Support our educational content for free when you purchase through links on our site. Learn more

Discover the 10 Fascinating Types of 3D Printing Technologies You Need to Know in 2024! 🚀

Have you ever wondered how a simple idea transforms into a tangible object right before your eyes? Welcome to the world of 3D printing, where imagination meets innovation! From creating intricate jewelry to manufacturing aerospace components, the types of 3D printing technologies available today are nothing short of magical. In this article, we’ll explore 10 unique types of 3D printing technologies that are shaping industries and revolutionizing the way we create.

Picture this: You’re at a tech expo, and you see a booth showcasing a 3D printer effortlessly crafting a complex, multi-colored figurine in mere minutes. You can’t help but marvel at the precision and creativity involved. This experience is just a glimpse into the incredible capabilities of modern 3D printing technologies. As we journey through this article, you’ll discover the strengths and weaknesses of each type, along with their real-world applications. So, buckle up—your 3D printing adventure is about to begin!

Key Takeaways

- Diverse Technologies: Explore 10 major types of 3D printing, each with unique processes and applications.

- Applications Galore: From medical devices to aerospace components, understand how these technologies are used across various industries.

- Pros and Cons: Get the lowdown on the advantages and disadvantages of each technology to help you make informed decisions.

- Future Trends: Stay ahead of the curve by learning about emerging trends and innovations in the 3D printing landscape.

Ready to dive deeper into the world of 3D printing? 👉 Shop top brands like Ultimaker and Formlabs to find the perfect printer for your next project! Check out Ultimaker here | Explore Formlabs here. Let’s get printing! 🖨️✨

Table of Contents

- Quick Tips and Facts About 3D Printing Types

- The Evolution of 3D Printing Technologies

- Diving Deep: The Major Types of 3D Printing

- Comparative Analysis: Advantages and Disadvantages of Each Type

- Applications of Different 3D Printing Technologies

- Choosing the Right 3D Printing Technology for Your Project

- Future Trends in 3D Printing Technologies

- Conclusion

- Recommended Links

- FAQ

- Reference Links

Quick Tips and Facts About 3D Printing Types

Welcome to the magical world of 3D printing! Whether you’re a seasoned pro or a curious newbie, there’s always something new to learn. Let’s dive into some quick tips and facts that will make you the life of any 3D printing party! 🎉

-

Versatility is Key: 3D printing isn’t just for making quirky toys (though that’s a fun part!). From medical implants to aerospace components, the possibilities are endless. Discover more about versatile 3D objects.

-

Materials Matter: From plastics to metals and even chocolate 🍫, the material you choose can make all the difference. Each type of 3D printing technology has its own material compatibility.

-

Precision and Speed: Different technologies offer varying levels of precision and speed. For example, SLA is known for high precision, while FDM is favored for speed.

-

Cost Considerations: While some 3D printers are budget-friendly, others might require you to break open your piggy bank. Remember, the cost often correlates with the printer’s capabilities.

-

Environmental Impact: 3D printing can be more sustainable than traditional manufacturing, but it’s essential to consider the lifecycle of the materials used.

Feeling inspired yet? Let’s delve into the fascinating history of how these technologies came to be!

The Evolution of 3D Printing Technologies

Once upon a time in the 1980s, a visionary named Chuck Hull invented stereolithography (SLA), marking the birth of 3D printing. Fast forward to today, and we’ve got a smorgasbord of technologies that would make even Willy Wonka jealous! 🍭

The Birth of a Revolution

-

SLA (1986): The first-ever 3D printing technology, using UV lasers to cure liquid resin. It set the stage for the additive manufacturing revolution.

-

FDM (1988): Introduced by Scott Crump, this technology made 3D printing more accessible and affordable. It’s like the Model T of 3D printers!

-

SLS and Beyond (1990s): The ’90s saw the rise of Selective Laser Sintering (SLS) and other technologies, expanding the range of materials and applications.

Modern Innovations

-

DMLS and EBM: These metal 3D printing technologies have transformed industries like aerospace and automotive, enabling the creation of complex, high-strength components.

-

CLIP and MJF: Recent innovations like Continuous Liquid Interface Production (CLIP) and Multi Jet Fusion (MJF) are pushing the boundaries of speed and material properties.

Curious about how these technologies stack up against each other? Let’s dive deeper!

Diving Deep: The Major Types of 3D Printing

Hold onto your hats, folks! It’s time for a whirlwind tour of the major 3D printing technologies. Each has its own quirks and superpowers, much like your favorite superhero team. 🦸♂️🦸♀️

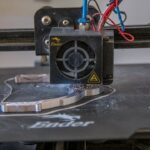

Fused Deposition Modeling (FDM)

Pros: ✅ Affordable, ✅ Easy to use, ✅ Wide range of materials

Cons: ❌ Lower resolution, ❌ Visible layer lines

FDM is like the trusty sidekick of 3D printing. It works by melting and extruding thermoplastic filaments, layer by layer. Perfect for prototypes and hobbyists!

Stereolithography (SLA)

Pros: ✅ High precision, ✅ Smooth surfaces

Cons: ❌ Resin handling, ❌ Longer print times

SLA uses a UV laser to cure liquid resin, creating intricate and detailed models. It’s the go-to for dental molds and jewelry. Learn more about SLA techniques.

Selective Laser Sintering (SLS)

Pros: ✅ No support structures, ✅ Complex geometries

Cons: ❌ Powder handling, ❌ Expensive

SLS uses a laser to fuse powdered materials, allowing for the creation of complex and durable parts. It’s popular in industrial applications.

Digital Light Processing (DLP)

Pros: ✅ Fast, ✅ High resolution

Cons: ❌ Limited build size, ❌ Resin handling

DLP is similar to SLA but uses a digital projector screen to flash entire layers at once. It’s like SLA’s speedy cousin!

Binder Jetting

Pros: ✅ Full-color printing, ✅ No heat

Cons: ❌ Post-processing required, ❌ Limited strength

Binder jetting uses a liquid binding agent to glue powder particles together. It’s perfect for colorful prototypes and sand casting molds.

Material Jetting

Pros: ✅ High accuracy, ✅ Multi-material

Cons: ❌ Expensive, ❌ Complex maintenance

Material jetting jets photopolymer droplets onto a build surface, curing them with UV light. It’s like a high-tech inkjet printer!

Multi Jet Fusion (MJF)

Pros: ✅ Fast, ✅ Strong parts

Cons: ❌ Limited material options, ❌ Costly

MJF uses a fusing agent and infrared light to create robust parts. It’s a favorite for functional prototypes and end-use parts.

Laminated Object Manufacturing (LOM)

Pros: ✅ Large builds, ✅ Low material cost

Cons: ❌ Lower resolution, ❌ Wasteful

LOM layers adhesive-coated paper, plastic, or metal laminates together, cutting each layer with a laser or blade.

Electron Beam Melting (EBM)

Pros: ✅ Strong metal parts, ✅ High-temperature materials

Cons: ❌ Costly, ❌ Limited to conductive materials

EBM uses an electron beam to melt metal powder, ideal for aerospace and medical implants.

Continuous Liquid Interface Production (CLIP)

Pros: ✅ Fast, ✅ Smooth surfaces

Cons: ❌ Limited material options, ❌ Resin handling

CLIP continuously pulls parts from a vat of resin, achieving impressive speeds and smooth finishes.

Comparative Analysis: Advantages and Disadvantages of Each Type

Let’s put on our analytical hats and break down the pros and cons of each 3D printing technology. Here’s a handy table to visualize the strengths and weaknesses:

| Technology | Advantages | Disadvantages |

|---|---|---|

| FDM | Affordable, Easy to use | Lower resolution |

| SLA | High precision, Smooth surfaces | Resin handling |

| SLS | No supports, Complex geometries | Powder handling |

| DLP | Fast, High resolution | Limited build size |

| Binder Jetting | Full-color, No heat | Post-processing |

| Material Jetting | High accuracy, Multi-material | Expensive |

| MJF | Fast, Strong parts | Limited materials |

| LOM | Large builds, Low cost | Lower resolution |

| EBM | Strong metal parts, High-temp materials | Costly |

| CLIP | Fast, Smooth surfaces | Resin handling |

Applications of Different 3D Printing Technologies

Now that we’ve covered the technical nitty-gritty, let’s explore where these technologies shine in the real world! 🌍

-

FDM: Great for prototyping and educational purposes. It’s the bread and butter of hobbyists and educators alike. Explore FDM in education.

-

SLA: Ideal for dental and jewelry applications, where precision is key.

-

SLS: Used in automotive and aerospace for complex and durable parts.

-

DLP: Perfect for small, detailed objects like figurines and dental models.

-

Binder Jetting: Employed for full-color prototypes and sand casting molds.

-

Material Jetting: Suited for medical models and high-fidelity prototypes.

-

MJF: Ideal for functional prototypes and end-use parts.

-

LOM: Used in packaging and architectural models.

-

EBM: Critical for aerospace components and medical implants.

-

CLIP: Great for rapid prototyping and smooth surface finishes.

Choosing the Right 3D Printing Technology for Your Project

Feeling overwhelmed by choices? Fear not! Here’s a step-by-step guide to help you choose the right technology for your project:

Step 1: Define Your Goals

- What are you printing? Is it a prototype, a final product, or an artistic piece?

- What material properties do you need? Consider strength, flexibility, and temperature resistance.

Step 2: Consider Your Budget

- What’s your budget? Remember, higher precision and speed often come at a higher cost.

Step 3: Evaluate the Technology

- Match your needs to the technology. Use the comparative table above to find the best fit.

Step 4: Test and Iterate

- Prototype and refine. Don’t be afraid to test different technologies and iterate until you find the perfect solution.

Future Trends in 3D Printing Technologies

The future of 3D printing is as bright as a supernova! 🌟 Here are some trends to keep an eye on:

-

Bioprinting: Printing tissues and organs is no longer science fiction. It’s happening, and it’s groundbreaking!

-

Sustainable Materials: Eco-friendly materials are gaining traction, reducing the environmental footprint of 3D printing.

-

Increased Automation: Automation in 3D printing will streamline processes, making it more accessible and efficient.

-

Enhanced Speed and Precision: Technologies like CLIP are pushing the boundaries of speed and accuracy.

-

Hybrid Manufacturing: Combining 3D printing with traditional manufacturing methods for optimized production.

Stay tuned for these exciting developments, and keep exploring the vast universe of 3D printing! 🚀

👉 CHECK PRICE on:

- Ultimaker 3D Printers: Amazon | Walmart | Ultimaker Official Website

- Formlabs SLA Printers: Amazon | eBay | Formlabs Official Website

Ready to print the future? Let’s go!

Conclusion

And there you have it, folks! We’ve taken a deep dive into the fascinating world of 3D printing technologies, exploring the major types, their advantages, and their applications. From the trusty FDM to the precision of SLA, each technology has its own unique characteristics that make it suitable for different projects.

Summary of Positives and Negatives

Positives:

- Versatility: 3D printing can create everything from prototypes to final products across various industries.

- Innovation: The technology is constantly evolving, with new methods and materials emerging that enhance capabilities.

- Customization: You can create highly customized items tailored to specific needs.

Negatives:

- Cost Variability: Some high-precision printers and materials can be quite expensive.

- Learning Curve: Certain technologies may require more technical knowledge and experience to operate effectively.

- Post-Processing Needs: Some methods, like SLA and SLS, may require additional finishing processes that can be time-consuming.

In conclusion, if you’re looking to venture into 3D printing, we confidently recommend starting with FDM for beginners or SLA for those needing high precision. Each technology offers unique benefits, so choose one that aligns with your goals. The future of 3D printing is bright, and we can’t wait to see what you create! 🌟

Recommended Links

👉 Shop 3D Printers:

- Ultimaker 3D Printers: Amazon | Walmart | Ultimaker Official Website

- Formlabs SLA Printers: Amazon | eBay | Formlabs Official Website

Books on 3D Printing:

- 3D Printing: A Practical Guide to Technology and Applications

- The 3D Printing Handbook: Technologies, Design and Applications

FAQ

How many types of 3D printing are there?

There are numerous types of 3D printing technologies, but the most common ones include FDM, SLA, SLS, DLP, Material Jetting, Binder Jetting, Multi Jet Fusion (MJF), and Electron Beam Melting (EBM). Each method has its unique processes and applications, making them suitable for different projects.

Read more about “Is PLA Biodegradable? … 🌱”

What are the 8 types of printing methods?

The eight prominent 3D printing methods are:

- Fused Deposition Modeling (FDM)

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

- Digital Light Processing (DLP)

- Material Jetting

- Binder Jetting

- Multi Jet Fusion (MJF)

- Electron Beam Melting (EBM)

Read more about “The 3D Printing Market: 10 Key Trends Shaping a USD 117.78 Billion Industry … 🤯”

What are the three types of 3D?

When broadly categorized, the three main types of 3D printing technologies are:

- Material Extrusion (FDM)

- Vat Polymerization (SLA and DLP)

- Powder Bed Fusion (SLS, MJF, EBM)

Read more about “What Is 3D Printing Used For? Discover 15 Incredible Applications in 2024! 🚀”

What is the difference between DLP and SLS?

DLP (Digital Light Processing) uses a digital light projector to cure liquid resin layer by layer, resulting in high detail and smooth surfaces. It is typically faster than SLA because it can cure an entire layer at once.

SLS (Selective Laser Sintering), on the other hand, uses a laser to sinter powdered material, layer by layer, without the need for support structures. This allows for complex geometries and strong parts but typically requires more post-processing.

What are some common applications for 3D printing?

3D printing is utilized in various sectors, including:

- Medical: Creating prosthetics, dental molds, and even bioprinting tissues.

- Aerospace: Manufacturing lightweight components and prototypes.

- Automotive: Rapid prototyping and custom parts production.

- Education: Hands-on learning tools and projects for students.

Read more about “The Ultimate Guide to the 3D Printing Process: 15 Must-Know Insights for 2024! 🚀”

How does 3D printing impact sustainability?

3D printing can reduce waste by producing only what is needed and allowing for the use of recycled materials. However, the environmental impact varies based on the materials and processes used, so it’s essential to choose sustainable options when possible.

Read more about “15 Incredible 3D Printing Uses That Will Transform Your World in 2024! 🚀”

Reference Links

- 3D Printing Technologies: Types and Advantages – 3DGence

- 3D Printing: An Overview – National Institute of Standards and Technology (NIST)

- Additive Manufacturing Technologies – Springer

Now that you’re equipped with all this knowledge, go forth and create amazing things with 3D printing! 🚀✨