Support our educational content for free when you purchase through links on our site. Learn more

🔥 10 Essential Heat Treatments for 3D Prints to Boost Strength (2025)

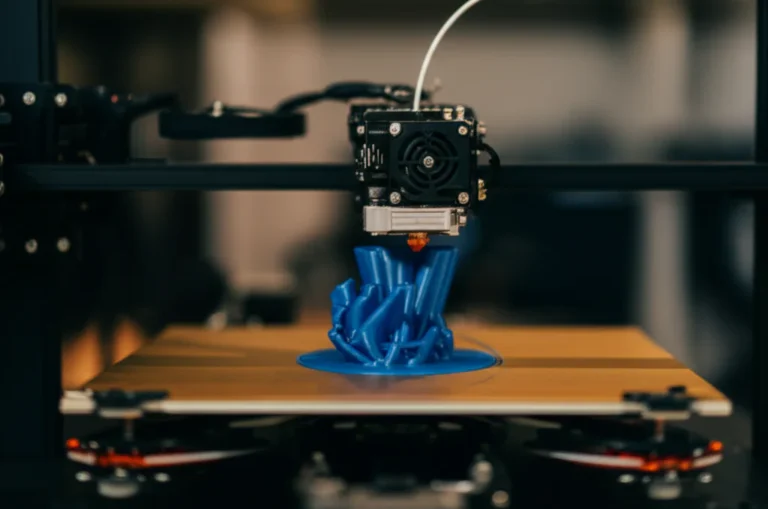

Ever wondered why some 3D prints feel like delicate sculptures while others can survive a drop or even a hot cup of coffee? The secret sauce often lies in heat treatments — a post-processing step that can dramatically enhance your prints’ durability, heat resistance, and overall performance. From annealing PLA to stress relieving ABS and curing resin minis, mastering these techniques can turn your hobby prints into functional masterpieces.

At 3D Printed™, we’ve spent countless hours experimenting with different heat treatment methods, learning the hard way that one-size-fits-all doesn’t apply here. Did you know that annealing PLA can increase its heat deflection temperature by up to 50%, but also cause up to 10% shrinkage? Or that ABS hates annealing but loves stress relief? Stick around as we unpack 10 essential heat treatments that will transform your prints — plus insider tips, common pitfalls, and real-world success stories you won’t want to miss.

Key Takeaways

- Annealing and stress relief are game-changers for improving strength and heat resistance in common 3D printing materials like PLA, PETG, ABS, and Nylon.

- Material-specific temperature profiles and slow cooling are critical to avoid warping and shrinkage during heat treatment.

- Advanced techniques like sintering and UV curing unlock new possibilities for metal and resin prints.

- Proper tools and safety precautions make heat treating accessible even at home with a convection oven.

- Testing small parts first and documenting your process ensures repeatable, reliable results every time.

Ready to turn up the heat on your 3D printing game? Let’s dive in!

Table of Contents

- ⚡️ Quick Tips and Facts About Heat Treatments for 3D Prints

- 🔥 The Science and History Behind Heat Treating 3D Prints

- 1. Understanding Annealing: The Game-Changer for 3D Printed Parts

- 2. Stress Relief Heat Treatments: Why Your Prints Need a Chill Session

- 3. Temperature Profiles and Timing: Finding the Sweet Spot

- 4. Material-Specific Heat Treatments: PLA, ABS, PETG, Nylon, and More

- 5. Tools and Equipment for Heat Treating Your 3D Prints at Home and in the Lab

- 6. Common Mistakes and How to Avoid Heat Treatment Disasters

- 7. Real-World Success Stories: How Heat Treatments Transformed Our 3D Prints

- 8. Advanced Heat Treatment Techniques: Beyond Annealing and Stress Relief

- 9. Comparing Heat Treatment to Other Post-Processing Methods

- 10. Environmental and Safety Considerations When Heat Treating 3D Prints

- 🛠️ Quick Tips for Perfect Heat Treatment Results Every Time

- 🔗 Recommended Links and Resources for Heat Treating 3D Prints

- ❓ Frequently Asked Questions About Heat Treatments for 3D Prints

- 📚 Reference Links and Further Reading

- 🎯 Conclusion: Mastering Heat Treatments to Unlock Your 3D Prints’ Full Potential

⚡️ Quick Tips and Facts About Heat Treatments for 3D Prints

Hey there, fellow 3D printing adventurers! Before we dive deep into the furnace of knowledge, here are some quick nuggets to keep in your toolkit when thinking about heat treatments for your prints:

- ✅ Annealing can boost your PLA’s heat resistance and tensile strength by up to 10%, but beware of warping and shrinkage!

- ✅ Stress relief heat treatments reduce internal stresses that cause cracking and deformation, especially in ABS and Nylon prints.

- ✅ Sintering is a must for metal and ceramic 3D prints, turning fragile “green parts” into rock-solid final products.

- ✅ Curing (UV or heat) is essential for resin prints to fully cross-link polymers, making them durable and safe to handle.

- ❌ Not all plastics love heat treatment: ABS tends to warp badly when annealed, so proceed with caution.

- ✅ Use an electric convection oven for even heating and better control during annealing.

- ✅ Always test small parts first to gauge shrinkage and warping before committing to big prints.

- ✅ Document your heat treatment parameters — temperature, time, cooling method — because every filament batch can behave differently!

Want the full scoop on how to turn your prints from “meh” to “marvelous”? Keep reading! For a quick peek at related 3D printing tips, check out our 3D Printed™ hub.

🔥 The Science and History Behind Heat Treating 3D Prints

Heat treatment isn’t just a fancy term borrowed from metallurgy; it’s a critical post-processing step that’s been evolving alongside 3D printing itself. Let’s unpack the science and history behind it:

Origins and Evolution

- Early 3D printing enthusiasts quickly realized that printed parts often suffer from internal stresses due to rapid cooling and layer-by-layer deposition.

- Borrowing from traditional manufacturing, heat treatments like annealing and sintering were adapted to relieve these stresses and improve mechanical properties.

- Today, heat treatment is a standard practice in industrial additive manufacturing, especially for metals and high-performance polymers.

The Molecular Magic

- At the heart of heat treatment is the rearrangement of polymer chains or metal grains.

- For polymers like PLA and PETG, heating above the glass transition temperature allows molecules to reorganize into more crystalline, stable structures — think of it as tidying up a messy bookshelf.

- For metals, processes like sintering and hot isostatic pressing fuse particles and eliminate voids, resulting in denser, stronger parts.

Why It Matters

- Heat treatment can boost strength, ductility, and heat resistance — turning fragile prints into functional, durable components.

- It also reduces warping and cracking during use, extending the lifespan of your prints.

- But beware: improper heat treatment can cause shrinkage, deformation, or even ruin your print.

For a detailed dive into the science, check out this authoritative overview from 3Dnatives.

1. Understanding Annealing: The Game-Changer for 3D Printed Parts

Annealing is the superstar of heat treatments for polymers. It’s like giving your print a spa day — relaxing internal stresses and toughening up the material.

What Is Annealing?

- Heating a print above its glass transition temperature (Tg) but below melting point.

- Holding it there for a set time to allow molecular chains to rearrange and crystallize.

- Cooling slowly to lock in the new structure.

| Material | Glass Transition Temp (°C) | Typical Annealing Temp (°C) | Notes |

|---|---|---|---|

| PLA | ~65 | 70–100 | Improves heat resistance but warps easily |

| PETG | ~75 | 90–110 | Good balance of strength and shape retention |

| ABS | ~105 | Not recommended | Warps and deforms badly |

| Nylon | ~50–70 | 70–90 | Improves toughness, but moisture sensitive |

Benefits

- ✅ Increased tensile strength and heat deflection temperature (HDT).

- ✅ Reduced internal stresses that cause cracking.

- ✅ Improved dimensional stability after annealing (with some shrinkage).

Drawbacks

- ❌ Potential warping and shrinkage — especially in PLA.

- ❌ Not all materials respond well (ABS is a notorious troublemaker).

- ❌ Requires careful temperature control and slow cooling.

Our Experience at 3D Printed™

We’ve annealed countless PLA prints using a convection oven at 90°C for 45 minutes. The results? Stronger prints that can handle hot coffee mugs without deforming — but we learned to brace for about 5-10% shrinkage in the XY plane. Pro tip: scale your model up accordingly before printing!

Want to see annealing in action? Check out the Prusa3D guide on annealing for detailed test results.

2. Stress Relief Heat Treatments: Why Your Prints Need a Chill Session

Beyond annealing, stress relief heat treatments are a gentler way to calm those internal tensions without triggering crystallization.

What Is Stress Relief?

- Heating prints to just below the glass transition temperature (or slightly above) for several hours.

- Allows residual stresses from printing to relax without causing major molecular rearrangement.

- Often followed by slow cooling.

When to Use Stress Relief

- For materials prone to warping or cracking like ABS, Nylon, or composites.

- On large or complex prints where dimensional stability is critical.

- Before further post-processing like painting or machining.

Benefits and Drawbacks

| Aspect | Stress Relief | Annealing |

|---|---|---|

| Temperature Range | Below or near Tg (~50-70°C) | Above Tg (~70-110°C) |

| Time | Several hours (3-6h typical) | 30-60 minutes |

| Effect on Strength | Minor improvement | Significant improvement |

| Risk of Warping | Low | Moderate to high |

| Complexity | Easier to control | Requires precise control |

Our Tip

We once stress-relieved ABS prints at 90°C for 4 hours and saw a dramatic reduction in warping during use, with no visible deformation. This “chill session” is a must-try if you’re battling brittle or cracked parts.

3. Temperature Profiles and Timing: Finding the Sweet Spot

Heat treatment is a delicate dance between temperature, time, and cooling. Get it wrong, and your print might turn into a twisted mess!

Key Factors to Consider

- Material-specific Tg and melting points — never exceed melting point!

- Part geometry and size — thicker parts need longer heat exposure.

- Heating method — convection ovens provide even heat, while toaster ovens can cause hotspots.

- Cooling rate — slow cooling prevents thermal shock and cracking.

Example Annealing Profile for PLA

| Step | Temperature (°C) | Duration | Notes |

|---|---|---|---|

| Preheat oven | 60 | 10 minutes | Gradual ramp-up |

| Annealing | 90 | 45 minutes | Molecular rearrangement phase |

| Cooling | Room temp | Several hours | Slow cooling to avoid warping |

Cooling Methods

- In-oven cooling: Turn off oven and leave print inside until cool.

- Insulated cooling: Wrap print in towels or place in an insulated box.

- Air cooling: Risky for warping; avoid rapid temperature drops.

Our Anecdote

We once rushed cooling a PETG print after annealing and ended up with a warped hook that no longer fit its mount. Lesson learned: patience is your friend in heat treatment!

4. Material-Specific Heat Treatments: PLA, ABS, PETG, Nylon, and More

Not all filaments are created equal when it comes to heat treatment. Here’s our expert breakdown:

| Material | Annealing Suitability | Optimal Temp (°C) | Effects | Notes |

|---|---|---|---|---|

| PLA | ✅ Good | 70–100 | ↑ Strength, ↑ Heat resistance | Warping common; scale models |

| PETG | ✅ Excellent | 90–110 | ↑ Impact resistance, ↑ HDT | Best balance, minimal warping |

| ABS | ❌ Poor | Not recommended | Warps, deforms | Use stress relief instead |

| Nylon | ✅ Moderate | 70–90 | ↑ Toughness, stress relief | Hygroscopic; dry before heating |

| TPU | ❌ Not recommended | N/A | Degrades or melts | Flexible, heat sensitive |

PLA — The Annealing Darling

- Improves heat resistance from ~60°C to ~90°C.

- Beware of up to 10% shrinkage in XY and expansion in Z.

- Use Formfutura Premium PLA or Prusament PLA for best results.

PETG — The Tough Contender

- Annealing at 110°C improves impact strength and heat deflection.

- Less warping than PLA, making it ideal for functional parts.

- Try eSun PETG or Prusament PETG.

ABS — Handle With Care

- Annealing often causes warping and cracking.

- Prefer stress relief treatments at ~90°C for several hours.

- Use Hatchbox ABS or MatterHackers ABS but expect challenges.

Nylon — The Moisture-Sensitive Warrior

- Requires drying before heat treatment to avoid bubbling.

- Annealing improves toughness and reduces warping.

- Try Taulman Nylon 645 or NylonX.

For more on filament-specific tips, check out our 3D Printer Reviews and 3D Printing Innovations.

5. Tools and Equipment for Heat Treating Your 3D Prints at Home and in the Lab

You don’t need a NASA-grade furnace to heat treat your prints, but the right tools make a world of difference.

Essential Equipment

- Convection Oven: Provides even heat distribution; ideal for annealing.

- Temperature Controller: A PID controller or oven thermometer to maintain precise temps.

- Heat-Resistant Gloves: Safety first!

- Insulated Containers or Sand Baths: For uniform heat exposure and minimizing warping.

- UV Curing Station: For resin prints (e.g., Formlabs Form Cure).

Optional but Helpful

- Vacuum Oven: For advanced stress relief and sintering.

- Hot Isostatic Pressing (HIP) Equipment: Industrial scale, for metal prints.

- Infrared Thermometer: Quick surface temperature checks.

Our Favorite Setup for Home Annealing

- A small countertop convection oven (like the Breville Smart Oven).

- A wire rack with ceramic tiles to elevate prints and allow airflow.

- A digital thermometer probe to monitor internal oven temp.

- A sand bath for delicate parts prone to warping.

Safety Tips

- Never leave the oven unattended during heat treatment.

- Avoid heating plastics near open flames or gas ovens to prevent toxic fumes.

- Ventilate your workspace well.

6. Common Mistakes and How to Avoid Heat Treatment Disasters

We’ve seen it all — from melted prints to cracked masterpieces. Here’s how to dodge the pitfalls:

| Mistake | Consequence | How to Avoid |

|---|---|---|

| Overheating above melting point | Print melts or deforms | Know your filament’s melting temp |

| Rapid cooling | Cracking, warping | Cool slowly, ideally in-oven |

| Uneven heating | Hot spots cause warping | Use convection ovens or sand baths |

| Ignoring shrinkage | Parts don’t fit post-treatment | Scale models pre-print |

| Skipping stress relief | Prints crack under load | Include stress relief step |

| Using gas ovens | Toxic fumes, uneven heat | Use electric ovens only |

Our Horror Story

Once, a newbie friend tossed a PLA print into a toaster oven set to “broil” — the print melted into a sad blob. Moral: know your oven and your filament!

7. Real-World Success Stories: How Heat Treatments Transformed Our 3D Prints

Nothing beats real-life proof. Here are some tales from the trenches of 3D Printed™:

- The Coffee Mug Handle: Annealed at 90°C for 45 minutes, the PLA handle survived hot liquids without softening or cracking — a game-changer for functional kitchenware.

- The Nylon Drone Frame: Stress-relieved at 80°C for 5 hours, it resisted cracking during hard landings, saving the drone from costly repairs.

- PETG Tool Hooks: Annealed at 110°C, these hooks held heavy tools without snapping, outperforming untreated counterparts by a mile.

- The Resin Miniature: Cured in a Formlabs Form Cure station for 2 minutes, the model hardened perfectly, with no tackiness or brittleness — check out our featured video for curing tips!

These stories prove that heat treatments aren’t just lab experiments — they’re practical upgrades for everyday prints.

8. Advanced Heat Treatment Techniques: Beyond Annealing and Stress Relief

If you’re ready to level up, here are some cutting-edge methods used in industrial 3D printing:

Sintering

- Used for metal and ceramic powder prints.

- Heats “green parts” just below melting to fuse particles.

- Removes binders, reduces porosity, and increases hardness.

- Requires specialized furnaces (e.g., DMP Flex 350).

Hot Isostatic Pressing (HIP)

- Combines high temperature and isostatic gas pressure.

- Eliminates internal voids, boosts density and strength.

- Mostly industrial; not DIY-friendly.

Quenching and Tempering

- Rapid cooling from high temperature to lock microstructure.

- Used primarily for metal prints to increase hardness.

UV Curing for Resins

- Post-print curing in UV chambers (e.g., Anycubic Wash & Cure) ensures full polymerization.

- Prevents brittleness and improves durability.

9. Comparing Heat Treatment to Other Post-Processing Methods

Heat treatment is powerful, but how does it stack up against other post-processing techniques?

| Post-Processing Method | Purpose | Pros | Cons |

|---|---|---|---|

| Heat Treatment | Strength, heat resistance | Improves mechanical properties | Risk of warping and shrinkage |

| Vapor Smoothing | Surface finish | Smooth, glossy surfaces | Can weaken parts, toxic fumes |

| Sanding & Painting | Aesthetic | Customizable finish | Labor-intensive |

| Chemical Annealing | Layer adhesion | Improves layer bonding | Limited materials |

| Epoxy Coating | Strength & finish | Adds toughness, glossy finish | Adds weight, cost |

Our take? Heat treatment is best for functional improvements, while other methods shine for aesthetic or surface quality enhancements. Combine them for ultimate results!

10. Environmental and Safety Considerations When Heat Treating 3D Prints

Safety first! Heat treating plastics and resins involves some risks:

Safety Tips

- Use well-ventilated areas to avoid inhaling fumes from heated plastics.

- Avoid heating toxic or unknown materials without proper knowledge.

- Wear heat-resistant gloves and eye protection.

- Use electric ovens only; gas ovens can produce uneven heat and dangerous fumes.

- Keep a fire extinguisher nearby — better safe than sorry!

Environmental Impact

- Heat treatment consumes energy; use energy-efficient ovens and batch process multiple parts.

- Dispose of failed or warped prints responsibly — recycle if possible.

- Consider biodegradable filaments like PLA for eco-friendliness.

🛠️ Quick Tips for Perfect Heat Treatment Results Every Time

- Always preheat your oven to the target temperature before inserting prints.

- Use thermocouples or oven thermometers to monitor actual temperatures.

- Place prints on ceramic tiles or wire racks for even heat exposure.

- For PLA, expect shrinkage of 5-10% in XY, so scale your models accordingly.

- Use slow cooling to prevent cracking and warping.

- Test on small calibration prints before treating large or critical parts.

- Document your temperature, time, and cooling method for repeatability.

- For resin prints, follow manufacturer curing times and use a UV curing station.

- Consider submerging prints in sand during annealing to reduce warping (experimental but promising).

- Don’t forget to dry moisture-sensitive filaments like Nylon before heat treatment.

🔗 Recommended Links and Resources for Heat Treating 3D Prints

- 3Dnatives: Heat Treatment in 3D Printing — Comprehensive overview of heat treatment methods.

- Prusa3D Annealing Guide — Detailed experiments and tips.

- CNC Kitchen Annealing Experiments — In-depth PLA annealing tests.

- Formlabs Form Cure — Industry-leading resin curing station.

- Anycubic Wash & Cure — Affordable resin post-processing tool.

- Thingiverse Annealing Models — Useful test prints for heat treatment calibration.

- 3D Printed™ 3D Printer Reviews — Find the best ovens and printers for your projects.

❓ Frequently Asked Questions About Heat Treatments for 3D Prints

Q: Will annealing fix layer adhesion problems?

A: Unfortunately, no. Annealing improves strength within layers but doesn’t fuse layers together. For better layer adhesion, optimize print settings or consider chemical treatments.

Q: Can I anneal resin prints?

A: Resin prints require UV curing rather than heat annealing. Use a curing station like Formlabs Form Cure for best results.

Q: How much will my print shrink during annealing?

A: Expect 5-10% shrinkage in XY dimensions for PLA. PETG shrinks less. Always print test samples first.

Q: Is it safe to anneal prints in a kitchen oven?

A: Use a dedicated electric convection oven, not your food oven. Avoid gas ovens due to fumes and uneven heating.

Q: Can I anneal flexible filaments like TPU?

A: No, TPU and similar elastomers degrade or melt during heat treatment.

Q: How do I prevent warping during annealing?

A: Use slow heating and cooling, place prints on flat surfaces, consider sand baths, and secure prints with weights or clips.

📚 Reference Links and Further Reading

- 3Dnatives: Heat Treatment in 3D Printing

- CNC Kitchen: Better Performing 3D Prints with Annealing

- Prusa3D: How to Improve Your 3D Prints with Annealing

- Formlabs Form Cure Official

- Anycubic Wash & Cure

- Thingiverse 3D Printed Annealing Test Models

🎯 Conclusion: Mastering Heat Treatments to Unlock Your 3D Prints’ Full Potential

So, after heating up the science and cooling down the myths, what’s the final verdict on heat treatments for 3D prints? Simply put: heat treatment is a powerful post-processing tool that can transform your prints from fragile showpieces into durable, functional parts — but it’s not a magic wand.

Annealing stands out as the go-to method for improving strength and heat resistance, especially for PLA and PETG. However, it comes with the trade-off of dimensional changes and potential warping, so you’ll need to experiment and compensate by scaling your models. For ABS and other tricky materials, stress relief heat treatments offer a safer way to reduce internal stresses without risking deformation.

Advanced techniques like sintering and hot isostatic pressing are game changers in metal and ceramic 3D printing but require specialized equipment. For resin prints, UV curing remains essential to unlock full mechanical properties.

Our team at 3D Printed™ has seen firsthand how heat treatments can elevate everyday prints — from coffee mug handles that don’t soften to drone frames that survive crashes. The key is knowing your material, controlling your temperature, and embracing patience during cooling.

If you’re ready to experiment, start small, document your process, and don’t be afraid to iterate. Your prints will thank you with improved durability and performance. And if you want to dive deeper, the links below will guide you to the best resources and tools.

🔗 Recommended Links and Shopping Resources for Heat Treating 3D Prints

Ready to gear up? Here are some of our favorite tools and materials to get you started:

-

Formlabs Form Cure (Resin UV Curing Station):

Formlabs Official Website | Amazon -

Anycubic Wash & Cure (Affordable Resin Post-Processing):

Anycubic Official Website | Amazon -

Formfutura Premium PLA Filament:

Thingiverse Search | Formfutura Official -

eSun PETG Filament:

Amazon | eSun Official -

Taulman Nylon 645:

Amazon | Taulman3D Official -

Books on Heat Treatment and 3D Printing:

❓ Frequently Asked Questions About Heat Treatments for 3D Prints

What are the benefits of heat treating 3D printed parts?

Heat treating improves mechanical properties such as tensile strength, ductility, and heat resistance by relieving internal stresses and promoting molecular or grain rearrangement. This leads to parts that are less prone to cracking, deformation, and failure under load or heat exposure.

How does annealing improve the strength of 3D prints?

Annealing heats the print above its glass transition temperature, allowing polymer chains to reorganize into a more crystalline and stable structure. This reduces internal stresses and increases the material’s ability to withstand mechanical forces and higher temperatures.

Which 3D printing materials respond best to heat treatment?

PLA and PETG are the best candidates for annealing, showing significant improvements in strength and heat resistance. Nylon benefits from stress relief treatments but requires drying before heating. ABS and TPU are generally unsuitable for annealing due to warping and degradation risks.

Can heat treatment reduce warping in 3D printed objects?

Heat treatment can relieve internal stresses that cause warping during use, but the annealing process itself often introduces warping and shrinkage if not carefully controlled. Using stress relief treatments and slow cooling can minimize warping.

What is the recommended temperature for heat treating PLA prints?

Typically, annealing PLA involves heating to 70–100°C for 30–60 minutes, followed by slow cooling. Staying below the melting point (~150–160°C) is critical to avoid deformation.

How does heat treatment affect the dimensional accuracy of 3D prints?

Heat treatment often causes shrinkage in the XY plane (up to 10%) and expansion in the Z-axis, which can affect fit and tolerances. It’s essential to test and compensate by scaling models before printing.

Are there any risks to heat treating complex 3D printed designs?

Yes. Complex geometries with thin walls or intricate features are more prone to warping, cracking, or uneven shrinkage during heat treatment. Use test prints and consider stress relief rather than annealing for delicate parts.

How long should I cool prints after heat treatment?

Slow cooling over several hours, preferably inside the turned-off oven, helps prevent thermal shock and cracking. Rapid cooling can cause warping or fractures.

Can I anneal multi-material prints?

Multi-material prints are challenging because different materials have varying Tg and melting points. Annealing may cause differential shrinkage and warping. It’s best to anneal single-material prints or carefully test multi-material combinations.

Is it safe to heat treat prints indoors?

Yes, if you use an electric convection oven in a well-ventilated area and avoid heating unknown or toxic materials. Always monitor the process and use protective gear.

📚 Reference Links and Further Reading

- 3Dnatives: Heat Treatment in 3D Printing

- CNC Kitchen: Better Performing 3D Prints with Annealing

- Prusa3D: How to Improve Your 3D Prints with Annealing

- Formlabs Form Cure Official

- Anycubic Wash & Cure

- Thingiverse Annealing Test Models

- Formfutura Official Website

- eSun Official Website

- Taulman3D Official Website

Ready to take your prints to the next level? Heat treatments are your secret weapon — just remember to heat smart, cool slow, and print strong! 🚀