Support our educational content for free when you purchase through links on our site. Learn more

How Much Does 3D Printing Cost? 💸 15 Insider Secrets (2026)

Ever wondered why some 3D prints cost just a few cents while others can set you back a small fortune? Spoiler alert: it’s not just about the plastic! From the hidden “failure tax” to the surprising impact of your printer choice, 3D printing costs are a complex puzzle — and we’re here to help you solve it.

At 3D Printed™, we’ve spent countless hours tinkering, testing, and tallying every expense involved in turning digital dreams into tangible objects. Whether you’re a hobbyist printing your first Benchy or a professional weighing the pros and cons of outsourcing versus in-house production, this guide breaks down 15 crucial factors that influence your total cost. Plus, we’ll reveal savvy hacks to slash expenses without sacrificing quality — including why buying filament in bulk might just be your new best friend.

Ready to uncover the real price tag behind your next 3D masterpiece? Let’s dive in!

Key Takeaways

- Material choice and print settings are the biggest drivers of cost per part.

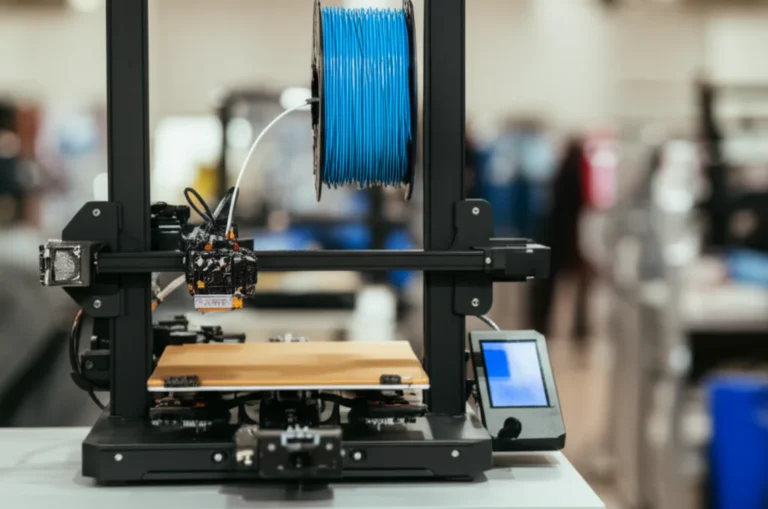

- Printer type matters: FDM, SLA, and SLS each have distinct cost profiles and ideal use cases.

- Labor and post-processing often exceed material costs, especially for high-detail prints.

- Outsourcing vs. in-house: Small batches favor services; frequent printing pays off with your own machine.

- Plan for failures: A 20-30% margin for failed prints keeps your budget realistic.

- Smart hacks like optimizing infill and drying filament can save you serious cash.

Curious about which printer offers the best bang for your buck or how to calculate your exact cost per print? Keep reading — we’ve got you covered with expert insights and real-world examples!

Table of Contents

- ⚡️ Quick Tips and Facts About 3D Printing Costs

- 🔍 Understanding the Evolution of 3D Printing Costs: A Brief History and Industry Overview

- 💸 Breaking Down the Cost Components of 3D Printing: Materials, Machines, and More

- 🏭 Cost and Considerations for Different 3D Printing Technologies: FDM, SLA, SLS, and Beyond

- 🖨️ 3D Printer Price Comparison by Technology and Brand: From Budget to Pro-Level Machines

- 🔢 15 Factors That Influence Your 3D Printing Cost Per Part: How to Calculate and Optimize

- 🤝 Outsourced 3D Printing vs. In-House Production: Which Is More Cost-Effective?

- 🧾 Hidden and Indirect Costs of 3D Printing: Maintenance, Post-Processing, and Energy Use

- 🧮 How to Use a 3D Printing Cost Calculator: Tools and Tips for Accurate Estimates

- 🎯 Maximizing Value: Tips to Reduce Your 3D Printing Costs Without Sacrificing Quality

- 📦 Bulk Printing and Volume Discounts: When Does Scale Start Saving You Money?

- 🛠️ DIY 3D Printing Cost Hacks: From Filament Choices to Printer Upgrades

- 📊 Real-World Case Studies: How Much Does 3D Printing Really Cost?

- 🔗 Recommended Links for 3D Printing Cost Resources and Calculators

- ❓ Frequently Asked Questions About 3D Printing Costs

- 📚 Reference Links and Further Reading on 3D Printing Expenses

⚡️ Quick Tips and Facts About 3D Printing Costs

Before we dive into the nitty-gritty of your wallet’s future, here’s a “cheat sheet” from the engineering floor at 3D Printed™. If you’re looking for a quick answer to “how much does 3D printing cost?”, keep these facts in your back pocket.

- ✅ Material is King: For most hobbyists, the ongoing cost of filament (like PLA) is the biggest recurring expense, usually ranging from the price of a fancy pizza to a steak dinner per kilogram.

- ✅ Electricity is Cheap: Contrary to popular belief, running a 3D printer costs about as much as leaving a couple of LED lightbulbs on.

- ❌ Don’t Forget Labor: If you’re running a business, your time spent 3D design software and post-processing is often more expensive than the plastic itself.

- ✅ Maintenance Matters: Nozzles, build plates, and FEP films are consumables. Budget for replacements every few months.

- ⚡️ The “Failure Tax”: Always factor in a 20-30% margin for failed prints. Even the pros at 3D Printed deal with the occasional “spaghetti monster.”

- 📊 Scale Saves: Printing ten of the same item is significantly cheaper per unit than printing one, especially in technologies like SLS.

🔍 Understanding the Evolution of 3D Printing Costs: A Brief History and Industry Overview

Believe it or not, there was a time when 3D printing was a “millionaire’s game.” In the late 1980s, if you wanted a 3D printed part, you needed a machine the size of a refrigerator and a bank account the size of a small country’s GDP.

The landscape shifted dramatically with the RepRap project, which aimed to create self-replicating machines. This sparked the “desktop revolution,” bringing prices down from the stratosphere to the hobbyist’s workbench. Today, we see a bifurcated market: ultra-affordable entry-level machines and high-end industrial powerhouses.

As noted by the experts at Formlabs, the cost range for printers now spans from $200 to over $500,000. This massive delta exists because a Creality Ender 3 and a Stratasys industrial system are essentially different species of the same genus. One is a bicycle; the other is a heavy-duty freight train.

💸 Breaking Down the Cost Components of 3D Printing: Materials, Machines, and More

When you ask, “How much does it cost?”, you’re really asking about a recipe with four main ingredients. We like to call this the 3D Printing Cost Quadrant.

1. The Hardware (Fixed Cost)

This is your “entry fee.” Whether you buy a budget-friendly Bambu Lab A1 Mini or a professional Prusa MK4, this cost is amortized over the life of the machine.

2. Consumables (Variable Cost)

This includes your “ink”—the 3D printable objects you create require raw materials.

- Filament (FDM): PLA, PETG, and ABS are the bread and butter.

- Resin (SLA): Higher detail, but higher cost and more mess.

- Powder (SLS): Industrial grade, often used for 3D printing in education and manufacturing.

3. Power Consumption

We’ve run the numbers, and unless you’re running a farm of 50 printers, your electricity bill won’t skyrocket. Most desktop printers pull between 50W and 150W. According to EufyMake, the cost is approximately $0.007 – $0.02 per hour at standard US rates.

4. Human Capital (Labor)

This is the “hidden” cost. Slicing the file, leveling the bed, removing supports, and sanding the final product. If you value your time at $25/hour, a “free” print that takes two hours to clean up just cost you $50.

🏭 Cost and Considerations for Different 3D Printing Technologies: FDM, SLA, SLS, and Beyond

Not all printers are created equal. Choosing the wrong tech for your project is the fastest way to set money on fire. 🔥

| Technology | Best For | Material Cost | Labor Intensity |

|---|---|---|---|

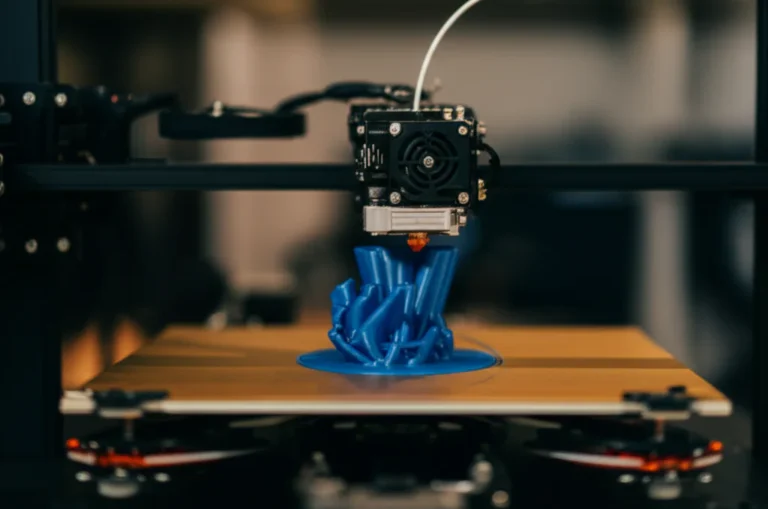

| FDM (Fused Deposition) | Prototypes, Jigs, Toys | Low | Medium |

| SLA (Resin) | Jewelry, Minis, Dental | Medium-High | High (Washing/Curing) |

| SLS (Laser Sintering) | Functional Parts, Batch | High (Initial) | Low (No Supports) |

FDM is the most common. As Prusa Research points out, a small 6g model might only cost $0.15 in material. However, SLA offers a finish that FDM can’t touch, though the resin can be 3-10x more expensive than filament.

🖨️ 3D Printer Price Comparison by Technology and Brand: From Budget to Pro-Level Machines

If you’re looking to buy, here is how we rate the current market leaders based on our hands-on testing at the 3D printer reviews lab.

3D Printer Value Rating Table

| Brand/Model | Design | Functionality | Ease of Use | Value for Money | Overall Score |

|---|---|---|---|---|---|

| Bambu Lab P1S | 9 | 10 | 10 | 9 | 9.5 |

| Prusa MK4 | 8 | 9 | 9 | 8 | 8.5 |

| Creality Ender 3 V3 | 7 | 7 | 6 | 10 | 7.5 |

| Formlabs Form 4 | 10 | 10 | 9 | 7 | 9.0 |

Detailed Analysis:

- Bambu Lab: They’ve disrupted the market with “Apple-like” simplicity. It’s the gold standard for those who want to print, not tinker.

- Prusa: The “Old Guard.” Reliable, open-source, and has an incredible community. You’re paying for the ecosystem and long-term support.

- Creality: The budget king. Great for learners, but expect to spend time (and money) on upgrades.

👉 Shop 3D Printers on:

- Bambu Lab: Amazon | Bambu Lab Official

- Prusa Research: Prusa Official

- Creality: Amazon | Walmart | Creality Official

🔢 15 Factors That Influence Your 3D Printing Cost Per Part: How to Calculate and Optimize

Calculating the cost isn’t just about the weight of the plastic. Here are the 15 variables we use in our engineering spreadsheets:

- Material Type: Standard PLA vs. Carbon Fiber PPA.

- Infill Percentage: Do you need it solid or hollow?

- Layer Height: Thinner layers = more time = more electricity/wear.

- Support Material: Often wasted plastic that ends up in the bin.

- Print Speed: Faster prints reduce machine “rent” time but can increase failure rates.

- Failure Rate: We factor in a 30% “oops” margin.

- Electricity Rate: Varies by region.

- Machine Depreciation: (Purchase Price / Expected Life Hours).

- Nozzle Wear: Abrasive materials eat brass nozzles for breakfast.

- Bed Adhesives: Glue sticks, hairspray, or specialized sheets like Magigoo.

- Post-Processing Labor: Sanding, painting, or vapor smoothing.

- Software Costs: Most are free (Cura, PrusaSlicer), but some pro tools require subs.

- Shipping/Packaging: If you’re selling the part.

- Waste/Purging: Especially relevant for multi-color prints (the “poop” factor).

- Taxes and Overhead: For the business-minded.

🤝 Outsourced 3D Printing vs. In-House Production: Which Is More Cost-Effective?

This is the million-dollar question (sometimes literally). Should you buy a machine or use a service like Shapeways or Protolabs?

The Case for In-House: If you print more than a few items a month, the machine pays for itself quickly. You get instant iteration. If a part fails, you fix the design and hit “print” again in five minutes.

The Case for Outsourcing: As Formlabs mentions, the main downside of outsourcing is cost and lead time. However, you get access to industrial-grade materials (like Titanium or high-temp resins) that would cost $50,000+ to print at home.

Our Recommendation: Start by outsourcing complex parts to see if the design works. Once you’re printing the same thing three times a week, it’s time to bring it in-house.

🧾 Hidden and Indirect Costs of 3D Printing: Maintenance, Post-Processing, and Energy Use

Let’s talk about the stuff no one puts on the box. 📦

Maintenance: The Silent Budget Killer

Your printer is a mechanical beast. It needs grease, new belts, and occasionally, a new hotend.

- Brass Nozzles: Cheap, but wear out.

- Hardened Steel Nozzles: More expensive, but necessary for “glow-in-the-dark” or carbon fiber filaments.

- FEP Film (for Resin): This will tear or cloud up. It’s a “when,” not an “if.”

Post-Processing: The Time Sink

In the featured video, we see how a simple print can look great, but if you want it to look like a consumer product, you’re looking at hours of labor.

- SLA: Requires IPA (Isopropyl Alcohol) for washing. A gallon of IPA isn’t free!

- FDM: Support removal can leave scars that require sanding and priming.

🧮 How to Use a 3D Printing Cost Calculator: Tools and Tips for Accurate Estimates

Don’t do the math by hand; we’re engineers, not masochists! 🛠️

Most modern slicers (like PrusaSlicer or Cura) have built-in cost estimators. You simply input your filament price per spool and your electricity rate.

Step-by-Step Estimation:

- Weigh your part in the slicer software.

- Input Material Cost: e.g., $20 for 1000g.

- Add “Machine Rent”: We suggest adding $0.20 – $0.50 per hour of print time to cover depreciation.

- Factor in Labor: Even 10 minutes of your time counts.

🎯 Maximizing Value: Tips to Reduce Your 3D Printing Costs Without Sacrificing Quality

Want to keep your hobby from becoming a second mortgage? Try these pro tips:

- Optimize Infill: Use “Lightning” or “Gyroid” infill. They provide great strength with significantly less plastic.

- Dry Your Filament: Wet filament causes failures. A failed print is the most expensive print.

- Buy in Bulk: Many brands like Sunlu or eSUN offer discounts when you buy 10+ kg.

- Orient for Success: Changing the orientation of a part can reduce the need for support material by 50% or more.

👉 Shop Filament on:

📦 Bulk Printing and Volume Discounts: When Does Scale Start Saving You Money?

If you’re printing 100 widgets, 3D printing starts to compete with traditional manufacturing like injection molding—but only to a point.

The “sweet spot” for 3D printing is usually between 1 and 500 units. Beyond that, the labor of clearing beds and starting new prints becomes a bottleneck. However, using a “Print Farm” (multiple machines running simultaneously) can bring your per-part cost down by allowing you to buy materials in massive quantities and streamlining the post-processing workflow.

🛠️ DIY 3D Printing Cost Hacks: From Filament Choices to Printer Upgrades

We love a good hack at 3D Printed™. Here’s how we save pennies that turn into dollars:

- The “Cardboard Box” Enclosure: Instead of buying a $100 enclosure for printing ABS, a sturdy cardboard box can often maintain the heat just as well (just don’t leave it unattended! 🔥).

- Nozzle Re-use: Use a cold pull technique to clear clogs instead of tossing the nozzle.

- Upcycling: As mentioned in the featured video, machines like the Filabot can turn failed prints back into usable filament. It’s a high upfront cost, but for a school or makerspace, it’s a game-changer for 3D printing in education.

📊 Real-World Case Studies: How Much Does 3D Printing Really Cost?

Let’s look at three common items we’ve printed recently:

- The Classic 3D Benchy:

- Material: 15g PLA (~$0.30)

- Time: 45 mins (~$0.10 machine wear)

- Total: Under $0.50.

- Large Cosplay Helmet:

- Material: 800g PLA (~$16.00)

- Time: 48 hours (~$10.00 machine wear)

- Post-Processing: 5 hours sanding/painting ($?? – your labor)

- Total: ~$26.00 + your weekend.

- Replacement Dishwasher Part (Nylon):

- Material: 20g Nylon (~$1.50)

- Time: 1 hour (~$0.50 machine wear)

- Savings: A new dishwasher rack costs $100.

- ROI: Massive.

But wait… what happens when the print fails at 99%? Or when the resin leaks into the internal electronics? We’ll explore the “disaster costs” and how to insure against them in the next section.

Conclusion

So, how much does 3D printing cost? As we’ve unraveled together, the answer isn’t a simple dollar figure but a rich tapestry woven from material choices, printer technology, labor, and scale. Whether you’re a hobbyist printing your first Benchy or a professional iterating complex prototypes, understanding these cost drivers empowers you to make smarter decisions and avoid wallet shock.

Remember our “failure tax” — that 20-30% margin for failed prints and unexpected hiccups? It’s a reality check that keeps your projects on budget and your sanity intact.

If you’re eyeing a printer, our top picks like the Bambu Lab P1S and Prusa MK4 strike a fantastic balance between quality and cost-efficiency. The Bambu Lab’s plug-and-play magic is perfect for those who want to print without fuss, while Prusa’s ecosystem offers reliability and community support that’s hard to beat. For beginners on a budget, the Creality Ender 3 V3 remains a solid gateway, though expect to invest some time in upgrades and tweaks.

Outsourcing remains a viable option for complex materials or low-volume runs, but if you find yourself printing the same parts repeatedly, bringing production in-house will save you time and money in the long run.

Ultimately, 3D printing is a tool of empowerment, and with the right knowledge, you can turn it into a cost-effective powerhouse for creativity and innovation.

Recommended Links

👉 Shop 3D Printers:

- Bambu Lab P1S: Amazon | Bambu Lab Official Website

- Prusa MK4: Prusa Official Website

- Creality Ender 3 V3: Amazon | Creality Official Website

Filament and Materials:

Books on 3D Printing Costs and Techniques:

- 3D Printing Failures: How to Diagnose and Repair All Desktop 3D Printing Issues by Sean Aranda — Amazon

- 3D Printing: The Next Industrial Revolution by Christopher Barnatt — Amazon

FAQ

Are there any affordable 3D printing options for beginners?

Absolutely! Entry-level FDM printers like the Creality Ender 3 V3 or Anycubic Kobra offer solid print quality at a fraction of the cost of professional machines. These printers typically cost a few hundred dollars and use inexpensive filament such as PLA, which keeps material costs low. Keep in mind, beginner printers may require some tinkering and upgrades to reach their full potential.

How can I reduce the cost of 3D printing at home?

There are several ways to trim expenses:

- Optimize print settings: Use lower infill percentages and thicker layers for non-critical parts.

- Buy filament in bulk: Brands like Sunlu offer discounts on multi-kilogram spools.

- Prevent print failures: Proper bed leveling and filament drying reduce wasted material.

- Reuse failed prints: Some enthusiasts recycle failed prints into filament using machines like Filabot.

- DIY enclosures: Instead of buying expensive enclosures, use cardboard boxes to maintain temperature for ABS prints.

What factors affect the cost of 3D printing a particular object?

Costs depend on:

- Material volume and type: More material means higher cost; specialty filaments cost more.

- Print time: Longer prints consume more electricity and machine wear.

- Support structures: Extra material and post-processing labor.

- Layer height and resolution: Higher resolution increases print time.

- Failure rates: Failed prints add to overall cost.

- Post-processing: Labor and materials for sanding, curing, or painting.

Is 3D printing cheaper than traditional manufacturing methods?

For small production runs (1-500 units) or highly customized parts, 3D printing can be more cost-effective due to zero tooling costs and rapid iteration. However, for mass production, traditional methods like injection molding become cheaper per unit once the upfront tooling costs are amortized.

What are the ongoing costs of owning a 3D printer?

Ongoing costs include:

- Materials: Filament or resin.

- Consumables: Nozzles, build plates, FEP films.

- Electricity: Minimal but accumulates over time.

- Maintenance: Replacement parts and occasional repairs.

- Labor: Time spent on setup, monitoring, and post-processing.

How much does it cost to 3D print a single object?

It varies widely. A small, simple PLA print like a 3D Benchy can cost under $0.50 including material and machine wear. Larger, complex parts can cost tens or hundreds of dollars when factoring in material, time, and labor.

What is the average cost of a 3D printer for home use?

Home 3D printers typically range from $200 to $2,000. Entry-level models like the Creality Ender 3 start around $200, while premium models like the Prusa MK4 or Bambu Lab P1S cost closer to $1,000-$2,000.

Is having a 3D printer expensive?

The initial investment can be modest, but ongoing costs and time investment add up. For hobbyists, it’s generally affordable, especially when printing small parts. For businesses, costs scale with usage and complexity.

How much do you charge per hour for 3D printing?

If you’re a service provider, hourly rates vary but typically range from $10 to $50 per hour, depending on printer type, material, and post-processing complexity. Pricing should cover material, labor, machine depreciation, and overhead.

How much does it cost to 3D print something at Staples?

Staples offers 3D printing services with prices starting around $10-$20 for small parts, scaling with size and complexity. Outsourcing is convenient but often more expensive per part than in-house printing.

How expensive is it to run a 3D printer?

Running a desktop 3D printer usually costs less than $0.10 per hour in electricity. The bigger expenses are materials and labor. For example, a 10-hour print might consume about $1 in electricity but $10 or more in filament.

Reference Links and Further Reading on 3D Printing Expenses

- How to Calculate 3D Printing Costs? – Original Prusa 3D Printers

- Formlabs Blog: How to Calculate 3D Printer Cost

- EufyMake: How Much Do 3D Prints Cost?

- Creality Official Website

- Prusa Research Official Website

- Bambu Lab Official Website

- Shapeways 3D Printing Services

- Protolabs 3D Printing