Support our educational content for free when you purchase through links on our site. Learn more

What Is a 3D Printing Product? Discover 10 Must-Know Facts! 🖨️ (2025)

Imagine holding in your hands a custom-designed object that didn’t exist a day ago — crafted layer by layer from a digital blueprint, with precision and creativity that traditional manufacturing can’t match. That’s the magic of a 3D printing product, a marvel that’s reshaping industries, hobbies, and even medicine. But what exactly qualifies as a 3D printing product? Is it just the printed object, or does it include the printer, the materials, and the software behind it? Spoiler alert: it’s all of the above, and then some!

In this comprehensive guide, we’ll unravel the full story behind 3D printing products — from the fascinating history and cutting-edge technologies to the incredible applications and future trends that will blow your mind. Plus, we’ll share insider tips from our expert engineers at 3D Printed™ and reveal how customization and sustainability are driving this revolution. Curious about how a simple filament spool transforms into a prosthetic limb or a supercar part? Stick around — the answers await!

Key Takeaways

- 3D printing products encompass printers, materials, software, and the final printed objects, each playing a vital role in the additive manufacturing ecosystem.

- Additive manufacturing builds objects layer by layer, enabling complex designs, customization, and reduced waste compared to traditional subtractive methods.

- Popular 3D printing products range from medical devices and aerospace components to personalized consumer goods and educational tools.

- The technology is rapidly evolving, with exciting trends like 4D printing, bioprinting, and large-scale construction on the horizon.

- Legal, ethical, and environmental considerations are critical as 3D printing becomes more widespread.

- Customization and creativity are the true game-changers, allowing products tailored perfectly to individual needs and tastes.

Ready to dive deeper and explore the full spectrum of 3D printing products? Let’s get started!

Table of Contents

- ⚡️ Quick Tips and Facts About 3D Printing Products

- 🔍 Understanding 3D Printing Products: What Are They Really?

- 📜 The Evolution of 3D Printing Products: A Journey Through Time

- 🧰 3D Printing Technology Explained: Processes, Materials, and Printers

- 🏭 10 Popular Types of 3D Printing Products and Their Uses

- 💡 Benefits and Advantages of 3D Printed Products in Everyday Life

- ⚙️ How 3D Printing Products Are Made: From Design to Finished Object

- 🛠️ Customization and Creativity: Why 3D Printing Products Are Game-Changers

- 📈 The Economic Impact of 3D Printing Products on Industries and Markets

- ⚖️ Legal and Ethical Considerations Surrounding 3D Printing Products

- 🧪 Health and Safety Tips When Using or Handling 3D Printed Products

- 🌍 Environmental Impact and Sustainability of 3D Printing Products

- 📚 Terminology and Jargon: Decoding 3D Printing Product Language

- 🔧 Troubleshooting Common Issues with 3D Printed Products

- 🎯 Future Trends: What’s Next for 3D Printing Products?

- 📝 Conclusion: Wrapping Up the World of 3D Printing Products

- 🔗 Recommended Links for 3D Printing Enthusiasts

- ❓ FAQ: Your Burning Questions About 3D Printing Products Answered

- 📖 Reference Links and Further Reading

Body

⚡️ Quick Tips and Facts About 3D Printing Products

Welcome, fellow makers and innovators, to the 3D Printed™ labs! Before we dive headfirst into the glorious rabbit hole of additive manufacturing, let’s arm you with some quick-fire facts. Think of this as your cheat sheet to understanding the universe of 3D printing products. What is a 3D printed item?, you ask? Let’s get you up to speed!

- It’s All About Adding, Not Subtracting: At its core, 3D printing, or additive manufacturing, builds objects layer by layer from a digital file. This is the polar opposite of traditional “subtractive” manufacturing, where you start with a block of material and cut away the excess. This fundamental difference is what makes 3D printing so revolutionary, leading to less material waste.

- From Six-Figure Giants to Desktop Minis: In the 1980s, owning a 3D printer would set you back a cool $300,000 or more! Today, you can get a decent quality Fused Deposition Modeling (FDM) printer for under $200, making this tech accessible to hobbyists and small businesses alike.

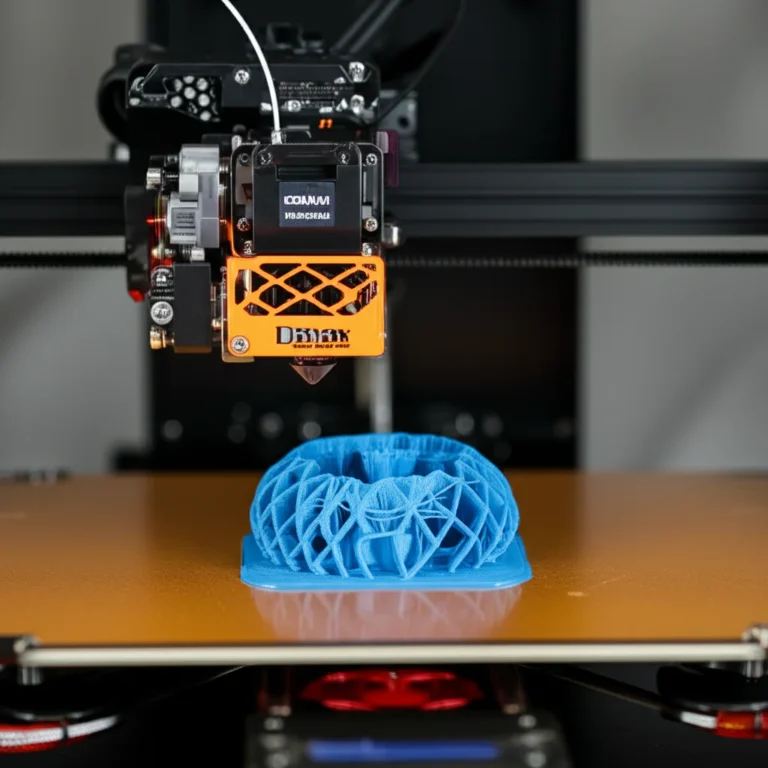

- FDM is King (for now): The most common process you’ll see is Fused Deposition Modeling (FDM), which involves melting a plastic filament and extruding it layer by layer. It’s affordable, versatile, and the workhorse of the consumer 3D printing world.

- Not Just Plastic: While plastics like PLA and PETG are common, 3D printing products can be made from an ever-expanding menu of materials, including metals, resins, ceramics, and even chocolate!

- Complexity is Free: One of the biggest “wow” factors is that creating a highly complex, intricate design costs no more to print than a simple block of the same size. This opens up a universe of design possibilities that are impossible or wildly expensive with traditional methods.

- A Booming Hobby: As of 2019, an estimated 2 million people worldwide had purchased a 3D printer for hobby use. That number has only skyrocketed since!

🔍 Understanding 3D Printing Products: What Are They Really?

So, what exactly is a 3D printing product? It’s a bit of a trick question because the term can refer to several things. Let’s break it down.

The Machines: The Creators

First, you have the 3D printer itself. This is the machine that does the magic, turning a digital blueprint into a physical object. These range from commercial-grade powerhouses engineered for business, like the Fusion3 F200 and EDGE printers, to specialized multi-material printers like the Stratasys J55 Prime, which is designed for creating stunningly realistic, full-color prototypes.

The Materials: The Building Blocks

Next are the materials—the filament, resin, or powder that the printer uses. Think of these as the ink for a 2D printer, but way cooler. The material you choose dictates the properties of your final object, whether it’s the strength of ABS plastic, the biodegradability of PLA, or the fine detail of a photopolymer resin.

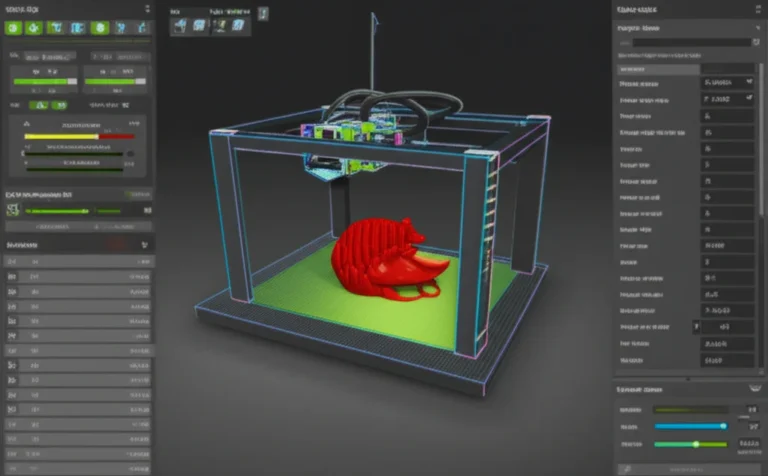

The Software: The Brains

Don’t forget the software! From 3D Design Software like CAD (Computer-Aided Design) programs where the object is designed, to the “slicer” software that cuts the digital model into layers and generates the instructions (G-code) for the printer, software is the invisible but essential part of the process.

The Objects: The Creations

Finally, and most excitingly, are the actual objects created by the printer. These are the tangible items you can hold in your hand, from a simple keychain to a complex prosthetic limb. These are the ultimate “3D printing products,” and their applications are virtually limitless, spanning industries from aerospace to healthcare.

📜 The Evolution of 3D Printing Products: A Journey Through Time

Believe it or not, the concepts behind 3D printing were bubbling up in science fiction as early as the 1940s! But the real journey began in the 1980s.

- The 1980s: The Dawn of Additive: This was the decade of invention. Chuck Hull filed a patent for Stereolithography (SLA) and founded 3D Systems, releasing the first commercial 3D printer, the SLA-1. Around the same time, S. Scott Crump developed Fused Deposition Modeling (FDM), the technology that would later democratize 3D printing. Back then, these machines were exclusively for rapid prototyping in industrial settings.

- The 1990s: Metal and More: The technology expanded to include metal sintering and melting processes, opening the door for more robust, industrial applications.

- The 2000s: The Open-Source Revolution: This was a game-changer! The RepRap project, an initiative to create an open-source, self-replicating 3D printer, kicked off in 2004. Then, in 2009, the key patents for FDM technology expired, blowing the market wide open for affordable, consumer-grade printers. We remember this time well; our workshop was suddenly filled with buzzing, whirring machines we’d built ourselves from kits!

- The 2010s to Today: The Cambrian Explosion: With affordable printers available, a massive community of makers and hobbyists emerged. We saw an explosion in 3D Printable Objects on sites like Thingiverse. Industries from aerospace (GE’s 3D printed fuel nozzles) to medicine (custom prosthetics) fully embraced the technology. Now, in the 2020s, we’re seeing things like the world’s first fully 3D-printed prosthetic eye and massive printers capable of building entire structures.

🧰 3D Printing Technology Explained: Processes, Materials, and Printers

Not all 3D printers are created equal. The technology they use defines what they can create, how fast they can do it, and with what materials. Here’s a look at the most common processes.

| Technology | Common Name(s) | How It Works | Common Materials | Best For |

|---|---|---|---|---|

| Material Extrusion | FDM, FFF | Melts and extrudes a thermoplastic filament layer by layer. | PLA, ABS, PETG, TPU | Hobbyists, rapid prototyping, low-cost models. |

| Vat Photopolymerization | SLA, DLP | Uses a UV light source to cure liquid resin into hardened plastic. | Photopolymer Resins | High-detail models, jewelry, dental applications. |

| Powder Bed Fusion | SLS, DMLS, SLM | Uses a laser to sinter or melt powdered material together. | Nylon, Metals (Titanium, Steel) | Functional parts, complex geometries, no supports needed. |

| Material Jetting | PolyJet, MJ | Jets droplets of photopolymer onto a build plate and cures them with UV light. | Photopolymer Resins | Realistic, multi-color, multi-material prototypes. |

| Binder Jetting | – | Deposits a binding adhesive onto powdered material. | Sand, Metal, Gypsum | Full-color models, large-scale sand casting molds. |

For a closer look at some of these machines, check out our 3D Printer Reviews.

🏭 10 Popular Types of 3D Printing Products and Their Uses

The real magic of 3D printing isn’t the printer; it’s what you can create with it. The applications are exploding across every industry imaginable. Here are just a few examples that get us excited.

- Custom Medical Devices & Prosthetics: From surgical guides to patient-matched implants and affordable, custom-fit prosthetics, 3D printing is revolutionizing healthcare.

- Aerospace and Automotive Components: Companies like GE and Koenigsegg use 3D printing to create lightweight, incredibly complex parts for jet engines and supercars that would be impossible to make otherwise.

- Rapid Prototypes: This is the classic application. Engineers and designers can print a prototype overnight, test it the next day, and iterate on a design in a fraction of the time and cost of traditional methods.

- Architectural Models: Architects can now print detailed, tangible scale models of their designs, helping clients visualize a project in a way a 2D drawing never could.

- Custom Footwear and Fashion: As the featured video shows, companies like Zellerfeld are printing entire shoes from a single, recyclable material. This allows for on-demand production and perfect customization.

- Personalized Consumer Goods: The possibilities are endless! Think custom phone cases, ergonomic mouse grips, or unique jewelry designed by you, for you.

- Niche Hobbyist Accessories: Got a niche hobby? 3D printing can serve it. As seen in the video, Printed Reef creates specialized, aesthetically pleasing accessories for reef aquariums—a market too small for traditional mass production.

- Innovative Office Organizers: The “B.Friends” organizers by Bene, also from the video, showcase how 3D printing’s unique layer lines can be embraced as a design feature, creating a product that “looks completely unique because it cannot be manufactured any other way.”

- Educational Tools: In schools, 3D printing is a powerful tool for teaching design, engineering, and problem-solving. It’s a cornerstone of modern 3D Printing in Education.

- Jigs, Fixtures, and Manufacturing Aids: In factories, 3D printing is used to create custom tools that make assembly lines more efficient, saving companies significant time and money.

👉 Shop 3D Models on:

- General Models: Thingiverse | MyMiniFactory | Cults3D

- Professional Models: CGTrader | TurboSquid

💡 Benefits and Advantages of 3D Printed Products in Everyday Life

Why are we so obsessed with 3D printing? Because its advantages are transformative.

- ✅ Unmatched Design Freedom: You can create incredibly complex internal structures and organic shapes that are simply impossible with traditional manufacturing.

- ✅ Speed and Rapid Prototyping: Go from a digital idea to a physical object in your hands in a matter of hours, not weeks. This drastically accelerates innovation.

- ✅ Cost-Effective for Low Volumes: For small production runs or one-off custom parts, 3D printing is far more economical because it eliminates the need for expensive molds or tooling.

- ✅ Mass Customization: The ability to tweak a design for each individual user without significant extra cost is a game-changer. Think custom-fit earbuds, personalized car parts, or perfectly tailored medical implants.

- ✅ Reduced Waste: Since it’s an additive process, you only use the material you need to build the part, creating significantly less waste than subtractive methods.

- ✅ On-Demand & Decentralized Manufacturing: Instead of massive warehouses, companies can maintain a “digital inventory” and print parts only when they’re needed, closer to the end-user. This could signal the beginning of a “Third Industrial Revolution.”

Of course, it’s not perfect.

- ❌ Slower for Mass Production: For producing thousands of identical, simple items, traditional methods like injection molding are still faster and cheaper.

- ❌ Material Limitations: While the range of materials is growing, it doesn’t yet cover every need, and some materials can be expensive.

- ❌ Post-Processing: Many 3D printed parts require some form of finishing—like sanding, polishing, or support removal—to achieve a final look.

⚙️ How 3D Printing Products Are Made: From Design to Finished Object

Ever wonder how a digital file becomes a physical thing? It’s a fascinating process that we live and breathe every day. Here’s the step-by-step journey:

- Step 1: The Digital Design (Modeling): It all starts with a 3D model. This is created using Computer-Aided Design (CAD) software. This can be anything from a professional engineering program to free, user-friendly software. The final design is typically exported as an STL or AMF file.

- Step 2: The Digital Slice (Slicing): You can’t just send a 3D model to the printer. You first need to run it through a slicing software. This program, or “slicer,” does exactly what its name implies: it slices the 3D model into hundreds or thousands of thin, horizontal layers. It then generates a file (usually G-code) that contains the precise instructions for the printer—like a treasure map telling the extruder where to move and when to deposit material for each layer.

- Step 3: The Physical Build (Printing): This is where the magic happens! The printer reads the G-code file and begins building the object, layer by painstaking layer. Whether it’s an FDM printer melting filament, an SLA printer curing resin, or an SLS printer sintering powder, the fundamental principle is the same: adding material sequentially to form the final shape.

- Step 4: The Final Touch (Finishing): Once the print is complete, it often needs a little TLC. This post-processing stage can involve removing support structures (temporary scaffolding printed to hold up overhanging parts), sanding or smoothing surfaces, painting, or assembling multiple printed parts.

🛠️ Customization and Creativity: Why 3D Printing Products Are Game-Changers

If there’s one area where 3D printing truly shines, it’s in its power to unlock limitless customization and creativity. Traditional manufacturing is built on standardization; 3D printing thrives on individuality.

Products Tailored to You

We’re talking about a level of personalization that was once science fiction.

- Perfect Fit: As mentioned, companies like Youmawo and Horizons Optical can 3D scan a customer’s face to create perfectly fitting, custom eyeglasses. No more slipping frames!

- Enhanced Functionality: The video’s example of the Jointlocker is brilliant. The designers needed to accommodate slight size variations in BIC lighters. The solution? “Grip fins” inside the lighter slot—a complex internal geometry that would be a nightmare for traditional molding but is a piece of cake for 3D printing. This is a prime example of 3D Printing Innovations.

- Modular and Upgradable: The Danish company Tons uses 3D printing for its minimalist cycling accessories. Their design allows for easy upgrades and modularity, letting users adapt the product to their needs over time. This print-on-demand model also eliminates waste from overproduction.

A New Aesthetic

3D printing isn’t just about function; it’s creating a new design language. The B.Friends office organizers, for instance, don’t hide their 3D printed origins—they celebrate them. The visible layer lines, created with an extra-large nozzle, give the product a unique, pottery-like texture that is central to its appeal. As the video states, “It looks completely unique because it cannot be manufactured any other way.” This embraces the process itself as a form of artistry.

📈 The Economic Impact of 3D Printing Products on Industries and Markets

3D printing isn’t just a cool hobby; it’s a disruptive economic force. Some have even called it the beginning of a Third Industrial Revolution. Here’s how it’s shaking things up.

- Lowering Barriers to Entry: By dramatically reducing the cost of prototyping and tooling, 3D printing allows small businesses and even individuals to develop and test physical products without massive upfront investment.

- On-Demand Manufacturing: The ability to print parts as needed reduces the need for large inventories and expensive warehousing. This “just-in-time” model makes supply chains more flexible and resilient.

- Enabling Niche Markets: As we saw with Printed Reef, 3D printing makes it economically viable to serve small, specialized markets. The cost to produce one custom aquarium part is the same as producing ten, making it perfect for low-volume, high-variety product lines.

- Reshoring and Localized Production: 3D printing could lead to a shift away from centralized mass production in overseas factories towards more localized, on-demand manufacturing. This reduces transportation costs and carbon emissions.

- New Business Models: Companies like Zellerfeld are pioneering new models built around exclusivity and on-demand production. By partnering with designers for limited runs of 3D printed shoes, they turn the longer production time into a feature, not a bug, building hype and brand loyalty.

By 2025, it’s estimated that additive manufacturing could impact 320 million workers in the manufacturing sector.

⚖️ Legal and Ethical Considerations Surrounding 3D Printing Products

With great power comes great responsibility, and 3D printing has opened a Pandora’s box of complex legal and ethical questions.

Intellectual Property (IP) Rights

This is the big one. How do you protect a design when it can be perfectly replicated from a digital file shared online?

- Copyright & Patents: It’s incredibly easy to download a patented design from a site like Thingiverse and print it, potentially infringing on the creator’s IP. Enforcing these rights on a global, decentralized scale is a massive challenge.

- The Future of Regulation: Lawmakers are struggling to keep up. Future regulations will likely focus on the digital files themselves rather than the physical objects.

Product Liability and Safety

Who is responsible if a 3D printed product fails?

- Is it the person who designed the file?

- The person who printed the object?

- The manufacturer of the printer or the material? Current safety regulations are based on centralized manufacturing and are difficult to apply to a world of home producers.

Controversial Applications

The ability to print certain items raises serious ethical concerns.

- Firearms: The online distribution of files for 3D printable firearms has sparked a major debate about regulation and public safety.

- Bioprinting: The futuristic possibility of printing human tissues and organs brings up profound ethical questions about consent, accessibility, and the very definition of life.

🧪 Health and Safety Tips When Using or Handling 3D Printed Products

Here at 3D Printed™, safety is our top priority. While 3D printing is an amazing hobby, the process involves heat, moving parts, and chemicals, so it’s crucial to take precautions.

- Ventilation is Key! 🌬️: Melting plastic can release Volatile Organic Compounds (VOCs) and ultrafine particles (UFPs) into the air. These can cause respiratory irritation and other health issues. Always operate your printer in a well-ventilated area. An enclosure with an exhaust fan and filter is even better.

- Hands Off! 🔥: Extruders and heated beds can reach very high temperatures. Be mindful of hot surfaces to avoid nasty burns.

- Watch for Moving Parts: Keep fingers, long hair, and loose clothing away from the printer’s moving axes to prevent mechanical injury.

- Handle Resins with Care: If you’re using an SLA or DLP printer, the liquid resins can be skin irritants. Always wear nitrile gloves and safety glasses when handling them.

- Food Safety: Just because a material is labeled “food-safe” doesn’t mean the printed object is. The tiny layer lines in an FDM print can trap bacteria. If you’re printing items that will contact food, be sure to seal them with a food-safe coating.

- Cleanliness is Godliness: Regularly clean your printer and workspace. Use a wet cloth or a HEPA vacuum to clean up dust and debris to avoid making particles airborne.

🌍 Environmental Impact and Sustainability of 3D Printing Products

The environmental story of 3D printing is a tale of two sides. It offers some incredible sustainability benefits but also presents new challenges.

The Good News ✅

- Less Material Waste: This is the most significant benefit. Additive manufacturing only uses the material needed for the part, unlike subtractive methods that can generate a lot of scrap.

- Lighter Parts: 3D printing allows for the creation of complex, hollow, or lattice-structured parts that are strong yet lightweight. In the aerospace and automotive industries, lighter parts mean better fuel efficiency and lower emissions.

- Localized Production: Printing products on-demand and locally reduces the need for long-distance shipping and the massive carbon footprint that comes with it.

The Challenges ❌

- Plastic Consumption: Most consumer 3D printing relies on plastics derived from fossil fuels. While materials like PLA (Polylactic Acid) are derived from renewable resources like corn starch and are biodegradable under industrial composting conditions, many other filaments are not.

- Energy Consumption: 3D printers, especially those that maintain high temperatures for hours or even days, can consume a significant amount of electricity.

- Waste from Failed Prints: Every 3D printing enthusiast has a “box of shame” filled with failed prints, support material, and prototypes. Managing this plastic waste is a growing concern.

The future lies in developing more sustainable, recyclable materials and more energy-efficient printers. Companies like Zellerfeld, which uses a single, 100% recyclable material for its shoes, are paving the way. As they note, “Every part of the shoe can just be ground up and then run back through a 3D printer.”

📚 Terminology and Jargon: Decoding 3D Printing Product Language

Stepping into the world of 3D printing can feel like learning a new language. Here’s a quick glossary of common terms to help you sound like a pro.

- Additive Manufacturing: The industrial term for 3D printing; the process of building an object layer by layer.

- Filament: The spool of plastic material (like PLA or ABS) used in FDM printers.

- Extruder: The “hot end” of an FDM printer that melts and pushes out the filament.

- Build Plate / Bed: The surface where the 3D print is built.

- G-Code: The language of 3D printers. It’s the instruction file created by the slicer that tells the printer exactly how to move.

- Infill: The internal structure of a 3D print. It’s usually a grid or pattern and is expressed as a percentage (e.g., 20% infill).

- Layer Height: The thickness of each individual layer. A smaller layer height results in a higher-resolution, smoother print but takes longer.

- SLA (Stereolithography): A 3D printing process that uses a laser to cure liquid resin into hardened plastic.

- SLS (Selective Laser Sintering): A process that uses a laser to fuse powdered material together.

- STL (Stereolithography File): The most common file format for 3D models used in 3D printing.

- Supports: Removable scaffolding printed to support overhanging parts of a model during the printing process.

🔧 Troubleshooting Common Issues with 3D Printed Products

Even with the best printer, things can go wrong. The final printed object can sometimes have frustrating flaws. Here are some of the most common issues and how to fix them.

- Warping (Edges Lifting Off the Bed): This happens when the plastic cools too quickly and contracts, causing the corners of the print to lift off the build plate.

- Solution: Use a heated bed, ensure the bed is level and clean, and add a “brim” or “raft” in your slicer settings to increase first-layer adhesion.

- Stringing or “Spider Webs”: Thin, wispy strands of plastic appear between different parts of your model.

- Solution: This is caused by filament oozing from the nozzle as it travels. Tweak your “retraction” settings in the slicer (this pulls the filament back slightly before a travel move). Lowering the nozzle temperature can also help.

- Layer Shifting: Suddenly, the layers are misaligned, creating a “stair-step” effect in your print.

- Solution: This is usually a mechanical issue. Check that your printer’s belts are properly tensioned and that nothing is obstructing the movement of the print head or bed.

- Poor First Layer: The first layer is the foundation of your entire print. If it doesn’t stick well or is uneven, the rest of the print is doomed.

- Solution: Level your bed! This is the most critical step. Also, make sure your nozzle’s Z-offset (the distance from the bed) is correct. You want the first layer to be slightly “squished” onto the plate.

- Under-Extrusion (Gaps in Layers): The print looks weak, brittle, or has missing layers because the printer isn’t extruding enough plastic.

- Solution: This could be a clogged nozzle, incorrect temperature settings, or tangled filament. Check for blockages and ensure your filament can feed smoothly.

🎯 Future Trends: What’s Next for 3D Printing Products?

The world of 3D printing is evolving at a breakneck pace. What seems like science fiction today will be on our desktops tomorrow. Here’s a glimpse of what the future holds.

- 4D Printing: This is the mind-bending next step. 4D printing involves creating objects that can change their shape or properties over time when exposed to a stimulus like heat, light, or water. Imagine a flat-packed piece of furniture that assembles itself when you add water!

- Bioprinting and Healthcare: The holy grail of medical 3D printing is the creation of viable, functional human organs for transplant, potentially eliminating organ donor waiting lists. We’re also seeing advances in 3D printed pills and even vaccines.

- Large-Scale Printing: We’re going big! In 2024, the world’s largest 3D printer, the Factory of the Future 1.0, was revealed. This technology is already being used to print everything from entire houses to the world’s first 3D-printed steel bridge in Amsterdam.

- Advanced Materials: Expect an explosion in new materials with incredible properties—stronger, lighter, more flexible, and more sustainable options that will unlock even more applications.

- AI and Automation: Artificial intelligence will play a bigger role in optimizing designs for 3D printing, automatically correcting file errors, and fine-tuning printer settings for perfect prints every time, making the technology even more accessible to everyone.

📝 Conclusion: Wrapping Up the World of 3D Printing Products

Phew! What a whirlwind tour through the fascinating universe of 3D printing products. From the humble beginnings of bulky, six-figure machines to today’s sleek desktop wonders, 3D printing has transformed from a niche industrial tool into a versatile technology that touches nearly every aspect of our lives.

We’ve seen that a 3D printing product isn’t just the printed object itself; it’s a symphony of hardware, software, materials, and human creativity working in harmony. Whether it’s a custom prosthetic limb, a jaw-dropping architectural model, or a quirky office organizer that proudly wears its layer lines, 3D printing products embody innovation and personalization.

The benefits are crystal clear: rapid prototyping, cost-effective customization, reduced waste, and the ability to create complex geometries impossible with traditional manufacturing. But it’s not without challenges—material limitations, post-processing needs, and legal and ethical questions all require thoughtful navigation.

Looking ahead, the future is dazzling. With advances in bioprinting, 4D printing, and large-scale additive manufacturing, the boundary between imagination and reality will blur even further. And for those wondering if 3D printing is just a fad? The millions of hobbyists, thriving businesses, and growing industrial applications say otherwise.

If you’re inspired to jump in, remember: start small, experiment, and embrace the quirks of the technology. The perfect print is just a few tweaks away!

🔗 Recommended Links for 3D Printing Enthusiasts

Ready to explore or expand your 3D printing journey? Here are some curated shopping and resource links to get you started or upgrade your setup:

-

Fusion3 F200 3D Printer:

Amazon | Fusion3 Official Website | Thingiverse – Fusion3 F200 -

Fusion3 EDGE 3D Printer:

Amazon | Fusion3 Official Website | Thingiverse – Fusion3 EDGE -

Stratasys J55 Prime:

Stratasys Official Website | Thingiverse – Stratasys J55 -

3D Design Software Recommendations:

Autodesk Fusion 360 | TinkerCAD | Blender -

Books on 3D Printing:

“3D Printing: The Next Industrial Revolution” by Christopher Barnatt | “Make: 3D Printing” by Anna Kaziunas France | “Fabricated: The New World of 3D Printing” by Hod Lipson & Melba Kurman

❓ FAQ: Your Burning Questions About 3D Printing Products Answered

What materials are commonly used in 3D printing products?

3D printing materials have come a long way! The most common materials include:

- PLA (Polylactic Acid): A biodegradable, plant-based plastic popular for its ease of use and low warping. Perfect for beginners and general-purpose prints.

- ABS (Acrylonitrile Butadiene Styrene): A tougher plastic with higher heat resistance but requires a heated bed and good ventilation due to fumes.

- PETG (Polyethylene Terephthalate Glycol): Combines strength and flexibility with easier printing than ABS.

- Resins: Used in SLA/DLP printers, offering high detail and smooth finishes but requiring careful handling.

- Nylon, TPU, and other specialty filaments: For flexible, durable, or engineering-grade parts.

- Metals: In industrial printers, metals like titanium, stainless steel, and aluminum are used via powder bed fusion or directed energy deposition.

The choice depends on your printer type, desired properties, and application.

How do 3D printing products differ from traditional manufacturing?

3D printing products differ fundamentally because they are additively manufactured—built layer by layer—rather than subtractively (cutting away material). This allows:

- Complex geometries that are impossible or prohibitively expensive with traditional methods.

- Customization and personalization without extra tooling costs.

- Reduced waste since only the needed material is used.

- Faster prototyping and shorter product development cycles.

However, traditional manufacturing still excels at mass production of simple parts, offering faster speeds and lower unit costs at scale.

What are the most popular items to 3D print at home?

Home 3D printers are great for:

- Functional tools and replacement parts: Clips, brackets, knobs, and custom mounts.

- Hobbyist models: Miniatures for tabletop games, cosplay props, and collectibles.

- Household items: Phone stands, cable organizers, planters, and kitchen gadgets.

- Educational models: Anatomical parts, geometric shapes, and science kits.

- Personalized gifts: Custom keychains, jewelry, and art pieces.

Sites like Thingiverse and MyMiniFactory are treasure troves for free and paid models.

How can I design my own 3D printing product?

Designing your own 3D printing product involves:

- Learning 3D modeling software: Start with beginner-friendly tools like TinkerCAD or jump into professional-grade software like Fusion 360.

- Understanding printer constraints: Know your printer’s build volume, layer resolution, and material capabilities.

- Designing with printing in mind: Avoid overhangs without supports, consider wall thickness, and plan for assembly if needed.

- Exporting the model: Save your design as an STL or AMF file.

- Slicing: Use slicer software (e.g., Cura, PrusaSlicer) to prepare the file for printing.

- Iterate: Print prototypes, test, and refine your design.

Practice and patience are key! Our 3D Design Software category is a great place to find tutorials and inspiration.

📖 Reference Links and Further Reading

For those who want to dig deeper, here are some authoritative sources and official pages:

- Wikipedia: 3D Printing — Comprehensive overview and history.

- Fusion3 Official Website — Industrial 3D printers for business & education.

- Stratasys J55 Prime — Official product page.

- Thingiverse — Massive repository of free 3D printable models.

- MyMiniFactory — Curated 3D models with quality control.

- Autodesk Fusion 360 — Industry-leading CAD software.

- 3D Printing Industry News — Stay updated on the latest trends and innovations.

- NIH 3D Print Exchange — Medical and scientific 3D models.

We hope this guide has answered your questions and sparked your curiosity. Now, what will you create? 🚀