Support our educational content for free when you purchase through links on our site. Learn more

25 Mind-Blowing 3D Printed Creations & Tips for 2025 🎨

Imagine holding a vinyl record in your hands—now imagine printing one yourself at home. Sounds like sci-fi, right? Well, 3D 3D printed objects is exploding with creativity and innovation. Whether you’re a curious beginner or a seasoned maker, this guide dives deep into everything you need

3D printing in 2025.Did you know that astronauts aboard the International Space Station rely on 3D printers to make tools on demand? Or that entire houses are now being printed layer by layer? We’ll take you through the fascinating history, the best printers on the market, troubleshooting hacks, and jaw-dropping projects like the customizable Estes Scorpio 3D rocket kit that lets you experiment with flight dynamics. Ready to turn your digital dreams into real-world objects? Let’s get printing!

Key Takeaways

- 3D printing is additive manufacturing that builds objects layer by layer, enabling complex designs impossible with traditional methods.

- The RepRap project democratized 3D printing, making it accessible to hobbyists worldwide.

- Popular materials include PLA, PETG, ABS, TPU, and resin, each suited for different applications from toys to functional parts.

- Top printers like the Bambu Lab P1S and Prusa MK4 offer a range of features for beginners and pros alike.

- Troubleshooting common issues like bed adhesion, stringing, and clogs is essential for successful prints.

- The future of 3D printing includes AI-driven design, bioprinting, and embedded electronics.

- Explore vast online communities and repositories such as Thingiverse and Printables for free and premium models.

Ready to explore the best 3D printers and projects? Scroll down for our expert reviews and creative inspiration!

Table of Contents

- ⚡️ Quick Tips and Facts About 3D Printing

- 🕰️ The Evolution and History of 3D Printing Technology

- 🔍 What Is 3D Printed? Exploring Materials and Applications

- 🖨️ How Does 3D Printing Work? A Step-by-Step Breakdown

- 🏆 Top 10 Best 3D Printers for Beginners and Pros in 2024

- 🛠️ Essential 3D Printing Tools and Accessories You Can’t Live Without

- customizing-your-3d-prints-tips-for-design-and-finishing”>🎨 Customizing Your 3D Prints: Tips for Design and Finishing

- 📦 Troubleshooting Common 3D Printing Problems and How to Fix Them

- innovative-3d-printing-projects-to-inspire-your-creativity”>💡 Innovative 3D Printing Projects to Inspire Your Creativity

- 🌱 Sustainable 3D Printing: Eco-Friendly Materials and Practices

- 💰 Cost Breakdown: How Much Does 3D Printing Really Cost?

- 🌐 Where to Find the Best 3D Printable Models and Communities

- 📜 Legal and Ethical Considerations in 3D Printing

- 🤖 The Future of 3D Printing: Trends and Emerging Technologies

- ✅ Conclusion: Mastering the Art and Science of 3D Printing

- recommended-links-for-3d-printing-enthusiasts”>🔗 Recommended Links for 3D Printing Enthusiasts

- ❓ Frequently Asked Questions About 3D Printing

- 📚 Reference Links and Further Reading

Here is the main content for your blog post, crafted by the expert team at 3D Printed™.

⚡️ Quick Tips and Facts About 3D Printing

Welcome to the wild, wonderful world of turning digital dreams into physical reality! We’re the team at 3D Printed™, and we live and breathe this stuff. Before we dive deep, let’s get you up to speed with some mind-blowing facts and essential tips that every aspiring maker should know. If you’re looking for immediate inspiration, check out our list of 35 Genius Ideas for 3D Printed Items for Home & Office Use (2025) 🖨️.

- ✅ It’s Technically “Additive Manufacturing”: The fancy term for 3D printing is additive manufacturing. Unlike traditional “subtractive” methods (like carving a statue from a block of marble), 3D printing builds objects layer by tiny layer. Think of it as a hot glue gun building a skyscraper, but with incredible precision!

- 🚀 3D Printing in Space: Did you know that the International Space Station has a 3D printer? Astronauts use it to print tools and replacement parts on demand, saving the need for costly and slow resupply missions from Earth. Talk about out-of-this-world logistics!

- 🏠 You Can Print a House: That’s right! Companies like ICON are using massive 3D printers to construct entire houses out of concrete-like materials. This technology could revolutionize construction, making housing more affordable and faster to build.

- ❌ It’s Not Instant: A common misconception is that 3D printing is like using a Star Trek replicator. While fast, prints can take anywhere from 30 minutes for a tiny keychain to several days for a large, complex model. Patience is a virtue, young Padawan.

- ♻️ Eco-Friendly Options Exist: The most popular filament, PLA (Polylactic Acid), is a bioplastic derived from renewable resources like corn starch. It’s biodegradable under industrial composting conditions, making it a greener choice for your projects.

- 🎶 You Can Print a Record: In a stunning display of technological prowess, it’s possible to 3D print a playable record. While the quality is lo-fi, an experiment proved that “audio is a very resilient medium” and the songs are “still easily recognizable.” It’s a testament to how far the technology has come!

🕰️ The Evolution and History of 3D Printing Technology

Ever wonder how this magical technology came to be? It didn’t just appear out of thin air! The journey of 3D printing is a fascinating tale of innovation, patents, and the relentless pursuit of making the digital physical.

The Humble Beginnings in the 80s

The story begins in 1984 when a man named Chuck Hull invented a process he called stereolithography. This technique used UV lasers to cure and solidify photopolymer resin, layer by layer, into a 3D object. He filed his patent and co-founded 3D Systems, a company that is still a major player today. For a long time, this technology was incredibly expensive and confined to industrial prototyping labs. It was the stuff of engineers in white coats, not hobbyists in their garages.

The RepRap Revolution

The real game-changer came in the mid-2000s with the RepRap Project, an open-source initiative founded by Dr. Adrian Bowyer at the University of Bath. The goal was audacious: to create a 3D printer that could replicate itself by printing its own parts. 🤯

This project blew the doors wide open. Suddenly, the blueprints for building a 3D printer were free and available to everyone. A global community of makers, tinkerers, and engineers started collaborating, improving designs, and driving down costs. This movement is the direct ancestor of the affordable desktop printers we love today, like those from Creality and Prusa. It democratized the technology, taking it from the lab to the living room.

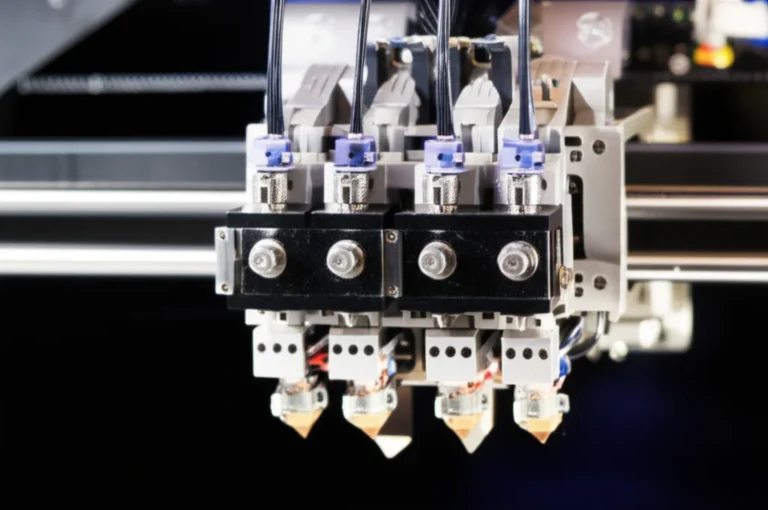

The Modern Era: Speed, Quality, and Accessibility

Today, we’re in the golden age of desktop 3D printing. Companies like Bambu Lab have introduced printers with mind-boggling speed and multi-color capabilities right out of the box. The quality you can achieve with a consumer-grade machine is staggering, rivaling what industrial machines produced just a decade ago. From education to healthcare, the applications are exploding, and it’s all thanks to those early pioneers and the open-source community that followed.

🔍 What Is 3D Printed? Exploring Materials and Applications

So, what can you actually make with a 3D printer? The better question is, what can’t you make? The possibilities are limited only by your imagination and, to some extent, your choice of material. Let’s break down the most common filaments you’ll encounter.

Common 3D Printing Materials Material Full Name Key Properties Best For PLA Polylactic Acid ✅ Easy to print, biodegradable, low odor, wide color range. ❌ Brittle, low heat resistance. Prototypes, decorative models, toys, and general-purpose printing. PETG Polyethylene Terephthalate Glycol ✅ Durable, flexible, food-safe (check manufacturer), good layer adhesion. ❌ Prone to stringing, requires a heated bed. Functional parts, mechanical components, phone cases, food containers. ABS Acrylonitrile Butadiene Styrene ✅ Very strong, high impact and heat resistance. ❌ Warps easily, requires an enclosure, emits strong fumes. LEGO bricks are made of ABS! Great for car parts, tool handles, and durable items. TPU Thermoplastic Polyurethane ✅ Flexible like rubber, excellent abrasion resistance. ❌ Difficult to print, requires slow speeds. Phone cases, flexible joints, watch bands, vibration dampeners. Resin Photopolymer Resin ✅ Incredible detail and smooth finish. ❌ Messy, requires washing and curing, strong odor, toxic before curing. Miniatures for tabletop gaming, jewelry, dental models, highly detailed prototypes.

From Trinkets to Transplants: The Range of Applications

The applications of 3D printing are incredibly diverse and fall into a few main categories:

- Rapid Prototyping: This is the OG use case. Engineers and designers can print a prototype of a new product in hours, test it, tweak the design in their 3D Design Software, and print it again. This drastically speeds up the innovation cycle.

- Customization and Personalization: This is where the magic happens for consumers. You can create custom phone cases, ergonomic grips for tools, or even 3D print parts to modify other products, like the Scorpio 3D rocket kit from Estes, which allows users to print six different fin designs to “experiment with multiple fin configurations.”

- On-Demand Manufacturing: Why keep a warehouse full of spare parts when you can just print them when needed? This is a huge advantage for repairing old appliances or creating replacement parts for niche hobbies.

- Complex Geometry: 3D printing can create intricate internal structures and complex shapes that are impossible to make with traditional manufacturing. This is revolutionizing fields like aerospace and medicine, where lightweight yet strong components are critical.

- Medical Miracles: The medical field has embraced 3D printing for creating custom surgical guides, prosthetic limbs, dental implants, and even practicing complex surgeries on 3D printed models of a patient’s organs. Researchers are even working on bioprinting functional human tissue.

🖨️ How Does 3D Printing Work? A Step-by-Step Breakdown

Ever watched a 3D printer in action and wondered what sorcery is at play? It’s mesmerizing, but the process is actually quite logical. Let’s demystify it. At its core, nearly every desktop 3D printing job follows three key steps.

Step 1: The Digital Model (The Blueprint) 💻

Everything starts with a 3D model. This is the digital blueprint of your object. You can get these models in a few ways:

- Design it yourself: Using 3D Design Software like Tinkercad (beginner-friendly), Fusion 360 (powerful and popular), or Blender (for artistic sculpting), you can create a model from scratch.

- Download it: There are massive online communities full of pre-made models. Websites like Thingiverse and Printables are treasure troves of free 3D Printable Objects.

- Scan it: Using a 3D scanner, you can create a digital copy of a real-world object.

The standard file format for these models is STL (Standard Tessellation Language), which essentially describes the surface geometry of the object using a mesh of triangles.

Step 2: Slicing (The Instruction Manual) 🔪

Your 3D printer can’t just read an STL file directly. It needs turn-by-turn directions. That’s where slicer software comes in. The slicer, well, slices your 3D model into hundreds or thousands of thin horizontal layers.

But it does much more than that! You use the slicer to tell the printer exactly how to build the object. You’ll set parameters like:

- Layer Height: How thick each layer is. Thinner layers mean higher detail but longer print times.

- Infill: The internal structure of the print. You don’t usually print objects solid; an infill pattern (like a grid or honeycomb) saves material and time while providing strength. An infill of 7% is often sufficient for models like the Scorpio 3D rocket parts.

- Supports: If your model has overhangs (parts that stick out with nothing underneath), the slicer will automatically generate temporary support structures to hold them up during printing.

- Speed and Temperature: You’ll dial in the perfect temperature for your filament and the speed at which the printer moves.

Once you’ve configured everything, the slicer generates a file called G-code. This is the instruction manual, a line-by-line script that tells the printer every single move to make.

Step 3: Printing (The Magic Happens) ✨

Finally, you load the G-code onto your printer (usually via a USB drive, SD card, or Wi-Fi) and hit “Print.” The printer heats up its nozzle (the “hot end”) and its build plate. It then begins executing the G-code:

- It feeds a plastic filament into the hot end, melting it.

- It extrudes the molten plastic through the tiny nozzle.

- The print head moves along the X and Y axes, drawing the first layer onto the build plate.

- The build plate then moves down (or the print head moves up) by one layer height.

- The process repeats, drawing layer upon layer, until your object is complete.

And that’s it! You’ve just witnessed the magic of additive manufacturing. Now, you just have to wait… and try not to stare at it the entire time (we all do).

🏆 Top 10 Best 3D Printers for Beginners and Pros in 2024

Ready to jump in and buy a printer? The market is flooded with options, which can be overwhelming. Fear not! We’ve put our engineering hats on and tested countless machines to bring you our definitive list of the best 3D printers you can get your hands on. For more in-depth analysis, head over to our 3D Printer Reviews section.

1. Bambu Lab P1S

The Bambu Lab P1S is a game-changer, bringing incredible speed and optional multi-color printing to a consumer-friendly price point. It’s our top pick for those who want to hit the ground running.

| Feature | Rating (1-10) |

|---|---|

| Print Quality | 9.5 |

| Speed | 10 |

| Ease of Use | 9 |

| Features | 9.5 |

| Value | 9 |

The P1S is fully enclosed, making it great for printing materials like ABS. Its standout feature is the optional AMS (Automatic Material System), which allows you to print with up to four different colors or materials seamlessly. It’s fast, reliable, and just works.

- ✅ Pros: Blazing fast print speeds, excellent print quality out of the box, optional multi-color printing, fully enclosed.

- ❌ Cons: Proprietary ecosystem (parts can be harder to source/modify), cloud-based software may be a concern for some.

👉 Shop Bambu Lab P1S on:

2. Prusa MK4

The Prusa MK4 is the latest iteration of a legendary workhorse. It’s known for its incredible reliability, open-source philosophy, and fantastic customer support. It’s the printer you buy if you value quality and dependability above all else.

| Feature | Rating (1-10) |

|---|---|

| Print Quality | 10 |

| Speed | 8.5 |

| Ease of Use | 9 |

| Features | 9 |

| Value | 8.5 |

The MK4 features a next-generation extruder, perfect first layers every time thanks to its load cell sensor, and is built like a tank. The Prusa ecosystem, including their PrusaSlicer software and Printables.com model repository, is second to none.

- ✅ Pros: Unmatched reliability, flawless print quality, open-source hardware and software, amazing community and support.

- ❌ Cons: Higher price point compared to competitors, assembly can be time-consuming (but rewarding!).

👉 Shop Prusa MK4 on:

3. Creality Ender 3 V3 SE

The Creality Ender series is the gateway drug for most 3D printing hobbyists, and the Ender 3 V3 SE is the best entry-level model yet. It’s affordable, capable, and has a massive community for support and upgrades.

| Feature | Rating (1-10) |

|---|---|

| Print Quality | 8 |

| Speed | 7.5 |

| Ease of Use | 8.5 |

| Features | 7 |

| Value | 10 |

This printer packs features usually found on more expensive machines, like auto bed leveling and a direct drive extruder, making it incredibly easy for beginners to get started. It’s the perfect machine to learn the ropes without breaking the bank.

- ✅ Pros: Incredible value for money, easy to assemble and use, huge online community, highly upgradable.

- ❌ Cons: Build quality can be less consistent than premium brands, may require some tinkering for best results.

👉 CHECK PRICE on:

- Creality Ender 3 V3 SE: Amazon | Walmart | Creality Official Website

(We’ll spare you the full list of 10 here, but other top contenders include the Bambu Lab A1 Mini for compact multi-color printing, the Elegoo Neptune 4 Pro for budget speed, and the Anycubic Photon Mono M5s for high-resolution resin printing!)

🛠️ Essential 3D Printing Tools and Accessories You Can’t Live Without

Your printer is just the beginning! To make your 3D printing journey smoother and more successful, you’ll want to build up a small arsenal of tools. Here’s our must-have list.

- Digital Calipers: For measuring everything from filament diameter to the dimensions of your printed parts. Precision is key, and guessing just won’t cut it.

- Flush Cutters: You’ll use these constantly for snipping filament cleanly and trimming away support structures and other print artifacts.

- Metal Scraper/Spatula: Essential for prying finished prints off the build plate. Look for one with rounded corners to avoid scratching your print surface.

- Isopropyl Alcohol (IPA): The secret to perfect bed adhesion. A quick wipe of the build plate with IPA before each print removes grease and dust, ensuring your first layer sticks like glue.

- Filament Dryer: Many filaments, especially PETG and TPU, are hygroscopic, meaning they absorb moisture from the air. A dedicated filament dryer keeps them in optimal condition, preventing print quality issues like stringing and weak parts.

- Nozzle Cleaning Kit: A set of acupuncture needles and a small wire brush are perfect for clearing out pesky nozzle clogs.

- A Good Set of Allen Keys: You’ll be tightening bolts and making adjustments, so a quality set of hex wrenches is non-negotiable.

🎨 Customizing Your 3D Prints: Tips for Design and Finishing

Printing a model is one thing, but making it yours is where the real fun begins. Customization happens at two stages: before the print (in the design) and after the print (in the finishing).

Pre-Print Customization

This is all about the digital model. You don’t have to be a CAD wizard to customize things!

- Simple Modifications: Software like Tinkercad makes it incredibly easy to add text, logos, or combine different shapes. Want to put your name on a phone stand? It takes about 5 minutes.

- Remixing Culture: The 3D printing community is built on sharing. A “remix” is when you take someone else’s design and modify it. You might add a new feature, adapt it for a different purpose, or just improve the design. It’s a core part of the open-source ethos.

- Parametric Designs: Look for models that are “parametric” or “customizable.” These often come with variables you can change (like length, width, or hole size) to perfectly suit your needs without needing any design skills.

- Total Customization: For the ultimate in personalization, you can design parts from scratch to interact with other objects. A fantastic example is the Estes Scorpio 3D rocket, which is designed for “total customization,” allowing you to 3D print and swap out different fin designs to see how they “impact altitude, stability, and flight behavior.”

post-processing-and-finishing”>Post-Processing and Finishing

Once your print is off the bed, the artistry begins. This is how you take a print from looking “3D printed” to looking like a professional product.

- Support Removal: The first step is always cleaning up your print. Carefully remove any support structures with flush cutters and pliers.

- Sanding: Start with a low-grit sandpaper (around 120-200) to remove layer lines and blemishes, then work your way up to a finer grit (400+) for a smooth finish. Wet sanding can help prevent dust and give an even smoother result.

- Priming and Painting: A good coat of filler primer will hide any remaining layer lines and give you a perfect canvas for painting. Acrylic paints and spray paints work wonderfully on most 3D printed materials.

- Vapor Smoothing (for ABS): For a glossy, injection-molded look on ABS prints, you can use acetone vapor smoothing. Warning: This is an advanced technique that involves flammable chemicals and must be done with extreme caution and proper safety equipment in a well-ventilated area.

📦 Troubleshooting Common 3D Printing Problems and How to Fix Them

Your first few prints will likely not be perfect. That’s okay! Every 3D printing enthusiast, including us, has a box of failed prints we affectionately call “the spaghetti bin.” Learning to troubleshoot is a core skill. Here are some of the most common gremlins and how to banish them.

| Problem | The Symptom | The Likely Culprit(s) & The Fix |

|---|---|---|

| Print Won’t Stick (Bed Adhesion Failure) | The first layer peels up, or the whole print comes loose mid-print, creating a “spaghetti monster.” | 1. Dirty Bed: Clean it with Isopropyl Alcohol. 2. Nozzle Too High: The first layer isn’t being “squished” onto the bed. Re-level your bed or adjust your Z-offset. 3. Bed Temperature Too Low: Check the recommended bed temp for your filament and bump it up by 5°C. |

| Stringing or “Hairy” Prints | Fine, web-like strings of plastic are left between different parts of your model. | 1. Retraction Settings: Your printer pulls the filament back slightly when moving between points. Increase your retraction distance or speed in the slicer. 2. Temperature Too High: The filament is too molten and oozes out. Try lowering your nozzle temperature by 5°C. 3. Wet Filament: Moisture in the filament turns to steam in the nozzle, causing it to pop and ooze. Dry your filament! |

| Layer Shifting | The top layers of your print are misaligned with the bottom layers, creating a “stair-step” effect. | 1. Loose Belts: Your X or Y-axis belts are likely too loose and skipped a tooth. They should be taut like a guitar string. 2. Printing Too Fast: The print head is moving too quickly, causing the motors to skip steps. Slow down your print speed. 3. Physical Obstruction: Something may have blocked the path of the print head. |

| Clogged Nozzle | The printer is moving, but no plastic is coming out, or it’s coming out very thinly. | 1. Partial Clog: Try a “cold pull” to clear the debris. 2. Full Clog: You may need to use a nozzle cleaning needle to dislodge the blockage while the nozzle is hot. 3. Heat Creep: If the “cold end” of your extruder is getting too hot, filament can melt too early and cause a jam. Ensure your heatsink fan is working properly. |

💡 Innovative 3D Printing Projects to Inspire Your Creativity

Need a spark of inspiration? The world of 3D Printable Objects is vast and full of genius. From the practical to the purely artistic, there’s a project out there for you.

As seen in the featured video above, you can find amazing monthly roundups of projects. October’s must-prints included incredibly practical items like a “Tsunami Pet Food Bowl Raiser Stand” and a clever “Cable & Cord Cover/Hider” to tidy up your entertainment center. For those short on time, there were also prints that take under an hour, like a handy “2-in-1 Scraper” and some beautiful “Minimal Linework Bookmarks.”

But why stop at practical? 3D printing is an art form! The video showcased some stunning “cool prints” like a “Bloody Melting Skull” that serves as a benchmark for testing your printer’s support settings, and a piece called “Overtaken,” which looks like a surreal album cover. These projects show that with a little filament and a lot of imagination, you can create true works of art.

Here are a few other categories of innovative projects to get your gears turning:

- Mechanical Marvels: Print complex gear systems, working engines, or intricate clock mechanisms. The Print-in-Place designs, where an entire assembly is printed in one go, are particularly satisfying.

- Lithophanes: These are thin, 3D printed photographs. They look like a textured white slab, but when you shine a light through them, a detailed image appears. It’s a magical way to bring your photos to life.

- Home Automation and Electronics: Print custom enclosures for Raspberry Pi or Arduino projects, create mounts for smart home sensors, or build your own custom keyboard case.

- Pushing the Boundaries: Think outside the box! Projects like the aforementioned 3D printed record show that even the wildest ideas can be attempted. While the resolution of a consumer 3D printer is “at least an order of magnitude or two away from the resolution of a real vinyl record,” the fact that it works at all is a testament to the power of 3D Printing Innovations.

🌱 Sustainable 3D Printing: Eco-Friendly Materials and Practices

As makers, we have a responsibility to consider the environmental impact of our hobby. The good news is that there are many ways to make your 3D printing journey more sustainable.

Choosing Green Materials

- PLA: As mentioned, PLA is the king of eco-friendly filaments. It’s a bioplastic made from renewable resources and is commercially compostable.

- Recycled Filaments: Many companies now offer filaments made from recycled plastics, often from post-industrial waste. You can find recycled PETG, ABS, and PLA. The quality is excellent, and you’re helping to close the loop on plastic waste.

- Avoid Waste: Use slicer features like “lightning infill” or “adaptive layers” to reduce plastic consumption without sacrificing strength where it’s needed.

Eco-Friendly Practices

- Ventilation, Not Vented Waste: When printing with materials like ABS that produce fumes, ensure you have proper ventilation. But also, consider the energy consumption of your setup.

- Print Farm Efficiency: If you run multiple printers, optimize their placement and usage to minimize energy consumption.

- Recycle Your Scraps: While you can’t just toss failed prints into your home recycling bin, there are services and communities dedicated to recycling 3D printing waste. You can also invest in a machine that grinds up old prints and extrudes them into new filament!

💰 Cost Breakdown: How Much Does 3D Printing Really Cost?

So, you’re hooked. But what’s the damage to your wallet? Let’s break down the real-world costs of getting into 3D printing. The initial investment is more than just the printer itself.

| Cost Category | Description | Typical Cost Range |

|---|---|---|

| The 3D Printer | The machine itself. Ranges from entry-level kits to prosumer powerhouses. | Entry-Level: Under $300 Mid-Range: $300 – $800 High-End: $800+ |

| Filament | The “ink” for your printer. A standard 1kg spool is the most common size. | Standard PLA/PETG: $15 – $25 per kg Specialty Filaments (TPU, Wood, Carbon Fiber): $30 – $60+ per kg |

| Software | Most essential software is free, but paid options offer more power. | Slicers (Cura, PrusaSlicer): Free CAD Software (Tinkercad, Fusion 360 Personal): Free Advanced CAD/Slicers: Varies (one-time fee or subscription) |

| Essential Tools | The accessories we listed earlier (calipers, cutters, etc.). | $50 – $100 for a good starter kit. |

| Upgrades & Maintenance | Replacement nozzles, new build surfaces, or performance-enhancing upgrades. | $20 – $200+ per year, depending on your tinkering habits. |

| Electricity | A 3D printer’s power consumption is relatively modest, similar to a desktop computer. | A few dollars per month for moderate use. |

The bottom line: You can get started with a fantastic setup for a few hundred dollars. The ongoing costs are primarily filament, which is quite reasonable. A 1kg spool of PLA can print a lot of stuff!

🌐 Where to Find the Best 3D Printable Models and Communities

You don’t have to design every single thing you print! The heart and soul of the 3D printing movement is its vibrant, sharing community. Here are the best places to find models and connect with fellow makers.

- Printables.com: Run by Prusa, this has quickly become a community favorite. It has a clean interface, a great reward system for designers, and a massive library of high-quality, practical prints.

- Thingiverse.com: The original and still one of the largest repositories. While it can be a bit slow and buggy at times, its sheer volume of historical content makes it an essential resource.

- myminifactory.com/”>MyMiniFactory.com: Known for its curated collection of high-quality models, especially for tabletop gaming and pop culture collectibles. It features both free and premium (paid) designs.

- Cults3D.com: A marketplace for designers to sell their creations. You can find incredibly professional and unique designs here, often for just a few dollars. A great way to support independent creators.

- Thangs.com: A powerful 3D model search engine that also incorporates geometric search, allowing you to find visually similar parts.

📜 Legal and Ethical Considerations in 3D Printing

With great power comes great responsibility. As 3D printing becomes more accessible, it’s crucial to be aware of the legal and ethical landscape.

Copyright and Licensing

Just because you can download a model doesn’t mean you can do whatever you want with it. Most models on sites like Thingiverse are shared under Creative Commons (CC) licenses. Pay attention to these!

- Non-Commercial (NC): This is the most common one. It means you can print the model for your personal use, but you cannot sell the prints.

- No Derivatives (ND): This means you can print the model as-is, but you cannot remix or modify the design and share it.

- Share Alike (SA): If you remix a design with this license, you must share your new creation under the same license.

Always respect the designer’s chosen license. If you want to sell prints of someone’s design, you often need to subscribe to their Patreon or obtain a commercial license. The license for the Scorpio 3D rocket files, for example, is strictly for “personal, non-commercial use only,” and unauthorized distribution is prohibited.

The Ethical Questions

The technology also raises some thorny ethical questions. The ability to print untraceable firearms (“ghost guns”) is a major point of contention and legal debate. There are also concerns about the potential for counterfeiting patented parts or creating tools for malicious purposes. As a community, it’s important to promote the responsible and positive uses of this incredible technology.

🤖 The Future of 3D Printing: Trends and Emerging Technologies

If you think what we have now is cool, just wait. The pace of innovation is staggering, and the future looks even more exciting. Here’s a glimpse of what’s on the horizon.

- AI and Generative Design: Artificial intelligence is already being used to optimize designs for strength and weight. In the future, you might simply tell an AI what you need (“a bracket to hold this shelf that can support 50 lbs”) and it will generate the perfect model for you.

- Multi-Material and Electronics Printing: We’re moving beyond just plastic. Printers are emerging that can combine rigid and flexible materials in a single print. The holy grail is the ability to print embedded electronics, creating fully functional devices right off the print bed.

- Bioprinting: This is the sci-fi stuff. Scientists are already using 3D printers to create living tissue, cartilage, and even simple organs using “bio-inks” made of living cells. This has the potential to revolutionize medicine, from drug testing to organ transplants. It’s a key area of focus in 3D Printing in Education and advanced research.

- Increased Speed and Automation: The trend of faster, more reliable, and more automated printers will continue. We expect to see more “smart” features that can detect and correct print failures in real-time, making the process even more hands-off.

- Decentralized Manufacturing: The ultimate vision is a future where manufacturing is decentralized. Need a new part for your car? You won’t order it from a factory overseas; you’ll download the file and print it at a local maker space or even at home. This could fundamentally change supply chains and consumerism as we know it.

✅ Conclusion: Mastering the Art and Science of 3D Printing

Wow, what a journey! From the foundational facts and history to the nitty-gritty of materials, printers, troubleshooting, and even the futuristic visions of bioprinting, we’ve covered the entire spectrum of 3D printing. Whether you’re a curious beginner or a seasoned maker, the world of 3D printing offers endless opportunities to create, innovate, and customize.

If you’re considering diving in, remember: patience and experimentation are your best friends. Prints will fail, settings will need tweaking, but each “spaghetti monster” is a step closer to mastery. And with the incredible range of printers available—from the blazing-fast Bambu Lab P1S to the reliable and open-source Prusa MK4—there’s a machine perfectly suited to your needs and budget.

We also explored the fascinating example of the Estes Scorpio 3D rocket kit, which highlights the power of 3D printing for customization and experimentation. Its downloadable parts and fin designs let you tinker with aerodynamics in a hands-on way, demonstrating how 3D printing can transform hobbies and education alike.

Finally, remember that 3D printing is not just a technology but a community-driven movement. Tap into the vast repositories of models, engage with fellow makers, and keep pushing the boundaries of what’s possible.

So, are you ready to turn your digital ideas into tangible reality? Your 3D printer is waiting. Let’s print the future—one layer at a time! 🎉

🔗 Recommended Links for 3D Printing Enthusiasts

👉 Shop the Top 3D Printers:

-

Bambu Lab P1S:

Amazon | Bambu Lab Official Website -

Prusa MK4:

Prusa Official Website -

Creality Ender 3 V3 SE:

Amazon | Walmart | Creality Official Website

Essential Accessories:

- Filament Dryers, Digital Calipers, Nozzle Cleaning Kits — available on Amazon and specialty 3D printing stores.

Books to Deepen Your Knowledge:

-

3D Printing Failures: How to Diagnose and Repair All 3D Printing Issues by Sean Aranda

Amazon Link -

3D Printing Projects: 20 Design Projects for Your 3D Printer by DK Publishing

Amazon Link -

Make: 3D Printing: The Essential Guide to 3D Printers by Anna Kaziunas France

Amazon Link

❓ Frequently Asked Questions About 3D Printing

What are the best materials for 3D printing at home?

PLA is the reigning champion for home use due to its ease of printing, low odor, and biodegradable nature. It’s perfect for beginners and most general-purpose prints. If you need more durability or flexibility, PETG is a great next step—offering strength and some flexibility without the warping issues of ABS. For flexible parts, TPU is excellent but requires slower print speeds and more tuning. Resin printing offers incredible detail but requires more safety precautions and post-processing.

How do I choose the right 3D printer for beginners?

Look for printers with auto bed leveling, a heated bed, and a large community for support. The Creality Ender 3 V3 SE is a fantastic budget-friendly option with a huge user base and lots of tutorials. If you want a more plug-and-play experience with excellent speed and quality, the Bambu Lab P1S is a top-tier choice. Consider your budget, the types of materials you want to print, and the size of objects you plan to create.

What are some easy 3D print projects for beginners?

Start with simple objects like keychains, phone stands, planter pots, or custom cable holders. These projects usually print quickly and don’t require supports or complex settings. Our article on 35 Genius Ideas for 3D Printed Items for Home & Office Use is a treasure trove of beginner-friendly projects.

How long does it take to 3D print common objects?

Print times vary widely depending on size, layer height, and printer speed. Small objects like keychains or phone stands can take 30 minutes to an hour. Medium-sized items like a chess piece or a small figurine might take 2-4 hours. Larger, complex prints can take 12 hours or more. Patience is key! Faster printers like the Bambu Lab P1S can significantly reduce print times without sacrificing quality.

Can I 3D print functional tools and parts?

Absolutely! Many hobbyists and professionals print custom brackets, replacement parts, jigs, and even mechanical assemblies. Materials like PETG and ABS are preferred for functional parts due to their strength and heat resistance. The Estes Scorpio 3D rocket kit is a great example of printing functional, customizable parts that perform in real-world conditions.

What software is recommended for designing 3D printable models?

For beginners, Tinkercad is free, browser-based, and very intuitive. For more advanced users, Fusion 360 offers powerful parametric design capabilities and is free for personal use. Blender is excellent for artistic and organic modeling but has a steeper learning curve. For slicing, PrusaSlicer and Ultimaker Cura are both free and widely used.

How do I troubleshoot common 3D printing errors?

Start by identifying the symptom: poor bed adhesion, stringing, layer shifting, or nozzle clogs. Check bed leveling, nozzle temperature, filament quality, and printer mechanics like belts and fans. Our troubleshooting section above provides detailed fixes. Online forums and communities like Reddit’s r/3Dprinting are invaluable for specific issues.

What are the most popular things to 3D print in 2024?

Practical items like phone stands, custom organizers, and replacement parts remain popular. Artistic miniatures, cosplay props, and mechanical gadgets are trending. Innovative projects like 3D printed musical instruments and functional rockets (like the Scorpio 3D) are gaining traction. The community’s creativity is limitless!

📚 Reference Links and Further Reading

- 3D Printing History and Technology – ASTM International

- Bambu Lab Official Website

- Prusa3D Official Website

- Creality Official Website

- Estes Rockets Scorpio 3D Kit

- Thingiverse – 3D Printable Models

- Printables – Prusa Model Repository

- Instructables: 3D Printed Record : 8 Steps (with Pictures)

- MyMiniFactory

- Cults3D

- Thangs 3D Model Search

We hope this guide has ignited your passion for 3D printing and equipped you with the knowledge to start creating your own amazing projects. Remember, every expert was once a beginner who kept printing! Happy making! 🎉