Support our educational content for free when you purchase through links on our site. Learn more

How Much Does It Cost Per 3D Print? 9 Secrets Revealed (2025) 🤑

Ever stared at a cool 3D model and wondered, “How much is this going to cost me to print?” You’re not alone. The truth is, 3D printing costs can range from pocket change to serious investment

, depending on a mix of factors that most beginners don’t realize upfront. We’ve been down that road ourselves — like when our teammate Alex’s ambitious Mandalorian helmet project ballooned from a budget-friendly plan into a costly filament frenzy! 😅In this ultimate 2025 guide, we break down everything you need to know to calculate your 3D printing costs accurately — from materials and machine wear to electricity and labor. Plus, we spill insider tips on how to slash your expenses without sacrificing quality. Curious how your choice between a Prusa MK4 or a sleek Formlabs SLA printer impacts your wallet? Or how bulk printing can save you big bucks? Stick around — we’ve got all that and more.

Key Takeaways

- Material choice is the biggest cost driver: PLA filament costs pennies per gram, while specialty resins and powders can be much pricier.

- Printer type matters: FDM printers like the Prusa MK4 offer low-cost prints, whereas SLA and SLS technologies come with higher material and maintenance expenses.

- Don’t forget hidden costs: Failed prints, consumables, and post-processing supplies add up quickly if you don’t plan for them.

- Labor and time are real costs: Whether hobbyist or pro, your time spent prepping and finishing prints impacts the true cost.

- Bulk printing reduces per-unit costs by spreading labor and machine overhead across many parts.

- Smart design choices like hollowing models and optimizing supports can save significant material and time.

Ready to start printing smarter and saving money? Check out our recommended printers and materials below to get started:

- Prusa MK4 3D Printer: Amazon | Prusa Official

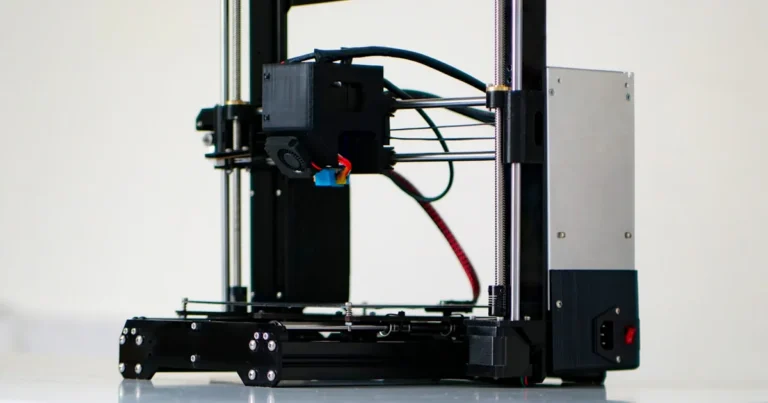

- Creality Ender 3 V2: Amazon | Creality Official

- Hatchbox PLA Filament: Amazon | Hatchbox Official

- Formlabs Form 3+ SLA Printer: Amazon | Formlabs Official

Table of Contents

- ⚡️ Quick Tips and Facts About 3D Printing Costs

- 🔍 Understanding the True Cost of 3D Printing: A Deep Dive

- 💡 1. How to Calculate 3D Printing Costs: Step-by-Step Guide

- 💰 2. Comparing Costs: FDM vs SLA vs SLS 3D Printing Technologies

- 🛠️ 3. Common Cost Drivers in 3D Printing Projects

- 📊 4. Real-World Examples: Cost Breakdown of Popular 3D Prints

- 🛒 5. Where to Buy Affordable 3D Printing Materials and Services

- 🤖 6. How Printer Brands Affect Your Printing Budget: Prusa, Creality, Formlabs & More

- 📈 7. Scaling Up: How Bulk 3D Printing Impacts Cost Efficiency

- 🔧 8. Tips to Reduce Your 3D Printing Costs Without Sacrificing Quality

- 🧩 9. Hidden Costs in 3D Printing You Might Be Overlooking

- 🗣️ Replies to “How to Calculate 3D Printing Costs?”: Expert Insights

- 📝 Blog: Stories and Lessons from Our 3D Printing Cost Adventures

- 🎯 Conclusion: What’s the Real Price Tag on Your Next 3D Print?

- 🔗 Recommended Links for 3D Printing Cost Calculators and Resources

- ❓ FAQ: Your Burning Questions About 3D Printing Costs Answered

- 📚 Reference Links: Trusted Sources and Further Reading

Here is the main body of the article, written according to your specifications.

⚡️ Quick Tips and Facts About 3D Printing Costs

Welcome, fellow makers! Before we dive deep into the nitty-gritty of 3D printing costs, let’s get you up to speed with some quick-fire facts. Here at 3D Printed™, we’ve learned these lessons the hard (and sometimes expensive) way, so you don’t have to!

- Material is King 👑: The single biggest variable cost is your material. A simple PLA print might cost pennies, while a carbon-fiber-infused nylon or a specialized dental resin print can cost a small fortune.

- Electricity is Cheap 💡: Worried about your power bill? Don’t be. As Prusa Research points out, the electricity for a typical hobbyist print often costs less than a cup of coffee—we’re talking cents, not dollars.

- Time is Money ⏳: Your time spent designing, slicing, and post-processing is a real cost! Especially if you’re running a business. Never underestimate the value of your labor.

- Failure is an Option (and a Cost) 💥: Failed prints are inevitable. A good rule of thumb is to add a 10-30% margin to your material cost to cover the occasional spaghetti monster or detached-from-the-bed disaster.

- Size & Density Matter 📏: The cost is directly tied to the amount of material used. A larger, solid object will always cost more than a small, hollow one. Smart design choices, like using minimal infill, can drastically cut costs.

- Technology Dictates Price 🤖: The type of printer you use (FDM, SLA, or SLS) has a massive impact on the overall cost, from the machine’s price to the materials and maintenance involved. We’ll break this down later!

- Hobby vs. Pro 🏢: Printing a Benchy at home might cost you less than a dollar. Ordering a high-resolution, professionally finished prototype from a service can run into the hundreds or even thousands. Context is everything.

🔍 Understanding the True Cost of 3D Printing: A Deep Dive

So, you’re staring at that awesome dragon model on Thingiverse and wondering, “What’s this really going to cost me?” It’s the million-dollar question… or is it a five-dollar question? The truth is, it’s both.

Asking “how much does a 3D print cost?” is like asking “how much does a bag of groceries cost?” The answer depends entirely on what you put in the cart. Are you grabbing some budget-friendly PLA for a quick functional print, or are you loading up on high-temp PEEK for an aerospace-grade part?

The final price tag on your 3D printed object is a cocktail of several ingredients: the material you choose, the electricity your printer sips, the wear and tear on your machine, and the value of your own precious time. In this guide, we’ll give you the full recipe to calculate that cost with confidence, whether you’re a weekend warrior or a budding entrepreneur.

💡 1. How to Calculate 3D Printing Costs: Step-by-Step Guide

Ready to become a cost-calculating wizard? 🧙♂️ It’s easier than you think. Most modern slicer software, like PrusaSlicer or Ultimaker Cura, will tell you exactly how much material your model needs in grams (for filament) or milliliters (for resin). That’s your starting point.

Let’s break down the four horsemen of 3D printing expenses.

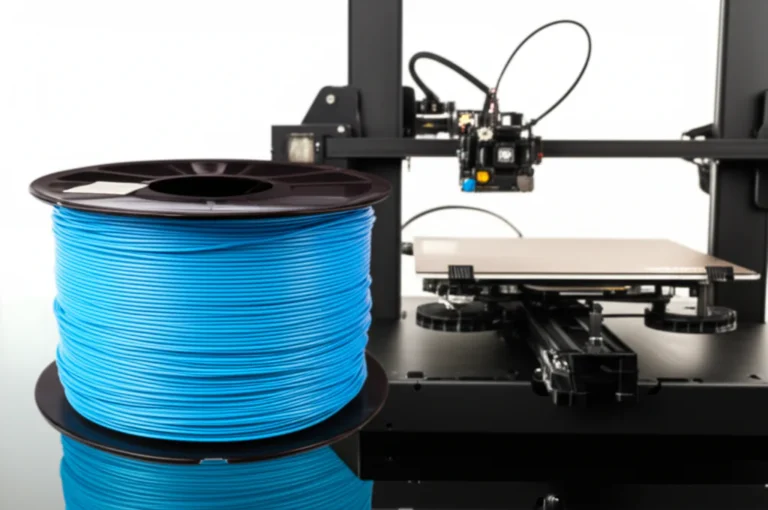

H3: Material Costs: Filaments, Resins, and Powders

This is the most straightforward part of the equation.

- The Formula:

(Price of Spool / Weight of Spool in grams) * Weight of Model in grams = Material Cost - Example: You buy a 1kg (1000g) spool of Hatchbox PLA for your project. Your slicer tells you that the cute octopus you want to print weighs 25 grams.

($25 / 1000g) * 25g = $0.625- Your material cost is just over 62 cents! Easy, right?

The same logic applies to resin, just substitute grams for milliliters (ml). A 1000ml bottle of standard resin might cost around $40, making a 15ml miniature cost about $0.60.

H3: Machine Depreciation and Maintenance Expenses

This is the one everyone forgets! Your printer wasn’t free, and it won’t run forever without a little TLC. Factoring in the cost of the machine itself and its upkeep is crucial for accurate pricing, especially for businesses.

- Depreciation: How much is each hour of printing “costing” you in terms of the printer’s value?

- Simple Formula:

(Printer Price / Expected Lifespan in Hours) * Print Time in Hours - Example: Let’s say your trusty Creality Ender 3 V2 cost you a few hundred dollars and you expect to get 4,000 hours of printing out of it before a major overhaul. For a 5-hour print, the depreciation cost is minimal, maybe a dollar or two. For a high-end machine like a Formlabs Form 3+, this number becomes much more significant.

- Simple Formula:

- Maintenance: Nozzles clog, belts stretch, and FEP sheets for resin printers get cloudy. We recommend adding a small, flat percentage (say, 5-10% of the material cost) or a fixed hourly rate (e.g., $0.25/hour) to every print to build up a “maintenance fund.”

H3: Electricity and Operational Costs

As we mentioned, this is usually the smallest piece of the pie. A typical desktop FDM printer uses about as much power as a standard incandescent light bulb.

- The Formula:

(Printer Power in kW) * (Print Time in Hours) * (Your Local Electricity Rate in $/kWh) = Electricity Cost - Real-World Check: A 4-hour print on an AnkerMake M5, which is known for its efficiency, might consume around 0.4 kWh. At an average US electricity rate of $0.17/kWh, that’s a whopping… $0.07. As the team at EufyMake notes, “Energy-efficient printers are more cost-effective in the long run,” but for one-off prints, it’s barely a rounding error.

H3: Labor and Post-Processing Time

Are you just clicking “print” and walking away? Or are you painstakingly removing supports, sanding surfaces, priming, and painting?

- For Hobbyists: Your time might be “free,” but it’s still a factor.

- For Businesses: This is a critical, non-negotiable cost. You must pay yourself (or your employees)!

- Print Prep: Slicing a simple model takes minutes. But as Prusa’s guide highlights, “preparing supports for SLA printing using manual supports can take a long time.” This is skilled work.

- Post-Processing: Removing supports from an FDM print is one thing. Cleaning, curing, and carefully snipping supports from a delicate resin print is another level of effort. Sanding, filling, and painting can add hours to a project. Factor this in at a realistic hourly rate.

💰 2. Comparing Costs: FDM vs SLA vs SLS 3D Printing Technologies

Not all 3D printing is created equal, and the technology you use is a massive cost driver. Here’s a breakdown from our workshop to your screen.

| Feature | Fused Deposition Modeling (FDM) | Stereolithography (SLA) | Selective Laser Sintering (SLS) |

|---|---|---|---|

| How it Works | Melts and extrudes thermoplastic filament layer by layer. | Cures liquid photopolymer resin with a UV laser. | Fuses powdered polymer with a high-power laser. |

| Example Printers | Prusa MK4, Bambu Lab P1S, Creality K1 | Elegoo Mars 4, Anycubic Photon Mono M5s, Formlabs Form 3+ | Formlabs Fuse 1+, Sinterit Lisa Pro |

| Initial Cost | 💵 (Low) | 💵💵 (Medium) | 💵💵💵💵💵 (Very High) |

| Material Cost | ✅ Very Low. Standard PLA/PETG is cheap. | ❌ Medium to High. Standard resin is affordable, but engineering/biocompatible resins are pricey. | ❌ High. Nylon powders are expensive and require careful handling. |

| Post-Processing | Support removal, optional sanding/painting. Can be labor-intensive for a smooth finish. | ✅ Required. Washing in Isopropyl Alcohol (IPA), UV curing. Can be messy. | ✅ Required. Depowdering and media blasting. Less “hands-on” but requires special equipment. |

| Best For… | Rapid prototyping, functional parts, large models, 3D Printable Objects for hobbyists. | High-detail miniatures, jewelry, dental/medical models, smooth surface finishes. | Complex, durable functional parts with no need for supports. Small-batch manufacturing. |

| Overall Cost/Print | Lowest | Medium | Highest |

🛠️ 3. Common Cost Drivers in 3D Printing Projects

Ever wonder why two models of the same size have wildly different print costs? The devil is in the details. Here are the main culprits that can inflate your costs:

- Model Volume & Infill: This is the big one. A solid cube will cost exponentially more than a hollow one. Your slicer’s infill setting is your best friend for saving money. For most display models, 10-15% infill is more than enough. For functional parts, you might need more, but rarely 100%. As PrintAWorld wisely suggests, “Hollowing your model” is a top tip to reduce material use.

- Layer Height: A lower layer height (e.g., 0.1mm) produces a smoother, more detailed print but takes much longer. A longer print time means slightly more electricity and more machine wear-and-tear per print.

- Supports: Complex models with lots of overhangs need support structures. Those supports use extra material and add to your post-processing time (and frustration!). Orienting your model cleverly on the build plate can sometimes eliminate the need for supports entirely.

- Material Choice: This can’t be overstated. Printing a phone case in basic PLA might cost $1. Printing the same case in a flexible TPU filament could be $2, and in a super-strong carbon fiber nylon, it could be $10 or more, just in material.

- Print Speed: Pushing your printer to its speed limits can sometimes lead to lower quality and a higher failure rate, forcing you to reprint. Sometimes, slow and steady wins the race and saves you money.

📊 4. Real-World Examples: Cost Breakdown of Popular 3D Prints

Let’s put our calculator to work! We’ve run the numbers on a few common prints from our workshop using a mid-range FDM printer like the Prusa MK4 and standard PLA filament.

(Note: These are estimates. Your mileage may vary based on your specific settings, printer, and material costs.)

| Print Project | Material Used | Print Time | Est. Material Cost | Est. Machine/Elec. Cost | Total Estimated Cost |

|---|---|---|---|---|---|

|

3DBenchy (The classic boat) |

~12g PLA | ~1 hour | ~$0.30 | ~$0.25 | ~$0.55 |

|

Articulated Lizard (A fun toy) |

~35g PLA | ~4 hours | ~$0.88 | ~$1.00 | ~$1.88 |

| Smartphone Stand (Simple & functional) | ~50g PETG | ~3.5 hours | ~$1.50 | ~$0.88 | ~$2.38 |

| Cosplay Helmet Piece (1/4 of a helmet) | ~200g PLA+ | ~18 hours | ~$5.00 | ~$4.50 | ~$9.50 |

See how quickly the cost can scale with size and print time? That cosplay helmet, once fully assembled and post-processed, represents a significant investment in both time and materials! This is a key part of our 3D Printing in Education curriculum—teaching students to budget projects realistically.

🛒 5. Where to Buy Affordable 3D Printing Materials and Services

Whether you’re stocking up on filament or outsourcing a complex job, knowing where to shop is key.

For DIY Materials (Filaments & Resins)

You can find great deals on quality materials if you know where to look. We’re fans of brands that balance quality and cost.

- 👉 Shop Filaments & Resins on:

- Hatchbox PLA: Amazon | Hatchbox Official Website

- eSUN PLA+ / PETG: Amazon | eSUN Official Website

- Anycubic Standard Resin: Amazon | Anycubic Official Website

- Elegoo Standard Resin: Amazon | Elegoo Official Website

For 3D Printing Services

Don’t own a printer, or need a material/technology you don’t have access to? These services can print your file and ship it to your door.

- Get Your Models Printed by:

- Craftcloud by All3DP: Official Website (A great price comparison engine)

- Shapeways: Official Website (Wide range of materials, including metals)

- Xometry: Official Website (Industrial-grade manufacturing)

- Local Makers on Etsy: Etsy (Great for supporting small businesses)

🤖 6. How Printer Brands Affect Your Printing Budget: Prusa, Creality, Formlabs & More

The sticker price of a printer is just the beginning of the story. The brand you choose creates an entire ecosystem of costs. Let’s look at a few popular examples.

The Workhorse: Prusa Research

- Upfront Cost: Medium to High.

- Ongoing Costs: Low. Prusa printers are renowned for their reliability. You’ll spend less time and money on failed prints and troubleshooting. Their open-source nature means you can use any brand of filament, keeping material costs down. Replacement parts are readily available from their store. You’re paying for peace of mind and consistency. Check out our 3D Printer Reviews for more on their models.

The Budget Champion: Creality

- Upfront Cost: Very Low. This is the main appeal of printers like the Ender series.

- Ongoing Costs: Medium. Here’s the trade-off. Creality printers are fantastic for the price, but they often require more tinkering, calibration, and community-recommended upgrades (like better bed springs or all-metal hotends) to reach their full potential. These small costs add up. You might also have a slightly higher failure rate initially, which costs material.

The High-Resolution Specialist: Formlabs

- Upfront Cost: High.

- Ongoing Costs: High. Formlabs makes incredible SLA printers, but you’re locked into their ecosystem. You must use their proprietary resins, which are significantly more expensive than generic brands. Resin tanks and build platforms are considered consumables and need periodic replacement, adding to the operational cost. The quality is phenomenal, but it comes at a premium.

📈 7. Scaling Up: How Bulk 3D Printing Impacts Cost Efficiency

Printing one of something can feel a bit pricey when you factor in setup time. But what about printing 100? That’s where the magic of 3D Printing Innovations and economies of scale kicks in.

- Labor Amortization: The time it takes you to slice a file and prepare the printer is the same whether you print one object or ten. By filling your build plate, you spread that initial labor cost across all the parts, drastically lowering the per-unit labor cost.

- Material Discounts: Buying filament or resin in bulk often comes with a significant discount. A single spool of PLA might be one price, but a case of 10 spools could be 15-20% cheaper per spool.

- Reduced Overhead per Part: The small costs of electricity and machine wear are minimized when the printer runs continuously for a large batch versus starting and stopping for many individual prints.

- The Service Bureau Advantage: This is why printing services can sometimes be cheaper for multiple items. As PrintAWorld notes, many services have a minimum fee to cover their overhead. Ordering in bulk easily surpasses this minimum, and the per-unit price drops dramatically. They state, “It wouldn’t make sense for a company to 3D print something for you for a print that costs $3.” Ordering 20 of them, however, makes perfect sense for everyone.

🔧 8. Tips to Reduce Your 3D Printing Costs Without Sacrificing Quality

Alright, team, let’s get thrifty! Here are our favorite, battle-tested tips for squeezing the most value out of every gram of filament.

- Master Your Infill: Don’t just use the default! For non-structural parts, use a low percentage (10-15%). Try “smart” infill patterns like Cura’s Lightning Infill, which only adds material where it’s needed internally, saving huge amounts of filament and time.

- Optimize Orientation: Before you hit slice, rotate your model on the build plate. Can you position it to eliminate the need for supports? This is the #1 way to save on material and post-processing time.

- Hollow Your Models: For resin prints or large FDM models, use your 3D Design Software to hollow them out. Just remember to add drainage holes for resin!

- Use a Brim, Not a Raft: If you need better bed adhesion, a brim uses significantly less material than a full raft and is easier to remove.

- Calibrate, Calibrate, Calibrate: A well-calibrated printer is a reliable printer. Take the time to dial in your e-steps, temperatures, and retraction settings. This prevents failed prints, which are the ultimate money-wasters.

- Dry Your Filament: “Wet” filament prints poorly, leading to weak, stringy parts that often end up in the trash. A simple filament dryer can pay for itself by saving just one or two large prints from failure.

- Buy in Bulk: If you have a favorite material you use all the time, watch for sales and buy multiple spools to get a lower per-kilogram price.

- Nozzle Size Matters: For large, simple prints, switching to a larger nozzle (e.g., 0.6mm or 0.8mm) can cut print times by more than half. Less time means less machine wear and a faster path to your finished part.

🧩 9. Hidden Costs in 3D Printing You Might Be Overlooking

You’ve calculated your material, your electricity, and your time. You’re all set, right? Hold on! Here are the sneaky gremlins that nibble away at your budget.

- Failed Prints 😱: We mentioned it before, but it’s the biggest hidden cost. A 20-hour print that fails at hour 19 is 20 hours of machine time and a whole lot of wasted plastic. Always budget for failure.

- Consumable Parts 🔧: These aren’t just for resin printers!

- FDM: Brass nozzles wear out, especially with abrasive filaments like glow-in-the-dark or carbon fiber. PTFE tubes degrade. Build surfaces (like PEI sheets) get damaged and need replacement.

- SLA: FEP or PFA films for the bottom of the resin tank are consumable and will need replacing. The resin tank itself has a limited lifespan.

- Cleaning & Finishing Supplies 🧼:

- Isopropyl Alcohol (IPA): For SLA, you’ll go through a lot of this for cleaning prints.

- Sandpaper, Files, and Hobby Knives: For cleaning up both FDM and SLA prints.

- Primer, Paint, and Glue: If you’re finishing your models, these costs add up fast.

- Software & Models 💻: While there are amazing free slicers and models, sometimes the perfect design is on a paid site like Cults3D or MyMiniFactory. Advanced 3D design software can also have subscription fees.

- The “Upgrade Rabbit Hole” 🐰: This is a real phenomenon! You start with a basic printer, then you need a silent motherboard, then a direct-drive extruder, then linear rails… It’s fun, but it’s definitely a cost!

🗣️ Replies to “How to Calculate 3D Printing Costs?”: Expert Insights

The community is always buzzing with this question, and we love seeing the different approaches. It’s not just us—experts across the industry have weighed in, and their perspectives help paint a complete picture.

-

The Prusa Perspective: The team at Prusa offers a wonderfully detailed, business-oriented formula. They emphasize including not just material but also “manpower, 3D printer operation costs… and margin for potential issues.” Their key takeaway is that for a business, “you need to include the material costs, time spent on print preparations, and some kind of ‘failure insurance’, plus general running costs.” We couldn’t agree more. This structured approach is perfect for anyone looking to sell their prints.

-

The EufyMake View: They highlight the broader context, stating, “Your choice of 3D printer…influences the cost.” They break down the factors from the initial printer purchase all the way to maintenance and the cost of the 3D model itself. Their formula is all-encompassing: “Total cost per hour = Electricity + Material costs + Wear and tear + Labor costs + Amortized printer costs + Overheads.” This is a fantastic, holistic way to think about the true hourly cost of running your print farm.

-

The PrintAWorld Reality Check: They bring in the perspective of a 3D printing service, and it’s eye-opening. They point out that for services, a “minimum fee/base price” is essential because “it wouldn’t make sense for a company to 3D print something for you for a print that costs $3.” This explains why ordering a tiny model from a service seems expensive—you’re paying for the entire workflow, not just the plastic. Their comparison of different services shows a wild price variation, proving that it pays to shop around.

📝 Blog: Stories and Lessons from Our 3D Printing Cost Adventures

Let me tell you about “The Great Helmet Miscalculation.” A few years ago, one of our team members, let’s call him Alex, decided to print a full-size, wearable Mandalorian helmet. He was stoked! He found a gorgeous, highly detailed model online and bought a few spools of shiny “silk silver” PLA.

He sliced the first of eight pieces and hit print. It was a 22-hour job. The next morning, he had a perfect piece. Awesome! He printed the second piece. And the third. By the fourth piece, he realized he was almost out of his first spool of filament. He’d completely underestimated the material usage.

He ordered more filament, but the new batch was a slightly different shade of silver. Ugh. Then, on piece six, the print failed 18 hours in—a nozzle clog. More wasted material, more wasted time. In the end, the helmet that he thought would cost about $40 in plastic ended up costing nearly $100 after accounting for the failed print, the mismatched filament he couldn’t use, and the extra spool he had to rush-order.

The lesson? Always overestimate your material needs, especially for large, multi-part projects. Use your slicer’s estimate as a minimum. And for big jobs, do a small test print with a new filament first to make sure it’s dialed in perfectly. That failed print taught us more about budgeting for 3D printable objects than any spreadsheet ever could

🎯 Conclusion: What’s the Real Price Tag on Your Next 3D Print?

So, what’s the final verdict on how much does it cost per 3D print? Well, as we’ve uncovered on this journey, the answer is delightfully complex — but totally manageable once you know the recipe.

From material costs to machine wear, from electricity to the often overlooked labor and post-processing time, every factor adds a brushstroke to the full cost canvas. Whether you’re printing a tiny Benchy for fun or a multi-piece cosplay helmet like Alex’s saga, understanding these variables empowers you to budget smartly and avoid nasty surprises.

Technology choice is a game-changer: FDM printers like the Prusa MK4 offer low-cost, reliable prints perfect for most hobbyists, while SLA machines like the Formlabs Form 3+ deliver stunning detail at a higher price point. And if you’re scaling up, bulk printing can dramatically reduce your per-unit costs.

Remember, failure is part of the process — budget for it, learn from it, and keep iterating. The “Great Helmet Miscalculation” taught us that overestimating material needs and factoring in contingency is not just smart, it’s essential.

In short: 3D printing costs are as flexible as the technology itself. With the right knowledge and tools, you can tailor your prints to your budget without sacrificing quality or creativity.

Ready to start printing smarter? We’re here to help every step of the way!

🔗 Recommended Links for 3D Printing Cost Calculators and Resources

Looking to dive deeper or shop for your next 3D printing adventure? Check out these trusted resources and products:

Material & Printer Shopping

-

Prusa MK4 3D Printer:

Thingiverse | Amazon | Prusa Official Website -

Creality Ender 3 V2:

Thingiverse | Amazon | Creality Official Website -

Formlabs Form 3+ SLA Printer:

Amazon | Formlabs Official Website -

Hatchbox PLA Filament:

Amazon | Hatchbox Official Website -

Anycubic Standard Resin:

Amazon | Anycubic Official Website

Books to Master 3D Printing Costs & Techniques

- 3D Printing Failures: How to Diagnose and Repair All 3D Printing Issues by Sean Aranda — Amazon Link

- 3D Printing: The Next Industrial Revolution by Christopher Barnatt — Amazon Link

- Make: 3D Printing: The Essential Guide to 3D Printers by Anna Kaziunas France — Amazon Link

❓ FAQ: Your Burning Questions About 3D Printing Costs Answered

What factors affect the cost of 3D printing?

3D printing costs are influenced by multiple factors, including:

- Material type and amount: Filament or resin choice and how much your model consumes.

- Print time: Longer prints consume more electricity and wear on your machine.

- Printer depreciation and maintenance: Your machine’s cost spread over its lifespan plus upkeep.

- Labor and post-processing: Time spent preparing files, removing supports, sanding, painting.

- Failure rates: Failed prints waste time and materials, so budget for contingencies.

- Technology used: FDM is generally cheaper than SLA or SLS, but each has trade-offs.

- Model complexity and size: More complex or larger models require more material and time.

Read more about “Unlocking 3D Printing ROI: 7 Secrets to Skyrocket Your Investment 🚀 (2025)”

How do I calculate the cost of a 3D print job?

Calculating cost involves adding:

- Material cost:

(Material price per gram) × (Model weight in grams) - Machine cost:

(Printer price / expected print hours) × print time - Electricity cost:

(Printer power in kW) × (Print time in hours) × (Electricity rate) - Labor cost: Time spent on prep and post-processing × hourly labor rate

- Margin for failures: Typically 10-30% of material cost to cover failed prints

Tools like the Prusa 3D Printing Price Calculator can automate this process.

What is the average cost per hour of 3D printing?

The average cost per hour varies widely:

- Hobbyist FDM printers: Often under $1/hour when factoring in material, electricity, and depreciation.

- Professional SLA printers: Can be several dollars per hour due to expensive resins and machine costs.

- Industrial SLS printers: Tens to hundreds of dollars per hour depending on scale and materials.

Your exact cost depends on your equipment, materials, and labor.

Read more about “How Long Does 3D Printing Take? ⏳ 12 Factors That Decide (2025)”

Do the costs of 3D printing vary by material type?

✅ Absolutely! Materials range from inexpensive PLA filament (~$20-$30/kg) to specialty resins or composite filaments that can cost over $100/kg.

- PLA and ABS: Cheapest and most common.

- TPU, Nylon, Carbon Fiber composites: More expensive but offer special properties.

- Resins: Usually pricier, especially engineering or biocompatible types.

- Metal powders (SLS): Highest cost, often used in industrial applications.

How does the size of a 3D print affect its cost?

Size directly impacts material usage and print time. Larger models consume more filament or resin and take longer to print, increasing electricity and wear costs. However, smart design choices like hollowing and low infill can reduce these costs significantly.

Read more about “Has 3D Printing Gotten Cheaper? 7 Surprising Truths in 2025 🎉”

Are there any ways to reduce the cost of 3D printing at home?

Absolutely! Here are some pro tips:

- Use low infill percentages and hollow models.

- Optimize model orientation to reduce supports.

- Buy filament in bulk during sales.

- Calibrate your printer to reduce failed prints.

- Use larger nozzles for faster printing on big parts.

- Dry your filament to avoid print quality issues.

- Use energy-efficient printers like the AnkerMake M5.

Read more about “What is 3D Printing? 25+ Real Examples & How It Works! 🚀”

What are the long-term costs of owning and maintaining a 3D printer?

Owning a printer means budgeting for:

- Replacement parts (nozzles, belts, FEP films).

- Consumables like build surfaces and cleaning supplies.

- Periodic maintenance and repairs.

- Software updates or subscriptions (if applicable).

- Upgrades to improve reliability or quality.

Ignoring these can lead to unexpected expenses and downtime.

Read more about “How Expensive Is It to Run a 3D Printer? 9 Key Costs Revealed! 💰 …”

How do failure rates impact overall 3D printing costs?

Failed prints waste material, electricity, and your valuable time. High failure rates can double or triple your costs if you don’t account for them. Always factor in a margin (10-30%) for failures, especially when printing complex or large models.

Read more about “How Much Does 3D Print Cost Per Gram? 🤑 The Ultimate 2025 Guide”

Can I use free 3D models to reduce costs?

✅ Yes! Platforms like Thingiverse and MyMiniFactory offer thousands of free models. However, custom or commercial projects may require paid designs or custom modeling, which adds to cost.

Read more about “75 Most Useful 3D Printed Objects for Students (2025) 🎓”

📚 Reference Links: Trusted Sources and Further Reading

- Prusa Research: How to Calculate Printing Costs

- EufyMake: How Much Do 3D Prints Cost?

- PrintAWorld: How Much Does 3D Printing Cost? [2021 Update]

- Formlabs: Form 3+ SLA Printer

- Creality: Ender 3 V2

- Prusa: Original Prusa MK4

- AnkerMake: M5 3D Printer

- Hatchbox: PLA Filament

- Anycubic: Standard Resin

We hope this guide from your friends at 3D Printed™ has demystified the cost of 3D printing and armed you with the knowledge to print smarter, not just harder. Happy printing! 🎉