Support our educational content for free when you purchase through links on our site. Learn more

What is 3D Printed? 2025 Guide 🚀

I still remember the first time I held a 3D-printed object—a tiny, perfectly detailed Yoda bust that took six hours to finish. My jaw dropped when I realized that the same machine that made that figurine could also crank out a working wrench or a custom phone case. Fast-forward to 2025, and the global 3D-printing market is set to top $44 billion—proof that this once-niche hobby is now reshaping everything from sneakers to space rockets. Stick around and you’ll learn the seven core technologies, the materials you never knew existed, and the jaw-dropping real-world uses that prove 3D printing is far more than plastic trinkets.

Key Takeaways

- 3D printed = additive manufacturing: building objects layer by layer instead of cutting away material.

- Seven main technologies dominate today—FDM for hobbyists, SLA for detail, SLS for strength, and more.

- Materials range from everyday PLA to titanium powder and even living cells.

- Real-world impact spans aerospace fuel nozzles, custom prosthetics, and 3D-printed houses.

- Accuracy vs. speed vs. cost is the eternal triangle—learn to balance them for perfect prints.

👉 Shop starter gear:

- Creality Ender 3: Amazon | Creality Official

- Hatchbox PLA: Amazon

- Elegoo Mars Resin Printer: Amazon

Table of Contents

- ⚡️ Quick Tips and Facts

- 🕰️ From Gutenberg to G-code: A Brief History of 3D Printing

- 🤔 So, What Is the Meaning of “3D Printed”?

- 🔍 How Does 3D Printing Work? The Layer-by-Layer Low-Down

- 🛠️ 7 Core 3D Printing Technologies & Processes You’ll Actually Meet in the Wild

- 🧵 Materials Matter: Plastics, Powders, Pastes & Beyond

- 🏭 3D Printing Industry Landscape: Who’s Who & What’s Hot

- 🌟 15 Real-World Examples of 3D Printing That’ll Make You Go “Whoa”

- 📏 Accuracy vs. Speed vs. Cost: The Eternal Triangle

- 🎨 Design for Additive Manufacturing (DfAM): Designing Like a Pro

- 🛡️ Safety, Sustainability & Ethics: Printing Responsibly

- 🚀 Future Trends: What’s Next After Next?

- 🧩 Troubleshooting & Maintenance Hacks From Our Garage

- 🏁 Conclusion

- 🔗 Recommended Links

- ❓ FAQ

- 📚 Reference Links

Here at 3D Printed™, we live and breathe filament fumes (safely, of course!). We’ve seen it all: the glorious first successful print, the soul-crushing spaghetti monster of a failed one, and the sheer magic of watching an idea become a real, tangible object. So, you’re asking, “What is the meaning of 3D printed?” Grab a seat, and let’s unravel this amazing technology together. It’s more than just a process; it’s a revolution you can hold in your hand.

⚡️ Quick Tips and Facts

Just dipping your toes in? Here’s the cheat sheet on 3D printing.

- It’s Additive, Not Subtractive: Think of it like building a snowman, one snowball at a time, rather than carving a statue from a block of ice. You add material, you don’t take it away.

- The Blueprint is Digital: Every 3D print starts as a digital file, a 3D model. You can design it yourself using software like Tinkercad or download one of millions of models from sites like Thingiverse.

- Layer by Layer: The printer reads the file and builds the object one super-thin layer at a time. It’s like a loaf of bread, but printed in a single, continuous slice.

- Not Just Plastic: While plastic filament is the most common material for hobbyists, professionals print with everything from metal and resin to concrete and even chocolate! 🍫

- It’s Older Than You Think: The core technology, Stereolithography, was patented way back in 1986. That’s the same year Top Gun first hit theaters!

- It’s a Game Changer: As the experts at 3DPrinting.com note, “As it evolves, 3D printing technology is destined to transform almost every major industry.” We couldn’t agree more!

🕰️ From Gutenberg to G-code: A Brief History of 3D Printing

You might think 3D printing is a recent fad, born in some Silicon Valley garage a few years ago. But its roots go much deeper! The journey from concept to the desktop printer whirring away in your workshop is a fascinating tale.

The earliest whispers of this tech date back to the 1970s, but the ’80s were the real launchpad. In 1986, a man named Charles “Chuck” Hull filed a patent for a process he called Stereolithography (SLA). He then co-founded 3D Systems, a company that is still a giant in the industry today. His first commercial printer, the SLA-1, was a beast that looked like it belonged in a research lab, not a living room.

Meanwhile, another pioneer, Scott Crump, was trying to make a toy frog for his daughter with a hot glue gun. This frustration led him to invent Fused Deposition Modeling (FDM), the technology most of us home-gamers use today. He and his wife founded Stratasys in 1989, and the rest is history.

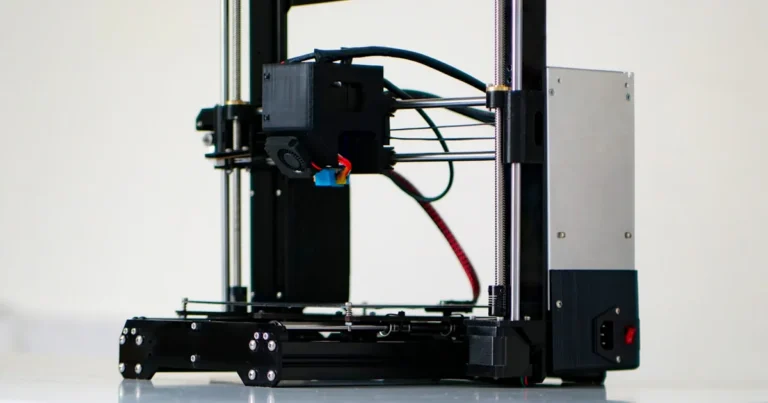

For years, these technologies were locked behind expensive patents, costing tens of thousands of dollars and accessible only to large corporations for rapid prototyping. But then, something amazing happened. In 2009, key patents for FDM technology expired. The floodgates opened! The open-source RepRap project—a project to create a 3D printer that could print most of its own components—exploded in popularity. This led to an explosion of affordable, desktop 3D printers like the ones from Creality and Prusa Research, turning a niche industrial tool into a global hobbyist movement.

🤔 So, What Is the Meaning of “3D Printed”?

Alright, let’s get to the heart of it. At its core, the term “3D printed” means an object was created through additive manufacturing (AM). This is the official, industry-approved term. Wikipedia puts it perfectly, stating that AM technologies “share the theme of material addition or joining throughout a 3D work envelope under automated control.”

Let’s break that down with a simple metaphor:

- ✅ Additive Manufacturing (3D Printing): Imagine building a LEGO castle. You start with nothing and add bricks one by one until your masterpiece is complete. You only use the bricks you need.

- ❌ Subtractive Manufacturing (Traditional): Now, imagine your castle is already trapped inside a giant block of wood. You have to chip, carve, and drill away all the excess wood to reveal the castle inside. This creates a lot of waste (sawdust, in this case).

This fundamental difference is why 3D printing is so powerful. It allows for incredibly complex shapes that would be impossible to carve or mold. As 3DPrinting.com points out, “3D printing enables you to produce complex shapes using less material than traditional manufacturing methods.” This efficiency and design freedom is a huge part of the answer to Is 3D Printing a Good Thing? 7 Surprising Truths You Need to Know 🚀 (2025). It’s not just a new way to make things; it’s a new way to think about making things.

So, while the industry might prefer the term “additive manufacturing,” for the rest of us, “3D printing” is the fun, accessible name for turning digital dreams into physical reality.

🔍 How Does 3D Printing Work? The Layer-by-Layer Low-Down

Ever wondered what’s actually happening inside that magic box? It’s a three-step dance between software and hardware. We’ve guided countless newcomers through this process, and trust us, it’s easier than it sounds!

Step 1: The Model (The Blueprint 🗺️)

Everything begins with a 3D model. This is the digital blueprint for your object. You have two main options here:

- Download It: The internet is a treasure trove of pre-made models. Communities like Thingiverse, MyMiniFactory, and Cults3D have millions of files—from phone stands to D&D miniatures—ready to download. Most are in .STL or .OBJ format.

- Design It: Feeling creative? You can design your own models from scratch! For beginners, we always recommend browser-based software like Tinkercad. It’s intuitive and free. For more advanced users, software like Fusion 360 or Blender offers limitless possibilities. Check out our guides on 3D Design Software to find the right fit for you.

Step 2: The Slice (The Instruction Manual 📜)

Your 3D printer can’t just read an .STL file directly. It needs instructions, specifically, how to build the model layer by layer. This is where slicer software comes in.

The slicer (popular options include Ultimaker Cura, PrusaSlicer, and Simplify3D) does exactly what its name implies: it “slices” your 3D model into hundreds or thousands of horizontal layers. It then generates a file (usually G-code) that tells the printer exactly where to move, how fast to go, and how much material to extrude for each and every layer. This is where you control settings like layer height (for detail), infill (for strength), and whether you need support structures for overhangs.

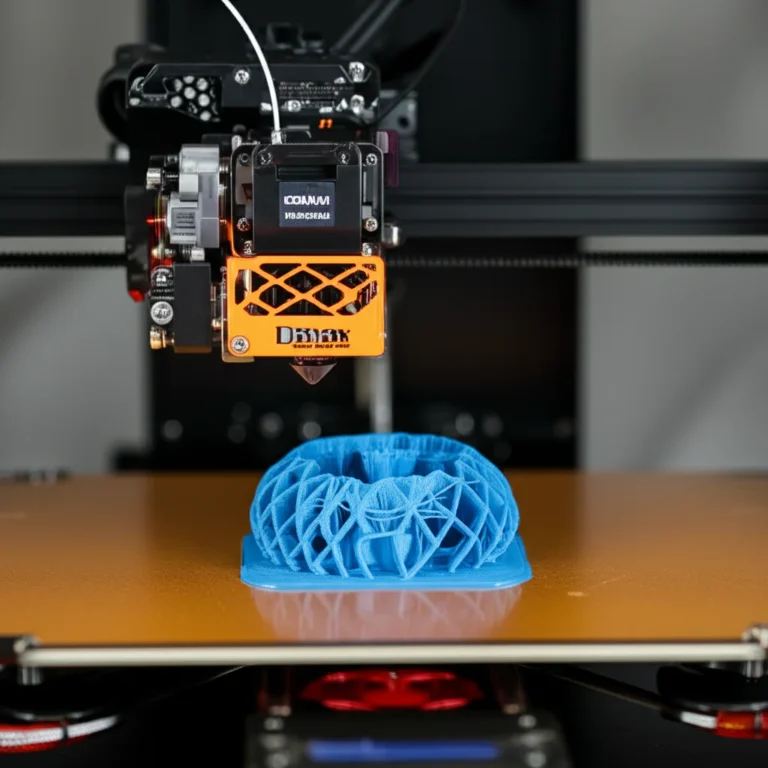

Step 3: The Print (The Magic ✨)

This is the fun part! You load the G-code file onto your printer (via SD card, USB, or Wi-Fi) and hit “Print.” The printer heats up its nozzle (for FDM) or prepares its resin vat (for SLA), and then meticulously begins its work, tracing each layer from the G-code file. Slowly but surely, your digital model emerges into the physical world.

It’s a process that requires patience, but watching it happen never gets old.

🛠️ 7 Core 3D Printing Technologies & Processes You’ll Actually Meet in the Wild

“3D Printing” isn’t just one thing. It’s an umbrella term for a whole family of technologies, each with its own strengths, weaknesses, and quirks. The International Organization for Standardization (ISO) officially recognizes seven distinct categories. Let’s meet the family!

| Technology Family | Common Acronym | How It Works | Common Materials | Best For |

|---|---|---|---|---|

| Material Extrusion | FDM / FFF | A filament is heated and squeezed through a nozzle, like a high-tech hot glue gun. | PLA, PETG, ABS, TPU | ✅ Hobbyists, rapid prototypes, functional parts. |

| Vat Photopolymerization | SLA / DLP | A UV light source cures liquid resin layer by layer in a vat. | Photopolymer Resins | ✅ High-detail miniatures, jewelry, dental molds. |

| Powder Bed Fusion | SLS / DMLS / MJF | A laser or binding agent fuses particles of powder together in a bed. | Nylon, Metals (Titanium, Steel) | ✅ Strong functional parts, complex geometries, no supports needed. |

| Material Jetting | MJ | Droplets of material are jetted onto a build plate and cured, like a 2D inkjet printer but in 3D. | Photopolymer Resins | ✅ Ultra-realistic, full-color, multi-material prototypes. |

| Binder Jetting | BJ | A liquid binding agent is selectively deposited to join powder particles. | Sand, Metals, Ceramics | ✅ Large sand-casting molds, full-color models, metal parts. |

| Directed Energy Deposition | DED | A nozzle melts material (wire or powder) as it’s being deposited, often to repair existing parts. | Metals (Titanium, Inconel) | ✅ Repairing large metal parts, adding features to existing components. |

| Sheet Lamination | LOM | Sheets of material (like paper or metal) are cut and bonded together layer by layer. | Paper, Plastic, Metal | ❌ Less common today, used for specific visual prototypes. |

For most people starting out, you’ll be dealing with Material Extrusion (FDM/FFF). It’s the most affordable and widespread technology, championed by brands like Creality, Prusa, and Bambu Lab. If you’re after incredible detail for things like miniatures, Vat Photopolymerization (SLA/DLP) from companies like Elegoo or Anycubic is your best bet. The other technologies are typically found in high-end industrial settings, making everything from rocket engines to custom medical implants.

🧵 Materials Matter: Plastics, Powders, Pastes & Beyond

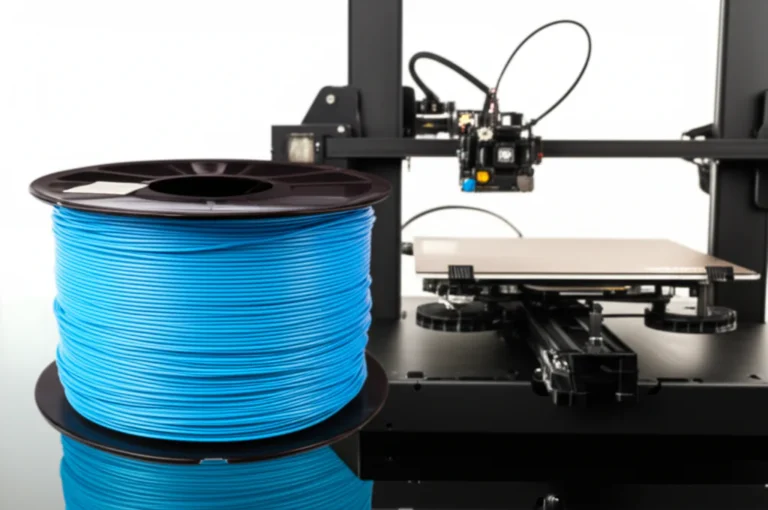

A 3D printer is nothing without its material. The stuff you feed your machine determines the look, feel, and strength of your final object. The world of 3D printing materials is vast and constantly expanding, but let’s cover the greatest hits.

H3: The Plastics: FDM/FFF Filaments

This is the bread and butter for most hobbyists. The two kings of the castle are:

- PLA (Polylactic Acid): The beginner’s best friend. It’s easy to print, comes in a rainbow of colors, is relatively inexpensive, and is made from renewable resources like corn starch. It’s perfect for visual models, toys, and general prototyping. ✅

- PETG (Polyethylene Terephthalate Glycol): PLA’s tougher, more durable cousin. It’s more heat-resistant and food-safe (check the specific brand’s MSDS!). It’s a fantastic all-rounder for functional parts that need to withstand a bit more stress, like printer parts or workshop tools. ✅

Other popular plastics include ABS (strong but tricky to print), TPU (flexible and rubbery, for things like phone cases), and high-performance composites filled with carbon fiber or wood.

👉 Shop Filaments on:

- Hatchbox PLA: Amazon

- Overture PETG: Amazon

- Prusament: Prusa Official Website

H3: The Resins: Vat Photopolymerization Liquids

For those seeking ultimate detail, liquid photopolymer resins are the answer. Used in SLA and DLP printers, these UV-curable liquids produce prints with incredibly smooth surfaces, perfect for jewelry casting, dental applications, and stunningly detailed miniatures. They come in various formulations, including standard, tough, flexible, and castable wax resins. ⚠️ Heads up: Liquid resins and their cleaning agents (like isopropyl alcohol) require good ventilation and personal protective equipment (gloves and safety glasses).

H3: The Powders: Powder Bed Fusion Materials

This is where things get industrial. Selective Laser Sintering (SLS) printers typically use nylon powders to create incredibly strong, slightly porous parts without the need for support structures. Direct Metal Laser Sintering (DMLS) takes it a step further, using powdered metals like titanium, aluminum, and stainless steel to print everything from lightweight aircraft components to custom surgical implants. This is the tech behind many of the medical and aerospace breakthroughs you hear about.

H3: The Exotics: Beyond the Big Three

The innovation doesn’t stop there! Researchers and companies are printing with:

- Concrete: To build entire houses and structures.

- Food: From custom-shaped pasta to intricate chocolate sculptures.

- Living Cells (Bioprinting): In the quest to one day print functional human organs for transplants. This is a major focus in the world of 3D Printing Innovations.

🏭 3D Printing Industry Landscape: Who’s Who & What’s Hot

3D printing has officially graduated from a niche prototyping tool to a full-blown manufacturing technology. The numbers don’t lie: the global 3D printing market is on a rocket-like trajectory, with some forecasts predicting it will be a worth over $44 billion by 2026.

So who are the big players on this futuristic playground?

- The Pioneers: Companies like 3D Systems (inventors of SLA) and Stratasys (inventors of FDM) are the established giants, focusing on high-end industrial and professional systems.

- The Industrial Innovators: HP made a huge splash with its Multi Jet Fusion (MJF) technology, which is incredibly fast for production runs. Companies like GE Additive are pushing the boundaries of metal printing for aerospace and medical fields.

- The Desktop Champions: This is where the revolution is for most of us. Brands like Creality, Elegoo, Anycubic, and Bambu Lab have made high-quality printing accessible and affordable for hobbyists, schools, and small businesses. Prusa Research, born from the open-source RepRap movement, is a beloved favorite for its quality and community focus.

- The Material Moguls: A whole ecosystem exists just to supply the printers. Companies like BASF, Polymaker, and eSUN are constantly developing new and improved filaments, resins, and powders.

The biggest trend right now? The shift from rapid prototyping to rapid manufacturing. Companies are no longer just printing models to see how a part looks; they’re printing the final, end-use parts themselves. This allows for on-demand production, massively complex designs, and supply chains that are shorter and more resilient. As Wikipedia notes, “3D printing has created a significant impact in the humanitarian and development sector. Its potential to facilitate distributed manufacturing is resulting in supply chain and logistics benefits.”

🌟 15 Real-World Examples of 3D Printing That’ll Make You Go “Whoa”

Still think 3D printing is just for making plastic trinkets? Think again. This technology is reshaping our world in ways both big and small. Here are 15 examples of amazing 3D Printable Objects and applications that show its true power.

- Aerospace Fuel Nozzles: GE Aviation famously 3D prints complex fuel nozzles for its LEAP jet engines. The printed version combines 20 individual parts into one, making it lighter and five times more durable.

- Customized Prosthetics: Organizations like e-NABLE use a global network of volunteers to 3D print and deliver custom-fitted prosthetic hands and arms for children and adults in need, often for a fraction of the cost of traditional prosthetics.

- High-Performance Footwear: Adidas uses Carbon’s DLS technology to 3D print the lattice-structure midsoles for its 4DFWD running shoes, providing precisely tuned cushioning and support.

- Dental Aligners and Crowns: That clear aligner straightening your teeth? The mold for it was almost certainly 3D printed. Dentists now also directly 3D print crowns, surgical guides, and dentures with incredible accuracy.

- Reconstructing Dinosaur Skeletons: Paleontologists scan and 3D print missing or fragile fossil bones to complete skeletons for study and museum display without risking damage to the priceless originals.

- On-Demand Movie Props: From the intricate helmets in The Mandalorian to futuristic gadgets, movie prop departments use 3D printing to quickly create detailed, custom props that would be difficult or time-consuming to make by hand.

- 3D Printed Houses: Companies like ICON are using massive 3D printers that extrude a proprietary concrete mix to build the walls of houses in a matter of days, offering a potential solution to housing shortages.

- Surgical Planning Models: Surgeons can 3D print an exact replica of a patient’s organ, like a heart or kidney, from a CT scan. This allows them to practice complex surgeries beforehand, reducing time in the operating room and improving patient outcomes.

- Custom Hearing Aids: The shells of nearly all modern in-the-ear hearing aids are 3D printed. A scan is taken of the person’s ear canal, and a perfectly fitted, comfortable shell is printed, a process that has revolutionized the industry.

- Automotive Jigs and Fixtures: Car manufacturers like Ford use 3D printing to create custom tools, jigs, and fixtures used on the assembly line, saving time and money compared to traditional machining.

- Personalized Jewelry: Jewelers use high-resolution resin printers to create intricate wax models for lost-wax casting, allowing for incredibly detailed and customized rings, pendants, and bracelets.

- Educational Tools: In schools around the world, 3D printing is bringing lessons to life. Students can print historical artifacts, molecular models, or their own engineering inventions, making learning tangible. It’s a cornerstone of modern 3D Printing in Education.

- Rocket Engines: It sounds like science fiction, but it’s not. Companies like Relativity Space are 3D printing almost their entire rockets, drastically reducing the number of parts and the time it takes to build them.

- Custom Eyewear: Forget one-size-fits-all frames. Companies are now offering 3D printed glasses that are custom-made to the exact dimensions of your face, ensuring a perfect, comfortable fit.

- Food Art: From Michelin-star restaurants creating intricate garnishes to companies developing 3D printers that can create custom-shaped pasta or chocolate, the culinary world is getting a taste of additive manufacturing.

📏 Accuracy vs. Speed vs. Cost: The Eternal Triangle

Welcome to the great balancing act of 3D printing! As you get deeper into this hobby, you’ll realize that you’re constantly making trade-offs between three key factors: Accuracy (or Quality), Speed, and Cost. You can usually pick two, but getting all three is the holy grail.

Let’s break it down from our team’s experience:

- Want it FAST and CHEAP? 🚀💰

- You’ll likely sacrifice accuracy. This means printing with a larger nozzle and thick layers. Your print will be done in a flash and won’t use much filament, but you’ll see very obvious layer lines, and fine details will be lost. This is great for rough drafts or functional parts where looks don’t matter.

- Want it ACCURATE and CHEAP? 🎯💰

- You’ll have to sacrifice speed. This is the sweet spot for most hobbyists. You’ll use a standard 0.4mm nozzle, set your layer height low (e.g., 0.12mm), and slow down the print speed. The result? A beautiful, detailed print. The catch? It might take 12, 24, or even 48 hours to finish. Patience is a virtue here!

- Want it FAST and ACCURATE? 🚀🎯

- Get ready to open your wallet, because you’re sacrificing low cost. This is the realm of high-end prosumer and industrial machines. Printers like the Bambu Lab X1-Carbon use advanced motion systems, input shaping, and powerful processors to print at incredible speeds without losing quality. Similarly, industrial SLA or MJF systems can produce detailed parts quickly, but the machines and materials cost a small fortune.

Our advice? Start in the “Accurate and Cheap” corner. Learn how to dial in your settings for quality prints on an affordable machine like a Creality Ender 3. Once you master the fundamentals, you can start experimenting with how to increase speed without sacrificing too much quality.

🎨 Design for Additive Manufacturing (DfAM): Designing Like a Pro

Here’s a secret: you can’t just take any 3D model and expect it to print perfectly. Great 3D prints start with great design—specifically, Design for Additive Manufacturing (DfAM). This means thinking like your printer and designing your part in a way that plays to its strengths and avoids its weaknesses.

Here are a few core DfAM principles we teach everyone on our team:

- Mind the Overhangs: FDM printers build from the ground up. They can’t print in mid-air! Any part of your model that juts out at an angle greater than about 45-60 degrees is called an overhang. To print these, you’ll need to add support structures—temporary pillars that you break off after the print is done. Good design minimizes or eliminates the need for supports, which saves time and material.

- Orientation Matters, A Lot: The way you orient your model on the build plate has a huge impact. FDM prints are strongest along their X and Y axes (the flat layers) and weakest between the layers (the Z-axis). If you’re printing a functional part like a hook, you should print it lying flat, not standing up, to maximize its strength.

- Embrace Complexity: This is the fun part! Unlike traditional manufacturing, complexity is often free in 3D printing. You can design internal lattice structures to make parts strong but lightweight, create curved internal channels for liquids, or consolidate multiple parts into a single, complex piece. This is where you can really get creative with your 3D Design Software.

- Know Your Tolerances: Parts that need to fit together, like a nut and a bolt, require careful attention to tolerances. Your printer isn’t perfectly accurate, so you need to design a small gap (e.g., 0.2mm) between the parts to ensure they’ll actually fit. We always print a small test piece first to dial in our tolerances before committing to a large print.

Thinking with these principles in mind will save you countless hours of frustration and failed prints.

🛡️ Safety, Sustainability & Ethics: Printing Responsibly

With great power comes great responsibility, and 3D printing is no exception. As this technology becomes more common, it’s crucial to consider its broader impact.

H3: Health and Safety 😷

Your 3D printer is a tool, not a toy. Here are the key safety points:

- Ventilation is Key: FDM printers, especially when using materials like ABS, can release Volatile Organic Compounds (VOCs) and Ultrafine Particles (UFPs) into the air. Printing in a well-ventilated area or using an enclosure with a filter is highly recommended. Studies have confirmed the importance of managing these emissions.

- Hot! Don’t Touch! The nozzle on an FDM printer can reach temperatures over 250°C (482°F), and the heated bed can be over 100°C (212°F). Be mindful of burns.

- Resin Safety: Liquid resins used in SLA/DLP printing are skin irritants. Always wear nitrile gloves and safety glasses when handling them.

- Moving Parts: Keep fingers, long hair, and loose clothing away from the moving parts of your printer.

H3: Sustainability ♻️

Is 3D printing green? It’s complicated.

- The Good: It drastically reduces material waste compared to subtractive manufacturing. It also enables localized, on-demand production, which can cut down on shipping and storage emissions.

- The Bad: Failed prints and support structures create plastic waste. While PLA is technically biodegradable, it only breaks down in industrial composting facilities, not your backyard compost bin.

- The Hopeful: There’s a growing market for recycled filament, and researchers are constantly working on more eco-friendly materials and ways to recycle failed prints at home.

H3: Ethics and Legal Issues ⚖️

The ability to print anything brings up some thorny questions:

- Intellectual Property: It’s incredibly easy to download and replicate a designer’s work from a site like Thingiverse. Always respect the creator’s license (e.g., Creative Commons) and give credit where it’s due. Printing patented objects for commercial use is a big no-no.

- Printed Firearms: This is the most controversial topic. The ability to print untraceable firearms has sparked intense debate and legal challenges around the world, pitting free speech against public safety concerns.

- Regulation: As 3D printed parts become more common in critical applications like aerospace and medicine, regulatory bodies like the FAA are developing strict certification processes to ensure safety and reliability.

🚀 Future Trends: What’s Next After Next?

If you think today’s technology is cool, just wait. The world of 3D printing is moving at lightning speed, and the future looks like something straight out of a sci-fi novel. Here are a few of the most exciting 3D Printing Innovations on the horizon.

- 4D Printing: This isn’t a typo. 4D printing involves creating objects that can change their shape or properties over time in response to a stimulus, like heat, light, or water. Imagine a flat-packed piece of furniture that assembles itself when you heat it, or a medical stent that changes shape inside the body.

- Bioprinting and Regenerative Medicine: This is the holy grail. Scientists are already using “bio-inks” made of living cells to print simple tissues like skin and cartilage. The ultimate goal, though still a long way off, is to 3D print fully functional, complex organs like hearts and kidneys for transplant, eliminating donor waitlists forever.

- Large-Scale Additive Manufacturing: We’re already printing houses, but what about bigger structures? Think bridges, wind turbine blades, or even habitats on the Moon or Mars using local materials (regolith). Companies are developing robotic arm-based systems that could make this a reality.

- AI-Powered Design and Slicing: Artificial intelligence is starting to play a huge role. Generative design software can create thousands of optimized design variations for a part that a human would never conceive of. AI will also make slicers smarter, automatically optimizing print settings for speed and strength and even detecting and correcting print failures in real-time.

- Multi-Material and Electronics Printing: The line between mechanical and electrical is blurring. Soon, desktop printers will be able to seamlessly print with multiple materials at once—combining rigid plastics, flexible materials, and conductive inks to print fully functional electronic devices, like a drone or a sensor, in a single print job.

The future isn’t just about printing faster or cheaper; it’s about printing things that are currently impossible to make.

🧩 Troubleshooting & Maintenance Hacks From Our Garage

Every 3D printing enthusiast has a “war story.” Mine involves a 36-hour print of a detailed Mandalorian helmet that failed at 95% because of a simple clogged nozzle. I nearly cried. But failure is the best teacher, and over the years, our team has learned a thing or two about keeping these machines happy.

Here’s one of the most common problems you’ll face and our go-to fix:

The Problem: Your first layer won’t stick to the build plate. The filament just gets dragged around by the nozzle, creating a sad plastic spaghetti monster.

This is the #1 issue that makes beginners want to throw their printer out the window. Don’t despair! 99% of the time, it’s one of three things:

- The Bed Isn’t Level: Your build plate needs to be perfectly level and at the correct distance from the nozzle across its entire surface. Most entry-level printers require manual leveling with a piece of paper. It’s tedious, but it’s the most important skill to learn. Check out our 3D Printer Reviews for models with auto-bed leveling—it’s a life-saver.

- The Nozzle is Too High or Too Low: This is called setting your “Z-offset.” Even on a level bed, if the nozzle is too high, the filament won’t get a good “squish” onto the plate. If it’s too low, it will block the filament from coming out. You want that first layer to be slightly flattened, not a perfectly round bead.

- The Bed is Dirty: Fingerprints are your enemy! The oils from your skin can prevent prints from adhering. Before every print, give your build plate a quick wipe-down with Isopropyl Alcohol (IPA) (90% or higher is best) on a lint-free cloth.

Our Pro-Tip Hack: If you’re still having trouble after leveling and cleaning, a light coating of hairspray (we swear by Aqua Net Extra Super Hold) or a thin layer from a standard purple glue stick on the build plate can work wonders for adhesion, especially with tricky materials. It’s an old-school trick, but it’s saved more of our prints than we can count.

🏁 Conclusion

So, what’s the meaning of “3D printed”? It’s the fascinating process of additive manufacturing, where digital designs come to life layer by layer, creating objects that range from simple toys to complex aerospace parts. We’ve traveled from the early days of Chuck Hull’s SLA patent in the ’80s to today’s vibrant ecosystem of desktop printers, industrial giants, and mind-bending innovations like bioprinting and 4D printing.

3D printing is not just a technology; it’s a paradigm shift. It empowers creators, disrupts supply chains, and unlocks design possibilities that were once science fiction. Whether you’re a hobbyist printing your first phone stand or an engineer fabricating a rocket engine component, the meaning of 3D printed is the same: turning imagination into reality with precision, creativity, and efficiency.

If you’re just starting out, focus on mastering the basics with affordable FDM printers and PLA filament. As you grow, explore resin printing for detail or industrial processes for strength and complexity. Remember, it’s a journey filled with trial, error, and triumph—and we’re here cheering you on every step of the way.

Ready to dive deeper? Check out our recommended gear and resources below to get printing today!

🔗 Recommended Links

👉 CHECK PRICE on:

- Creality Ender 3 Series: Amazon | Creality Official Website

- Prusa i3 MK3S+: Prusa Official Website | Amazon

- Bambu Lab X1-Carbon: Bambu Lab Official Website | Amazon

- Elegoo Mars Resin Printer: Amazon | Elegoo Official Website

- Hatchbox PLA Filament: Amazon

- Overture PETG Filament: Amazon

- Prusament Filament: Prusa Official Website

- Aqua Net Hairspray (for bed adhesion): Amazon

Books to deepen your 3D printing knowledge:

- 3D Printing Failures: How to Diagnose and Repair All Desktop 3D Printing Issues by Sean Aranda — Amazon

- Fabricated: The New World of 3D Printing by Hod Lipson and Melba Kurman — Amazon

- Make: 3D Printing: The Essential Guide to 3D Printers by Anna Kaziunas France — Amazon

❓ FAQ

What are the benefits of 3D printing over traditional manufacturing methods?

3D printing offers unmatched design freedom, allowing the creation of complex geometries impossible with subtractive methods. It reduces material waste by adding only what’s needed, supports rapid prototyping with quick turnaround times, and enables customization and on-demand production, which can dramatically reduce inventory and shipping costs. Additionally, it democratizes manufacturing, making it accessible to individuals and small businesses.

How does the 3D printing process work from design to final product?

The process starts with a digital 3D model, created or downloaded. This model is then processed by slicer software, which converts it into layer-by-layer instructions (G-code) for the printer. The printer builds the object by depositing material layer upon layer—whether by extruding molten filament (FDM), curing resin with UV light (SLA), or fusing powder with lasers (SLS). After printing, post-processing steps like support removal, sanding, or curing may be required.

What types of materials can be used for 3D printing and what are their applications?

Materials range widely:

- Plastics (PLA, PETG, ABS): Common for prototypes, toys, and household items.

- Resins: High-detail miniatures, dental molds, jewelry.

- Metals (Titanium, Stainless Steel): Aerospace parts, medical implants.

- Concrete: Construction and housing.

- Food and Bioprinting Materials: Culinary arts and medical research.

Each material has unique properties suited to different applications, from flexible TPU for phone cases to biocompatible resins for surgical guides.

What are some popular things to 3D print for beginners and experienced makers?

Beginners often start with functional household items like phone stands, cable organizers, or simple toys. Experienced makers dive into complex mechanical parts, customized prosthetics, detailed miniatures, and even multi-material prints combining flexible and rigid components. Check out our 3D Printable Objects category for inspiration.

How has 3D printing technology advanced in recent years and what innovations can we expect?

Recent advances include multi-material and full-color printing, AI-assisted design and slicing, large-scale construction printing, and bioprinting of living tissues. The future promises 4D printing (objects that change shape), integrated electronics printing, and faster, more reliable machines that bring industrial capabilities to desktop users.

What are the limitations and challenges of 3D printing and how can they be overcome?

Limitations include print speed, material constraints, surface finish quality, and size restrictions. Challenges like warping, layer adhesion, and failed prints can be mitigated by proper printer calibration, choosing the right materials, and mastering slicing settings. Safety concerns require proper ventilation and handling protocols. Ongoing research and community knowledge-sharing continue to push these boundaries.

Can I 3D print functional items like tools, jewelry, and household objects, or is it just for prototypes and models?

Absolutely! Many functional items are 3D printed daily. Tools like wrenches, clamps, and replacement parts can be printed with durable materials like PETG or nylon. Jewelry designers use resin printing for intricate pieces. Household objects such as custom knobs, planters, and kitchen gadgets are also popular. The key is selecting the right material and design for the intended use.

📚 Reference Links

- 3D Printing – Wikipedia

- What is 3D Printing? – 3DPrinting.com

- 3D PRINTING Definition & Meaning – Merriam-Webster

- 3D Systems Official Site

- Stratasys Official Site

- Prusa Research Official Site

- HP 3D Printing Solutions

- GE Additive

- Creality Official Site

- Elegoo Official Site

- Bambu Lab Official Site