Support our educational content for free when you purchase through links on our site. Learn more

12 Surprising Drawbacks of 3D Printing You Need to Know (2025) 🖨️

Imagine spending hours printing a sleek drone frame only to have it snap mid-flight because of a hidden weakness in the print. Sounds frustrating, right? That’s exactly what happened to one of our 3D Printed™ team members — a perfect example of why understanding the drawbacks of 3D printing is just as important as celebrating its mind-blowing possibilities. From material quirks and post-processing headaches to environmental concerns and cost traps, 3D printing isn’t all sunshine and rainbows.

In this article, we’ll unpack 12 major drawbacks you might not expect, backed by real stories, expert insights, and practical tips. Whether you’re a hobbyist, educator, or industry pro, knowing these pitfalls upfront will save you time, money, and headaches — and help you decide when 3D printing is your best friend or when to look elsewhere.

Key Takeaways

- Material limitations and build size constraints can restrict what and how you print.

- Post-processing adds significant time and effort beyond the print itself.

- 3D printing is slow and costly for mass production compared to traditional methods.

- Layer adhesion issues can cause parts to be brittle or fail unexpectedly.

- Environmental impact isn’t negligible — energy use and plastic waste matter.

- Proper maintenance and calibration are essential to avoid print failures.

- Hybrid manufacturing often offers the best balance for industrial applications.

Ready to explore the full list and learn how to overcome these challenges? Let’s dive in!

👉 Shop 3D Printers & Materials:

- Prusa i3 MK3S+: Thingiverse | Amazon | Prusa Official Website

- Creality Ender 3: Thingiverse | Amazon | Creality Official Website

- Hatchbox Filament: Amazon | MatterHackers

Table of Contents

- ⚡️ Quick Tips and Facts About 3D Printing Drawbacks

- 🔍 The Evolution and Background of 3D Printing Technology

- 1️⃣ Top 12 Drawbacks of 3D Printing You Should Know

- 💡 Hidden Challenges: Material Limitations and Quality Issues in 3D Printing

- ⏳ Speed and Scalability: Why 3D Printing Isn’t Always the Fastest Solution

- 💰 Cost Considerations: When 3D Printing Can Break the Bank

- 🛠️ Maintenance and Technical Hurdles: Keeping Your 3D Printer Happy

- 🌍 Environmental Impact: Is 3D Printing Truly Green?

- 🔄 Post-Processing Pain Points: The Extra Work After Printing

- ⚖️ Comparing 3D Printing Advantages and Disadvantages: A Balanced View

- 📈 Industry-Specific Drawbacks: When 3D Printing Falls Short

- 🧰 Tips and Tricks to Overcome Common 3D Printing Drawbacks

- 📚 Get Expert Advice and Resources on 3D Printing Challenges

- ❓ Related Frequently Asked Questions (FAQs) About 3D Printing Drawbacks

- 🏁 Conclusion: Should You Embrace or Avoid 3D Printing?

- 🔗 Recommended Links for Deep Diving Into 3D Printing

- 📖 Reference Links and Further Reading

⚡️ Quick Tips and Facts About 3D Printing Drawbacks

Before we dive into the nitty-gritty of 3D printing’s drawbacks, here’s a quick cheat sheet from your pals at 3D Printed™:

- Limited materials: Most 3D printers work best with a handful of plastics and metals — forget about printing your morning coffee or a full-size car part in one go.

- Build size constraints: Even the fanciest printers have print beds that limit how big your masterpiece can be.

- Post-processing is a must: Your print isn’t done when the nozzle stops moving — sanding, cleaning, and curing await!

- Speed vs. volume: 3D printing shines for prototypes and small batches but struggles to compete with injection molding for mass production.

- Layer adhesion issues: Parts can delaminate or be brittle depending on the printing tech and orientation.

- Cost traps: Materials and maintenance can add up, especially for high-end machines.

- Environmental impact: It’s not all green; energy use and non-recyclable filaments can hurt the planet.

- Copyright headaches: Easy replication means counterfeits and IP theft are real risks.

Want to see how these stack up in detail? Keep reading — we’ll unpack each with stories, stats, and tips! Also, if you’re curious about durability, check out our deep dive on Do 3D printed things last? for some eye-opening insights.

🔍 The Evolution and Background of 3D Printing Technology

3D printing, aka additive manufacturing, started as a niche tech in the 1980s with Chuck Hull’s stereolithography patent. Fast forward to today, and it’s a booming industry projected to hit $83 billion by 2029 (source: 3DS.com).

How 3D Printing Works: The Basics

- Layer-by-layer magic: Printers build objects from digital CAD files by stacking ultra-thin layers of material — typically 0.1 mm thick.

- Materials: Plastics like PLA, ABS, PETG; metals like titanium and stainless steel; even concrete and chocolate!

- Tech types: FDM (Fused Deposition Modeling), SLA (Stereolithography), SLS (Selective Laser Sintering), and more.

This tech revolutionized prototyping, education, and even aerospace manufacturing. But with great power comes… well, some pesky drawbacks we’ll explore next.

1️⃣ Top 12 Drawbacks of 3D Printing You Should Know

Let’s break down the biggest pain points we’ve seen from our community and industry pros:

| Drawback | Explanation | Impact Level (1-10) |

|---|---|---|

| 1. Limited Material Choices | Not all plastics/metals are printable; food-safe and recyclable options are scarce. | 8 |

| 2. Small Build Volume | Print beds limit object size; large parts require assembly. | 7 |

| 3. Post-Processing Required | Support removal, sanding, curing add time and effort. | 8 |

| 4. Slow for Mass Production | Cost per unit doesn’t drop much with volume, unlike injection molding. | 9 |

| 5. Layer Adhesion Weakness | Parts can delaminate or be brittle depending on print orientation and method. | 7 |

| 6. High Material Costs | Specialty filaments and powders can be pricey. | 6 |

| 7. Printer Maintenance | Regular calibration, nozzle cleaning, and part replacement needed. | 6 |

| 8. Print Failures & Waste | Failed prints waste time and materials. | 7 |

| 9. Environmental Concerns | Energy-intensive machines and non-biodegradable plastics. | 7 |

| 10. Intellectual Property Risks | Easy replication leads to counterfeiting and copyright infringement. | 8 |

| 11. Regulatory and Safety Issues | Potential misuse for weapons or counterfeit goods. | 7 |

| 12. Design Limitations | Some complex designs still challenge printers or require supports that waste material. | 6 |

This table is a snapshot, but each point deserves its own spotlight — so let’s unpack them with juicy details and real-world examples.

💡 Hidden Challenges: Material Limitations and Quality Issues in 3D Printing

Material variety is a biggie. While PLA and ABS plastics dominate desktop printing, they’re not always durable or heat-resistant enough for functional parts. Metals like titanium and stainless steel require industrial-grade printers like the Markforged Metal X or EOS M 290 — pricey and complex beasts (Markforged Official, EOS Official).

Food safety? Most filaments aren’t FDA approved for food contact. So your 3D printed cookie cutter might be cute but not safe for baking. For food-safe prints, you need specialized materials like PETG or food-grade resins, which can be harder to find and more expensive.

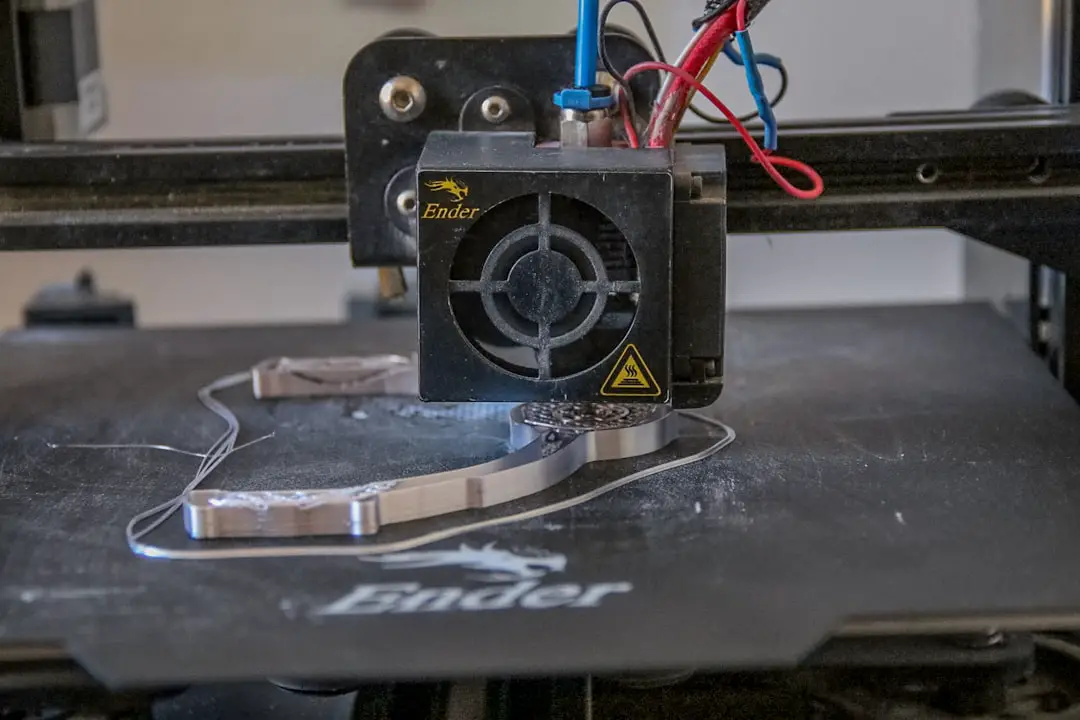

Print quality varies wildly by printer and settings. Cheaper FDM printers like the Creality Ender 3 can produce visible layer lines and weak spots, while SLA printers like the Formlabs Form 3 offer smoother finishes but smaller build volumes (Creality Ender 3 on Thingiverse, Formlabs Official).

User anecdote: One of our team members printed a drone frame on an Ender 3, only to have it snap mid-flight due to layer delamination. Lesson learned: material and printer choice can make or break your project.

⏳ Speed and Scalability: Why 3D Printing Isn’t Always the Fastest Solution

3D printing is a marathon, not a sprint — especially for large batches. While you can crank out a prototype in hours, printing hundreds or thousands of parts? That’s a different story.

- Injection molding can produce tens of thousands of parts daily, slashing per-unit costs dramatically.

- 3D printing speed depends on layer height, infill density, and object complexity. A large, dense print can take 12+ hours or more.

- HP’s Multi Jet Fusion (MJF) tech can print 300 small parts at once, but still can’t match injection molding’s volume (source: Builtin.com).

Pro tip: Use 3D printing for prototyping, custom parts, or low-volume runs. For mass production, consider hybrid approaches or traditional manufacturing.

💰 Cost Considerations: When 3D Printing Can Break the Bank

At first glance, 3D printing seems affordable — especially with desktop models like the Prusa i3 MK3S+ or Anycubic Vyper. But costs can pile up:

| Cost Factor | Details | Impact on Budget |

|---|---|---|

| Printer Purchase | From budget (~$200) to industrial ($100k+) | Medium to High |

| Filament/Resin | Specialty materials cost more; metal powders expensive | Medium to High |

| Maintenance | Nozzle replacements, bed leveling, cleaning supplies | Medium |

| Failed Prints | Wasted material and time | Medium |

| Post-Processing Tools | Sandpaper, solvents, UV curing stations | Low to Medium |

User story: We had a newbie enthusiast who bought a cheap printer, then spent months troubleshooting failed prints and buying replacement parts — turning a “budget” hobby into a costly affair.

Bottom line: Factor in ongoing costs, not just the sticker price.

🛠️ Maintenance and Technical Hurdles: Keeping Your 3D Printer Happy

3D printers are like pets — they need regular care:

- Calibration: Bed leveling and nozzle height must be spot-on for good prints.

- Cleaning: Nozzles clog, fans gather dust, and belts stretch.

- Software updates: Firmware and slicer software evolve constantly.

- Troubleshooting: Warping, stringing, and layer shifts are common headaches.

Ignoring maintenance leads to print failures and frustration. Brands like Ultimaker and Prusa offer excellent support and user communities to ease this pain (Ultimaker Official, Prusa Official).

🌍 Environmental Impact: Is 3D Printing Truly Green?

3D printing is often touted as eco-friendly because it’s additive (less waste than subtractive machining). But the reality is nuanced:

- Energy consumption: Industrial printers can be energy hogs.

- Material waste: Failed prints and support structures generate plastic waste.

- Non-recyclable filaments: Many plastics aren’t biodegradable.

- Recycling efforts: Some companies reuse powder or recycle failed prints (source: Builtin.com).

Eco-friendly tips: Use PLA (biodegradable), recycle failed prints with filament recyclers, and choose energy-efficient printers.

🔄 Post-Processing Pain Points: The Extra Work After Printing

Your print isn’t done when the nozzle stops! Post-processing can be a chore:

- Support removal: Often requires cutting or dissolving supports.

- Sanding and smoothing: To remove layer lines and improve aesthetics.

- Curing: SLA prints need UV curing for strength.

- Painting and sealing: For color and durability.

This adds time and skill requirements, sometimes doubling total project time. But the payoff? A professional-looking final product.

⚖️ Comparing 3D Printing Advantages and Disadvantages: A Balanced View

| Aspect | Advantages ✅ | Disadvantages ❌ |

|---|---|---|

| Design Freedom | Complex geometries impossible with traditional methods | Design limitations due to supports and print orientation |

| Customization | Easy to customize one-off parts | Not cost-effective for mass production |

| Speed (Prototyping) | Rapid prototyping accelerates design cycles | Slow for large-scale manufacturing |

| Material Variety | Growing range of plastics, metals, composites | Still limited compared to traditional manufacturing |

| Cost | Low initial investment for hobbyists | High material and maintenance costs for pros |

| Environmental Impact | Less waste than subtractive methods | Energy use and plastic waste concerns |

This table sums up why 3D printing is a fantastic tool — but not a one-size-fits-all solution.

📈 Industry-Specific Drawbacks: When 3D Printing Falls Short

Different industries face unique challenges with 3D printing:

- Aerospace: Requires ultra-high precision and certified materials; layer adhesion and porosity can be deal-breakers.

- Medical: Biocompatibility and sterilization standards limit material choices.

- Automotive: Large parts and high-strength requirements challenge print size and durability.

- Fashion: Material flexibility and finish quality can be lacking for wearable items.

For these sectors, hybrid manufacturing or traditional methods often complement 3D printing.

🧰 Tips and Tricks to Overcome Common 3D Printing Drawbacks

Don’t let drawbacks scare you off! Here’s how to tackle them:

- Choose the right printer for your needs: Desktop FDM for hobbyists, SLA for detail, industrial for metals.

- Optimize print settings: Layer height, infill, and print orientation affect strength and speed.

- Use quality filaments: Brands like Hatchbox, Prusament, and MatterHackers offer reliable materials.

- Regular maintenance: Keep your printer calibrated and clean to avoid failures.

- Post-processing tools: Invest in sanding kits, UV curing stations, and support removal tools.

- Recycle and reuse: Use filament recyclers like the Filabot to reduce waste (Filabot Official).

- Join communities: Forums like Reddit’s r/3Dprinting and manufacturer support groups are goldmines for troubleshooting.

📚 Get Expert Advice and Resources on 3D Printing Challenges

Looking for more wisdom? Here are some trusted resources:

- TWI Global’s 3D Printing FAQs: Deep dive into pros and cons with industrial insights (TWI Global).

- 3DS.com Blog: Industry trends and tech updates (3DS Official Blog).

- BuiltIn.com Hardware Section: Real-world pros and cons from startups and experts (BuiltIn Hardware).

- 3D Printed™ Categories:

❓ Related Frequently Asked Questions (FAQs) About 3D Printing Drawbacks

Q: Can 3D printed parts be as strong as traditionally manufactured ones?

A: Sometimes! It depends on the material, printer, and print orientation. Industrial printers using metal powders can produce aerospace-grade parts, but consumer FDM prints often have weaker layer adhesion.

Q: Why do 3D prints fail?

A: Common causes include poor bed adhesion, incorrect temperature settings, clogged nozzles, or design errors. Regular maintenance and calibration help reduce failures.

Q: Is 3D printing environmentally friendly?

A: It can be, especially when using biodegradable filaments and recycling waste. However, energy use and plastic waste remain concerns.

Q: What’s the largest object I can 3D print?

A: It depends on your printer’s build volume. Industrial printers can handle larger parts, but often large objects are printed in sections and assembled.

Q: Are there legal issues with 3D printing?

A: Yes, copyright infringement and counterfeiting are growing concerns as 3D printing becomes more accessible.

For more FAQs, check out our full 3D Printing FAQ section.

🏁 Conclusion: Should You Embrace or Avoid 3D Printing?

So, are there any drawbacks of 3D printing? Absolutely — but don’t let that scare you off! Like any powerful tool, 3D printing comes with its quirks and challenges. From material limitations and print size restrictions to post-processing headaches and cost traps, it’s not a magic wand that solves every manufacturing problem overnight.

However, the benefits — such as unparalleled design freedom, rapid prototyping, and customization — often outweigh these cons for hobbyists, educators, and industries pushing innovation. Whether you’re printing a custom drone frame, a replacement part, or experimenting with new materials, understanding these drawbacks upfront helps you plan smarter and avoid frustration.

Remember our team member’s drone story? It’s a perfect example: knowing your printer’s limits and material strengths can save your project (and your wallet). And if you want durable prints, check out our Do 3D printed things last? article for tips on longevity.

Our confident recommendation: Embrace 3D printing as a creative and prototyping powerhouse, but pair it with realistic expectations and a willingness to learn. For mass production or ultra-high precision needs, consider hybrid approaches or traditional manufacturing. Keep experimenting, maintain your gear, and join the vibrant 3D printing community — the future is additive!

🔗 Recommended Links for Deep Diving Into 3D Printing

Ready to level up your 3D printing game? Here are some top picks for printers, materials, and books to fuel your journey:

-

3D Printers:

- Prusa i3 MK3S+: Thingiverse | Amazon | Prusa Official Website

- Creality Ender 3: Thingiverse | Amazon | Creality Official Website

- Formlabs Form 3 (SLA): Thingiverse | Amazon | Formlabs Official Website

-

Filaments and Materials:

- Hatchbox PLA: Amazon | MatterHackers

- Prusament: Prusa Official Website

- Filabot Filament Recycler: Filabot Official Website

-

Books:

❓ Frequently Asked Questions (FAQs) About 3D Printing Drawbacks

What are the common limitations of 3D printing technology?

3D printing is limited by material availability, build volume, and print speed. Most consumer printers handle plastics like PLA and ABS but struggle with metals or flexible materials without industrial-grade machines. Build volumes restrict the size of single prints, often requiring assembly for larger objects. Additionally, printing can be slow, especially for high-resolution or dense parts, making it less suitable for mass production. Layer adhesion can cause mechanical weaknesses, and post-processing is often necessary to achieve desired finishes.

How does the cost of 3D printing affect its accessibility and usability?

While entry-level 3D printers are affordable, ongoing costs such as filament/resin, maintenance, and failed prints add up. Industrial printers and specialty materials can be prohibitively expensive. This cost structure makes 3D printing highly accessible for hobbyists and prototyping but less cost-effective for large-scale manufacturing. Users must balance initial investment with material costs and time spent troubleshooting or post-processing.

What are the potential environmental impacts of 3D printing and its materials?

3D printing can reduce waste compared to subtractive manufacturing, but it’s not inherently green. Energy consumption, especially for industrial printers, can be high. Many filaments are petroleum-based plastics that are not biodegradable or easily recyclable. Failed prints and support structures generate plastic waste. However, biodegradable filaments like PLA and filament recycling technologies help mitigate these impacts. Choosing energy-efficient printers and sustainable materials is key to reducing the environmental footprint.

What are the main differences between DIY 3D printing and professional 3D printing services?

DIY 3D printing offers hands-on control, lower upfront costs, and customization but requires technical know-how, maintenance, and patience with trial and error. Professional services provide high-quality prints, a wider range of materials (including metals and composites), and larger build volumes but at higher costs and less direct control. Services like Shapeways or Sculpteo offer industrial-grade prints without the hassle of owning a machine, ideal for complex or large projects.

How do post-processing requirements impact the overall 3D printing workflow?

Post-processing often doubles the time investment in 3D printing. Removing supports, sanding, curing (for resin prints), and painting are necessary for functional or aesthetic quality. This extra work demands additional tools, skills, and workspace, which can be a barrier for beginners or those expecting “print and go” simplicity.

Can 3D printing replace traditional manufacturing methods?

Not entirely. While 3D printing excels at rapid prototyping, customization, and complex geometries, traditional methods like injection molding or CNC machining remain superior for mass production, material variety, and mechanical strength. Many industries use a hybrid approach, leveraging 3D printing for design iteration and traditional manufacturing for scale.

📖 Reference Links and Further Reading

- Pros and Cons of 3D Printing | Dassault Systèmes

- TWI Global: What is 3D Printing? Pros and Cons

- BuiltIn.com: Pros and Cons of 3D Printing

- Markforged Official Website

- EOS Official Website

- Prusa Official Website

- Creality Official Website

- Formlabs Official Website

- Filabot Official Website

- 3D Printed™ Categories: 3D Printable Objects

- 3D Printed™ Categories: 3D Printing Innovations

- 3D Printed™ Categories: 3D Design Software

- 3D Printed™ Categories: 3D Printing in Education

- 3D Printed™ Categories: 3D Printer Reviews

Ready to take your 3D printing journey to the next level? Dive into our recommended links and resources — and remember, every great print starts with understanding the challenges! 🚀