Support our educational content for free when you purchase through links on our site. Learn more

Are There Limitations to 3D Printing? 12 Surprising Facts (2025) 🚀

Imagine designing a complex, custom gadget overnight and holding a physical prototype in your hands the next day. Sounds like sci-fi? Well, that’s the promise of 3D printing—a technology revolutionizing manufacturing, education, healthcare, and even art. But here’s the twist: despite all the hype, 3D printing isn’t without its quirks and constraints. Ever wondered why some projects take forever to print, or why your shiny new print needs hours of sanding before it looks good? Or why certain materials just don’t behave as expected?

In this deep dive, we unravel 12 surprising limitations of 3D printing that every enthusiast and professional should know in 2025. From size restrictions and material challenges to post-processing headaches and intellectual property puzzles, we cover it all. But don’t worry—we also share how innovators are tackling these hurdles and what the future holds. Ready to see if 3D printing is the right tool for your next project? Let’s get started!

Key Takeaways

- Build volume limits mean you often need to print large objects in parts and assemble them.

- Material options are growing but still limited, impacting strength, flexibility, and finish.

- Print speed and post-processing can add significant time and effort to your project.

- Precision and surface quality vary by technology and require skillful design and finishing.

- Intellectual property and security concerns are real in the digital age of 3D printing.

- Skill gaps exist, but plentiful tutorials and communities can help you master the craft.

- Innovations like multi-material printing, faster tech, and sustainable materials are shrinking these limitations.

Ready to explore printers and materials that fit your needs?

- 👉 Shop Prusa i3 MK3S+ printers: Thingiverse | Prusa Official

- Explore Formlabs SLA printers: Thingiverse | Formlabs Official

- Find quality filaments: Amazon 3D Printing Filaments | MatterHackers

Table of Contents

- ⚡️ Quick Tips and Facts: Unpacking 3D Printing’s Reality

- 🚀 The 3D Printing Revolution: A Brief History and Its Current Landscape

- 1. 📏 Size Matters: Physical Constraints and Build Volume Limitations

- 2. ⏳ The Need for Speed: Production Throughput and Batch Manufacturing Challenges

- 3. 💰 The Cost Conundrum: High Material and Equipment Expenses

- 4. 🛠️ Post-Processing Pains: The Hidden Workload and Finishing Requirements

- 5. 🎯 Precision and Surface Finish: When Perfection is Elusive and Tolerances are Tight

- 6. 🧪 Material World: The Current Palette of 3D Printable Materials and Their Properties

- 7. 💪 Strength and Durability: Mechanical Properties, Anisotropy, and Structural Integrity

- 8. 🎨 Color and Multi-Material Printing: Beyond Monochromatic Dreams and Functional Integration

- 9. 🧠 Design Complexity and Software Hurdles: The Digital Frontier and CAD/Slicing Challenges

- 10. 🌍 Environmental Footprint: Sustainability Challenges and Waste Management

- 11. 🔒 Intellectual Property and Security Concerns: The Digital Wild West and Design Protection

- 12. 🧑💻 Skill Gap and Learning Curve: Mastering the Machines and Advanced Techniques

- ⚖️ 3D Printing: A Balanced Perspective – Advantages vs. Limitations in Additive Manufacturing

- 🌟 Overcoming Obstacles: Innovations Addressing 3D Printing Limitations and Future Solutions

- 🏗️ Where 3D Printing Still Struggles: Industries and Applications Facing Specific Hurdles

- 🔮 The Horizon Ahead: Future Advancements and the Shrinking Gap of 3D Printing Limitations

- ✅ Conclusion: Is 3D Printing Limited? Absolutely, But It’s Evolving!

- 🔗 Recommended Links for Further Exploration

- ❓ Frequently Asked Questions (FAQ) About 3D Printing Limitations

- 📚 Reference Links and Sources

⚡️ Quick Tips and Facts: Unpacking 3D Printing’s Reality

⚡️ Quick Tips and Facts: Unpacking 3D Printing’s Reality

3D printing, also known as additive manufacturing, is a game-changer, but it’s not a magic bullet. There are definitely limitations to consider before you jump headfirst into the world of 3D printed creations.

3D Printing: Not a One-Size-Fits-All Solution

Think of it like this: 3D printing is like a powerful tool in your workshop. It can create amazing things, but it’s not the right tool for every job. You wouldn’t use a hammer to screw in a screw, right? Similarly, 3D printing has its strengths and weaknesses.

3D Printing Limitations: A Quick Overview

Here are some key limitations to keep in mind:

- Build Size: Most 3D printers have a limited build volume, meaning you can’t print objects that are too large.

- Material Selection: The range of printable materials is still growing, but it’s not as diverse as traditional manufacturing methods.

- Print Speed: 3D printing can be slow, especially for complex designs.

- Surface Finish: The surface finish of 3D printed objects can sometimes be rough and require post-processing.

- Cost: 3D printers and materials can be expensive, especially for industrial-grade equipment.

- Design Complexity: Designing for 3D printing requires specific skills and software.

3D Printing: A Balancing Act

While there are limitations, 3D printing offers incredible advantages, like customization, rapid prototyping, and on-demand production. The key is to understand both the strengths and weaknesses to make informed decisions about when and how to use this technology.

🚀 The 3D Printing Revolution: A Brief History and Its Current Landscape

🚀 The 3D Printing Revolution: A Brief History and Its Current Landscape

The journey of 3D printing has been a fascinating one, starting with humble beginnings and evolving into a technology that’s transforming industries.

From Early Prototypes to Modern Marvels

The roots of 3D printing can be traced back to the 1980s, with the invention of stereolithography (SLA) by Chuck Hull in 1983. This groundbreaking technology used a UV laser to solidify liquid photopolymer resin, layer by layer.

Since then, 3D printing has exploded in popularity, with various technologies emerging, including:

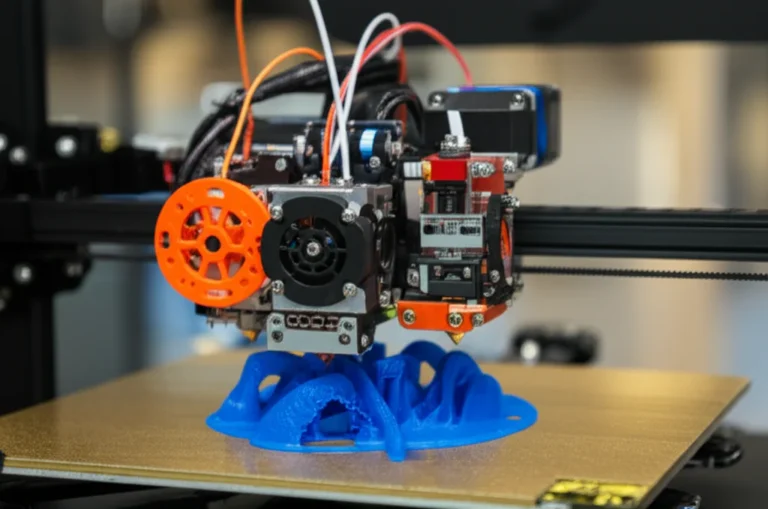

- Fused Deposition Modeling (FDM): This popular method extrudes heated thermoplastic filament through a nozzle, building up layers.

- Selective Laser Sintering (SLS): This process uses a laser to fuse powdered materials, creating strong and durable parts.

- Direct Metal Laser Sintering (DMLS): This advanced technology allows for the printing of metal parts with high precision.

3D Printing Today: A World of Possibilities

Today, 3D printing is used in a wide range of industries, from aerospace and automotive to healthcare and education. It’s revolutionizing the way we design, manufacture, and even create.

The Future of 3D Printing: Pushing the Boundaries

The future of 3D printing is bright, with ongoing research and development focused on:

- New Materials: Expanding the range of printable materials to include more advanced composites, ceramics, and even biomaterials.

- Increased Speed: Developing faster printing processes to meet the demands of high-volume production.

- Improved Resolution: Enhancing the precision and detail of 3D printed objects.

- Multi-Material Printing: Creating objects with multiple materials, allowing for complex functionalities.

3D printing is constantly evolving, and its potential is only beginning to be realized.

1. 📏 Size Matters: Physical Constraints and Build Volume Limitations

📏 Size Matters: Physical Constraints and Build Volume Limitations

One of the most common limitations of 3D printing is the build volume. This refers to the maximum size of an object that can be printed within the printer’s chamber.

The Build Volume: A Physical Constraint

Think of it like baking a cake: You need a pan that’s big enough to accommodate the batter. Similarly, 3D printers have a physical space where the printing process takes place.

Build Volume: A Spectrum of Sizes

The build volume of 3D printers varies greatly depending on the type and size of the printer.

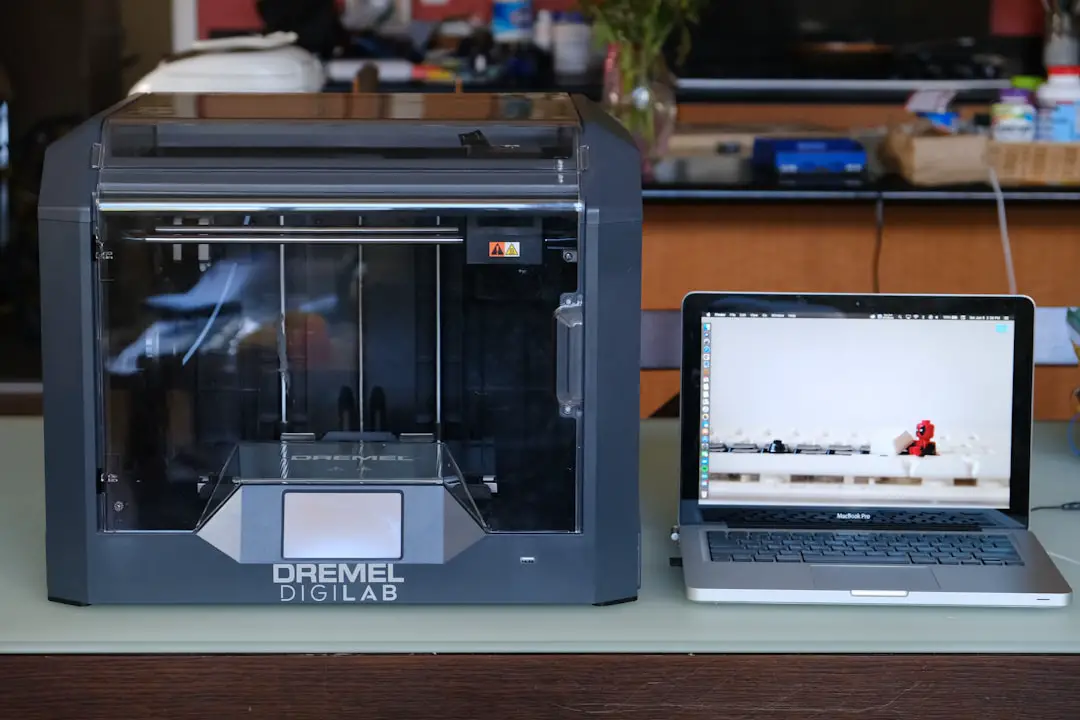

- Desktop 3D printers: These printers typically have a build volume of around 200 x 200 x 200 mm.

- Industrial 3D printers: These printers can have build volumes that are much larger, up to several meters in each dimension.

Overcoming Build Volume Limitations

If you need to print an object that’s larger than your printer’s build volume, you have a few options:

- Splitting the Design: You can design the object in multiple parts and print them separately, then assemble them later.

- Using a Larger Printer: If you need to print large objects regularly, consider investing in a larger 3D printer.

- Outsource Printing: You can outsource the printing to a service that has larger printers.

Build Volume: A Key Consideration

The build volume is a crucial factor to consider when choosing a 3D printer. Make sure to select a printer that can accommodate the size of the objects you plan to print.

2. ⏳ The Need for Speed: Production Throughput and Batch Manufacturing Challenges

⏳ The Need for Speed: Production Throughput and Batch Manufacturing Challenges

While 3D printing is often touted for its speed, it’s important to remember that it’s not always as fast as traditional manufacturing methods. The print time can vary significantly depending on the complexity of the design, the size of the object, and the material used.

Print Time: A Factor of Complexity

Think of it like building a Lego model: A simple model can be built quickly, but a complex model with intricate details will take much longer. The same principle applies to 3D printing.

3D Printing: Not Always the Fastest Option

For simple objects, 3D printing can be very fast. But for complex objects or large batches, traditional manufacturing methods like injection molding or CNC machining can be more efficient.

3D Printing: A Trade-Off Between Speed and Customization

3D printing offers the advantage of customization, allowing you to create unique designs that wouldn’t be possible with traditional methods. However, this customization comes at the cost of speed.

Overcoming Speed Limitations

There are ways to overcome the speed limitations of 3D printing:

- Optimize Your Design: Simplify your design to reduce the print time.

- Use Faster Printing Technologies: Some 3D printing technologies, like Digital Light Processing (DLP), are faster than others.

- Invest in Multiple Printers: If you need to print large batches, consider investing in multiple 3D printers.

Speed: A Balancing Act

The speed of 3D printing is a trade-off between customization and efficiency. Consider your needs and choose the right approach for your project.

3. 💰 The Cost Conundrum: High Material and Equipment Expenses

💰 The Cost Conundrum: High Material and Equipment Expenses

3D printing can be a cost-effective solution for prototyping and small-scale production, but it’s important to acknowledge that the initial investment in equipment and materials can be significant.

3D Printers: A Range of Prices

The cost of 3D printers varies greatly depending on the type, features, and build volume.

- Desktop 3D printers: These printers are relatively affordable, starting at around a few hundred dollars.

- Industrial 3D printers: These printers can cost tens of thousands or even hundreds of thousands of dollars.

3D Printing Materials: A Cost Factor

The cost of 3D printing materials also varies depending on the type and quality of the material.

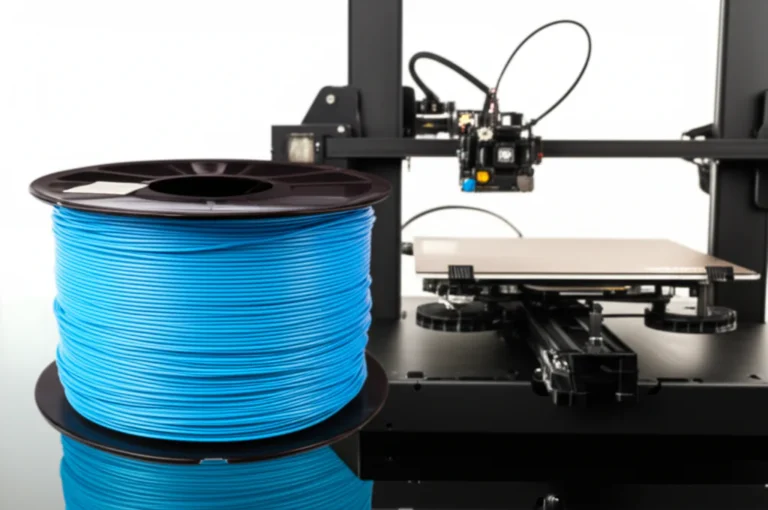

- Thermoplastic filaments: These are the most common materials used in 3D printing, and they are relatively inexpensive.

- Metal powders: These materials are used for printing metal parts, and they are significantly more expensive than thermoplastic filaments.

3D Printing: A Cost-Effective Solution for Prototyping

For prototyping and small-scale production, 3D printing can be a cost-effective solution because it eliminates the need for expensive tooling and molds.

3D Printing: A Challenge for Mass Production

For mass production, 3D printing can be more expensive than traditional manufacturing methods, especially when considering the cost of materials, labor, and equipment.

Overcoming Cost Limitations

There are ways to reduce the cost of 3D printing:

- Choose Affordable Materials: Use less expensive materials for prototyping or non-critical applications.

- Optimize Your Design: Simplify your design to reduce the amount of material used.

- 👉 Shop Around for Materials: Compare prices from different suppliers to find the best deals.

- Consider Outsourcing: Outsource printing to a service that has lower costs.

Cost: A Key Consideration

The cost of 3D printing is a significant factor to consider when making decisions about whether or not to use this technology. Weigh the costs and benefits carefully to determine if it’s the right solution for your needs.

4. 🛠️ Post-Processing Pains: The Hidden Workload and Finishing Requirements

🛠️ Post-Processing Pains: The Hidden Workload and Finishing Requirements

While 3D printing can create amazing objects, the journey doesn’t always end with the print. Many 3D printed objects require post-processing to achieve the desired finish and functionality.

Post-Processing: A Necessary Step

Think of it like baking a cake: You don’t just pull it out of the oven and serve it. You need to let it cool, frost it, and maybe even decorate it. Similarly, 3D printed objects often require additional steps to make them ready for use.

Common Post-Processing Steps

Here are some common post-processing steps:

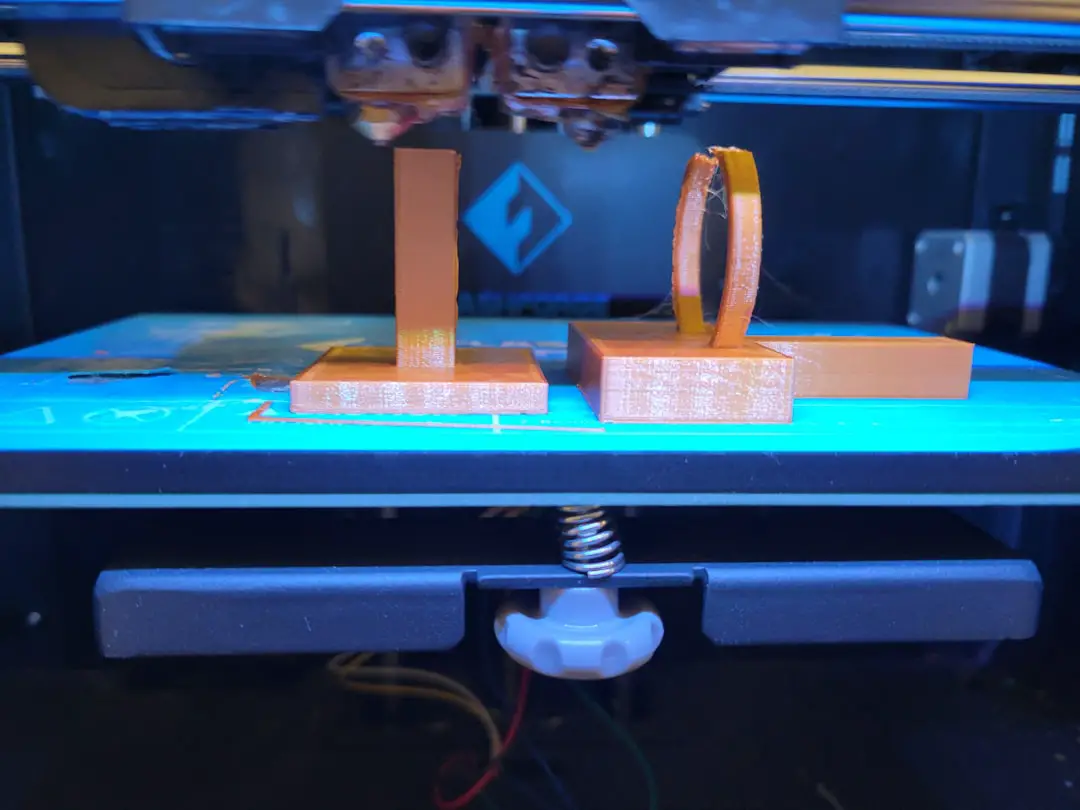

- Removing Support Structures: Many 3D printing technologies require support structures to be printed along with the object. These structures need to be removed after the print is complete.

- Cleaning: 3D printed objects can have excess material or dust that needs to be cleaned off.

- Sanding and Smoothing: The surface finish of 3D printed objects can be rough, so sanding and smoothing may be necessary to achieve a desired look.

- Painting and Finishing: You can paint or apply other finishes to 3D printed objects to enhance their appearance or provide additional protection.

Post-Processing: A Time and Effort Investment

Post-processing can be time-consuming and require specialized tools and skills. It’s important to factor in the time and effort required for post-processing when planning your 3D printing projects.

Overcoming Post-Processing Challenges

There are ways to reduce the need for post-processing:

- Design for Printability: Design your objects to minimize the need for support structures.

- Use Materials That Require Less Post-Processing: Some materials, like PLA, require less post-processing than others.

- Invest in Post-Processing Tools: Consider investing in tools like sanders, polishers, and paint sprayers to make post-processing easier.

Post-Processing: A Real-World Example

We once printed a complex model of a robot arm for a client. The model required extensive support structures, which took hours to remove. We also had to sand and smooth the surface to achieve a professional finish. This experience taught us the importance of planning for post-processing and allocating sufficient time and resources.

Post-Processing: A Key Consideration

Post-processing is an integral part of the 3D printing process. Don’t underestimate the time and effort required for this step. Plan ahead and be prepared to invest the necessary resources.

5. 🎯 Precision and Surface Finish: When Perfection is Elusive and Tolerances are Tight

🎯 Precision and Surface Finish: When Perfection is Elusive and Tolerances are Tight

3D printing is known for its ability to create complex geometries, but it’s not always perfect. The precision and surface finish of 3D printed objects can vary depending on the printing technology, the material used, and the settings of the printer.

Precision: A Matter of Layers

3D printing works by building up layers of material. The thickness of these layers can affect the precision of the final object.

- Thinner layers: Thinner layers result in a smoother surface finish and higher precision.

- Thicker layers: Thicker layers can result in a more visible layer pattern and lower precision.

Surface Finish: A Range of Textures

The surface finish of 3D printed objects can range from smooth to rough, depending on the printing technology and the material used.

- SLA (Stereolithography): This technology produces objects with a smooth surface finish.

- FDM (Fused Deposition Modeling): This technology can produce objects with a more visible layer pattern, especially when using thicker layers.

Tolerances: A Key Consideration

Tolerances refer to the allowable variation in the dimensions of a part. 3D printing can have tighter tolerances than some traditional manufacturing methods, but it’s still important to consider the tolerances of your printer and material when designing your objects.

Overcoming Precision and Surface Finish Limitations

There are ways to improve the precision and surface finish of 3D printed objects:

- Use a High-Resolution Printer: Printers with a smaller nozzle size and the ability to print thinner layers can produce more precise objects.

- Post-Processing: Sanding, smoothing, and polishing can help to improve the surface finish of 3D printed objects.

- Design for Printability: Design your objects to minimize the need for support structures, which can sometimes leave marks on the surface.

Precision and Surface Finish: A Balancing Act

The precision and surface finish of 3D printed objects are a trade-off between cost, speed, and quality. Consider your needs and choose the right approach for your project.

6. 🧪 Material World: The Current Palette of 3D Printable Materials and Their Properties

🧪 Material World: The Current Palette of 3D Printable Materials and Their Properties

One of the most exciting aspects of 3D printing is the growing range of printable materials. From plastics to metals to ceramics, the possibilities are expanding rapidly.

3D Printing Materials: A Diverse Palette

Here are some of the most common 3D printing materials:

- Thermoplastics: These are the most widely used materials in 3D printing, and they include:

- PLA (Polylactic Acid): Biodegradable, easy to print, and relatively inexpensive.

- ABS (Acrylonitrile Butadiene Styrene): Strong and durable, but can be prone to warping.

- PETG (Polyethylene Terephthalate Glycol): Flexible and impact-resistant, but can be prone to scratches.

- Nylon (Polyamide): Strong and durable, but can be more challenging to print.

- Metals: 3D printing is increasingly being used to print metal parts, including:

- Stainless Steel: Durable and corrosion-resistant.

- Titanium: Lightweight and strong, often used in aerospace and medical applications.

- Aluminum: Lightweight and easy to machine.

- Ceramics: 3D printing is also being used to print ceramic parts, which offer high temperature resistance and hardness.

- Composites: 3D printing can be used to create composite materials, which combine the properties of different materials.

Material Properties: A Key Consideration

The properties of 3D printing materials are crucial to consider when choosing the right material for your project. Here are some important properties to consider:

- Strength: How much force can the material withstand before breaking?

- Stiffness: How much does the material bend or deform under load?

- Durability: How well does the material resist wear and tear?

- Heat Resistance: How well does the material withstand high temperatures?

- Chemical Resistance: How well does the material resist chemicals?

Material Selection: A Balancing Act

Choosing the right material for your 3D printing project is a balancing act. Consider the properties of the material, the application of the object, and the cost of the material.

The Material World: A Constant Evolution

The range of 3D printing materials is constantly expanding, with new materials and technologies emerging all the time. Stay up-to-date on the latest developments to explore the full potential of 3D printing.

7. 💪 Strength and Durability: Mechanical Properties, Anisotropy, and Structural Integrity

💪 Strength and Durability: Mechanical Properties, Anisotropy, and Structural Integrity

While 3D printing offers incredible design freedom, it’s important to understand the mechanical properties of 3D printed objects. The strength and durability of a 3D printed object can be influenced by factors like the printing technology, the material used, and the design of the object.

Mechanical Properties: A Key Consideration

Think of it like building a house: You need to use strong and durable materials to ensure that the house can withstand the elements and the weight of the occupants. Similarly, the mechanical properties of 3D printed objects are crucial for their performance and longevity.

Anisotropy: A Challenge for 3D Printing

One of the challenges of 3D printing is anisotropy. This refers to the fact that the mechanical properties of a 3D printed object can vary depending on the direction of the load.

- Layer-by-Layer Construction: 3D printing builds up objects layer by layer, which can create a difference in strength between the layers and the direction of the load.

- Infill Density: The infill density, which refers to the amount of material used to fill the interior of the object, can also affect the strength and durability.

Structural Integrity: A Critical Factor

The structural integrity of a 3D printed object is essential for its performance and safety. It’s important to design objects that can withstand the stresses they will be subjected to.

Overcoming Strength and Durability Limitations

There are ways to improve the strength and durability of 3D printed objects:

- Choose Strong Materials: Select materials that are known for their strength and durability, such as ABS, Nylon, or metal.

- Optimize Your Design: Design your objects to minimize stress concentrations and to distribute the load evenly.

- Use Infill: Use a high infill density to increase the strength of the object.

- Post-Processing: Post-processing techniques like heat treatment or annealing can improve the strength and durability of 3D printed objects.

Strength and Durability: A Balancing Act

The strength and durability of 3D printed objects are a trade-off between cost, weight, and performance. Consider your needs and choose the right approach for your project.

8. 🎨 Color and Multi-Material Printing: Beyond Monochromatic Dreams and Functional Integration

🎨 Color and Multi-Material Printing: Beyond Monochromatic Dreams and Functional Integration

3D printing has traditionally been limited to single-color prints, but the landscape is changing. Multi-material printing and color printing are opening up new possibilities for design and functionality.

Multi-Material Printing: A World of Possibilities

Multi-material printing allows you to print objects with multiple materials, creating objects with complex functionalities. For example, you could print an object with a flexible material for one part and a rigid material for another part.

Color Printing: Adding a Touch of Creativity

Color printing allows you to print objects in multiple colors, adding a touch of creativity and visual appeal. This is especially useful for creating prototypes, models, and decorative objects.

Multi-Material and Color Printing: A Growing Trend

Multi-material and color printing are becoming increasingly popular, with new technologies and materials emerging all the time.

Overcoming Color and Multi-Material Printing Limitations

There are still some limitations to multi-material and color printing:

- Material Compatibility: Not all materials are compatible with each other, so it’s important to choose materials that can be printed together.

- Print Speed: Multi-material and color printing can be slower than single-material printing.

- Cost: Multi-material and color printing can be more expensive than single-material printing.

Color and Multi-Material Printing: A Future of Innovation

Multi-material and color printing are exciting developments in the world of 3D printing. They offer new possibilities for design, functionality, and aesthetics. As these technologies continue to evolve, we can expect to see even more innovative applications in the future.

9. 🧠 Design Complexity and Software Hurdles: The Digital Frontier and CAD/Slicing Challenges

🧠 Design Complexity and Software Hurdles: The Digital Frontier and CAD/Slicing Challenges

3D printing opens up a world of design possibilities, but it also presents new challenges. Designing for 3D printing requires specific skills and software, and the process can be more complex than traditional design methods.

3D Design Software: A Digital Toolkit

You’ll need 3D design software to create your 3D models. There are many different software options available, ranging from free and open-source software to professional-grade software.

- Free and Open-Source Software: Tinkercad, Blender, and FreeCAD are popular options for beginners.

- Professional-Grade Software: SolidWorks, Autodesk Inventor, and Fusion 360 are industry-standard software used by professionals.

Slicing Software: The Bridge Between Design and Print

Once you’ve created your 3D model, you’ll need to use slicing software to convert it into a format that your 3D printer can understand. Slicing software divides your 3D model into thin layers, creating instructions for the printer to follow.

- Popular Slicing Software: Cura, PrusaSlicer, and Simplify3D are popular options for slicing 3D models.

Design Complexity: A Factor to Consider

The complexity of your design can affect the print time, the amount of material used, and the overall success of the print. It’s important to design your objects with printability in mind.

Overcoming Design and Software Challenges

There are ways to overcome the challenges of designing for 3D printing:

- Learn 3D Design Software: Take online courses or tutorials to learn the basics of 3D design software.

- Experiment with Slicing Settings: Experiment with different slicing settings to find the optimal settings for your printer and material.

- Use Online Resources: There are many online resources available to help you with 3D design and printing, including [for 3D models & printable related queries:] Thingiverse, Cults3D, and Yeggi.

Design and Software: A Key Consideration

Designing for 3D printing requires a different mindset than traditional design methods. It’s important to understand the capabilities and limitations of 3D printing and to use the right software tools to create printable designs.

10. 🌍 Environmental Footprint: Sustainability Challenges and Waste Management

🌍 Environmental Footprint: Sustainability Challenges and Waste Management

As 3D printing gains popularity, it’s crucial to consider its environmental impact. The production of 3D printers, materials, and the printing process itself can contribute to pollution and resource depletion.

3D Printing: A Double-Edged Sword

While 3D printing can reduce waste by allowing for on-demand production and eliminating the need for large inventories, it’s important to acknowledge that the production of 3D printers and materials can have a significant environmental impact.

Sustainability Challenges: A Growing Concern

Here are some of the sustainability challenges associated with 3D printing:

- Energy Consumption: 3D printing can be energy-intensive, especially for larger printers and longer print times.

- Material Production: The production of 3D printing materials can contribute to pollution and resource depletion.

- Waste Management: 3D printing can generate waste, including failed prints, support structures, and excess material.

Overcoming Sustainability Challenges

There are ways to reduce the environmental impact of 3D printing:

- Use Sustainable Materials: Choose materials that are biodegradable, recyclable, or made from recycled materials.

- Optimize Your Design: Design your objects to minimize the amount of material used and to reduce the print time.

- Reduce Energy Consumption: Use energy-efficient printers and print settings.

- Proper Waste Management: Recycle or dispose of waste materials responsibly.

Sustainability: A Shared Responsibility

The sustainability of 3D printing is a shared responsibility. As consumers, we can choose to support companies that are committed to sustainability. As manufacturers, we can strive to develop more sustainable printing technologies and materials.

11. 🔒 Intellectual Property and Security Concerns: The Digital Wild West and Design Protection

🔒 Intellectual Property and Security Concerns: The Digital Wild West and Design Protection

The accessibility of 3D printing raises concerns about intellectual property and design protection. With the ability to easily replicate designs, there’s a risk of counterfeiting and unauthorized copying.

Intellectual Property: A Vital Asset

Intellectual property, such as patents, trademarks, and copyrights, is a vital asset for businesses and individuals. It protects their creations and allows them to profit from their innovations.

3D Printing: A Challenge for Intellectual Property Protection

3D printing can make it easier to copy designs, which can undermine intellectual property rights. For example, someone could easily scan a 3D printed object and create a copy of it.

Security Concerns: A Growing Threat

There are also security concerns associated with 3D printing. For example, someone could hack into a 3D printer and print unauthorized designs.

Overcoming Intellectual Property and Security Challenges

There are ways to address these challenges:

- Design Protection: Use design patents or copyrights to protect your designs.

- Secure Your Printers: Use strong passwords and security measures to protect your printers from unauthorized access.

- Use Digital Rights Management (DRM): Some 3D printing software offers DRM features that can help to prevent unauthorized copying.

Intellectual Property and Security: A Key Consideration

Intellectual property and security are important considerations for anyone using 3D printing. Take steps to protect your designs and your printers from unauthorized access.

12. 🧑💻 Skill Gap and Learning Curve: Mastering the Machines and Advanced Techniques

🧑💻 Skill Gap and Learning Curve: Mastering the Machines and Advanced Techniques

While 3D printing is becoming more accessible, it still requires a certain level of skill and knowledge. Mastering the machines and advanced techniques can take time and effort.

3D Printing: A Learning Curve

Think of it like learning to play a musical instrument: It takes practice and dedication to master the skills. Similarly, 3D printing requires a learning curve.

Skill Gap: A Challenge for Adoption

There’s a growing skill gap in the field of 3D printing. Many people are interested in using 3D printing, but they lack the necessary skills and knowledge.

Overcoming the Skill Gap

There are ways to overcome the skill gap:

- Online Courses and Tutorials: There are many online courses and tutorials available to teach you the basics of 3D printing. Check out our article on the 25 Must-Know 3D Printing Tutorials to Master in 2025 🖨️.

- Community Forums and Groups: Join online forums and groups to connect with other 3D printing enthusiasts and learn from their experiences.

- Hands-On Workshops: Attend hands-on workshops to get practical experience with 3D printing.

Skill Development: A Continuous Process

3D printing is a constantly evolving field, so it’s important to continue learning and developing your skills. Stay up-to-date on the latest technologies and techniques to maximize your potential.

⚖️ 3D Printing: A Balanced Perspective – Advantages vs. Limitations in Additive Manufacturing

⚖️ 3D Printing: A Balanced Perspective – Advantages vs. Limitations in Additive Manufacturing

3D printing, or additive manufacturing, is a revolutionary technology with the potential to transform industries. However, it’s crucial to acknowledge its limitations alongside its advantages.

3D Printing Advantages: A Powerful Toolkit

- Rapid Prototyping: 3D printing allows for rapid prototyping, enabling designers to quickly create and test different designs.

- Customization: 3D printing allows for highly customized designs, enabling the creation of unique and personalized objects.

- On-Demand Production: 3D printing enables on-demand production, eliminating the need for large inventories and reducing waste.

- Complex Geometries: 3D printing allows for the creation of complex geometries that would be difficult or impossible to manufacture using traditional methods.

- Lightweight Designs: 3D printing allows for the creation of lightweight designs, reducing material usage and improving efficiency.

- Reduced Tooling Costs: 3D printing eliminates the need for expensive tooling and molds, making it a cost-effective solution for prototyping and small-scale production.

3D Printing Limitations: A Reality Check

- Build Volume: Most 3D printers have a limited build volume, restricting the size of objects that can be printed.

- Material Selection: The range of printable materials is still limited compared to traditional manufacturing methods.

- Print Speed: 3D printing can be slow, especially for complex designs and large batches.

- Surface Finish: The surface finish of 3D printed objects can be rough and require post-processing.

- Cost: 3D printers and materials can be expensive, especially for industrial-grade equipment.

- Design Complexity: Designing for 3D printing requires specific skills and software.

- Post-Processing: Many 3D printed objects require post-processing to achieve the desired finish and functionality.

- Precision and Tolerances: The precision and tolerances of 3D printed objects can vary depending on the printing technology, material, and settings.

- Strength and Durability: The strength and durability of 3D printed objects can be influenced by factors like the printing technology, material, and design.

- Environmental Impact: The production of 3D printers, materials, and the printing process itself can contribute to pollution and resource depletion.

- Intellectual Property: The accessibility of 3D printing raises concerns about intellectual property protection and design counterfeiting.

- Skill Gap: Mastering 3D printing requires a certain level of skill and knowledge, and there’s a growing skill gap in the field.

3D Printing: A Powerful Tool with Limitations

While 3D printing offers incredible advantages, it’s important to acknowledge its limitations. By understanding both the strengths and weaknesses of 3D printing, you can make informed decisions about when and how to use this technology.

🌟 Overcoming Obstacles: Innovations Addressing 3D Printing Limitations and Future Solutions

🌟 Overcoming Obstacles: Innovations Addressing 3D Printing Limitations and Future Solutions

The limitations of 3D printing are not insurmountable. Researchers and engineers are constantly working to overcome these challenges, pushing the boundaries of what’s possible with additive manufacturing.

Innovations: A Path to Progress

Here are some of the innovations that are addressing the limitations of 3D printing:

- Larger Build Volumes: New 3D printers are being developed with larger build volumes, enabling the printing of larger objects.

- New Materials: Researchers are developing new materials that are stronger, more durable, and more versatile.

- Faster Printing Technologies: New printing technologies are being developed that are faster and more efficient.

- Improved Surface Finish: New printing technologies and post-processing techniques are being developed to improve the surface finish of 3D printed objects.

- Multi-Material Printing: Multi-material printing technologies are becoming more sophisticated, allowing for the creation of objects with complex functionalities.

- Automated Post-Processing: Automated post-processing systems are being developed to reduce the time and effort required for post-processing.

- Design Software Advancements: Design software is becoming more user-friendly and powerful, making it easier to design for 3D printing.

- Sustainable Materials and Processes: Researchers are developing more sustainable materials and printing processes to reduce the environmental impact of 3D printing.

- Intellectual Property Protection: New technologies and legal frameworks are being developed to protect intellectual property in the age of 3D printing.

- Education and Training: More educational resources and training programs are becoming available to address the skill gap in 3D printing.

The Future of 3D Printing: A World of Possibilities

The future of 3D printing is bright, with ongoing research and development focused on overcoming the limitations of this technology. As these innovations continue to emerge, we can expect to see even more amazing applications of 3D printing in the years to come.

🏗️ Where 3D Printing Still Struggles: Industries and Applications Facing Specific Hurdles

🏗️ Where 3D Printing Still Struggles: Industries and Applications Facing Specific Hurdles

While 3D printing is making significant strides, there are still certain industries and applications where it faces specific hurdles.

Industries Facing Challenges

- Mass Production: 3D printing is still not as cost-effective as traditional manufacturing methods for mass production.

- Automotive: While 3D printing is being used for prototyping and specialized parts in the automotive industry, it’s still not widely used for mass production of car parts.

- Aerospace: 3D printing is being used for some parts in the aerospace industry, but it’s still not widely used for critical components.

- Construction: 3D printing is being used for some construction applications, but it’s still not widely used for building entire structures.

Applications Facing Challenges

- High-Performance Applications: 3D printing is still not as reliable as traditional manufacturing methods for high-performance applications, such as those requiring high strength, durability, or precision.

- Medical Devices: 3D printing is being used for some medical devices, but it’s still not widely used for implantable devices or critical components.

- Food Production: 3D printing is being used for some food applications, but it’s still not widely used for mass production of food products.

Overcoming Industry and Application Challenges

Overcoming these challenges will require further innovation and development in areas such as:

- Material Science: Developing new materials that are stronger, more durable, and more versatile.

✅ Conclusion: Is 3D Printing Limited? Absolutely, But It’s Evolving!

We’ve taken a deep dive into the fascinating world of 3D printing and uncovered its many strengths and limitations. From the physical constraints of build volume to the challenges of material selection, print speed, post-processing, and intellectual property concerns, 3D printing is far from perfect. But—and this is a big but—it’s a technology that’s rapidly evolving and pushing boundaries every day.

Remember our cake analogy? 3D printing is like a versatile oven: it can bake intricate, customized cakes that traditional ovens can’t, but it requires the right recipe, tools, and patience. Whether you’re a hobbyist printing miniatures or an engineer prototyping aerospace parts, understanding these limitations helps you make smarter choices.

The good news? Innovations in materials, printer design, multi-material and color printing, and software are steadily chipping away at these barriers. Plus, the growing community and educational resources make mastering 3D printing more accessible than ever.

So, should you jump on the 3D printing bandwagon? Absolutely ✅—but with your eyes wide open. Know its quirks, plan for post-processing, and embrace the learning curve. The future is bright, and with a little savvy, you’ll be creating amazing things that once seemed impossible.

🔗 Recommended Links for Further Exploration

Ready to explore or upgrade your 3D printing setup? Here are some trusted platforms and resources to get you started:

-

Prusa i3 MK3S+ (Highly Recommended Desktop Printer):

Thingiverse | Prusa Official Website -

Formlabs Form 3 (SLA Printer for High-Resolution Prints):

Thingiverse | Formlabs Official Website -

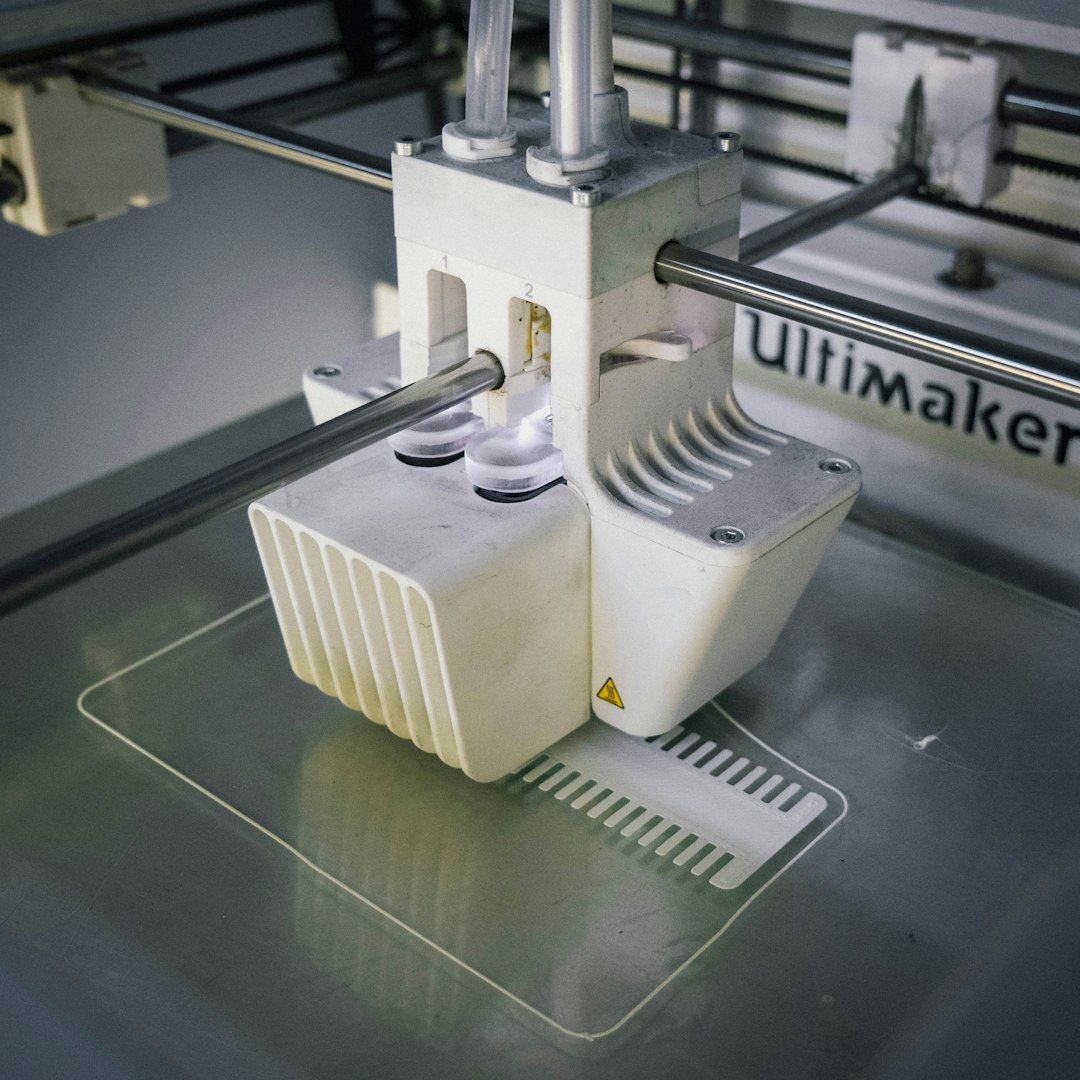

Ultimaker S5 (Industrial-Grade FDM Printer):

Thingiverse | Ultimaker Official Website -

Materials and Filaments:

Amazon 3D Printing Filaments | MatterHackers -

Books on 3D Printing:

“3D Printing: The Next Industrial Revolution” by Christopher Barnatt — Amazon Link

“Fabricated: The New World of 3D Printing” by Hod Lipson and Melba Kurman — Amazon Link

❓ Frequently Asked Questions (FAQ) About 3D Printing Limitations

What are the common limitations of 3D printing technology?

3D printing limitations include:

- Build volume constraints: Most printers have a limited print size, requiring large objects to be split and assembled.

- Material restrictions: Not all materials are printable; many lack the mechanical properties or biocompatibility needed for certain applications.

- Print speed: Complex or large prints can take hours or days.

- Surface finish and precision: Layer lines and rough textures often require post-processing.

- Mechanical strength and anisotropy: Parts can be weaker along layer lines, affecting durability.

- Cost: High-end printers and specialty materials can be expensive.

- Skill requirements: Designing and printing require technical know-how.

These limitations mean 3D printing is best suited for prototyping, customization, and low-volume production rather than mass manufacturing.

Read more about “How Does 3D Printing Work Exactly? 12 Secrets Unveiled! 🖨️ (2025)”

How do the limitations of 3D printing affect the types of objects that can be created?

The limitations directly influence design choices:

- Size: Large objects must be modular or printed in parts.

- Complexity: While intricate geometries are possible, very thin walls or unsupported overhangs may fail.

- Material properties: Objects requiring high strength, heat resistance, or flexibility may need specialized materials or alternative manufacturing.

- Surface finish: Aesthetic parts may need additional finishing.

- Functional parts: Mechanical stresses and anisotropy must be considered to avoid premature failure.

Thus, 3D printing excels at customized, complex, or low-volume items but struggles with large, high-strength, or mass-produced parts.

What are the cost limitations of 3D printing and how do they impact large-scale production?

Cost factors include:

- Equipment: Industrial printers can be costly to purchase and maintain.

- Materials: Specialty filaments, resins, or metal powders are expensive.

- Time: Slow print speeds increase labor and machine usage costs.

- Post-processing: Additional finishing steps add time and expense.

For large-scale production, these costs often exceed those of traditional manufacturing like injection molding, which benefits from economies of scale. Therefore, 3D printing is generally not cost-effective for mass production but shines in prototyping, customization, and small batch runs.

Are there any workarounds or solutions to overcome the limitations of 3D printing for complex or large projects?

Absolutely! Here are some practical strategies:

Splitting and Assembly

- Break large models into smaller parts that fit your printer’s build volume, then assemble post-printing with adhesives or fasteners.

Hybrid Manufacturing

- Combine 3D printing with traditional methods (e.g., print complex components, machine critical surfaces).

Material Selection

- Use composites or reinforced filaments (carbon fiber, glass fiber) to improve strength and durability.

Advanced Technologies

- Explore industrial printers with larger build volumes or multi-material capabilities (e.g., HP Multi Jet Fusion, Carbon M2).

Design Optimization

- Use topology optimization and design for additive manufacturing (DfAM) principles to reduce material use and improve printability.

Outsourcing

- Use professional 3D printing services like Shapeways or Sculpteo for specialized materials or large-scale prints.

📚 Reference Links and Sources

- TWI Global: Pros and Cons of 3D Printing

- Hubs: 3D Printing Geometry Restrictions

- National Center for Biotechnology Information (NCBI): Advancements and Limitations in 3D Printing Materials and Applications

- Prusa Research: Original Prusa i3 MK3S+

- Formlabs: Form 3 SLA Printer

- Ultimaker: Ultimaker S5

- Thingiverse: 3D Printable Models

- MatterHackers: 3D Printing Materials

Ready to dive deeper? Check out our 3D Printing Innovations and 3D Printable Objects categories for inspiration and expert tips!