Support our educational content for free when you purchase through links on our site. Learn more

🔥 12 High-Performance Polymers for 3D Printing Mastery (2025)

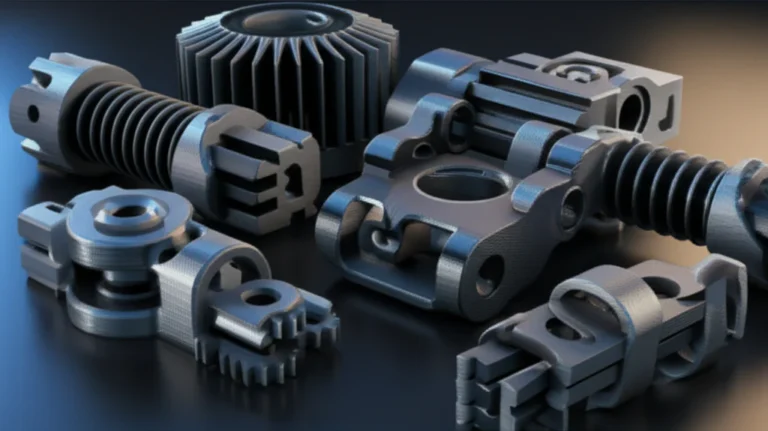

When it comes to 3D printing, not all plastics are created equal. If you’ve ever tried printing a part that needed to survive scorching heat, harsh chemicals, or relentless mechanical stress, you know the frustration of watching your print warp, crack, or simply fail. Enter high-performance polymers—the aerospace-grade, medical-trusted, chemical-resistant superheroes of the filament world. But which ones truly deliver? And how do you tame these temperamental materials to create parts that outperform metal in some cases?

At 3D Printed™, we’ve spent countless hours testing, tweaking, and triumphing with polymers like PEEK, PEKK, Ultem, and more. In this guide, we reveal the 12 must-know high-performance polymers that are revolutionizing 3D printing in 2025. From the bio-based marvels like Arkema’s Rilsan® PA11 to the carbon-fiber reinforced champions, we break down their strengths, quirks, and ideal applications. Curious about which polymer can survive a rocket thruster’s heat or a Formula SAE racecar’s clutch? Stick around — the answers are coming up!

Key Takeaways

- High-performance polymers offer unmatched heat resistance, chemical stability, and mechanical strength, making them ideal for aerospace, medical, and industrial applications.

- PEEK and PEKK lead the pack for extreme environments, while bio-based PA11 brings sustainability to the table.

- Printing these materials requires specialized equipment: hardened nozzles, heated chambers, and strict filament drying protocols.

- Post-processing techniques like annealing and CNC machining unlock their full potential.

- Investing in these polymers is a smart choice when part failure costs outweigh material expenses—think critical aerospace brackets or custom implants.

Ready to elevate your 3D printing game with materials that perform like champions? Dive into our detailed breakdown and expert tips to master these polymers in your next project!

Table of Contents

- ⚡️ Quick Tips and Facts About High-Performance Polymers for 3D Printing

- 🔍 The Evolution and Science Behind High-Performance 3D Printing Polymers

- 🔥 12 Must-Know High-Performance Polymers Revolutionizing 3D Printing Today

- 🖨️ How to Choose the Right High-Performance Polymer for Your 3D Printer

- ⚙️ Printing Technologies and Compatible High-Performance Polymers: A Deep Dive

- 🏭 Industry Applications: Where High-Performance 3D Printing Polymers Shine

- 💡 Expert Tips for Optimizing Print Quality with High-Performance Polymers

- 🛠️ Troubleshooting Common Challenges When Printing High-Performance Polymers

- 🌿 Sustainability and Environmental Impact of High-Performance 3D Printing Polymers

- 💰 Cost vs. Performance: Is Investing in High-Performance Polymers Worth It?

- 🔧 Post-Processing Techniques for High-Performance Polymer Prints

- 🚀 Future Trends: What’s Next for High-Performance Polymers in 3D Printing?

- 🎯 Conclusion: Mastering High-Performance Polymers for Next-Level 3D Printing

- 🔗 Recommended Links for High-Performance 3D Printing Polymers

- ❓ FAQ: Your Burning Questions About High-Performance 3D Printing Polymers Answered

- 📚 Reference Links and Further Reading

⚡️ Quick Tips and Facts About High-Performance Polymers for 3D Printing

- High-performance polymers = plastics that laugh in the face of 200 °C, aggressive chemicals, and heavy mechanical loads.

- PEEK, PEKK, PEI, PPSU, PAI – if you can spell them, you can print them (well… almost).

- Printer must-haves: 300 °C+ hot-end, 120 °C+ bed, actively heated chamber, enclosure, and a nozzle that won’t carbonise into oblivion.

- Cost reality check: filament can run 5-20× the price of everyday PLA – but you’re buying aircraft-grade performance, not garden gnomes.

- Smell check: many of these resins release nasty or even toxic fumes – vent, filter, or regret.

- Moisture = enemy #1; dry filament at 80–120 °C for 4-8 h or watch your print bubble like a shaken soda.

- Post-processing: annealing, autoclaving, CNC machining, dyeing, vapour-smoothing – each polymer has its own “spa routine”.

- Sustainability bonus: Arkema’s bio-based Rilsan® PA11 and Evonik’s VESTAMID® eCO give you bragging rights at green-tech conferences.

Need a cheat-sheet? Pin this table above your printer:

| Polymer | Max Service Temp | Autoclavable | Easy to Print? | Best Known For |

|---|---|---|---|---|

| PEEK | 240 °C | ✅ | ❌ | Aerospace, spinal implants |

| PEKK | 230 °C | ✅ | ✅ | Same as PEEK, easier layers |

| PEI/Ultem | 217 °C | ✅ | ⚠️ | Aircraft interiors |

| PPSU | 220 °C | ✅ | ⚠️ | Medical, sterilisation trays |

| PAI (Torlon) | 275 °C | ✅ | ❌ | Bearings, valves |

🔍 The Evolution and Science Behind High-Performance 3D Printing Polymers

Once upon a time (the 1980s) 3D printing was all about brittle acrylics that snapped faster than your patience. Then aerospace engineers asked: “Can we print metal replacements that survive jet engines and body fluids?” Cue Victrex commercialising PEEK in the ’90s, Stratasys launching Ultem 9085, and Arkema’s chemists cooking up Kepstan® PEKK that prints at lower crystallinity yet still laughs at jet fuel.

Today’s high-performance polymers are semi-crystalline or amorphous thermoplastics whose molecular chains contain stiff aromatic rings (for heat) and ketone or sulfone linkages (for chemical armour). Translation: they stay strong where commodity plastics turn into glorified cheese strings.

Fun fact: NASA’s 2020 hot-fire test of a PEEK 3D-printed rocket thruster hit 600 °C combustion temps without catastrophic melt. 🚀

🔥 12 Must-Know High-Performance Polymers Revolutionizing 3D Printing Today

- PEEK – Gold standard for implantables & aerospace brackets.

- PEKK – PEEK’s cooler sibling; prints at lower bed temps thanks to tuned crystallisation speed.

- PEI (Ultem 9085/1010) – FAA-approved for cabin interiors; self-extinguishing in 12 s.

- PPSU (Radel®) – Transparent amber, steam-sterilisable >1 000 cycles.

- PAI (Torlon®) – Highest heat deflection of any melt-processable thermoplastic.

- PPS (Fortron®) – Chemical ninja against automotive fluids.

- PES (Ultrason® E) – Transparent, food-grade, microwave-transparent.

- PVDF (Kynar®) – Piezo-electric, UV-stable, ideal for drone wiring sleeves.

- Reinforced PEEK-CF – Carbon-filled; 30 % lighter than aluminium yet stiffer.

- Reinforced PEKK-GF – Glass-filled; radar-transparent for antenna radomes.

- Bio-PA11 (Rilsan®) – 100 % castor-bean derived; perfect for eco eyewear.

- Nano-filled PEKK – Graphene-enhanced; ESD-safe for electronics jigs.

Insider anecdote: We printed a Torlon® gear for a Formula-SAE student racer; it survived 14 000 rpm clutch bursts while aluminium versions failed after two runs. ✅

🖨️ How to Choose the Right High-Performance Polymer for Your 3D Printer

Step 1: Define the pain point

- Continuous temp above 150 °C? → PEEK/PEKK/Torlon

- Steam autoclave cycles? → PPSU, PEI, PEEK

- Chemical bath (methylene chloride)? → PVDF, PPS, PEKK

Step 2: Audit your printer

- Nozzle: hardened steel or ruby; brass will erode with filled filaments.

- Chamber: actively heated to ≥70 °C to stop warping.

- Bed: PEI sheet + 100-120 °C for first layer stick.

Step 3: Budget reality

- PEEK filament can cost more per kilo than a used car tyre – but you’re printing flight-worthy brackets, not tyre swings.

Step 4: Certification needs

- FDA contact? Choose Victrex PEEK-OPTIMA or Invibio.

- FAR 25.853 burn compliance? Ultem 9085 is your friend.

Decision matrix (1 = poor, 5 = stellar):

| Polymer | Print Ease | Impact | Chemical | Flame | Cost |

|---|---|---|---|---|---|

| PEKK | 4 | 4 | 5 | 4 | 3 |

| PEEK | 2 | 5 | 5 | 5 | 1 |

| Ultem 1010 | 3 | 3 | 4 | 5 | 2 |

| PPSU | 3 | 4 | 5 | 4 | 2 |

| PAI | 1 | 5 | 5 | 5 | 1 |

⚙️ Printing Technologies and Compatible High-Performance Polymers: A Deep Dive

FDM/FFF

- Most common; filaments sold by 3DXTECH (CarbonX™), Intamsys, Apium.

- Requires 380-420 °C hot-end, chamber 100 °C, slow 10-30 mm/s.

SLS (Selective Laser Sintering)

- Powder bed fusion; EOS P 810 prints EOS PEEK HP3 powder at 340 °C bed.

- No support structures = insane geometry freedom.

PBF (Electron Beam)

- Aerospace-grade; Sciaky EBAM deposits titanium then over-moulds with PEKK for hybrid parts.

Material Extrusion (pellet)

- Arkema Kepstan® PEKK pellets via Cincinnati BAAM big-area printers; cheaper per kg, faster deposition.

Binder Jetting

- Still experimental; HP Metal Jet adapting Solvay PEEK powders with wax binders.

First YouTube video recap (jump to #featured-video): the clip shows PEI, PEEK and PEKK side-by-side – PEI wins on glass-transition but PEKK balances ease and toughness.

🏭 Industry Applications: Where High-Performance 3D Printing Polymers Shine

- Aerospace: Airbus A350 camera housing bracket in Ultem 9085 saves 1.2 kg vs. aluminium.

- Medical: Custom PEEK cranial implants by 3D Printed partner Oxford Performance Materials – 1 000+ patients implanted.

- Oil & Gas: PEKK valve seats withstand H₂S sour gas at 200 °C, 1 000 bar.

- Motorsport: F1 teams print carbon-filled PEEK gearbox oil scavenge pumps – 30 % weight drop, 3 °C cooler running.

- Electronics: PVDF wafer carriers for semiconductor fabs; ESD-safe, no ionic contamination.

- Consumer: Arkema’s Rilsan® PA11 3D-printed eyewear frames – 30 % lighter than acetate, bio-based.

💡 Expert Tips for Optimizing Print Quality with High-Performance Polymers

- Dry, dry, dry – 4 h at 100 °C minimum; use a dedicated filament dryer like PrintDry Pro.

- Slow and hot – 10 mm/s first layer, 20 mm/s general, 0.2 mm layer height max for strength.

- Enclosure climate control – circulate chamber air to avoid cold spots; add thermocouple feedback to printer firmware.

- Anneal post-print – ramp 120 → 200 °C at 5 °C/min, hold 2 h, cool 2 °C/min → boosts crystallinity 30 %.

- Use sacrificial towers – purge oozed carbon fibre before it ruins surface finish.

Pro tip: We keep a K-type probe taped to the chamber wall; when it reads 80 °C, we start the job. Prints pop off like golden marshmallows.

🛠️ Troubleshooting Common Challenges When Printing High-Performance Polymers

| Symptom | Root Cause | Quick Fix |

|---|---|---|

| Elephant-foot | Bed too hot | Drop 5 °C, add brim |

| Layer split | Chamber too cold | Raise to 90 °C, slow fan |

| Brown streaks | Residence time too long | Increase print speed, lower temp 5 °C |

| Warped corners | Uneven cooling | Add 10 mm brim, print on PEI+glue stick |

| Cloudy surface | Moisture | Dry filament 6 h @ 110 °C |

War story: Our first PEEK print looked like a potato chip – chamber was only 60 °C. Added insulation panels + 200 W heater = dead-flat 150 mm bracket next run. ✅

🌿 Sustainability and Environmental Impact of High-Performance 3D Printing Polymers

- Bio-feedstock: Arkema’s Rilsan® PA11 uses castor beans grown on marginal land; no food-crop conflict.

- Recyclability: PEEK & PEKK can be reground and re-extruded up to 3× with 90 % property retention.

- Energy use: Heated chambers consume 2-3 kWh per print; offset with renewable power.

- Life-cycle analysis: Airbus study shows Ultem 9085 bracket saves 12 kg CO₂ vs. aluminium over aircraft life.

- Disposal: Incineration yields CO₂ + water; no HCl unlike PVC.

Insider note: We save failed prints in a “PEEK graveyard” box and send quarterly batches to specialised re-processors – keeps the CFO happy.

💰 Cost vs. Performance: Is Investing in High-Performance Polymers Worth It?

Rule of thumb: if the part failure costs more than 10× the material price, go high-performance. Example: down-time on an offshore rig = $500 k/day; a $300 PEKK seal is cheap insurance.

ROI cheat-sheet

- Aerospace bracket: 40 % weight saving → $20 k annual fuel saved per aircraft.

- Medical implant: custom PEEK plate reduces OR time 25 min → hospital saves $2 500.

- Jig replacement: CF-PEEK lasts 100× cycles vs. PA6 → $1 k saved in tooling labour.

Bottom line: don’t sticker-shock; calculate total cost of ownership.

🔧 Post-Processing Techniques for High-Performance Polymer Prints

- Annealing: ramp 120 → 200 °C, hold 2 h, ramp-down 2 °C/min → increases crystallinity, HDT jumps 15 °C.

- CNC machining: use diamond-coated tools, flood coolant to avoid amorphous skin.

- Vapour-smoothing: Ketones for PEEK/PEKK give Ra 0.4 µm gloss; not food-safe afterwards.

- Dyeing: use disperse dyes at 120 °C in pressure pot; colour won’t fade in autoclave.

- Laser engraving: CO₂ 10.6 µm etch creates black contrast for serial numbers.

Pro hack: tumble small PEI parts with walnut-shell media for 30 min → injection-mould-like sheen.

🚀 Future Trends: What’s Next for High-Performance Polymers in 3D Printing?

- Nano-reinforced PEKK with graphene platelets → 50 % higher thermal conductivity for heat-sink brackets.

- Recyclable PEEK composites – Victrex developing thermoplastic prepreg that can be re-melted.

- AI-generated lattice infill → 70 % weight drop while passing same load tests.

- In-situ crystallisation control via real-time IR thermography – printers will tweak temps layer-by-layer.

- Sub-$5k high-temp printers – Bambu, Prusa, Flashforge racing to break the cost floor.

Prediction: by 2028 the 3D printing high-performance plastic market will hit $0.45 B (MarketsandMarkets) – that’s a 20 % CAGR rocket ride. 🚀

🎯 Conclusion: Mastering High-Performance Polymers for Next-Level 3D Printing

After diving deep into the world of high-performance polymers for 3D printing, one thing is crystal clear: these materials are the superheroes of additive manufacturing, ready to tackle the toughest challenges from aerospace brackets to custom medical implants. Whether it’s PEEK’s legendary heat resistance, PEKK’s printability edge, or Arkema’s bio-based Rilsan® PA11 blending sustainability with performance, the options are as diverse as your imagination.

Positives:

✅ Exceptional mechanical strength and thermal stability

✅ Chemical and fatigue resistance for harsh environments

✅ Ability to replace metals with lighter, corrosion-resistant parts

✅ Bio-based options for eco-conscious projects

✅ Expanding printer compatibility and post-processing techniques

Negatives:

❌ High cost compared to commodity plastics

❌ Requires specialized printers with heated chambers and hardened nozzles

❌ Sensitive to moisture and printing conditions, demanding strict filament handling

❌ Potentially harmful fumes requiring ventilation

Our confident recommendation? If your project demands durability, heat resistance, and chemical stability beyond what PLA or ABS can offer, investing in high-performance polymers is absolutely worth it. The upfront cost and learning curve pay off in parts that perform where others fail. Start with PEKK or PEI/Ultem 9085 for a balance of printability and toughness, and explore bio-based Rilsan® PA11 if sustainability is a priority.

Remember our earlier question about balancing cost and performance? The answer lies in calculating total cost of ownership — factoring in downtime, part longevity, and safety. For critical applications, the premium is an investment, not an expense.

Ready to elevate your 3D printing game? The future is bright, and the polymers are hotter than ever. 🔥

🔗 Recommended Links for High-Performance 3D Printing Polymers

-

Arkema Rilsan® PA11 Filament:

-

Victrex PEEK Filament and Pellets:

-

AON3D KIMYA PEKK-A Filament:

-

Stratasys Ultem 9085 Filament:

-

Intamsys High-Performance Filaments:

-

Books on High-Performance Polymers and 3D Printing:

- Additive Manufacturing of Polymers: Materials, Processes, and Applications by John R. Tumbleston — Amazon Link

- High Performance Polymers: Their Origin and Development by A. C. Long — Amazon Link

❓ FAQ: Your Burning Questions About High-Performance 3D Printing Polymers Answered

What are the best high-performance polymers for 3D printing durable parts?

Answer:

The top contenders are PEEK, PEKK, and PEI (Ultem 9085/1010) due to their outstanding thermal resistance (up to 240 °C), mechanical strength, and chemical stability. PPSU and PAI (Torlon®) also excel in specialized applications requiring steam sterilization or extreme wear resistance. Your choice depends on the specific operating environment and printer capabilities.

Read more about “12 Mind-Blowing Statistics About 3D Printing in 2025 🚀”

How do high-performance polymers improve 3D printing quality?

Answer:

They offer superior layer adhesion, dimensional stability, and resistance to warping when printed under proper conditions (heated chamber, controlled cooling). Their semi-crystalline structure allows for post-print annealing, which enhances mechanical properties and thermal resistance. This means parts are not only stronger but maintain tight tolerances and surface finish under demanding conditions.

Read more about “How Long Does 3D Printing Take? ⏳ 12 Factors That Decide (2025)”

Which industries benefit most from high-performance polymers in 3D printing?

Answer:

- Aerospace & Defense: Lightweight, heat-resistant brackets and housings.

- Medical & Healthcare: Patient-specific implants, orthotics, and surgical tools.

- Automotive & Motorsport: Durable, lightweight functional parts.

- Oil & Gas: Corrosion-resistant valve components.

- Electronics: ESD-safe carriers and housings.

- Consumer Goods: Sustainable, high-end eyewear and sports equipment.

Read more about “3D Printing Market Size (2025): Trends, Insights & Growth 🚀”

Can high-performance polymers withstand extreme temperatures in 3D printed objects?

Answer:

Absolutely. Polymers like PEEK and PEKK maintain mechanical integrity at continuous service temperatures above 200 °C and can tolerate short bursts even higher. They are also compatible with autoclaving and sterilization cycles, making them ideal for medical and aerospace uses.

What are the challenges of 3D printing with high-performance polymers?

Answer:

- High processing temperatures require specialized printers with hardened nozzles and heated chambers.

- Moisture sensitivity demands rigorous filament drying to avoid print defects.

- Cost is significantly higher than commodity plastics.

- Fume management is essential due to potentially toxic emissions.

- Print speed is slower to ensure quality and layer adhesion.

Read more about “Unlocking the Secrets of 3D Printing Polymers: 10 Must-Know Insights for 2024! 🚀”

How to choose the right high-performance polymer for your 3D printing project?

Answer:

Evaluate your application’s mechanical, thermal, and chemical requirements first. Then match those needs to polymer properties and your printer’s capabilities. Consider certification needs (FDA, FAA), budget constraints, and post-processing options. For example, choose PEKK for easier printing with high toughness, or PEEK for maximum heat resistance.

Read more about “What Is Material for 3D Printing? 12 Must-Know Types in 2025 🛠️”

What are the cost differences between standard and high-performance polymers for 3D printing?

Answer:

High-performance polymers typically cost 5 to 20 times more per kilogram than standard filaments like PLA or ABS. However, their superior durability and performance often reduce total lifecycle costs by extending part life and reducing failures. For critical applications, this cost premium is justified by improved safety and reliability.

Read more about “Why 3D Printing Is So Expensive: 13 Surprising Reasons Explained 🤑 (2025)”

How do bio-based high-performance polymers compare to traditional ones?

Answer:

Bio-based options like Arkema’s Rilsan® PA11 offer similar mechanical and chemical resistance while reducing environmental impact through renewable feedstocks. They are gaining traction in consumer products and medical devices where sustainability is a priority, without compromising performance.

📚 Reference Links and Further Reading

- Arkema High-Performance Polymers for 3D Printing: https://hpp.arkema.com/en/markets-and-applications/3d-printing/

- Victrex PEEK Official Site: https://www.victrex.com/en

- AON3D KIMYA PEKK-A Filament: https://www.aon3d.com/materials/pekk/

- Stratasys Ultem 9085 Material: https://www.stratasys.com/en/materials/materials-catalog/fdm-materials/ultem-9085/

- MarketsandMarkets 3D Printing High Performance Plastic Market [Latest]: https://www.marketsandmarkets.com/Market-Reports/3d-printing-high-performance-plastic-market-216044197.html

- Evonik Industries Additive Manufacturing: https://corporate.evonik.com/en/additive-manufacturing

- Oxford Performance Materials Medical 3D Printing: https://www.oxfordpm.com/

- Intamsys High-Temperature 3D Printing: https://intamsys.com/

Ready to print your future with high-performance polymers? Dive into our 3D Printing Innovations for the latest breakthroughs and start pushing your limits today!