Support our educational content for free when you purchase through links on our site. Learn more

Dyeing 3D Prints: 10 Expert Techniques to Transform Your Models 🎨 (2025)

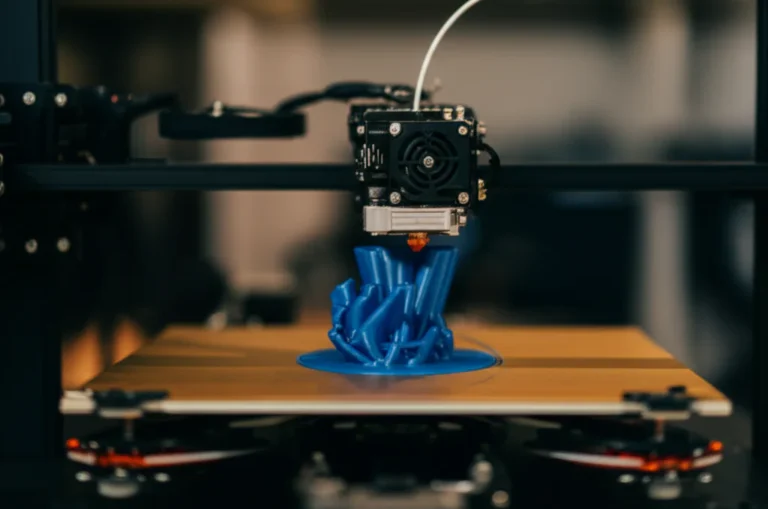

Ever stared at your freshly printed 3D model and thought, “This looks great, but it could really pop with some color”? You’re not alone! Dyeing 3D prints is the secret sauce that takes your creations from plain plastic to vibrant works of art. But here’s the kicker: not all materials or dyes behave the same, and a misstep can leave you with blotchy colors or warped prints.

At 3D Printed™, we’ve spent years experimenting with everything from nylon to resin, mastering the perfect dye baths, and even unlocking advanced effects like gradients and marbling. Did you know that nylon soaks up dye like a sponge, while PLA stubbornly refuses to budge? Or that a sous vide cooker can be your best friend for precise temperature control during dyeing? Keep reading, because we’re spilling all the insider tips, tricks, and product recommendations that will have your 3D prints bursting with color in no time!

Key Takeaways

- Nylon is the easiest and most vibrant material to dye, while PLA is generally resistant and better suited for painting.

- Use synthetic disperse dyes like Jacquard iDye Poly or Rit DyeMore for the best color penetration and durability.

- Temperature control is crucial—too hot and your print warps; too cool and the dye won’t absorb evenly.

- Preparation matters: clean, smooth, and dry your prints before dyeing for flawless results.

- Advanced techniques like gradient dyeing and masking open up creative possibilities beyond solid colors.

- Always seal dyed prints with a clear coat to protect your masterpiece from fading and wear.

Ready to dive into the colorful world of 3D print dyeing? Let’s get started!

Table of Contents

- ⚡️ Quick Tips and Facts About Dyeing 3D Prints

- 🎨 The Colorful Evolution: History and Science Behind Dyeing 3D Printed Parts

- 🖨️ Understanding Your 3D Prints: Materials and Their Dyeing Compatibility

- 🔍 1. Preparing Your 3D Print for Dyeing: Cleaning, Smoothing, and Priming

- 🎨 2. Choosing the Right Dye: Types, Brands, and Colorfastness

- 💧 3. Dyeing Techniques: Immersion, Brush, Spray, and Airbrush Methods

- 🧪 4. Step-by-Step Guide to Dyeing 3D Prints: From Start to Finish

- 🛠️ 5. Troubleshooting Common Dyeing Issues: Uneven Color, Fading, and Streaks

- 🌈 6. Advanced Color Effects: Gradient, Marbling, and Multi-Color Dyeing

- 🔬 7. Post-Dyeing Treatments: Sealing, Finishing, and Protecting Your Colored Prints

- ⚙️ 8. Dyeing Different 3D Printing Materials: PLA, ABS, Nylon, PETG, and Resin

- 💡 9. Eco-Friendly and Safe Dyeing Practices: Non-Toxic Dyes and Disposal Tips

- 🛒 10. Best Brands and Products for Dyeing 3D Prints: Our Top Picks and Reviews

- 🧰 Essential Tools and Accessories for Dyeing 3D Prints

- 🤔 Frequently Asked Questions About Dyeing 3D Prints

- 📚 Recommended Links and Resources for 3D Print Dyeing Enthusiasts

- 📝 Reference Links and Scientific Studies on 3D Print Dyeing

- 🏁 Conclusion: Mastering the Art of Dyeing Your 3D Prints

Here at 3D Printed™, we’ve spent countless hours turning spools of bland, single-color filament into vibrant, eye-popping creations. Let’s be honest, a plain white or grey print just doesn’t have the same pizzazz, does it? We’ve dunked, dipped, and dyed more plastic than we can count, learning from every streaky mess and every perfectly saturated success. Now, we’re pulling back the curtain to share everything we know about the transformative art of dyeing 3D prints. Get ready to level up your projects from monochrome to magnificent!

⚡️ Quick Tips and Facts About Dyeing 3D Prints

Jumping right in? Here’s the lowdown on giving your 3D prints a splash of color.

- Not all plastics are created equal: Nylon is the undisputed champion of dye absorption. It soaks up color like a sponge! Other materials like PETG, PVB, and some resins also take dye well, while PLA is notoriously stubborn.

- Choose your dye wisely: Standard fabric dyes won’t cut it. You need dyes specifically for synthetic materials. Brands like Rit DyeMore for Synthetics and Jacquard iDye Poly are the go-to choices for the 3D printing community. “Do NOT use regular Rit dye. It will do nothing. Use their synthetic dye called DyeMore.”

- Temperature is critical: Heat is your best friend in this process. It opens up the pores of the plastic, allowing the dye to penetrate. However, too much heat can warp your precious print into a sad, melty puddle. A good starting point for nylon is around 140°F (60°C). For PETG, you’ll need to get “HOT HOT HOT right up the the point where the plastic starts to deform then dial back your temperature ten degrees less next time.”

- Cleanliness is next to godliness: Any grease, fingerprints, glue, or residue on your print will act as a dye-repellent, leaving you with a splotchy, uneven finish. Clean your parts thoroughly before they take a dip!

- Dye the part, not the filament: While you can dye raw filament, it often results in uneven color. The dye struggles to penetrate the core, leading to a “lighter color and striping” when printed. For the best results, always dye the finished 3D Printable Objects.

- Safety first! 🧪 Always work in a well-ventilated area, wear gloves, and use dedicated equipment. As one forum user wisely noted, “Any equipment used for dyeing should not later be used for food, including the cooker.”

🎨 The Colorful Evolution: History and Science Behind Dyeing 3D Printed Parts

Remember the early days of desktop 3D printing? We were just thrilled to get a recognizable shape off the build plate! Color was a luxury, often limited to the filament you bought. But the maker spirit is restless, isn’t it? We quickly moved from simple prints to complex designs, and with that came the desire for custom colors that filament manufacturers just couldn’t provide.

The science is pretty cool, actually. Most 3D printing plastics are polymers, long chains of molecules. When you heat them in a dye bath, the polymer chains gain energy and move apart slightly. This process, known as reaching the glass transition temperature, opens up microscopic pores in the plastic’s surface. The dye molecules, now free to move in the hot water, zip into these pores. As the plastic cools, the pores close, trapping the dye permanently inside. It’s less like painting a surface and more like infusing color deep within the material itself! This is a fantastic example of the everyday 3D Printing Innovations that happen in workshops around the world.

🖨️ Understanding Your 3D Prints: Materials and Their Dyeing Compatibility

Before you start boiling pots of colorful water, you need to know your material. Trying to dye PLA with the same method as Nylon is like trying to fit a square peg in a round hole—it just won’t work. We’ve put together this handy chart based on our experience and community wisdom.

| Material | Dye Compatibility | Recommended Dye Type | Key Tips & Tricks |

|---|---|---|---|

| Nylon (PA) | ✅ Excellent | Synthetic (Rit DyeMore, iDye Poly) | The easiest material to dye. Absorbs color deeply and evenly. A great starting point for beginners. |

| PETG | ✅ Good | Synthetic (Rit DyeMore, iDye Poly) | Requires higher heat than Nylon. Can be prone to striping if color doesn’t penetrate fully. Translucent PETG works best. |

| PVB | ✅ Good | Synthetic or Alcohol Inks | Very hygroscopic, so it soaks up dye well. Can achieve beautiful “stained glass” effects. |

| SLA/DLP Resin | ✅ Good (Varies) | Synthetic (iDye Poly) | Works well with many UV-cured resins, especially clear ones. Always test on a failed print first! |

| ABS | ⚠️ Tricky | Synthetic (Rit DyeMore, iDye Poly) | Can be dyed, but requires very high temperatures close to its warping point. Use caution and a precise temperature controller. |

| PLA | ❌ Very Poor | N/A | Generally does not accept dye. The molecular structure is too dense. You’re better off painting PLA prints. |

🔍 1. Preparing Your 3D Print for Dyeing: Cleaning, Smoothing, and Priming

You wouldn’t paint on a dirty canvas, right? The same principle applies here. Proper preparation is 90% of the battle for a flawless dye job.

Step 1: The Deep Clean

First things first, get rid of any post-processing remnants. This includes:

- Support Material: Carefully remove all support structures.

- Adhesives: As the first YouTube video on this topic highlights, you must clean your print of any glue, hairspray, or blue tape residue. A little warm water and soap usually do the trick. For stubborn stuff, a gentle scrub with isopropyl alcohol (IPA) works wonders.

- Oils and Fingerprints: Even the natural oils from your hands can create a barrier. Wear gloves and give the print a final wash with soap and water before it goes into the dye bath.

Step 2: To Smooth or Not to Smooth?

This is a matter of personal preference. Layer lines can either be a charming characteristic of 3D printing or an unsightly texture.

- Sanding: If you want a perfectly smooth, injection-molded look, you’ll need to sand your print. Start with a lower grit sandpaper (like 220) and work your way up to a finer grit (400 or higher). This will also help the dye absorb more evenly.

- Vapor Smoothing: For materials like ABS or PVB, vapor smoothing can create a glossy, smooth surface that takes dye beautifully. This is an advanced technique that requires serious safety precautions!

We find that for most decorative parts from our favorite 3D Design Software, a light sanding is all that’s needed to get a professional-looking finish.

🎨 2. Choosing the Right Dye: Types, Brands, and Colorfastness

Welcome to the wonderful world of synthetic dyes! Forget that all-purpose dye you have for cotton t-shirts; it’s useless here. You need the heavy hitters designed for plastics like polyester and nylon.

| Dye Type | Recommended Brands | Best For | Pros | Cons |

|---|---|---|---|---|

| Disperse Dyes (Synthetic) | Rit DyeMore for Synthetics, Jacquard iDye Poly | Nylon, PETG, PVB, Resin | ✅ Deep, vibrant, permanent color. ✅ Widely available. ✅ Can be mixed for custom shades. | ❌ Requires a hot water bath. ❌ Can be messy. |

| Alcohol Inks | Jacquard Piñata Colors, Ranger Alcohol Inks | PVB, Translucent Filaments | ✅ No heat required. ✅ Great for subtle, pastel, or “stained glass” effects. | ❌ Sits on the surface, less durable. ❌ Can weaken layer adhesion if over-applied. |

Our team’s favorite? Jacquard iDye Poly. It comes in a convenient dissolvable packet, which minimizes messy powder spills. Plus, the color range is fantastic. For a deeper dive into product performance, check out our 3D Printer Reviews section where we often test finishing techniques.

💧 3. Dyeing Techniques: Immersion, Brush, Spray, and Airbrush Methods

The most common method is full immersion, but it’s not the only way to add a splash of color!

- Immersion Dyeing (The Classic): This is the go-to method for solid, even color. You submerge your entire part in a hot dye bath. It’s reliable, effective, and what we’ll focus on in our step-by-step guide. It’s as straightforward as the video host says: “Dyeing nylon 3D prints is just as easy as boiling pasta.”

- Brush-On Dyeing: You can mix your synthetic dye with a carrier and paint it on for targeted coloring. This is great for details but can be tricky to get an even coat.

- Spray/Airbrush Application: For a super-fine, even coat or gradient effects, you can use an airbrush to apply alcohol inks. This is an advanced technique that requires more specialized equipment.

🧪 4. Step-by-Step Guide to Dyeing 3D Prints: From Start to Finish

Ready to transform your print? Let’s do this! We’ll focus on the immersion method with synthetic dye, as it’s the most popular and reliable.

- Gear Up for Safety: Put on your rubber gloves and safety glasses. Make sure your workspace is covered to prevent stains.

- Prepare the Dye Bath: In a dedicated stainless steel pot, mix your Jacquard iDye Poly or Rit DyeMore with water according to the package instructions. A good rule of thumb is to use enough water to fully submerge your part.

- Heat It Up: Gently heat the dye bath on a stove or hot plate. Use a thermometer! For Nylon, aim for 140-160°F (60-70°C). For PETG, you’ll need to go hotter, closer to its deformation temperature, but be careful! A sous vide cooker is a fantastic tool for this, as it provides precise temperature control. As one user discovered, “I am never going back – sous vide is the way to go!”

- Submerge the Print: Once your bath is at the right temperature, carefully place your cleaned 3D print into the pot. It will likely float, so use a weight to keep it fully submerged. A rock or a chunk of metal tied with wire works well.

- The Waiting Game: This is where art meets science. The longer you leave the part in, the darker the color will be. The Instructables guide notes, “there’s not much difference between the 20min, 15min and 10min ones, but the 5min one is definitely lighter than the rest.” We recommend checking every 5 minutes until you reach your desired shade. Keep the part moving gently for the most even color.

- The Cold Shock: Once you’re happy with the color, use tongs to remove the print from the hot dye bath. Immediately plunge it into a container of cold water. This “cold shock” helps to close the plastic’s pores and lock in the color.

- Rinse and Dry: Rinse the part under cool running water until the water runs clear. Pat it dry with a paper towel and let it air dry completely. For hygroscopic materials like Nylon, you can pop it in a filament dryer for a few hours to remove any absorbed water.

🛠️ 5. Troubleshooting Common Dyeing Issues: Uneven Color, Fading, and Streaks

Did your dye job come out looking more like a tie-dye disaster than a solid color? Don’t worry, it happens to the best of us. Here are some common culprits and how to fix them.

- Problem: Splotches and light spots.

- Cause: Almost certainly due to an unclean print. Grease, oil, or glue residue prevented the dye from absorbing.

- Solution: Strip the color (if possible) and start over, paying extra special attention to the cleaning step.

- Problem: Streaky or uneven color, especially on PETG.

- Cause: The dye didn’t fully penetrate the plastic. This can be due to the temperature being too low or not enough time in the dye bath. As one forum user noted about solid PETG, “the blend is inconsistent, resulting in a lighter color and striping.”

- Solution: Increase the temperature slightly (without warping the print!) and/or leave it in the dye bath for longer. Using translucent filament often yields better results.

- Problem: The color is too light.

- Cause: Not enough dye concentrate, temperature was too low, or the dyeing time was too short.

- Solution: Easy fix! Just put it back in the dye bath for another round. You can also add more dye concentrate to the water.

- Problem: The color is fading over time.

- Cause: This can happen with prolonged UV exposure (sunlight).

- Solution: Apply a UV-resistant clear coat or sealant after dyeing to protect the color for years to come.

🌈 6. Advanced Color Effects: Gradient, Marbling, and Multi-Color Dyeing

Once you’ve mastered solid colors, why not get a little more creative?

- Gradient (Ombré) Effect: This is surprisingly easy! Simply submerge your print into the dye bath and slowly pull it out over a period of time. The part that stays in the longest will be the darkest, creating a beautiful fade.

- Multi-Color Dyeing: This requires some patience. Dye the entire part in the lightest color you want to use. Then, use high-quality waterproof tape (like vinyl masking tape) to mask off the areas you want to keep that color. Now, dip the part in your next, darker color! Repeat for as many colors as you want.

- Masking and Sandblasting: The Instructables article suggests a brilliant technique: dye a part a dark color, then mask off a pattern and sandblast the exposed areas. This removes the surface color, creating a stunning two-tone effect. “It can be super easy to achieve multiple shades if you take time to mask your part and think strategically about your polishing process.”

🔬 7. Post-Dyeing Treatments: Sealing, Finishing, and Protecting Your Colored Prints

You’ve achieved the perfect color! Now, let’s make sure it lasts. While dyeing infuses color into the plastic, a protective top coat is always a good idea, especially for parts that will be handled frequently or exposed to sunlight.

- Clear Coats: A simple spray-on acrylic clear coat (available in matte, satin, or gloss finishes) will do the trick. Brands like Krylon and Rust-Oleum make excellent, widely available options. This adds a layer of protection against scratches and UV rays.

- Polishing: For a super glossy finish, you can polish your dyed part with a plastic polish like Novus. This works best on parts that have been sanded smooth before dyeing.

⚙️ 8. Dyeing Different 3D Printing Materials: PLA, ABS, Nylon, PETG, and Resin

Let’s take a deeper dive into the specifics for each material. What works for one can be a disaster for another!

Nylon: The Star Pupil

As we’ve said, Nylon is a dream to work with. Its hygroscopic nature means it readily absorbs water-based dyes. You can achieve deep, rich colors with relatively low heat and short dye times. It’s the most forgiving material for beginners.

PETG: The High-Maintenance Cousin

PETG can be dyed effectively, but it demands more heat. You need to get the water very hot, which risks warping. The key is to find that sweet spot right below its glass transition temperature. A precise digital thermometer or sous vide setup is highly recommended.

PVB: The Artistic Choice

PolyVinyl Butyral (PVB) is interesting because it’s soluble in isopropyl alcohol. This opens the door to using alcohol inks for unique, translucent effects. When dyed with synthetic dyes, it can produce stunning “stained glass” looks, especially when smoothed with IPA vapor.

Resin: The Wild Card

Dyeing SLA/DLP resin prints is very possible, particularly with clear or translucent resins. The process is similar to dyeing Nylon, using iDye Poly in a hot water bath. However, different resin formulations will react differently, so always test on a scrap piece first.

ABS and PLA: The Problem Children

ABS requires very high heat to accept dye, making it prone to warping. It’s possible, but difficult. PLA, for all its popularity in printing, is largely resistant to dyeing. Its molecular structure is too tightly packed to allow dye molecules in. For PLA, your best bet is priming and painting.

💡 9. Eco-Friendly and Safe Dyeing Practices: Non-Toxic Dyes and Disposal Tips

While dyeing is fun, let’s be responsible makers.

- Dye Choice: Some dyes are less hazardous than others. The Jacquard iDye Poly is often cited as being safe enough to pour down the drain once cooled, according to the Instructables guide. Always check the manufacturer’s safety data sheet (SDS).

- Reuse Your Dye Bath: Don’t dump your dye after one use! You can store it in a sealed container and reuse it multiple times. One user on the Prusa forums mentioned, “Keep your old dye! It will work just as well 6-8 month from now if you keep it somewhere dark.”

- Ventilation: Work in a well-ventilated area to avoid inhaling fumes from the hot dye bath.

- Dedicated Tools: Never, ever, ever use pots, tongs, or thermometers for food after they’ve been used for dyeing. Keep a separate set of tools just for your workshop projects.

🛒 10. Best Brands and Products for Dyeing 3D Prints: Our Top Picks and Reviews

After countless tests, two brands consistently rise to the top for dyeing 3D prints. They are the undisputed champions in our workshop.

| Product | Overall Rating | Ease of Use | Color Vibrancy | Material Compatibility |

|---|---|---|---|---|

| Jacquard iDye Poly | 9.5/10 | 10/10 | 9/10 | 9/10 |

| Rit DyeMore for Synthetics | 9/10 | 8/10 | 10/10 | 9/10 |

Jacquard iDye Poly

This is our team’s top pick. The main reason? The dissolvable packet. You just drop the whole thing into the pot. No messy powder to measure or spill. It provides excellent, consistent results on Nylon, PETG, and Resin. The color selection is robust, and they can be easily mixed.

- 👉 CHECK PRICE on:

Rit DyeMore for Synthetics

A very close second, and sometimes easier to find locally in craft stores. Rit is a legendary name in dyes, and their synthetic line is fantastic. The colors are incredibly vibrant, perhaps even more so than iDye Poly right out of the bottle. The only minor drawback is that it’s a liquid you have to pour and measure, which can be a bit messier.

- 👉 CHECK PRICE on:

🧰 Essential Tools and Accessories for Dyeing 3D Prints

Having the right gear makes the process smoother, safer, and more successful. Here’s our must-have list:

- ✅ A Dedicated Pot: Stainless steel is best as it won’t stain.

- ✅ Heat Source: A hot plate or a stove you don’t cook food on.

- ✅ Thermometer: A digital meat thermometer or candy thermometer is perfect for monitoring the temperature.

- ✅ Tongs or Pliers: For safely adding and removing your print from the hot water.

- ✅ Rubber Gloves: To protect your hands from dye and heat.

- ✅ A Weight: To keep your print submerged.

- ✅ Cold Water Bath: A separate container for the “cold shock.”

- ✅ (Optional but Recommended) Sous Vide Cooker: For ultimate, set-it-and-forget-it temperature control.

🤔 Frequently Asked Questions About Dyeing 3D Prints

-

Can you dye PLA 3D prints?

Unfortunately, no. PLA is highly resistant to standard dyeing methods. You are much better off priming and painting your PLA prints. -

What is the best temperature for dyeing 3D prints?

It depends entirely on the material! For Nylon, a good starting point is 140°F (60°C). For PETG, you need to go much hotter, often above 160°F (70°C), but be careful not to warp the print. -

Will the color rub off?

No. When done correctly, the dye penetrates the surface of the plastic and becomes a permanent part of the print. It won’t rub off, chip, or peel like paint. -

Can I mix dyes to create custom colors?

Absolutely! This is one of the biggest advantages of dyeing. You can mix colors from the same brand (e.g., mix red and blue Rit DyeMore) to create your own unique shades. -

How long does it take to dye a 3D print?

This can range from 5 minutes for a light shade to over an hour for a deep, dark color. It depends on the material, temperature, and desired color intensity.

📚 Recommended Links and Resources for 3D Print Dyeing Enthusiasts

Want to learn even more? Here are some of the best resources we’ve found.

- Instructables Guide: A great visual walkthrough of dyeing a resin part with iDye Poly. Dye a 3D Printed Part : 6 Steps – Instructables

- Prusa3D Community Forum: An incredibly detailed thread with user experiences dyeing various filaments, especially PETG and PVB. Dyeing filaments (PETG, PVB, Nylon, PLA?) – Prusa3D Forum

- YouTube Tutorial: A fantastic video guide focusing on dyeing Nylon parts, full of practical tips. Featured Video Link

📝 Reference Links and Scientific Studies on 3D Print Dyeing

For the engineers and scientists among us, here are the links to the sources we’ve referenced throughout this article.

- Prusa3D Community Forum Discussion on Dyeing Filaments. https://forum.prusa3d.com/forum/english-forum-general-discussion-announcements-and-releases/dyeing-filaments-petg-pvb-nylon-pla/

- YouTube Video: “How to Dye Nylon 3D Prints”. Summary provided.

- Instructables Article: “Dye a 3D Printed Part”. https://www.instructables.com/Dye-a-3D-Printed-Part/

🏁 Conclusion: Mastering the Art of Dyeing Your 3D Prints

So, there you have it — the full spectrum of knowledge to turn your plain 3D prints into dazzling, colorful masterpieces! From understanding the science behind dye absorption to picking the perfect dye and mastering the technique, you’re now equipped to take your projects to the next level.

Our journey revealed that Nylon is the superstar when it comes to dyeing ease and vibrancy, while PETG and PVB offer exciting possibilities with a bit more finesse. PLA and ABS? They’re the stubborn siblings best left to painting rather than dyeing.

When it comes to products, Jacquard iDye Poly shines with its user-friendly dissolvable packets and consistent, vibrant results. Rit DyeMore for Synthetics is a close contender, offering intense colors but requiring a bit more hands-on mixing. Both are excellent choices, and your preference might come down to availability or personal workflow.

Remember, preparation is key — clean, smooth, and ready your prints before the dye bath. Temperature control is your secret weapon, and a sous vide cooker can be a game-changer for precision. And don’t forget post-dye sealing to keep those colors popping for years to come.

Finally, dyeing isn’t just about color — it’s a creative playground. Whether you’re chasing gradients, marbling, or multi-color magic, the possibilities are as limitless as your imagination.

Ready to dive in? Your next print is waiting to be transformed!

📚 Recommended Links and Shopping Resources

Ready to get your hands on the best dyes and tools? Here’s where to find them:

-

Jacquard iDye Poly:

-

Rit DyeMore for Synthetics:

-

Jacquard Piñata Alcohol Ink (for PVB and artistic effects):

-

Essential Tools:

-

Books on Dyeing and Finishing:

-

Tutorials and Guides:

🤔 Frequently Asked Questions About Dyeing 3D Prints

What types of filament work best for dyeing 3D prints?

Nylon is the top choice due to its porous, hygroscopic nature, which allows dyes to penetrate deeply and evenly. PETG and PVB also accept dyes well but require higher temperatures or specialized dyes like alcohol inks. Resin prints, especially clear ones, can be dyed with synthetic dyes but require testing due to variability in resin formulations. PLA and ABS are generally poor candidates for dyeing; PLA’s dense molecular structure resists dye absorption, and ABS requires dangerously high temperatures to dye effectively.

How do you prepare a 3D print for dyeing?

Preparation is crucial for success:

- Clean thoroughly: Remove all oils, fingerprints, glue residues, and support material.

- Smooth the surface: Sanding or vapor smoothing can improve dye absorption and final appearance.

- Dry completely: Moisture can interfere with dye uptake.

- Use gloves to avoid recontamination.

Can you dye 3D prints made from PLA or ABS?

- PLA: ❌ Generally no. PLA’s tightly packed polymer chains prevent dye molecules from penetrating. Painting or airbrushing is a better option.

- ABS: ⚠️ Possible but tricky. ABS requires very high temperatures near its deformation point to accept dye, risking warping. Proceed with caution and precise temperature control.

What are the best dyes to use for coloring 3D prints?

Synthetic disperse dyes designed for polyester and nylon are best. Jacquard iDye Poly and Rit DyeMore for Synthetics are widely recommended for their vibrant colors and ease of use. For artistic effects on PVB or translucent prints, alcohol inks like Jacquard Piñata Alcohol Ink offer subtle, translucent finishes.

How long should you soak a 3D print in dye for vibrant colors?

Soaking time varies by material and desired intensity:

- Nylon: 10–20 minutes typically suffices.

- PETG: May require longer or higher temperatures.

- Longer soaking deepens color but risks warping or uneven absorption.

- Always monitor and test with short intervals to avoid over-dyeing.

Are there any safety tips for dyeing 3D printed objects?

Absolutely:

- Use dedicated equipment (pots, utensils) not used for food.

- Work in a well-ventilated area.

- Wear rubber gloves and eye protection.

- Avoid inhaling fumes from hot dye baths.

- Dispose of dye solutions responsibly and reuse when possible.

- Keep children and pets away from dyeing areas.

Can dyeing 3D prints affect their durability or finish?

Dyeing itself does not weaken the plastic because the dye molecules embed within the polymer chains. However, using alcohol inks excessively can weaken layer adhesion, especially on PVB or resin prints. Post-dye sealing with clear coats can protect the finish and enhance durability.

How do you achieve multi-color or gradient effects with dyeing?

By controlling immersion depth and timing, you can create gradient (ombré) effects by slowly pulling the print out of the dye bath. For multi-color designs, dye the lightest color first, mask off areas, then dye darker colors sequentially. Masking and sandblasting post-dye can also create striking two-tone effects.

Can you dye filament before printing?

Yes, but it’s tricky. Dyeing filament often results in uneven color penetration and can affect print quality. Dyeing finished prints yields more consistent and vibrant results. If you want to experiment, consider alcohol inks applied during filament unspooling for subtle effects.

📝 Reference Links and Scientific Studies on 3D Print Dyeing

-

Prusa3D Forum Discussion on Dyeing Filaments (PETG, PVB, Nylon, PLA):

https://forum.prusa3d.com/forum/english-forum-general-discussion-announcements-and-releases/dyeing-filaments-petg-pvb-nylon-pla/ -

Instructables Guide: Dye a 3D Printed Part : 6 Steps

https://www.instructables.com/Dye-a-3D-Printed-Part/ -

Jacquard iDye Poly Official Product Page

https://www.jacquardproducts.com/idye-poly -

Rit DyeMore for Synthetics Official Page

https://www.ritdye.com/type/dyemore-for-synthetics/ -

Jacquard Piñata Alcohol Ink Official Page

https://www.jacquardproducts.com/pinata-alcohol-ink -

Krylon Clear Coats for Post-Dye Protection

https://www.krylon.com/en/products/clear-coatings/uv-resistant-clear-coating

With these insights, tools, and safety tips, you’re well on your way to becoming a dyeing maestro. Remember, every print is a new canvas — so experiment, have fun, and let your creativity run wild! 🎨✨