Support our educational content for free when you purchase through links on our site. Learn more

Ceramic 3D Printing Materials: 6 Game-Changing Options to Know in 2025 🔥

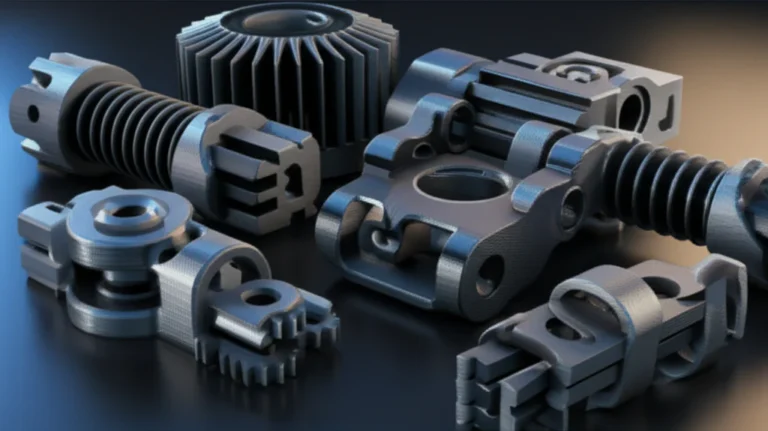

Imagine holding a part in your hand that’s as tough as a diamond, can survive furnace temperatures hotter than molten lava, and was created layer by layer from a digital file. Welcome to the fascinating world of ceramic 3D printing materials—where ancient craftsmanship meets cutting-edge technology. Whether you’re an engineer prototyping aerospace components, a dentist crafting patient-specific crowns, or an artist shaping intricate pottery, the right ceramic material can make all the difference.

Did you know that some ceramic parts shrink by up to 30% during sintering? That’s just one of the quirks you’ll learn to master in this comprehensive guide. We’ll take you through the top 6 ceramic materials used in 3D printing today—from the versatile Alumina to the biomedical marvel Hydroxyapatite—explaining their unique properties, printing methods, and real-world applications. Plus, we’ll share insider tips from our own lab adventures, including how we turned a kiln disaster into a perfect alumina print!

Key Takeaways

- Ceramic 3D printing combines digital precision with materials that withstand extreme heat, wear, and corrosion.

- Alumina and Zirconia are the most popular technical ceramics, offering strength, biocompatibility, and electrical insulation.

- Printing technologies include SLA/DLP with ceramic resins, binder jetting, extrusion, and direct ink writing—each with pros and cons.

- Post-processing steps like debinding and sintering are critical and require careful control to avoid shrinkage and cracking.

- Applications span aerospace, biomedical, industrial, electronics, and art, unlocking new design freedoms and performance levels.

- Emerging trends include multi-material printing and more accessible desktop ceramic printers, making this field more exciting than ever.

Ready to fire up your creativity and engineering skills? Let’s dive into the materials that are shaping the future of ceramic 3D printing!

Table of Contents

- ⚡️ Quick Tips and Facts: Your Gateway to Ceramic 3D Printing

- 🏺 The Ancient Art Meets Modern Tech: A Brief History of Ceramic Additive Manufacturing

- 🤔 Why Ceramic 3D Printing? Unlocking Unrivaled Material Properties

- 🔬 Diving Deep into Ceramic 3D Printing Materials: A Comprehensive Guide

- 1. Alumina (Aluminum Oxide): The Workhorse of Advanced Ceramics

- 2. Zirconia (Zirconium Dioxide): Strength, Biocompatibility, and Beauty

- 3. Silicon Carbide (SiC): Extreme Heat and Chemical Resistance

- 4. Silicon Nitride (Si3N4): High Performance and Lightweight

- 5. Hydroxyapatite (HAp): The Biomedical Bone Builder

- 6. Other Emerging Ceramic Materials for 3D Printing

- 🛠️ How Ceramic 3D Printing Works: Technologies and Processes Explained

- 🚀 Applications of 3D Printed Ceramic Parts: Where Innovation Takes Shape

- 🚧 Challenges and Considerations in Ceramic Additive Manufacturing

- 💡 Our Team’s Insights: Real-World Experience with Ceramic 3D Printing

- 🔮 The Future is Fired: Emerging Trends in Ceramic 3D Printing Materials

- ✅ Conclusion: Embracing the Ceramic Revolution

- 🔗 Recommended Links: Dive Deeper!

- ❓ FAQ: Your Burning Questions Answered

- 📚 Reference Links: Our Sources of Wisdom

Here at 3D Printed™, we’ve seen it all, from the gooiest resin failures to the most triumphant, dimensionally perfect prints. But let’s talk about a class of materials that truly gets our engineering hearts racing: ceramics. Forget everything you think you know about pottery class. We’re diving into the world of technical ceramics, where 3D printing is creating parts that can withstand insane temperatures, corrosive chemicals, and intense electrical voltages. It’s a fusion of ancient art and futuristic technology, and we’re here to be your guide.

⚡️ Quick Tips and Facts: Your Gateway to Ceramic 3D Printing

Jumping into ceramic 3D printing can feel like firing up a kiln for the first time – exciting but a little intimidating! Here are some quick-fire facts to get you started.

- It’s a Two-Step Process: Unlike printing with PLA or ABS, ceramic 3D printing is rarely a “print-and-done” affair. Most processes involve printing a “green” part (a mixture of ceramic powder and a binder), which then needs to be post-processed.

- 🔥 Debind and Sinter: This post-processing is crucial. First, the binder is burned away in a process called debinding. Then, the part is fired in a high-temperature kiln or furnace in a process called sintering. This fuses the ceramic particles together, creating a dense, solid object.

- Shrinkage is Real! During sintering, your part will shrink—sometimes by as much as 20-30%! This is a critical design consideration that you must account for in your 3D Design Software.

- Not Just Clay: While you can absolutely 3D print with traditional clays, the real revolution is in technical ceramics like Alumina, Zirconia, and Silicon Carbide. These materials have incredible properties that plastics can’t touch.

- ✅ Biocompatible Materials: Many 3D printable ceramics, like Zirconia and Hydroxyapatite, are biocompatible, making them perfect for advanced medical and dental applications, like the crowns made from BEGO’s VarseoSmile Crown plus.

- Multiple Technologies: There isn’t just one way to print ceramics. The main methods include Stereolithography (SLA) with ceramic-filled resins, Binder Jetting with ceramic powders, and Material Extrusion (FDM) with ceramic-infused filaments or pastes.

🏺 The Ancient Art Meets Modern Tech: A Brief History of Ceramic Additive Manufacturing

Humans have been making things from clay for millennia, from simple pottery to intricate tiles. The basic principle has always been the same: shape the wet clay, dry it, and fire it in a kiln to make it hard and durable. For centuries, the shaping part was done by hand, on a wheel, or in a mold.

The leap to additive manufacturing (AM), or 3D printing, is a game-changer. It applies that same ancient principle of building an object layer by layer, but with digital precision. Early research began in the 1990s, but for a long time, the technology was incredibly expensive and complex, confined to high-tech research labs.

The real shift came when companies started making the technology more accessible. Brands like Eazao brought clay extrusion printers to the desktop, proudly proclaiming you can “turn your home into a custom pottery studio.” On the more industrial side, Formlabs introduced materials like their Alumina 4N Resin, which works with their popular SLA printers, dramatically lowering the barrier to entry for creating high-performance technical ceramic parts. This is a huge step in 3D Printing Innovations.

🤔 Why Ceramic 3D Printing? Unlocking Unrivaled Material Properties

So, why go through all the trouble of printing with ceramics when we have amazing polymers like ASA and PETG? As the first YouTube video on filament properties explains, materials like ASA are great for outdoor use due to their UV resistance, but they simply can’t compete when it comes to extreme environments. That’s where ceramics come in.

The Power of Technical Ceramics: Beyond the Basics

Technical ceramics (or advanced ceramics) are engineered for performance. They leave traditional materials in the dust when it comes to:

- 🌡️ Extreme Temperature Resistance: While most plastics soften and deform at a couple of hundred degrees Celsius, many technical ceramics can withstand temperatures well over 1,500°C (2,732°F).

- 💪 Incredible Hardness & Wear Resistance: Advanced ceramics are exceptionally hard, making them highly resistant to scratching, wear, and abrasion.

- ⚡ Electrical Insulation: Most ceramics are fantastic electrical insulators, which is why they’re used for things like spark plugs and high-voltage components.

- 🧪 Chemical Inertness: They are highly resistant to corrosion and chemical attack, making them ideal for handling aggressive substances.

- ** biocompatibility:** Certain ceramics are non-toxic and don’t react with the human body, opening doors for medical implants.

Benefits of Additive Manufacturing for Ceramic Parts

Pairing these amazing materials with 3D printing unlocks a whole new world of possibilities.

- ✅ Design Freedom: Traditional ceramic manufacturing is limited by molds and machining. 3D printing allows for incredibly complex geometries, like internal cooling channels, lattice structures, and parts with organic shapes that would be impossible to make otherwise.

- ✅ Rapid Prototyping & Iteration: Need to test a new design for a heat shield? The Air Force Research Laboratory used Formlabs Alumina 4N Resin to do just that, stating, “The combination allowed us to iterate quickly and affordably on designs without having to wait for expensive tooling to be made.”

- ✅ Cost-Effective for Low Volumes: Creating molds for traditional ceramic injection molding is wildly expensive. For custom parts or small production runs, 3D printing is far more economical.

- ✅ Part Consolidation: You can combine multiple simple parts into a single, complex 3D printed component, reducing assembly time and potential points of failure.

🔬 Diving Deep into Ceramic 3D Printing Materials: A Comprehensive Guide

Ready to get your hands dirty? Let’s break down the most common and exciting ceramic materials you can use in your 3D printer.

1. Alumina (Aluminum Oxide): The Workhorse of Advanced Ceramics

If there’s one go-to material in the world of technical ceramics, it’s Alumina (Al₂O₃). It’s versatile, relatively low-cost (for a technical ceramic!), and offers a fantastic balance of properties.

- Key Features: High hardness, excellent electrical insulation, good thermal conductivity, and high-temperature resistance.

- Best For: Electrical insulators, thread guides, sandblasting nozzles, jigs and fixtures for high-temperature processes, and wear-resistant components.

- Our Take: We’ve had a blast experimenting with Formlabs Alumina 4N Resin. It truly makes printing a high-purity (99.99%) alumina part accessible. As Dr. Malte Hartmann of Bosch Advanced Ceramics noted, “Formlabs opens up a new chapter for the additive manufacturing of ceramics.” The workflow is straightforward if you’re familiar with SLA, though the debinding and sintering steps require precision (and a good kiln!).

2. Zirconia (Zirconium Dioxide): Strength, Biocompatibility, and Beauty

Zirconia (ZrO₂) is the tough guy of the ceramics world. It has exceptional strength and fracture toughness, far exceeding other ceramics. It’s also known for its brilliant white color and biocompatibility.

- Key Features: Extremely high strength and fracture toughness, excellent wear resistance, low thermal conductivity, and biocompatibility.

- Best For: Dental crowns and bridges, medical implants, luxury watch casings, cutting tools, and oxygen sensors.

- Our Take: The dental industry has fully embraced Zirconia. Materials like the ceramic-filled VarseoSmile Crown plus from BEGO demonstrate how 3D printing can create permanent, patient-specific restorations that are both strong and aesthetically pleasing. Its “antagonist-friendly” nature means it’s less likely to wear down opposing teeth, a huge plus for dental work.

3. Silicon Carbide (SiC): Extreme Heat and Chemical Resistance

When things get really hot or corrosive, you call in Silicon Carbide. This material is incredibly hard and maintains its strength at very high temperatures.

- Key Features: Exceptional hardness (nearly as hard as diamond), maintains strength at high temperatures, excellent thermal shock resistance, and superb chemical resistance.

- Best For: Kiln furniture, components for semiconductor manufacturing, heat exchangers, rocket nozzles, and automotive brake discs.

- Our Take: Printing with SiC is still a highly specialized and challenging process, often requiring advanced binder jetting or direct ink writing systems. It’s not for the faint of heart, but for applications that demand the ultimate in performance, there’s no substitute.

4. Silicon Nitride (Si₃N₄): High Performance and Lightweight

Silicon Nitride is another high-performance ceramic known for its incredible thermal shock resistance—meaning it can handle rapid temperature changes without cracking. It’s also surprisingly lightweight for a ceramic.

- Key Features: Outstanding thermal shock resistance, high strength and toughness, good wear resistance, and lower density than other technical ceramics.

- Best For: Ball bearings, engine components, welding nozzles, and metal forming tools.

- Our Take: Like Silicon Carbide, this is an advanced material primarily used in industrial and research settings. The ability to 3D print complex Silicon Nitride parts is a major focus of 3D Printing in Education and R&D, especially for aerospace and automotive applications.

5. Hydroxyapatite (HAp): The Biomedical Bone Builder

This one is truly special. Hydroxyapatite is a calcium phosphate material that is the primary mineral component of human bone and teeth. This makes it incredibly biocompatible and bioactive.

- Key Features: Excellent biocompatibility, bioactive (promotes bone growth), and osteoconductive.

- Best For: Bone grafts, synthetic bone scaffolds for tissue engineering, and coatings for metallic implants to improve integration with the body.

- Our Take: HAp is at the forefront of medical 3D Printing Innovations. The ability to print custom-shaped bone scaffolds that the body can slowly replace with natural tissue is nothing short of revolutionary.

6. Other Emerging Ceramic Materials for 3D Printing

The world of ceramic 3D printing is constantly expanding. Researchers are working with a huge range of materials, including:

- Porcelain and Stoneware Clays: Made accessible by printers like the Eazao Potter, these are perfect for artists and designers looking to create custom pottery and sculptures.

- Boron Carbide (B₄C): An extremely hard material used for body armor and nuclear applications.

- Glass-Ceramics: These materials combine the properties of glass and ceramics and can be 3D printed to create complex components with tailored thermal expansion properties.

🛠️ How Ceramic 3D Printing Works: Technologies and Processes Explained

So, how do you actually turn a digital file into a solid ceramic part? It’s not as simple as hitting “print” on your FDM machine. Let’s look at the most common technologies.

Stereolithography (SLA) & Digital Light Processing (DLP) for Ceramic Resins

This method uses a liquid resin that is heavily loaded with fine ceramic powder. A UV light source (a laser for SLA, a projector for DLP) selectively cures the resin layer by layer, solidifying it into the desired shape.

- Process:

- Print: The part is printed in the ceramic-filled resin. At this stage, it’s a “green” part, where the ceramic particles are held together by the cured polymer binder.

- Wash: The green part is washed in a solvent (like the Formlabs Ceramic Wash Solution) to remove any uncured resin.

- Debind & Sinter: The part goes through a two-stage firing process in a kiln to burn out the polymer binder and then sinter the ceramic particles into a fully dense part.

- Pros: ✅ Excellent detail and surface finish. ✅ Relatively accessible technology thanks to systems like Formlabs.

- Cons: ❌ Material options can be limited. ❌ The debinding and sintering process requires a programmable kiln and careful attention to firing schedules.

Binder Jetting: Speed and Scale for Ceramic Powders

Binder Jetting works by spreading a thin layer of ceramic powder and then using an inkjet-style printhead to selectively deposit a liquid binding agent, sticking the powder together where needed.

- Process:

- Print: The printer builds the part layer by layer in a bed of powder.

- Depowder: The finished green part is carefully excavated from the surrounding loose powder.

- Sinter: The part is then sintered in a furnace to burn off the binder and fuse the ceramic powder.

- Pros: ✅ Fast printing speeds. ✅ No support structures needed (the loose powder supports the part). ✅ Good for larger parts and batch production.

- Cons: ❌ Green parts are very fragile. ❌ Surface finish may be rougher than SLA.

Material Extrusion (FDM/FFF) with Ceramic Filaments

This is the method most familiar to hobbyists. It involves a filament that is a composite of ceramic powder and a polymer binder. It’s extruded through a heated nozzle, just like PLA or ABS.

- Process:

- Print: The part is printed on a standard FDM printer (though a hardened nozzle is highly recommended).

- Debind & Sinter: Just like with SLA, the printed green part must be fired to remove the binder and densify the ceramic.

- Pros: ✅ Uses affordable and common FDM printers. ✅ Upgrade kits like the Eazao Kit can convert existing printers.

- Cons: ❌ Can be prone to delamination. ❌ Achieving high density and strength after sintering can be challenging.

Direct Ink Writing (DIW): Precision and Custom Geometries

DIW involves extruding a viscous ceramic paste or “ink” through a fine nozzle. This method offers incredible control over the material deposition.

- Process:

- Print: A pneumatic or mechanical system precisely pushes the ceramic paste through the nozzle to build the part.

- Dry & Sinter: The printed part is dried and then sintered in a kiln.

- Pros: ✅ Wide range of possible materials. ✅ Excellent for creating fine structures like lattices and scaffolds.

- Cons: ❌ Slower printing speeds. ❌ The rheology (flow properties) of the ink is critical and can be difficult to perfect.

Post-Processing: Debinding and Sintering – The Critical Steps

We can’t stress this enough: post-processing is everything in ceramic 3D printing. A perfect green part can be ruined by a bad firing schedule.

- Debinding: This is the slow, careful heating process that burns away the polymer binder. If you heat it too quickly, the binder can boil and create bubbles or cracks in your part.

- Sintering: This is the high-temperature step where the ceramic particles fuse together. This is where the part shrinks and gains its final strength and density. The exact temperature and duration are critical to achieving the desired material properties. You’ll need a programmable kiln or furnace that can reach the very high temperatures required for technical ceramics.

🚀 Applications of 3D Printed Ceramic Parts: Where Innovation Takes Shape

The unique properties of 3D printed ceramics are enabling breakthroughs across numerous industries. These aren’t just 3D Printable Objects for your desk; they are high-performance components solving real-world problems.

Aerospace and Defense: Pushing the Boundaries of Performance

In aerospace, every gram counts, and components are pushed to their absolute limits.

- Heat Shields & Turbine Components: The extreme temperature resistance of materials like Alumina and Silicon Carbide makes them ideal for parts that are exposed to hot gases in engines and exhaust systems.

- Lightweight Mirrors: For space telescopes and satellites, 3D printing can create complex, lightweight support structures for mirrors out of materials with low thermal expansion.

- Radomes: These are the aerodynamic “noses” that protect radar equipment on aircraft. 3D printed ceramics can be used to create radomes with specific dielectric properties that are transparent to radio waves.

The Air Force Research Laboratory has used Formlabs’ Alumina 4N Resin for everything from prototyping turbine engine parts to creating custom fixtures for high-temperature testing, highlighting how the technology accelerates R&D.

Biomedical and Dental: Custom Implants and Prosthetics

This is one of the most impactful areas for ceramic 3D printing.

- Dental Restorations: As we saw with BEGO’s VarseoSmile Crown plus, 3D printing allows for the rapid, cost-effective creation of patient-specific crowns, veneers, and bridges that are strong, aesthetic, and biocompatible.

- Bone Scaffolds: Using materials like Hydroxyapatite, surgeons can implant 3D printed scaffolds that are perfectly shaped to a patient’s defect. These scaffolds encourage natural bone to grow into them, eventually dissolving away.

- Surgical Tools: Custom, sterilizable surgical guides and tools can be printed from Zirconia.

Industrial and Chemical: Wear Parts and Corrosion Resistance

In harsh industrial environments, parts made from metal or plastic quickly wear out or corrode.

- Nozzles and Valves: For handling abrasive slurries or corrosive chemicals, ceramic nozzles and valve components last significantly longer than their metal counterparts.

- Jigs, Fixtures, and Kiln Furniture: Custom hangers and supports can be 3D printed to hold parts during heat treatment or firing processes, optimizing oven space and improving consistency.

- Casting Tools: 3D printed ceramic molds and cores are used in investment casting to create complex metal parts.

Electronics and RF: Insulators and High-Frequency Components

The excellent electrical insulating properties of ceramics are critical for the electronics industry.

- Insulators and Housings: Alumina is widely used for high-voltage insulators, connector housings, and terminal blocks.

- Substrates for Circuits: 3D printing allows for the creation of complex 3D circuit substrates with integrated channels and features.

- RF and Microwave Components: Materials with specific dielectric properties can be printed to create filters, antennas, and other components for high-frequency applications.

Art and Design: Unleashing Creative Freedom

Let’s not forget the artists! Printers like those from Eazao are putting the power of digital ceramics into the hands of creators. They can produce intricate sculptures, complex vases, and unique decorative tiles that would be impossible to create by hand. This technology truly blurs the line between craft and code.

🚧 Challenges and Considerations in Ceramic Additive Manufacturing

We wouldn’t be doing our job if we didn’t give you the full picture. Ceramic 3D printing is amazing, but it’s not without its challenges. This isn’t as simple as loading a filament and hitting go.

Material Shrinkage and Distortion: The Sintering Saga

This is the big one. As the binder burns out and the ceramic particles fuse during sintering, the part shrinks significantly.

- The Problem: The shrinkage is not always perfectly uniform. Thick sections might shrink at a different rate than thin sections, leading to warping, cracking, or distortion. Gravity can also cause the part to slump or deform while it’s in its “softened” state in the kiln.

- The Solution: You must design for shrinkage! This means scaling up your digital model in your 3D Design Software to compensate. It often takes a few test prints to dial in the exact scaling factor for your specific material and geometry. Using simulation software can also help predict and mitigate distortion.

Surface Finish and Resolution: Aiming for Perfection

The final surface finish depends heavily on the printing technology.

- SLA/DLP: Generally produces the best surface finish right off the printer, with very fine layer lines.

- Binder Jetting: Can have a slightly grainy texture from the powder particles.

- FDM/DIW: Layer lines will be more visible, similar to polymer FDM printing.

While the sintering process can smooth out some minor imperfections, it can also highlight others. Post-processing steps like sanding, tumbling, or glazing may be needed to achieve a perfectly smooth surface.

Cost of Materials and Equipment: An Investment in Innovation

Let’s be real: this is a more expensive hobby or business venture than standard 3D printing.

- Printers: While desktop clay printers and SLA systems have lowered the barrier, high-performance industrial machines can still be very costly. Check out our 3D Printer Reviews for more info on different systems.

- Materials: Technical ceramic powders and resins are specialty materials and cost more than a spool of PLA.

- The Kiln: You can’t forget the furnace! A programmable, high-temperature kiln is a necessary piece of equipment and a significant investment.

Process Complexity and Expertise Required

Success in ceramic 3D printing requires a blend of digital design skills, material science knowledge, and a bit of old-fashioned craft. You need to understand how to design for the process, how to handle green parts delicately, and how to develop and execute a precise firing schedule. It’s a steep learning curve, but the results are incredibly rewarding.

💡 Our Team’s Insights: Real-World Experience with Ceramic 3D Printing

Here at the 3D Printed™ lab, we’ve had our fair share of both spectacular successes and… well, let’s call them “learning opportunities.”

Anecdotes from the Lab: Our First Successful Alumina Print

I’ll never forget our first attempt with the Formlabs Alumina 4N resin. We designed a small, intricate heat sink for an electronics project—something with lots of thin fins that would be a nightmare to machine. The SLA printing part was flawless. We washed it, dried it, and placed our precious little green part in the kiln. We programmed the multi-stage firing schedule we’d found online, crossed our fingers, and waited.

The next day, we opened the kiln to find… a pile of ceramic dust and a few cracked shards. We had ramped up the temperature way too fast during the debinding stage. The binder outgassed violently, and our beautiful part basically exploded. It was a humbling moment!

We tried again, this time following the Formlabs firing schedule to the letter. The slow, patient ramp-up felt like torture. But when we opened the kiln this time, we found a perfectly formed, dense white ceramic heat sink. It was smaller, sure, but it was hard as a rock and dimensionally accurate. Tapping it with a metal tool produced a satisfying clink. That was the moment we knew this technology was something special.

Choosing the Right Material and Process: A Practical Guide

The biggest question we get is, “Which material and process should I use?” Here’s our quick-and-dirty guide:

- For Artists and Hobbyists: If you want to make custom pottery, sculptures, or art pieces, a clay extrusion (FDM/DIW) system like an Eazao printer is your best bet. It’s accessible, uses affordable materials, and is focused on creative expression.

- For High-Detail Prototypes & Technical Parts: If you need high resolution, a great surface finish, and access to technical materials like Alumina, an SLA-based system like the Formlabs ecosystem is the way to go. It’s perfect for engineers, researchers, and product designers.

- For Production and Large Parts: If you’re looking to do small-scale production or create larger ceramic components, Binder Jetting is the technology to look into. It’s faster and more scalable, though the initial investment is higher.

Tips for Optimizing Your Ceramic 3D Prints

- Wall Thickness is Key: Avoid sudden, drastic changes in wall thickness. Try to keep it as uniform as possible to promote even shrinkage and reduce stress.

- Fillet Your Edges: Sharp internal corners are stress concentration points. Adding a small fillet or radius to these corners can dramatically reduce the risk of cracking during sintering.

- Support Your Green Parts: Green parts are fragile! When moving them from the printer to the kiln, support them properly. For binder jetted parts, leaving them partially embedded in the loose powder during transport can help.

- Document Everything: Keep a detailed log of your prints. Note the material batch, print settings, and especially the exact firing schedule you used. When you have a success, you’ll want to be able to replicate it!

🔮 The Future is Fired: Emerging Trends in Ceramic 3D Printing Materials

If you think what we have now is cool, just wait. The field of ceramic additive manufacturing is evolving at a blistering pace. Here’s what we’re most excited about.

Multi-Material Ceramic Printing: A Game Changer?

Imagine printing a single component that has both electrically conductive and insulating ceramic sections. Or a part that combines a dense, hard ceramic with a porous, bone-integrating one. Multi-material printing, where different types of ceramic pastes or resins are deposited within the same part, is a major area of research. This will allow for the creation of truly functional, integrated devices that we can only dream of today.

Advanced Composites and Hybrid Materials

Researchers are developing new composite materials, like Ceramic Matrix Composites (CMCs), where ceramic fibers are embedded in a ceramic matrix. These materials are incredibly tough and fracture-resistant, making them ideal for next-generation jet engine components and hypersonic vehicle parts. 3D printing is a key enabling technology for creating complex CMC geometries.

Increased Accessibility and Desktop Solutions

The trend started by companies like Eazao and Formlabs will continue. We predict we’ll see more affordable, user-friendly desktop systems capable of printing a wider range of technical ceramics. This will further democratize the technology, putting it into the hands of more small businesses, universities, and even ambitious makers. The development of more reliable, “one-click” debinding and sintering solutions will also be a huge step forward.

✅ Conclusion: Embracing the Ceramic Revolution

Ceramic 3D printing is no longer a niche reserved for high-tech labs and industrial giants — it’s becoming accessible, versatile, and downright exciting. From the ultra-pure Alumina 4N Resin by Formlabs, which brings high-performance ceramics to desktop SLA printers, to the Eazao line of clay extrusion printers that empower artists and hobbyists alike, the landscape is rich with options tailored to different needs and skill levels.

Positives:

- Formlabs Alumina 4N Resin offers unmatched purity (99.99%), excellent mechanical and thermal properties, and integrates seamlessly with the popular Formlabs SLA ecosystem. It’s a breakthrough for engineers and researchers needing complex, high-performance ceramic parts without the prohibitive costs of traditional manufacturing.

- Eazao printers provide an affordable, user-friendly entry point for creative ceramic printing, using real clay and porcelain materials with direct extrusion methods. Perfect for artists, educators, and makers wanting to explore ceramic forms.

- BEGO’s VarseoSmile Crown plus material exemplifies how ceramic 3D printing is revolutionizing dental prosthetics, combining biocompatibility, strength, and aesthetic appeal with a digital workflow.

Negatives:

- Ceramic 3D printing demands careful post-processing, including debinding and sintering, which require specialized equipment and expertise.

- Shrinkage and distortion during sintering remain challenging, necessitating design compensation and iterative testing.

- The cost of materials and kilns can be a barrier for hobbyists and small businesses.

But here’s the kicker: the potential rewards far outweigh these hurdles. Whether you’re an engineer prototyping turbine parts, a dentist crafting custom crowns, or an artist shaping unique pottery, ceramic 3D printing opens doors to designs and performance levels previously unimaginable.

Remember our kiln mishap story? It perfectly illustrates that patience and precision are your best friends in this space. Follow recommended firing schedules, respect the material’s quirks, and you’ll be rewarded with parts that are as durable as they are beautiful.

If you’re eager to dip your toes into ceramic 3D printing, start small, learn the process, and scale up. The future is fired, and it’s bright.

🔗 Recommended Links: Dive Deeper!

Ready to explore or shop? Here are some top picks and resources to get you started:

- Formlabs Alumina 4N Resin:

- Eazao Ceramic 3D Printers:

- BEGO VarseoSmile Crown plus:

- Ceramic 3D Printing Books:

- Additive Manufacturing of Ceramics by S. Bose, S. Vahabzadeh, A. Bandyopadhyay — Amazon Link

- Ceramic 3D Printing: Fundamentals and Applications by C. B. Williams — Amazon Link

❓ FAQ: Your Burning Questions Answered

What are the best ceramic materials for 3D printing?

The best ceramic material depends on your application:

- Alumina (Al₂O₃): Great all-rounder with high hardness and electrical insulation.

- Zirconia (ZrO₂): Best for dental and biomedical applications due to strength and biocompatibility.

- Silicon Carbide (SiC): Ideal for extreme heat and chemical resistance.

- Hydroxyapatite (HAp): Perfect for bone scaffolds and biomedical implants.

Each material has trade-offs in terms of mechanical properties, thermal behavior, and printability. For beginners, Alumina resins like Formlabs Alumina 4N are excellent starting points.

How does ceramic 3D printing differ from plastic 3D printing?

Ceramic 3D printing involves printing a green part composed of ceramic powder bound by a polymer or binder, followed by debinding and sintering to remove the binder and densify the ceramic. Plastic printing typically involves melting and depositing thermoplastics that solidify upon cooling, requiring no post-firing.

Ceramics require:

- Specialized post-processing (kiln firing).

- Design compensation for shrinkage (up to 30%).

- More fragile green parts.

Plastics are easier and faster but lack the extreme properties ceramics provide.

Can ceramic 3D printing materials be used for functional parts?

✅ Absolutely! Ceramic parts are used in:

- Aerospace components (heat shields, turbine parts).

- Dental crowns and implants.

- Industrial nozzles and wear parts.

- Electrical insulators and RF components.

With proper processing, ceramic 3D printed parts can match or exceed traditionally manufactured ceramics in performance.

What are the advantages of using ceramic materials in 3D printing?

- Extreme temperature and chemical resistance.

- High hardness and wear resistance.

- Electrical insulation and dielectric properties.

- Biocompatibility for medical applications.

- Design freedom for complex geometries.

- Cost-effective prototyping and small-batch production.

Which industries benefit most from ceramic 3D printing materials?

- Aerospace and Defense: For lightweight, heat-resistant parts.

- Biomedical and Dental: Custom implants and restorations.

- Industrial Manufacturing: Wear-resistant and corrosion-resistant components.

- Electronics: Insulators and RF devices.

- Art and Design: Unique ceramic artworks and decorative objects.

How to choose the right ceramic material for your 3D printing project?

Consider:

- Mechanical requirements: Strength, toughness, wear resistance.

- Thermal environment: Operating temperatures.

- Chemical exposure: Corrosion or chemical resistance needed.

- Biocompatibility: For medical or dental use.

- Printing technology compatibility: Resin-based SLA, binder jetting, or extrusion.

Consult datasheets and, if possible, test small prints to evaluate performance.

What post-processing techniques are needed for ceramic 3D printed objects?

- Washing: To remove uncured resin (SLA/DLP).

- Debinding: Slow thermal treatment to remove binders without damaging the part.

- Sintering: High-temperature firing to densify and strengthen the ceramic.

- Finishing: Sanding, polishing, or glazing to improve surface finish.

Proper kiln programming and handling are critical to avoid cracking or warping.

📚 Reference Links: Our Sources of Wisdom

- Formlabs Alumina 4N Resin

- Eazao Ceramic 3D Printers

- BEGO VarseoSmile Crown plus

- Air Force Research Laboratory on Ceramic 3D Printing

- Additive Manufacturing of Ceramics (Book)

- 3D Printing Industry: Ceramic 3D Printing Overview

- Materials Science of Ceramics – ASM International

- National Institute of Standards and Technology (NIST) – Ceramic Materials

We hope this comprehensive guide has fired up your curiosity and equipped you with the knowledge to start your own journey into ceramic 3D printing. Whether you’re crafting the next generation of aerospace components or your first custom vase, the world of ceramics awaits your creativity and engineering prowess!