Support our educational content for free when you purchase through links on our site. Learn more

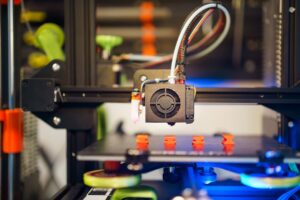

What are the Most Common 3D Printing Uses in 2023?

Welcome to 3D Printed™, your ultimate guide to all things 3D printing! In this article, we will explore the most common uses of 3D printing in 2023. Whether you’re a beginner or an experienced enthusiast, we’ve got you covered. So let’s dive in and discover the exciting world of 3D printing!

Table of Contents

- Quick Answer

- Quick Tips and Facts

- Manufacturing Applications

- Medical Applications

- Industrial Applications

- Sociocultural Applications

- Conclusion

- FAQ

- Recommended Links

- Reference Links

Quick Answer

The most common uses of 3D printing in 2023 include manufacturing, medical, industrial, and sociocultural applications. 3D printing is revolutionizing various industries by enabling rapid prototyping, customization, and cost-effective production.

Quick Tips and Facts

- 3D printing, also known as additive manufacturing, is the process of creating three-dimensional objects by layering materials.

- Different types of 3D printing technologies include Fused Filament Fabrication (FFF), Stereolithography (SLA), Selective Laser Sintering (SLS), and more.

- The global market for 3D printers and services was worth $2.2 billion in 2012 and is projected to reach $550 billion annually by 2025.

- 3D printing offers numerous advantages, such as reduced waste, faster production, and the ability to create complex geometries.

Manufacturing Applications

Manufacturing is one of the primary areas where 3D printing has made a significant impact. Here are some common manufacturing applications:

- Rapid Prototyping: 3D printing allows designers and engineers to quickly create prototypes, enabling faster product development cycles and reducing costs.

- Customization: With 3D printing, manufacturers can easily create customized products tailored to individual customer needs, such as personalized jewelry or unique home decor items.

- Tooling: 3D printing is used to create agile tooling, which enables faster and more cost-effective production processes.

- Mass Production: While traditionally associated with prototyping, 3D printing is increasingly being used for small-scale mass production, especially for complex or low-volume parts.

- Distributed Manufacturing: Cloud-based additive manufacturing enables decentralized and geographically independent production, reducing supply chain complexities.

Medical Applications

The medical field has embraced 3D printing for a wide range of applications. Here are some common medical uses:

- Surgical Planning: 3D printing allows surgeons to create patient-specific models for preoperative planning, enhancing surgical precision and reducing risks.

- Patient-Matched Implants: Customized implants, such as prosthetics or dental implants, can be 3D printed to perfectly fit an individual’s anatomy, improving patient outcomes.

- Bio-Printing: Researchers are exploring the use of 3D printing to create living tissues and organs, potentially revolutionizing regenerative medicine and transplantation.

- Medical Devices: 3D printing enables the production of complex medical devices, such as hearing aids or prosthetic limbs, with improved functionality and comfort.

- Pharmaceutical Formulations: 3D printing is being used to create personalized medication with precise dosages, making it easier for patients to adhere to their treatment plans.

Industrial Applications

3D printing is transforming various industries by offering innovative solutions to complex challenges. Here are some common industrial applications:

- Automotive: 3D printing is used in the automotive industry for rapid prototyping, customized parts, and tooling, leading to faster innovation and reduced costs.

- Aerospace: The aerospace industry benefits from 3D printing by creating lightweight and complex components, reducing fuel consumption and improving performance.

- Architecture: Architects and designers use 3D printing to create intricate models, enabling better visualization and communication of their designs.

- Consumer Goods: 3D printing allows for the production of unique and customizable consumer goods, such as fashion accessories or home decor items.

- Electronics: 3D printing is used to create complex electronic components, such as circuit boards or sensors, with improved functionality and integration.

Sociocultural Applications

Beyond the industrial and medical sectors, 3D printing has also found its way into various sociocultural applications. Here are some examples:

- Education: 3D printing is being integrated into educational curricula to teach students about design, engineering, and problem-solving.

- Art and Design: Artists and designers are using 3D printing to create unique sculptures, jewelry, and other artistic creations that were previously impossible to produce.

- Archaeology and Paleontology: 3D printing allows for the creation of accurate replicas of ancient artifacts and fossils, preserving cultural heritage and facilitating research.

- Humanitarian Aid: 3D printing is used in disaster-stricken areas to quickly produce essential items, such as medical supplies or temporary shelters.

Conclusion

3D printing has revolutionized various industries, from manufacturing to medicine, by enabling rapid prototyping, customization, and cost-effective production. As the technology continues to advance, we can expect even more exciting applications in the future. So whether you’re a hobbyist, professional, or simply curious, 3D printing offers endless possibilities for creativity and innovation.

Remember, if you want to explore more about 3D printing, check out our related articles on Beginner’s Guides, 3D Printable Objects, Materials for 3D Printing, and Commercial 3D Printing Projects.

FAQ

What are the 4 most common types of 3D printing?

The four most common types of 3D printing are Fused Filament Fabrication (FFF), Stereolithography (SLA), Selective Laser Sintering (SLS), and Polyjet Printing. Each technology has its own advantages and is suitable for different applications.

Read more about “What Products Can Be Made by 3D Printing? …”

What are the common materials used in 3D printing?

The common materials used in 3D printing include plastics (such as PLA and ABS), resins, metals (such as titanium and aluminum), ceramics, and even food-grade materials. The choice of material depends on the desired properties and the specific application.

Read more about “… The Most Useful 3D Prints in PLA: A Comprehensive Guide”

Can I 3D print electronics?

Yes, 3D printing can be used to create complex electronic components, such as circuit boards or sensors. This field, known as 3D printed electronics, combines traditional 3D printing techniques with conductive materials to produce functional electronic devices.

Is 3D printing environmentally friendly?

3D printing can be more environmentally friendly compared to traditional manufacturing methods. It reduces waste by only using the necessary amount of material and allows for local production, reducing transportation emissions. However, the environmental impact also depends on the materials used and the disposal of waste generated during the printing process.

Read more about “Is 3D Printed Stuff Plastic? …”

Recommended Links

- 2023 The Most Useful 3D Printed Objects: A Comprehensive Guide

- Beginner’s Guides

- 3D Printable Objects

- Materials for 3D Printing

- Commercial 3D Printing Projects