Support our educational content for free when you purchase through links on our site. Learn more

How Long Does 3D Printing Take? ⏳ 12 Factors That Decide (2025)

Ever stared at your 3D printer’s progress bar and wondered, “Will this finish before my next coffee break… or next week?” You’re not alone! The truth is, 3D printing times can wildly vary—from a quick 30-minute trinket to a multi-day cosplay masterpiece. But what exactly controls this ticking clock? Is it the printer? The material? The model? Spoiler alert: it’s all of the above, and then some.

In this ultimate 2025 guide, we’ll unravel the 12 key factors that dictate how long your prints take, from model complexity and layer height to printer tech and post-processing. Plus, we’ll share insider tips from our 3D Printed™ team to help you slash print times without sacrificing quality. Ready to become a time-bending print wizard? Let’s dive in!

Key Takeaways

- Print time depends on multiple factors: model size, complexity, layer height, infill, material, and printer type all play crucial roles.

- Speed vs. quality is a balancing act: faster prints often mean lower detail or more post-processing.

- Post-processing can double your project time: support removal, curing, sanding, and painting add hours or days.

- Optimizing slicer settings and model design can drastically reduce print times.

- Choosing the right printer for your project (FDM vs. resin vs. SLS) impacts speed and finish.

- High-speed printers like Bambu Lab X1 Carbon and Creality K1 Max offer game-changing print speeds.

👉 Shop High-Speed 3D Printers:

Whether you’re a casual hobbyist or a pro designer, understanding these factors will help you plan your prints better, avoid frustrating delays, and get your masterpieces in hand faster. Ready to master the clock? Keep reading!

Table of Contents

- ⚡️ Quick Tips and Facts

- ⏱️ The Grand Question: Unraveling 3D Printing Duration

- 📜 A Glimpse into the Past: The Evolution of Print Speed

- ⚙️ The Time Bandits: Factors That Dictate Your Print Speed

- 1. 📏 Model Complexity & Size: From Tiny Trinkets to Titanic Builds

- 2. 📐 Layer Height & Resolution: The Devil’s in the Details (and the Time!)

- 3. 🕸️ Infill Density & Pattern: Hollow Hopes or Solid Solutions?

- 4. 🚀 Print Speed Settings: The Need for Speed (or Not!)

- 5. 🧵 Material Type: Filaments, Resins, and Powders – Oh My!

- 6. 🖨️ Printer Technology: FDM, SLA, SLS – A Race Against Time?

- 7. 🌡️ Cooling & Curing Requirements: Patience is a Virtue

- ⏳ Beyond the Print Bed: Pre-Print & Post-Print Time Considerations

- ⚡️ Turbocharging Your Prints: Strategies to Slash Print Times

- 🌍 Real-World Scenarios: How Long Do Common Prints Really Take?

- 🧘 The Patience Paradox: When Slow and Steady Wins the Race

- 🚧 Troubleshooting Time Traps: Common Delays and How to Avoid Them

- 🔮 The Future of Fast: What’s Next for 3D Printing Speed?

- ✅ Conclusion: Your Time, Your Print, Your Masterpiece!

- 🔗 Recommended Links

- ❓ FAQ

- 📚 Reference Links

⚡️ Quick Tips and Facts

So, you’re wondering, “How long does 3D printing take?” 🤔 It’s the million-dollar question, and honestly, it’s like asking “How long is a piece of string?” The answer is always: it depends! But don’t worry, we’re here to unravel that string for you. From our years of tinkering, printing, and occasionally pulling our hair out, we’ve gathered some quick insights:

- Average Print Time: For most common FDM (Fused Deposition Modeling) desktop printers, a small, simple object (think a keychain or a chess piece) can take anywhere from 30 minutes to a couple of hours. A medium-sized, moderately complex print (like a phone case or a small vase) might clock in at 4-8 hours. Large or highly detailed models? We’re talking 24 hours to several days! 🤯 As Raise3D aptly puts it, “Small, simple objects: ~1 hour. Complex designs: Several hours or days.”

- Speed vs. Quality: This is the eternal dilemma! You can almost always print faster, but you’ll likely sacrifice detail and surface finish. Conversely, aiming for museum-quality prints means slowing things way down. It’s a delicate dance!

- The “Cubic Inch” Rule of Thumb: While not precise, some estimate that a cubic inch of material can take anywhere from 20 minutes to over an hour to print, depending on all the variables we’re about to dive into.

- Beyond the Print: The actual printing time is just one piece of the puzzle. Don’t forget to factor in designing, slicing, printer setup, and crucial post-processing (like support removal, sanding, or curing for resin prints). This can add significant time!

- Durability vs. Speed: Ever wondered, Do 3D printed things last? Often, prints designed for durability might take longer due to higher infill or stronger materials.

⏱️ The Grand Question: Unraveling 3D Printing Duration

Alright, let’s get down to brass tacks. You’ve got a brilliant idea, a cool 3D model, and your printer is humming with anticipation. But then it hits you: “How long is this going to take?!” It’s a question that plagues every 3D printing enthusiast, from the absolute beginner to the seasoned pro. We’ve all been there, staring at the progress bar, willing it to move faster, or worse, realizing a 2-hour print just became a 12-hour marathon because of one tiny setting.

The truth is, there’s no single, universal answer. 3D printing isn’t like baking a cake where you just set a timer. It’s more like growing a bonsai tree – a delicate process influenced by countless variables. As Prtwd.com wisely states, “There are many factors that affect the time it takes to 3D print something, that’s why how long it takes to 3D print varies on a project basis.” So, let’s embark on a journey to demystify these “time bandits” and give you the power to predict (and even control!) your print durations. Ready to become a time-traveler of the print bed? Let’s go!

📜 A Glimpse into the Past: The Evolution of Print Speed

Before we dive into the nitty-gritty of current print times, let’s take a quick stroll down memory lane. When 3D printing first emerged from the labs in the 1980s, it was a slow, painstaking process. Early machines were clunky, expensive, and incredibly deliberate. Think of the first FDM patents by Chuck Hull of 3D Systems (though FDM specifically was developed by Scott Crump of Stratasys in the late 80s). These pioneers were more concerned with if they could print something, not how fast.

In those early days, a small prototype could take days, if not weeks, to complete. Materials were limited, and the software was rudimentary. Fast forward to the early 2010s with the rise of the RepRap movement and open-source hardware, and suddenly, 3D printers became accessible to the masses. This explosion of innovation, which you can read more about in our 3D Printing Innovations section, brought about a fierce competition for speed, reliability, and affordability.

Today, we have printers like the Bambu Lab X1 Carbon or the Creality K1 Max that boast incredible print speeds (up to 500-600mm/s!) that would have been unimaginable a decade ago. This leap in speed is thanks to advancements in motion systems (CoreXY kinematics), faster processors, better hotends, and sophisticated firmware like Klipper. It’s a far cry from the days when 50mm/s was considered “fast.” This historical context helps us appreciate just how far we’ve come and why understanding the underlying technology is key to mastering print times.

⚙️ The Time Bandits: Factors That Dictate Your Print Speed

Ah, the culprits! These are the primary variables that conspire to either speed up or slow down your 3D printing journey. Understanding them is your first step to becoming a print time wizard. Let’s break them down, one by one.

1. 📏 Model Complexity & Size: From Tiny Trinkets to Titanic Builds

This is perhaps the most obvious factor. A tiny, simple cube will print much faster than a massive, intricate dragon. But it’s not just about physical dimensions; complexity plays a huge role.

- Size (Volume): The larger the object, the more material it requires, and thus, the more time it takes for the printer to lay down that material. A keychain (say, 20x20x5mm) might be done in 30 minutes, while a full-size cosplay helmet could take days. Raise3D notes: “Small objects (keychain, chess piece): 30 minutes to an hour. Medium objects (smartphone case, vase): Up to 5-6 hours. Large objects (helmet, large decor): Over 24 hours or days.”

- Part Geometry & Detail: A solid, blocky object prints faster than one with intricate details, thin walls, or complex overhangs. Why? Because complex geometries often require more precise movements, slower speeds, and crucially, support structures. Lattice structures, for example, are notoriously time-consuming. As Raise3D points out, “Complex geometries, like lattice structures, take longer than solid cubes.”

- Hollow vs. Solid: A hollow model (with minimal infill) will print significantly faster than a solid one, as less material needs to be extruded. This is a common optimization strategy!

Our Anecdote: “I once tried to print a highly detailed miniature of a dragon for a D&D campaign,” recalls Alex from our team. “It was only about 10cm tall, but the wings had so many tiny, delicate scales and sharp points. My slicer estimated 18 hours! I almost fell out of my chair. I ended up scaling it down and simplifying some features in Tinkercad to cut it down to a more manageable 8 hours. Lesson learned: detail costs time!”

2. 📐 Layer Height & Resolution: The Devil’s in the Details (and the Time!)

Think of your 3D print as being built up layer by microscopic layer, like a stack of pancakes. Layer height is the thickness of each of those pancakes.

- Thinner Layers (e.g., 0.1mm): Result in higher resolution, smoother surfaces, and finer details. Perfect for miniatures, jewelry, or aesthetic pieces. However, the printer has to print more layers to achieve the same height, significantly increasing print time. Snapmaker’s “Smooth Surface” Benchy test at 0.12mm layer height took 2 hours 6 minutes, compared to 1 hour 10 minutes at 0.16mm.

- Thicker Layers (e.g., 0.2mm – 0.3mm+): Lead to faster prints but with more visible layer lines and less detail. Ideal for functional prototypes, large objects where aesthetics aren’t paramount, or quick drafts. Raise3D’s examples show a figurine at 0.1mm taking >6 hours, while a basic shape at 0.3mm+ takes 1-2 hours.

| Layer Height (FDM) | Resolution | Print Speed | Best For |

|---|---|---|---|

| 0.05mm – 0.1mm | Very High | Very Slow | Miniatures, jewelry, highly detailed models, smooth finishes |

| 0.15mm – 0.2mm | Good | Moderate | Balanced prints, functional parts, general models |

| 0.25mm – 0.3mm+ | Low | Fast | Prototypes, large objects, quick drafts, structural parts |

Pro Tip: For many functional prints, a 0.2mm layer height offers a great balance of speed and quality. For truly rapid prototyping, don’t be afraid to go up to 0.28mm or even 0.32mm if your nozzle and printer can handle it!

3. 🕸️ Infill Density & Pattern: Hollow Hopes or Solid Solutions?

Unless you’re printing a vase (which is typically a single wall, no infill), your 3D model will have an internal structure called infill. This lattice-like pattern provides strength and support to the outer walls.

- Density: This is the percentage of the internal volume that’s filled with material.

- Low Infill (5-15%): Fastest, uses least material, but results in weaker parts. Great for decorative items or models that don’t need to bear weight. Snapmaker’s “Fast Print” Benchy used sparse/low infill.

- Medium Infill (20-40%): A good balance of strength and print time. Suitable for most functional parts.

- High Infill (50-100%): Slowest, uses most material, but creates very strong, dense parts. Essential for mechanical components or parts under high stress. Raise3D states a 10-20% infill for decorative items might take ~4 hours, while 70-100% for mechanical parts could take >12 hours.

- Pattern: The shape of the infill (e.g., grid, honeycomb, gyroid, lightning). Some patterns are faster to print than others because they require less travel or simpler movements.

- Lightning Infill: This is a fantastic option for speed and material saving. It only prints infill where it’s needed to support the top layers, leaving the rest hollow. It’s surprisingly strong for many applications!

- Grid/Lines: Simple and fast, but can have issues with layer adhesion.

- Gyroid: Slower to print but offers excellent isotropic strength (strength in all directions) and uses less material than solid infill.

Our Take: “I almost always start with 10-15% infill for most of my prints,” says Sarah, our resident design guru. “Unless it’s a part that needs to withstand serious force, like a bracket for my workshop, I find that’s plenty strong and saves me hours of printing time. Plus, less filament used means more prints for my buck!”

4. 🚀 Print Speed Settings: The Need for Speed (or Not!)

This is the most direct way to influence print time. Your slicer software (like PrusaSlicer, Cura, or Simplify3D) allows you to set the speed at which your printer’s hotend moves.

- Higher Speeds (e.g., 80-150mm/s+): Faster prints, but can lead to reduced print quality (ghosting, ringing, poor layer adhesion, skipped steps) if your printer isn’t tuned for it. Modern printers like the Bambu Lab P1S or Creality K1 are designed for high speeds, often exceeding 200mm/s.

- Lower Speeds (e.g., 30-60mm/s): Slower prints, but generally result in higher quality, more accurate dimensions, and better adhesion. Ideal for detailed prints or challenging materials.

- Different Speeds for Different Features: Most slicers allow you to set different speeds for different parts of the print:

- Perimeters/Walls: Often printed slower for better surface finish.

- Infill: Can be printed much faster.

- First Layer: Crucially slow for optimal bed adhesion.

- Travel Speed: How fast the nozzle moves when not extruding. Faster travel reduces stringing and overall time.

Fact Check: Raise3D suggests that “Increasing print speed can cut printing time by 15-20%.” However, it’s a balancing act. Pushing your printer too fast can lead to failed prints, which means 100% wasted time!

Nozzle Size: This also ties into print speed. A larger nozzle (e.g., 0.6mm or 0.8mm) can extrude more plastic per second, allowing for faster prints, especially for larger objects or those where fine detail isn’t critical. A 0.6mm nozzle can reduce print time by up to 25% compared to a 0.4mm nozzle, according to Raise3D. However, it will also result in thicker layer lines and less detail.

5. 🧵 Material Type: Filaments, Resins, and Powders – Oh My!

The material you choose significantly impacts print time due to its specific thermal and mechanical properties.

- FDM Filaments:

- PLA (Polylactic Acid): Generally the fastest to print. It has a lower melting point and cools quickly, allowing for higher print speeds. It’s also very forgiving.

- PETG (Polyethylene Terephthalate Glycol): Slightly slower than PLA. Requires higher temperatures and can be more prone to stringing, which might necessitate slower retraction speeds.

- ABS (Acrylonitrile Butadiene Styrene): Slower than PLA and PETG. Requires higher temperatures and often an enclosed printer to prevent warping, which means slower cooling and potentially slower print speeds.

- TPU (Thermoplastic Polyurethane) / Flexible Filaments: These are notoriously slow. Their flexibility means they can buckle in the extruder if pushed too fast, often requiring print speeds of 20-40mm/s. Snapmaker notes this specifically.

- Nylon: Slower due to its need for good layer bonding and controlled cooling to prevent warping.

- Resin (SLA/DLP/LCD):

- While resin printers are often faster for highly detailed, small objects compared to FDM, their speed is determined by the exposure time per layer and the Z-axis lift speed. Faster resins require less exposure time. The total print time is less affected by the complexity of the layer (e.g., printing 10 miniatures on one plate takes roughly the same time as printing one, as long as they fit).

- Powder (SLS):

- SLS printers can be very fast for batch production of complex parts, as they don’t require supports. However, the pre-heating and post-cooling cycles of the powder bed can add significant time to the overall process.

Our Experience: “I remember my first attempt at printing with TPU,” says Mark, our resident troubleshooting expert. “I just used my standard PLA profile. The print failed spectacularly within minutes, a tangled mess of spaghetti! I had to drop the speed to a snail’s pace, and suddenly a 2-hour PLA print became a 6-hour TPU endurance test. It’s all about knowing your material!”

6. 🖨️ Printer Technology: FDM, SLA, SLS – A Race Against Time?

The fundamental technology your printer uses has a massive impact on how long it takes to create a part.

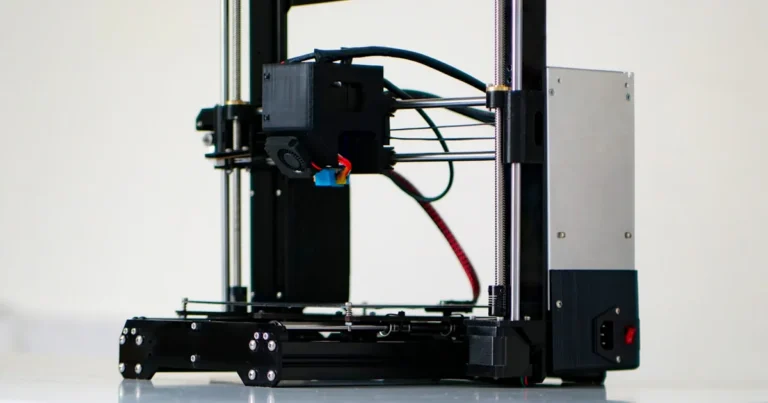

- FDM (Fused Deposition Modeling):

- How it works: Melts plastic filament and extrudes it layer by layer.

- Speed: Varies wildly. Hobbyist FDM printers typically operate between 20-100mm/s, but high-speed FDM printers can reach 500-600mm/s. Generally good for larger, less detailed objects.

- Examples: Creality Ender 3 V3 KE, Prusa i3 MK4, Bambu Lab X1 Carbon.

- Typical Print Time (small/medium): 1-8 hours. Raise3D suggests a standard vase takes 4-6 hours.

- SLA (Stereolithography) / DLP / LCD (Resin Printers):

- How it works: Uses a laser (SLA) or UV light (DLP/LCD) to cure liquid resin layer by layer.

- Speed: Often faster than FDM for small, highly detailed objects, especially when printing multiple items on the same build plate. The time per layer is constant regardless of how much is on the layer (within the build area). LCD printers tend to be faster than SLA due to curing an entire layer at once.

- Examples: Elegoo Mars 4 Ultra, Anycubic Photon Mono M5s, Formlabs Form 4.

- Typical Print Time (small/medium): 2-6 hours for a small, detailed figurine. Prtwd.com estimates ~5 hours for an SLA miniature and ~4 hours for an LCD miniature.

- SLS (Selective Laser Sintering):

- How it works: Uses a laser to fuse powdered material (like Nylon) layer by layer.

- Speed: Can be very efficient for batch production of complex, strong parts as no support structures are needed. However, the overall process (heating, printing, cooling) can be lengthy.

- Examples: Formlabs Fuse 1, Sinterit Lisa X.

- Typical Print Time (medium/complex): 10-12 hours for a complex part, plus significant cooling time.

| Technology | Best Use Case | Typical Speed Range | Pros for Speed | Cons for Speed |

|---|---|---|---|---|

| FDM | General purpose, large parts, functional prototypes | 20-600 mm/s | Fast for large, simple objects; continuous extrusion | Slower for fine detail; requires supports |

| SLA/DLP/LCD | High detail, miniatures, jewelry, smooth surfaces | Layer-based (seconds per layer) | Constant layer time regardless of complexity (within layer); excellent detail | Post-processing time; smaller build volumes |

| SLS | Complex geometries, strong functional parts, batch production | Layer-based (minutes per layer) | No supports needed; efficient batching | Long pre-heat/cool cycles; industrial scale |

7. 🌡️ Cooling & Curing Requirements: Patience is a Virtue

This factor is often overlooked when estimating print time, but it’s crucial, especially for certain materials and technologies.

- FDM Cooling: Proper cooling is essential for FDM prints to solidify quickly and prevent warping or drooping, especially for overhangs. PLA benefits from aggressive cooling, allowing faster printing. ABS, however, requires minimal or no cooling to prevent layer delamination and warping, which can slow down the overall process.

- Resin Curing: After a resin print is finished, it’s not truly done! It needs to be washed (to remove uncured resin) and then UV cured to achieve its final strength and hardness. This post-curing process can take anywhere from 10 minutes to several hours depending on the size of the part and the strength of your UV curing station. Raise3D estimates 1-2 hours for washing and curing SLA prints.

- SLS Cooling: SLS prints emerge from a hot powder bed. They need to cool down slowly and evenly to prevent warping and ensure part integrity. This cooling process can take many hours, sometimes even overnight, before the parts can be safely excavated from the powder bed. Raise3D suggests 2-4 hours for powder removal, but the cooling itself can be much longer.

Our Personal Story: “I once printed a batch of resin miniatures for a friend,” recounts Emily, our community manager. “The actual printing took about 3 hours for the whole plate. But then I spent another hour washing them, and they needed 30 minutes in the UV curing station. So, what seemed like a 3-hour print was actually closer to 4.5 hours of active work, plus the passive curing time. Always factor in the post-print steps!”

⏳ Beyond the Print Bed: Pre-Print & Post-Print Time Considerations

Thinking the clock stops when the print finishes? Think again! The journey from idea to finished object involves several crucial steps that add to your overall time investment. These are often forgotten but can be significant “time sinks.”

🎨 Design & Slicing Software Prep: The Digital Blueprint Phase

Before a single layer is laid down, you need a 3D model, and then you need to prepare it for your printer.

- 3D Model Creation/Acquisition:

- Designing from Scratch: If you’re creating your own model using 3D Design Software like Fusion 360, Blender, SolidWorks, or even simpler tools like Tinkercad, this can take anywhere from minutes for a simple shape to days or weeks for complex engineering parts or artistic sculptures. This is often the most time-consuming part of the entire process for custom projects.

- Downloading Pre-made Models: If you’re using a model from sites like Thingiverse, Cults3D, or MyMiniFactory, this step is much faster – just a few clicks!

- Slicing Software Preparation: Once you have your 3D model (usually an STL or OBJ file), you need to “slice” it. This involves using software like PrusaSlicer, Cura, or Simplify3D to convert the 3D model into G-code, which your printer understands.

- Orientation: Deciding how to orient your part on the build plate can drastically affect print time and support requirements. Minimizing height (Z-axis) often reduces time, as Raise3D notes.

- Support Generation: If your model has overhangs or bridges, you’ll need support structures. Generating these, especially complex ones, takes time in the slicer and adds to print time.

- Parameter Tweaking: Adjusting layer height, infill, print speed, temperatures, and other settings can take anywhere from 5 minutes for a standard profile to hours of fine-tuning for a challenging print or a new material. This is where you become the conductor of your print’s symphony!

Our Anecdote: “I spent an entire evening designing a custom organizer for my desk drawers in Fusion 360,” says Chris, our content lead. “The actual print time was about 6 hours for all the pieces, but the design phase was easily 4-5 hours of trial and error, measuring, and tweaking. It’s a hidden time cost, but so rewarding when it works!”

🛠️ Printer Setup & Calibration: Getting Ready for Liftoff

Even with a perfectly sliced file, your printer needs to be ready to go.

- Loading Filament/Resin: A quick task, usually a minute or two.

- Bed Leveling/Calibration: Crucial for successful first layers.

- Manual Leveling: Can take 5-15 minutes of careful adjustment.

- Auto-Leveling (e.g., BLTouch, CR-Touch): Much faster, often just a 1-2 minute routine before each print or once per session.

- Preheating: Your print bed and hotend need to reach their target temperatures. This can take 5-15 minutes depending on the printer and material. Raise3D suggests preheating the print bed as a speed-up tip.

- First Layer Inspection: We always recommend watching the first few layers. If bed adhesion fails here, you’ve wasted minutes, not hours, and can restart. This vigilance can save you from a “spaghetti monster” print failure hours later!

🧼 Support Removal & Finishing Touches: The Art of Post-Processing

The print is done! 🎉 But wait, there’s more. This is where the raw print transforms into a finished product.

- Support Removal: If your print required supports, you’ll need to remove them.

- Simple Supports: A few minutes with pliers or your fingers.

- Complex or Dense Supports: Can take tens of minutes to several hours of careful work, especially for delicate models or if supports are difficult to reach. Raise3D mentions complex supports might add 10 hours to a print, and removal can be lengthy.

- Water-soluble Supports (e.g., PVA): While they make removal easy, they require soaking time (hours) and can add to the overall process.

- Washing & Curing (for Resin Prints): As mentioned, resin prints need a wash in IPA (Isopropyl Alcohol) and then UV curing. This is a non-negotiable step. Raise3D estimates 1-2 hours for washing and curing SLA prints.

- Sanding & Smoothing: For FDM prints, if you want a smooth surface, you’ll be sanding. This can be a quick buff or hours of meticulous work with various grits.

- Painting & Finishing: This is where artistic flair comes in!

- Simple Paint Job: A few hours.

- Complex Multi-color Painting: Can take days or even weeks for highly detailed models like cosplay props or miniatures. Raise3D states a small figurine might take 1-3 days to paint, while a cosplay helmet could take a week or more.

- Other Finishes: Priming, filling, clear coating, or even metal plating (which can take 2-5 days for a medium object, according to Raise3D, or even 2-3 weeks for processes like gold plating as per Prtwd.com).

Table: Post-Processing Time Estimates

| Post-Processing Step | FDM (Typical) | Resin (SLA/DLP/LCD) (Typical) | SLS (Typical) |

|---|---|---|---|

| Support Removal | 10 min – 2 hrs | 5 min – 1 hr (often easier) | 0 (no supports) |

| Washing | N/A | 10 min – 30 min | N/A |

| Curing | N/A | 10 min – 2 hrs | N/A |

| Powder Removal | N/A | N/A | 2 – 4 hrs |

| Sanding/Smoothing | 30 min – 5 hrs | 10 min – 1 hr | N/A (rougher finish) |

| Painting/Finishing | 1 hr – Days | 1 hr – Days | 1 hr – Days |

As you can see, the “post-print” phase can easily double or triple your total project time, especially for high-quality or aesthetic pieces. Don’t underestimate it!

⚡️ Turbocharging Your Prints: Strategies to Slash Print Times

Alright, you’ve got the knowledge of the “time bandits.” Now, let’s talk about how to fight back! Here are our top strategies to speed up your 3D printing process without sacrificing too much quality. Remember, it’s always a balance!

1. 💡 Optimize Your Model: Less is Often More!

The fastest print is the one that uses the least material and has the simplest geometry.

- Scale Down: This is a no-brainer. A smaller model means less material and fewer layers. Raise3D states, “Printing a model at 80% of its original size could halve the printing time.” This is a powerful lever!

- Hollow Out: If your part doesn’t need to be solid, make it hollow or use minimal infill. This drastically reduces print time and material usage.

- Simplify Geometry: Can you remove unnecessary details or complex curves without compromising functionality or aesthetics? A simpler model means fewer complex movements for the printer.

- Design for Printability: When designing your own models, consider print orientation from the start. Minimize overhangs to reduce support material, and design parts that can be printed in separate, simpler pieces and then assembled. This is a core tenet of 3D Printable Objects.

2. 🎛️ Tweak Slicer Settings: Your Secret Speed Dial

Your slicer software is your control panel for print speed. Master it!

- Increase Layer Height: As discussed, going from 0.1mm to 0.2mm can significantly cut print time. For prototypes, even 0.28mm or 0.32mm can be acceptable.

- Reduce Infill Density: For non-structural parts, drop your infill to 5-10%. Consider “Lightning” infill for even faster results. Raise3D suggests 10-15% infill can substantially reduce time.

- Increase Print Speed (Overall & Specifics):

- Start by increasing the overall print speed setting.

- Then, fine-tune specific speeds: increase infill speed, travel speed, and potentially outer wall speed if quality isn’t paramount.

- Use a Larger Nozzle: Switching from a standard 0.4mm nozzle to a 0.6mm or even 0.8mm nozzle can dramatically reduce print time by allowing more material to be extruded per pass. This is especially effective for large, less detailed prints. Raise3D claims up to 25% reduction.

- Optimize Support Settings: Use tree supports (often more efficient), reduce support density, or use support blockers in your slicer to prevent supports in areas where they aren’t strictly necessary.

- Fewer Perimeters/Walls: Reduce the number of outer walls if strength isn’t critical. Fewer walls mean less extrusion time.

- Enable “Combing” or “Avoid Crossing Perimeters”: These settings can reduce travel moves and stringing, indirectly saving time by preventing print failures and reducing post-processing.

- Adaptive Layers: Some slicers offer adaptive layer height, where fine layers are used for detailed areas and thicker layers for simpler sections, optimizing both speed and quality.

Our Recommendation: “When I’m just testing a fit or concept, I’ll crank up the layer height to 0.28mm, drop the infill to 5% lightning, and use a 0.6mm nozzle on my Prusa MK3S+,” says Alex. “It’s ugly, but it prints in a fraction of the time, and that’s all I need for a quick iteration!”

3. 🎯 Choose the Right Printer for the Job: Speed vs. Precision

Not all printers are created equal when it comes to speed.

- High-Speed FDM Printers: If speed is your primary concern for FDM, invest in a printer designed for it. Look for features like CoreXY kinematics, powerful stepper motors, Klipper firmware, and high-flow hotends. Brands like Bambu Lab (e.g., X1 Carbon, P1S), Creality (e.g., K1, K1 Max), and Voron (DIY builds) are leading the charge here.

- 👉 CHECK PRICE on:

- Bambu Lab X1 Carbon: Bambu Lab Official

- Creality K1 Max: Amazon | Creality Official

- 👉 CHECK PRICE on:

- Resin Printers for Detail: For small, highly detailed objects, a resin printer (SLA/DLP/LCD) will often be faster and produce superior results than an FDM printer, as the layer cure time is often constant regardless of the complexity of the layer.

- 👉 CHECK PRICE on:

- Elegoo Mars 4 Ultra: Amazon | Elegoo Official

- Anycubic Photon Mono M5s: Amazon | Anycubic Official

- 👉 CHECK PRICE on:

- Consider a 3D Printing Service: If you need a part quickly and don’t have the right printer (or the time), a professional 3D printing service like Xometry or Shapeways can offer rapid turnaround times, often within days. Prtwd.com also suggests this as a speed-up method.

For more insights into different printer types, check out our 3D Printer Reviews section.

4. 🧪 Material Selection: The Unsung Hero of Print Duration

As we discussed, your filament or resin choice plays a role.

- PLA for Speed: For most general-purpose prints where extreme strength or heat resistance isn’t needed, PLA is your go-to for speed. It prints at lower temperatures and cools quickly, allowing for faster layer deposition.

- 👉 Shop PLA Filament on: Amazon | Prusa Research | Hatchbox Official

- Avoid Slow Materials (if time is critical): If you’re in a rush, try to avoid materials like TPU or certain engineering filaments that inherently require slower print speeds or specific environmental controls.

- Fast-Curing Resins: For resin printing, some resins are formulated for faster curing times, requiring less UV exposure per layer. This can shave minutes off each layer, adding up to significant time savings over a full print.

5. 🧩 Multi-Part Printing & Batching: Efficiency in Numbers

If you need multiple copies of a small part, or several different small parts, printing them simultaneously can be a huge time-saver.

- Batch Printing: Instead of printing one chess piece, then another, then another, arrange several on your build plate and print them all at once. For FDM, the print head will travel between them, but the overall time per part will be significantly reduced compared to sequential printing. Raise3D notes that “Printing four small gears simultaneously could be twice as fast as printing them one after the other.”

- Resin Printer Advantage: This is where resin printers truly shine. Printing 10 small miniatures on a resin printer takes almost the exact same amount of time as printing one, because the entire layer is cured simultaneously. The only difference is the amount of resin used.

- Sequential Printing (FDM): Some FDM printers and slicers allow for “sequential printing” or “print one at a time” mode. This means the printer completes one part entirely before moving to the next. This can be faster for multiple tall objects that would otherwise require the nozzle to travel over already printed parts, but it requires careful planning to avoid collisions.

Our Team’s Workflow: “Whenever I have a few small things to print, I’ll throw them all onto the build plate in Cura,” says Sarah. “Even if it adds an hour to the total print time, it means I don’t have to come back to the printer multiple times to start new jobs. It’s about optimizing my personal time as much as the printer’s!”

🌍 Real-World Scenarios: How Long Do Common Prints Really Take?

Let’s get practical! We’ve talked about the factors, but what does that mean for actual objects you might want to print? Here are some common examples based on our collective experience and industry benchmarks.

⛵ The Humble Benchy: A Rite of Passage

Ah, the 3D Benchy! This iconic little tugboat is the quintessential benchmark print for FDM printers. It’s designed to test overhangs, bridging, small details, and more. Almost every 3D printer enthusiast has printed at least one. You can find the model on Thingiverse.

- Dimensions: Approximately 60mm x 31mm x 48mm.

- Typical Print Time:

- Standard Quality (0.2mm layer, 20% infill, 60mm/s): 1 hour to 1 hour 30 minutes.

- Fast Print (0.24mm layer, 10% infill, 100mm/s+): 45 minutes to 1 hour. Snapmaker’s “Fast Print” Benchy at 0.24mm layer and 160mm/s took 50 minutes.

- High Quality (0.12mm layer, 25% infill, 40mm/s): 1 hour 45 minutes to 2 hours 30 minutes. Snapmaker’s “Smooth Surface” Benchy at 0.12mm layer and 60mm/s took 2 hours 6 minutes.

Our Benchy Story: “My very first Benchy on my Ender 3 V2 took almost 2 hours,” recalls Mark. “I was so impatient! But it came out surprisingly well. Now, with a tuned Klipper setup and a 0.6mm nozzle, I can blast out a decent Benchy in about 35 minutes. It’s a great way to see how far your printer has come!”

📱 A Custom Phone Case: Practicality in a Pinch

A popular functional print, a custom phone case can be a quick and practical project. You can find many designs on MyMiniFactory.

- Dimensions: Varies by phone model, but typically around 150mm x 75mm x 10mm.

- Material: Often PLA or PETG for rigidity, or TPU for flexibility.

- Typical Print Time (FDM):

- PLA/PETG (0.2mm layer, 15-20% infill): 3 to 6 hours.

- TPU (0.2mm layer, 15-20% infill, slower speed): 6 to 10 hours.

- Typical Print Time (Resin – for rigid cases):

- Standard Resin (0.05mm layer): 2 to 4 hours (plus post-processing).

User Review Snippet: “I printed a custom iPhone 15 Pro Max case in TPU on my Prusa MK4. It took about 7 hours, but the fit is perfect, and it feels great in hand. Worth the wait!” – Reddit User, r/3Dprinting

🎭 A Complex Cosplay Prop: Epic Builds, Epic Times

This is where print times really start to soar! Cosplay props often involve large, intricate pieces that need to be strong and detailed. Think helmets, armor pieces, or weapon replicas. You can find amazing cosplay models on Cults3D.

- Dimensions: Can be very large, often requiring multiple parts to be printed and assembled.

- Material: Usually PETG or ABS for durability, or PLA for easier printing and finishing.

- Typical Print Time (FDM):

- A single helmet piece (e.g., front half, 0.2mm layer, 15-20% infill): 12 to 36 hours.

- An entire helmet (multiple pieces): 3 to 7 days of continuous printing, often spread over weeks with breaks.

- Full armor set: Weeks to months of printing.

- Post-Processing: This is where the real time sink is for cosplay. Sanding, filling, priming, painting, and assembly can easily add days to weeks to the total project time. Raise3D mentions a cosplay helmet painting can take a week or more.

Our Cosplay Saga: “My partner was obsessed with making a full Mandalorian helmet,” shares Emily. “We printed it on our Creality CR-10S Pro V2 in four main pieces. Each piece was about 24-30 hours. So, just the printing was over 4 days! Then came the sanding, filling with Bondo, more sanding, priming, painting… that was another two weeks of evenings and weekends. It looked incredible, but it was a true test of patience!”

🔧 A Functional Prototype: From Idea to Iteration

For engineers, designers, or hobbyists developing new products, 3D printing is invaluable for rapid prototyping. The goal here is often speed and iteration, not necessarily perfect aesthetics.

- Dimensions: Highly variable, from small brackets to medium-sized enclosures.

- Material: Often PLA or PETG for ease of printing and reasonable strength.

- Typical Print Time (FDM):

- Small bracket/connector (0.28mm layer, 10% infill, 100mm/s+): 1 to 3 hours.

- Medium enclosure/housing (0.2mm layer, 15% infill): 5 to 12 hours.

- Typical Print Time (Resin – for detailed prototypes):

- Small, intricate mechanical part (0.05mm layer): 2 to 5 hours (plus post-processing).

Fact: Many companies use 3D printing to go from concept to physical prototype in a matter of hours or days, drastically reducing development cycles compared to traditional manufacturing methods. This is a huge win for 3D Printing in Education and industry alike.

🧘 The Patience Paradox: When Slow and Steady Wins the Race

We’ve spent a lot of time talking about how to speed things up, but here’s a little secret: sometimes, the best way to save time is to slow down. 🤯

It sounds counterintuitive, right? But think about it. Pushing your printer to its absolute limits can lead to:

- Print Failures: A print that fails halfway through means 100% wasted time, filament, and effort. You have to clean the bed, potentially clear a clog, and start all over again. A 10-hour print that fails at hour 8 is far worse than a 12-hour print that succeeds on the first try.

- Poor Quality: A print that finishes quickly but looks terrible, has weak layer adhesion, or is dimensionally inaccurate might not be fit for purpose. You might end up reprinting it anyway, or spending hours in post-processing trying to fix flaws.

- Increased Post-Processing: Faster prints often mean more visible layer lines, stringing, or artifacts that require more sanding, scraping, or cleaning. This can negate any time saved during the actual printing.

Our Philosophy: “I’ve learned the hard way that a little patience goes a long way,” says Chris. “I used to try to print everything at 150mm/s. Now, for anything important, I’ll dial it back to 80-100mm/s, maybe even 60mm/s for the outer walls. The print quality is so much better, and I rarely have failures. It means less frustration and ultimately, less wasted time.”

So, before you hit that “print” button, ask yourself: Is speed truly the most important factor for this specific print? Or would a slightly longer, more reliable print save you headaches (and time!) in the long run? For critical functional parts or highly aesthetic models, embracing the “patience paradox” is often the wisest choice.

🚧 Troubleshooting Time Traps: Common Delays and How to Avoid Them

Even with the best planning, things can go wrong. These “time traps” can turn a quick print into an all-day (or all-night) ordeal. Knowing them is half the battle!

- 1. ❌ Failed First Layer Adhesion:

- The Trap: The filament doesn’t stick to the build plate, resulting in a spaghetti mess or the print detaching early.

- Time Lost: Minutes to hours of print time, plus cleanup.

- Avoid It: Calibrate your bed regularly (manual or auto-leveling). Ensure your bed is clean (IPA for most surfaces, soap and water for glass). Use adhesion aids like glue stick (Elmer’s Purple Glue Stick is a team favorite!), hairspray, or PEI sheets. Get your first layer Z-offset dialed in perfectly – it should be slightly squished, not round.

- 2. ❌ Clogged Nozzle:

- The Trap: Filament stops extruding, leaving gaps or an incomplete print.

- Time Lost: Hours of print time, plus significant troubleshooting and repair time.

- Avoid It: Use quality filament. Ensure proper retraction settings to prevent heat creep. Don’t leave your hotend at high temperatures for extended periods without printing. Perform cold pulls or hotend cleanings periodically.

- 3. ❌ Filament Run-Out or Tangling:

- The Trap: Your spool runs out, or the filament gets tangled, stopping the print.

- Time Lost: Print pauses, potential print failure if not caught quickly, time to untangle/replace.

- Avoid It: Weigh your filament before large prints or use a filament run-out sensor. Store filament properly to prevent tangles. Always check your spool before a long print!

- 4. ❌ Power Outages or Printer Crashes:

- The Trap: Unexpected power loss or software/firmware glitch.

- Time Lost: Entire print lost (unless your printer has power-loss recovery).

- Avoid It: Use a UPS (Uninterruptible Power Supply) for critical prints. Ensure your printer’s firmware is stable. Many modern printers (like the Prusa i3 MK4) have excellent power-loss recovery features.

- 5. ❌ Warping or Layer Delamination:

- The Trap: Corners lift off the bed, or layers separate mid-print.

- Time Lost: Hours of print time, plus wasted material.

- Avoid It: Use an enclosure for materials like ABS. Ensure proper bed temperature and cooling settings for your material. Use a brim or raft for better bed adhesion.

- 6. ❌ Leaving Printer On Overnight / Unattended:

- The Trap: While convenient, it carries risks like filament jams, print failures, or even fire hazards. Snapmaker specifically warns against this.

- Time Lost: Potentially catastrophic failure, fire, or just a ruined print.

- Avoid It: Install smoke detectors near your printer. Ensure your printer has thermal runaway protection enabled (a critical safety feature!). Consider a webcam for remote monitoring (e.g., using OctoPrint). Use quality power supplies. If you must print overnight, ensure your setup is robust and safe.

- 7. ❌ Pausing and Resuming Prints:

- The Trap: While possible, pausing a print for an extended period (e.g., overnight) can lead to visible layer lines, poor adhesion at the pause point, or even nozzle clogs.

- Time Lost: Potential print quality degradation, leading to reprinting.

- Avoid It: Only pause if absolutely necessary. If you do, try to pause at a layer change, allow for partial cooling, and ensure the bed temperature is similar when resuming.

By being proactive and understanding these common pitfalls, you can significantly reduce the chances of a print failure, ultimately saving you precious time and filament!

🔮 The Future of Fast: What’s Next for 3D Printing Speed?

We’ve come a long way from the snail-paced printers of yesteryear, but the quest for speed is far from over! The 3D printing world is constantly innovating, and here’s what we’re excited about for the future of rapid fabrication:

- Input Shaping & Klipper Firmware: These technologies are already revolutionizing FDM speeds. By compensating for vibrations and resonances in the printer’s frame, input shaping allows for much faster accelerations and print speeds without sacrificing quality. Klipper, an open-source firmware, enables this and more, pushing desktop FDM printers to speeds previously only seen in industrial machines.

- High-Flow Hotends & Extruders: To print faster, you need to melt and push plastic faster. New hotend designs (like the Rapido Hotend or Revo High Flow) and high-performance extruders (like Bondtech LGX or Orbiter) are being developed to handle extreme flow rates, allowing for faster material deposition.

- Multi-Nozzle & Multi-Tool Systems: Imagine a printer with multiple print heads working simultaneously on different parts of the same object, or even different materials! While some multi-nozzle systems exist (like the Prusa XL), they are becoming more refined and common, promising significant speed gains for complex or multi-material prints.

- Faster Resin Curing: For resin printers, advancements in UV light sources (e.g., more powerful LEDs, larger arrays) and more reactive resins are constantly reducing layer exposure times, making resin printing even faster. Projects like Carbon’s Digital Light Synthesis (DLS) technology, which uses oxygen-permeable windows to achieve continuous liquid interface production, are already demonstrating incredible speeds in industrial settings.

- Automated Post-Processing: The biggest time sink often comes after the print. We’re seeing more automated solutions for support removal (e.g., dissolvable supports, automated washing stations for resin), and even robotic arms for sanding and finishing. This will drastically reduce the overall time from digital model to finished product.

- AI-Powered Slicing: Imagine a slicer that uses artificial intelligence to analyze your model and printer, then automatically optimizes every setting for the fastest possible print without compromising quality. This isn’t science fiction; it’s already in development!

The future of 3D printing is undeniably fast, efficient, and increasingly automated. So, while your current print might take a while, rest assured that tomorrow’s machines are already being engineered to shave off those precious hours!

✅ Conclusion: Your Time, Your Print, Your Masterpiece!

Phew! What a journey through the fascinating world of 3D printing times. We’ve unraveled the mystery behind that ever-elusive question: “How long does 3D printing take?” From the tiniest keychain to the most epic cosplay helmet, the answer is a complex tapestry woven from your model’s size and complexity, printer technology, material choice, and your own patience (or impatience!).

Remember, speed and quality are often at odds, but with smart choices—like optimizing your model, tweaking slicer settings, and picking the right printer and material—you can find the sweet spot that fits your project and timeline. Whether you’re printing a quick prototype or a detailed miniature, understanding these factors empowers you to plan better and avoid those dreaded time traps.

And speaking of printers, if you’re looking to turbocharge your print times, consider high-speed models like the Bambu Lab X1 Carbon or Creality K1 Max—they’re game changers in the speed department without sacrificing quality. For detailed miniatures, resin printers like the Elegoo Mars 4 Ultra offer a fantastic balance of speed and precision.

So, next time you hit “Print,” you’ll know exactly what to expect—and how to make it faster, smoother, and more enjoyable. Because at the end of the day, your print is not just an object; it’s your masterpiece, crafted layer by layer with care and knowledge.

Happy printing, and may your prints always finish on time! 🚀✨

🔗 Recommended Links

👉 CHECK PRICE on:

- Bambu Lab X1 Carbon: Amazon | Bambu Lab Official Website | Thingiverse

- Creality K1 Max: Amazon | Creality Official Website | Thingiverse

- Elegoo Mars 4 Ultra: Amazon | Elegoo Official Website | MyMiniFactory

- Anycubic Photon Mono M5s: Amazon | Anycubic Official Website | Thingiverse

Books on 3D Printing Speed and Optimization:

- 3D Printing Failures: How to Diagnose and Repair All 3D Printing Issues by Sean Aranda — Amazon

- Mastering 3D Printing by Joan Horvath and Rich Cameron — Amazon

- 3D Printing: The Next Industrial Revolution by Christopher Barnatt — Amazon

❓ FAQ

What factors affect the speed of 3D printing?

Several key factors influence how long your 3D print will take:

- Model Size and Complexity: Larger and more intricate models require more layers and complex movements, increasing print time.

- Layer Height: Thinner layers mean more layers to print, increasing time but improving detail.

- Infill Density and Pattern: Higher infill percentages and complex patterns take longer.

- Print Speed Settings: Faster speeds reduce time but may compromise quality.

- Material Type: Some materials require slower speeds or longer cooling times.

- Printer Technology: FDM, SLA, and SLS have different speed profiles.

- Support Structures: More supports add to print time.

- Post-Processing Needs: Washing, curing, sanding, and painting add hours or days.

Understanding these helps you balance speed and quality effectively.

Read more about “Is PLA Biodegradable? 15 Truths Every 3D Printer Must Know (2025) 🌿”

How can I estimate the print time for my 3D printing project?

Estimating print time involves:

- Using Your Slicer Software: Most slicers (Cura, PrusaSlicer, Simplify3D) provide print time estimates based on your settings.

- Considering Model Size and Layer Height: Larger models and finer layers increase time.

- Factoring in Printer Speed and Material: Different printers and materials print at different speeds.

- Adding Post-Processing Time: Don’t forget support removal, curing, and finishing.

For rough guidance, a cubic inch of material can take 20 minutes to over an hour, but always rely on your slicer’s estimate and experience.

Read more about “What Are Most 3D Printed Objects Made of Today? Top 11 Materials (2025) 🛠️”

What is the average print time for common 3D printing objects?

- Small Objects (keychains, chess pieces): 30 minutes to 1 hour.

- Medium Objects (phone cases, vases): 3 to 6 hours.

- Large or Detailed Objects (helmets, cosplay props): 12 hours to several days.

- Miniatures (resin prints): 2 to 6 hours plus post-processing.

These are averages; your actual times may vary based on settings and printer.

Read more about “What is the Most Complex 3D Printed Object? Top 10 Revealed! 🤯 …”

Can I speed up 3D printing time without sacrificing quality?

Absolutely, but it requires smart trade-offs:

- Optimize Model Design: Simplify geometry, hollow out parts, and scale down where possible.

- Adjust Slicer Settings: Increase layer height, reduce infill, use faster print speeds selectively.

- Use Larger Nozzles: Allows more material extrusion per pass.

- Choose the Right Printer: High-speed printers can maintain quality at faster speeds.

- Batch Print: Print multiple parts simultaneously to save setup time.

However, pushing too hard can cause print failures or poor quality, so test and tune carefully.

Read more about “50+ Must-Have 3D Printing Resources for Makers in 2025 🚀”

How important is post-processing time in the overall 3D printing timeline?

Post-processing can often take as long or longer than the print itself, especially for resin or highly detailed prints. Tasks like support removal, washing, curing, sanding, and painting add hours or days. Planning for this is essential to get your final product ready on time.

Read more about “Unlocking the Secrets of 3D Printing Polymers: 10 Must-Know Insights for 2024! 🚀”

Is it safe to leave my 3D printer running overnight to save time?

While tempting, leaving your printer unattended overnight carries risks such as filament jams, print failures, or even fire hazards. If you must, ensure your printer has thermal runaway protection, use a smoke detector nearby, and consider remote monitoring with a webcam. Safety first!

📚 Reference Links

- Raise3D: How Long Does 3D Printing Take?

- Snapmaker: How Long Does It Take to 3D Print Something?

- Prtwd.com: How Long Does 3D Printing Take?

- Bambu Lab Official: https://us.store.bambulab.com/

- Creality Official: https://www.creality.com

- Elegoo Official: https://www.elegoo.com

- Anycubic Official: https://www.anycubic.com

- PrintAWorld: How Long Does 3D Printing Take in 2021

For more tips and guides, visit our 3D Printable Objects and 3D Printing Innovations categories at 3D Printed™!