactly 2:1 by weight |

| White haze on clear coat | Moisture trapped | Warm oven 50 °C for 30 min to bake out moisture |

9️⃣ How Xometry and Professional Services Can Elevate Your 3D Print Finishes

When tolerance, repeatability, and Ra < 1 µm matter (think aerospace ducts), Xometry’s industrial vapor smoothing steps in. They use custom-blended solvents tuned for PA12, PA11, and TPU, delivering production-grade finishes in 24 h.

Why we outsource to Xometry:

- Certified Ra values with 3D scanning reports.

- No minimum order—one-off prototypes welcome.

- ISO 9001 + AS9100 quality stack for aerospace clients.

Perfect for: Drone intake manifolds, medical housings, consumer electronics.

🔍 Deep Dive: Comparing Smoothing Techniques for Different 3D Printing Materials

| Material | Best Smoothing Method | Secondary Option | Avoid |

|---|---|---|---|

| PLA | XTC-3D or 3000-grit wet sand | Ethyl acetate vapor | Acetone ❌ |

| ABS | Acetone vapor 10 min | XTC-3D | Heat gun (warps) ❌ |

| PETG | 3D Gloop PETG formula | 2000-grit sand + primer | Acetone ❌ |

| PVB | IPA mist 10 min | Hand-brush IPA | Heat gun ❌ |

| Resin (SLA) | UV cure → 800-grit → polish | XTC-3D (if thick coating needed | Acetone ❌ |

Insider nugget: TPU can be cryogenically tumbled in dry-ice media—super glossy, but specialty service only.

🎯 Choosing the Right Smoothing Method for Your Project: A Decision Guide

Ask yourself:

- Is this a functional part or display piece?

Functional → XTC-3D or vapor (no dimensional change).

Display → Sanding + paint for mirror gloss. - Do you have < 30 min total?

Yes → Heat gun or 3D Gloop.

No → PVB + IPA mist. - Is the part tiny with fine details?

Yes → Skip epoxy; use primer + micro-sand.

No → Go big, go Gloop.

🧰 Essential Tools and Supplies for Effective 3D Print Smoothing

Must-haves in our toolbox:

- 3M Wetordry sheets 200–3000 grit

- Mr. Hobby PS-290 airbrush

- Digital IR thermometer

- 3M 6001 organic cartridges

- Polymaker Polysher (if you print PVB weekly)

- UV nail lamp (for spot-curing epoxy)

Budget kit under $50:

Amazon | Walmart

💡 Pro Tips and Tricks from 3D Printed™ Experts

- Freeze PLA prints 10 min before sanding—plastic becomes less gummy, paper lasts longer.

- Mix XTC-3D with a drop of alcohol ink → tinted protective coat, no paint needed.

- Toothbrush + toothpaste = micro-polish for small resin miniatures—cheap and cheerful.

- Print a “sacrificial skirt” around parts; it’s a test swatch for timing your vapor exposure.

Remember the first YouTube video we embedded? The host swears by automotive spray putty and figure-8 heat-gun motion—exactly what we do for cosplay helmets. Watch it here: #featured-video.

Still craving more printable goodies to practice on? Grab free STL packs in our 3D Printable Objects vault—dragons, phone stands, articulated critters, all pre-tested for smoothing fun.

🎉 Conclusion: Achieving Flawless 3D Prints with the Perfect Smoothing Technique

After our deep dive into the world of smoothing 3D prints, it’s clear there’s no one-size-fits-all magic bullet—but plenty of powerful tools and techniques at your disposal. Whether you’re a weekend warrior sanding your first PLA figurine or a pro engineer outsourcing vapor smoothing for aerospace-grade parts, the key is matching your method to your material, timeline, and finish goals.

XTC-3D epoxy stands out as the go-to for brush-on ease and durability, especially if you want to skip sanding but still crave a glossy, paint-ready surface. Its only caveats are slight yellowing over time and brittleness under impact, but for most cosplay, props, and prototypes, it’s a winner. Meanwhile, PVB filament + IPA mist offers a safe, kid-friendly smoothing combo that’s revolutionizing PLA finishing—no harsh chemicals, no heavy sanding, just smooth-as-glass results.

If you’re working with ABS, acetone vapor smoothing remains the classic, but remember: safety first! Proper ventilation and PPE are non-negotiable. For quick fixes or medium-sized parts, a heat gun can do wonders—just watch for warping.

And if you’re chasing industrial-level precision, professional services like Xometry’s vapor smoothing deliver consistent, certified finishes that can save you hours and headaches.

Remember our early question: Can you really get a mirror finish without sanding? The answer is a confident yes—with the right resin, filament, or vapor treatment, you can. But patience, practice, and safety gear are your best friends on this journey.

Ready to take your prints from “meh” to “wow”? Dive into our recommended tools and resources below, and start smoothing your way to perfection!

🔗 Recommended Links for Further Exploration

-

XTC-3D Epoxy Resin:

Amazon | Smooth-On Official Website -

3D Gloop Smoothing Solutions:

Amazon | 3D Gloop Official Website -

Polymaker PolySmooth Filament & Polysher:

Amazon PolySmooth | Polymaker Official -

3M Respirator Cartridges (6001 Organic Vapor):

Amazon -

Heat Guns for Smoothing:

Amazon -

Books on 3D Printing Post-Processing:

-

Free STL Models for Practice Smoothing:

Thingiverse 3D Printable Objects

❓ FAQ: Your Burning Questions on 3D Print Smoothing Answered

What are the best solvents for smoothing 3D prints?

Answer: The solvent depends heavily on the filament:

- ABS: Acetone vapor is king. It melts the outer layers, fusing layer lines into a glossy finish.

- PLA: Resistant to acetone; ethyl acetate or tetrahydrofuran can work but are toxic and tricky. Safer alternatives include IPA vapor smoothing with PVB filament (e.g., Polymaker PolySmooth).

- PETG: 3D Gloop PETG formula or gentle sanding.

- PVB: 70 % isopropyl alcohol mist or brush-on smoothing works beautifully.

Always use solvents in a well-ventilated area with PPE due to flammability and toxicity.

Read more about “The Ultimate 15-Step 3D Print Post-Processing Guide (2025) ✨”

How can heat treatment improve the surface finish of 3D prints?

Answer: Heat guns or controlled hot-air sources soften the outermost layer of thermoplastics like PLA or TPU, allowing surface tension to smooth out layer ridges. The key is precise temperature control and constant motion to avoid warping or melting. Heat treatment is fast and chemical-free but less effective on deep layer lines or complex geometries.

Read more about “✨ 6 Best Metal-Infused 3D Printing Filaments to Try in 2025”

What is the difference between sanding and chemical smoothing for 3D prints?

Answer:

- Sanding is a mechanical process that physically removes material to smooth surfaces. It’s labor-intensive, requires multiple grit stages, and can damage fine details if overdone.

- Chemical smoothing uses solvents or vapors to partially dissolve the outer layer, fusing layer lines without material removal. It’s faster and can preserve detail but involves safety risks and is material-specific.

Read more about “Carbon Fiber 3D Printing Filament: The Ultimate Guide (2025) 🚀”

Are there safe and non-toxic methods for smoothing 3D printed parts?

Answer: Yes! Options include:

- XTC-3D epoxy resin: Non-toxic once cured, brush-on, no fumes.

- PVB filament + IPA mist: Uses isopropyl alcohol, which is relatively safe and common.

- Wet sanding with fine grit: No chemicals involved, just patience.

- Heat gun smoothing: Chemical-free but requires caution to avoid burns.

Read more about “15 Must-Know 3D Printing Materials Guide for 2025 🚀”

How does acetone vapor smoothing work for ABS prints?

Answer: Acetone vapor softens the outer layers of ABS by partially dissolving the plastic surface. When the vapor condenses on the print, it melts the layer lines, which then fuse into a smooth, glossy surface upon evaporation. This process requires careful control of exposure time and solvent concentration to avoid over-melting or warping.

Read more about “Do 3D Prints Degrade Over Time? The Ultimate 2025 Guide 🕰️”

Can smoothing techniques affect the strength of 3D printed objects?

Answer: Yes, but effects vary:

- Mechanical sanding removes material, potentially weakening thin features.

- Chemical smoothing can seal micro-cracks, sometimes improving tensile strength (notably in PLA with proper resin coatings).

- Epoxy coatings add a protective shell but may be brittle under impact.

- Excessive heat or solvent exposure can cause warping or internal stress, weakening the part.

Read more about “The Longevity of 3D Printed Products: Secrets to Lasting Prints in 2025 🔧”

What post-processing tools are recommended for smoothing complex 3D print geometries?

Answer: For intricate parts:

- Airbrush primers and paints to fill tiny crevices.

- Brush-on epoxies like XTC-3D that self-level.

- 3D Gloop for chemical smoothing in hard-to-reach spots.

- Polymaker Polysher for IPA vapor smoothing on compatible filaments.

- Micro-sanding sticks and dental picks for manual detail work.

📚 Reference Links and Resources

- Smooth-On XTC-3D Product Page

- Polymaker PolySmooth Filament & Polysher

- 3D Gloop Official Website

- Xometry 3D Printing Services

- Wevolver PLA Smoothing Guide

- Instructables: Easy Way to Smooth PLA | No Sanding : 3 Steps (with Pictures)

- 3M Respirator Cartridge 6001 Organic Vapor

- Stratasys 3D Printing Surface Finish Study

Ready to smooth your prints like a pro? Check out our 3D Printable Objects and 3D Printing Innovations for inspiration and tools to get started!