Support our educational content for free when you purchase through links on our site. Learn more

Are 3D Prints Made of Plastic? Discover 10 Fascinating Facts You Didn’t Know! [2024] 🤔

Have you ever marveled at the wonders of 3D printing? You’re not alone! From intricate jewelry to custom prosthetics, 3D printing has transformed how we create and innovate. But here’s a question that often stumps both novices and enthusiasts alike: Are 3D prints made of plastic? The answer is a resounding yes, but there’s so much more to the story! 🌍

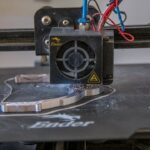

Imagine this: You’re at a tech expo, surrounded by the latest gadgets, when a 3D printer catches your eye. It’s whirring away, layer by layer, creating a stunning model right before your eyes. You can’t help but wonder what materials are being used. Are they durable? Eco-friendly? How do they stack up against traditional manufacturing? This article dives deep into the world of 3D printing materials, particularly plastics, and uncovers the secrets behind this revolutionary technology. From the common types of plastics used to the industries being transformed, we’ve got all your burning questions covered!

Key Takeaways

- 3D prints are primarily made from plastics, with PLA, ABS, and PVA being the most common materials.

- PLA is biodegradable and ideal for beginners, while ABS offers strength and versatility for functional parts.

- 3D printing is more environmentally friendly than traditional manufacturing, often using less energy and generating less waste. 🌱

- Electroplating 3D printed parts can enhance their appearance and durability, opening new possibilities for customization.

- Industries like aerospace, automotive, and healthcare are being revolutionized by 3D printing technology.

If you’re ready to dive into the world of 3D printing, check out our recommended links for 3D printers and filament options to kickstart your journey!

- 👉 Shop 3D Printers on: Amazon | Walmart | Etsy

- 👉 Shop PLA Filament on: Amazon | Walmart | 3D Printer Filament Official

Now, let’s unravel the mystery behind 3D printing and discover what makes these plastic marvels so special!

Table of Contents

- Quick Tips and Facts About 3D Printing with Plastic

- The Evolution of 3D Printing: A Material Perspective

- Basic 3D Printing Materials: What You Need to Know

- Diving Deep: Types of Plastic Used in 3D Printing

- Cost Factors in 3D Printing: What to Expect

- Is 3D Printing Difficult? Debunking the Myths

- Essential Questions to Ask Before Buying a 3D Printer

- Industries Revolutionized by 3D Printing Technology

- The Benefits of 3D Printing: Why You Should Care

- Can You Electroplate 3D Printed Parts? The Shiny Truth

- Plating Your 3D Products: The SPC Advantage

- Common Misconceptions About 3D Printing with Plastic

- 3D Printing and Sustainability: Is It Eco-Friendly?

- Future Trends in 3D Printing Materials

- Conclusion

- Recommended Links

- FAQ

- Reference Links

Quick Tips and Facts About 3D Printing with Plastic

- Yes, many 3D prints are made of plastic. 🤖

- PLA (Polylactic acid): Biodegradable, eco-friendly, comes in soft and hard forms. 🌿

- ABS (Acrylonitrile butadiene styrene): Strong, safe, popular for home printers and toys. 🎀

- PVA (Polyvinyl alcohol plastic): Low-cost, dissolvable, used for support materials. 💧

- PC (Polycarbonate): High temperature printing, used for fasteners and molding trays. 🔩

If you’re interested in learning more about the various materials that can be 3D printed at home, check out our article on What Materials Can Be 3D Printed at Home? Discover 15 Amazing Options for 2024! 📚

The Evolution of 3D Printing: A Material Perspective

The history of 3D printing dates back to the 1960s, but it wasn’t until the 1980s that the first commercial 3D printing technologies emerged. 📆 One of the earliest materials used in 3D printing was stereolithography (SLA) resin, which is still widely used today. 💡

In the 1990s, fused deposition modeling (FDM) became a popular method for 3D printing, using melted plastic to create objects. 🔩 This technology paved the way for the development of affordable and accessible 3D printing for consumers.

Today, 3D printing has evolved to include a wide range of materials, from plastics and metals to ceramics and glass. 🌈 The development of new materials and technologies continues to push the boundaries of what is possible with 3D printing.

Basic 3D Printing Materials: What You Need to Know

Types of Plastic Used in 3D Printing

| Material | Description | Uses |

|---|---|---|

| PLA | Biodegradable, eco-friendly | Prototyping, model making |

| ABS | Strong, safe, popular for home printers | Toys, household items |

| PVA | Low-cost, dissolvable | Support materials, molds |

| PC | High temperature printing | Fasteners, molding trays |

Other 3D Printing Materials

- Powders: Polyamide (Nylon), Alumide

- Resins: High-detail resins, Paintable resins, Transparent resins

- Metals: Stainless steel, Bronze, Nickel, Aluminum, Titanium

- Other: Carbon fiber, Graphite and graphene, Nitinol, Paper

Diving Deep: Types of Plastic Used in 3D Printing

PLA (Polylactic acid)

- Biodegradable and eco-friendly

- Comes in soft and hard forms

- Popular for prototyping and model making

- Can be used with a variety of 3D printing technologies

ABS (Acrylonitrile butadiene styrene)

- Strong and safe

- Popular for home printers and toys

- Can be used with FDM and SLA 3D printing technologies

- Can be post-processed with paint and other finishes

Cost Factors in 3D Printing: What to Expect

Printers

- Consumer-grade: Hundreds of dollars

- Business-grade: $1,000 to $5,000

- Industrial-grade: Tens of thousands of dollars

Materials

- Plastic filament: Less than $20 per kg

- Resins and flexible materials: More expensive

- Specialty materials (metals, carbon fiber): Most expensive

Is 3D Printing Difficult? Debunking the Myths

- Myth: 3D printing is only for experts and professionals.

- Reality: With the right equipment and training, anyone can learn to 3D print.

- Myth: 3D printing is too expensive for personal use.

- Reality: While high-end 3D printers can be expensive, there are many affordable options available for personal use.

Essential Questions to Ask Before Buying a 3D Printer

- What is your budget?

- What type of objects do you want to print?

- What is your level of experience with 3D printing?

- What kind of support and resources do you need?

Industries Revolutionized by 3D Printing Technology

- Aerospace: Lightweight, complex components

- Automotive: Custom parts, reduced production time

- Healthcare: Custom implants, prosthetics, and surgical models

- Fashion: Custom jewelry, shoes, and accessories

The Benefits of 3D Printing: Why You Should Care

- Time savings: On-demand printing, reduced lead times

- Cost savings: Reduced material waste, efficient production

- Versatility: Wide range of materials and designs

- On-site sourcing: Reduced dependence on overseas manufacturing

- Eco-friendly production: Reduced waste, fewer shipping requirements

Can You Electroplate 3D Printed Parts? The Shiny Truth

- Yes, you can electroplate 3D printed parts

- Electroplating can enhance the appearance and durability of 3D printed parts

- Common electroplating materials include copper, nickel, and chrome

Plating Your 3D Products: The SPC Advantage

- SPC offers a range of electroplating services for 3D printed parts

- Their expertise and high-quality equipment ensure a professional finish

- Contact SPC to learn more about their electroplating services

Common Misconceptions About 3D Printing with Plastic

- Myth: 3D printing with plastic is too expensive.

- Reality: While high-end 3D printers can be expensive, there are many affordable options available for personal use.

- Myth: 3D printing with plastic is too difficult.

- Reality: With the right equipment and training, anyone can learn to 3D print with plastic.

3D Printing and Sustainability: Is It Eco-Friendly?

- 3D printing can be more sustainable than traditional manufacturing methods

- 3D printing uses less energy and produces fewer emissions

- Biodegradable and renewable materials are becoming increasingly popular

Future Trends in 3D Printing Materials

- Increased use of biodegradable and renewable materials

- Development of new materials with unique properties

- Advances in metal and ceramic 3D printing

To learn more about the latest trends and innovations in 3D printing, check out our article on What Materials Can Be 3D Printed at Home? Discover 15 Amazing Options for 2024! 📚

Conclusion

In summary, 3D printing with plastic is a versatile and innovative technology that has significantly transformed various industries. The most common materials like PLA, ABS, and PVA offer a range of benefits, from eco-friendliness to durability. 🌍 However, each material comes with its own set of pros and cons.

Positives:

- PLA is biodegradable and easy to use, making it ideal for beginners.

- ABS offers strength and versatility, perfect for functional parts.

- PVA is excellent for support structures in complex prints.

Negatives:

- PLA can be less durable under heat compared to ABS.

- ABS requires specific conditions for printing, such as a heated bed, which can be a hurdle for some users.

- PVA is not suitable for all applications due to its dissolvable nature.

Overall, we confidently recommend exploring 3D printing with plastic as a fantastic way to unleash your creativity and produce functional objects. Whether you’re a hobbyist or a professional, the possibilities are virtually endless! So, roll up your sleeves, grab your filament, and start printing! 🚀

Recommended Links

- 👉 Shop 3D Printers on: Amazon | Walmart | Etsy

- 👉 Shop PLA Filament on: Amazon | Walmart | 3D Printer Filament Official

- Books on 3D Printing:

FAQ

What are 3D prints made of?

3D prints are primarily made from a variety of materials, with plastics being the most common. Popular types include PLA, ABS, and PETG, each offering unique properties suitable for different applications. Other materials like metals, ceramics, and even biomaterials are also used, depending on the specific requirements of the print.

Read more about “What Materials Can Be 3D Printed at Home? Discover 15 Amazing Options for 2024! 🖨️”

Is 3D printing environmentally friendly?

Yes, 3D printing can be more environmentally friendly than traditional manufacturing methods. It often uses less energy and generates less waste. Many 3D printing materials, like PLA, are biodegradable and made from renewable resources. Additionally, the ability to print on-demand reduces the need for mass production and long-distance shipping. 🌱

Read more about “Is 3D printing environmentally friendly?”

Are 3D printed houses made of plastic?

While 3D printed houses are not typically made solely of plastic, some innovations use recycled plastics in combination with other materials like concrete and mortar. These materials help create sustainable housing solutions that minimize waste and environmental impact. For more details, check out What material are 3D printed houses made of? – COBOD.

Read more about “3D Printing Statistics: 75+ Facts and Trends You NEED to Know … 🤯”

Can 3D prints be recycled?

Yes, many 3D printed materials, especially plastics like PLA and ABS, can be recycled. Some companies even offer services to recycle used filament and prints into new products. However, the recycling process can vary based on the material used, so it’s essential to check local recycling guidelines.

What are the best practices for 3D printing with plastic?

- Choose the right material for your project.

- Calibrate your printer to ensure the best results.

- Use a heated bed for materials like ABS to prevent warping.

- Store filament properly to avoid moisture absorption.

Read more about “Unlocking the Secrets of 3D Printing Polymers: 10 Must-Know Insights for 2024! 🚀”